Used NISSHINBO 1834N #9225894 for sale

URL successfully copied!

Tap to zoom

ID: 9225894

Vintage: 2008

Laminator

Single platen laminator

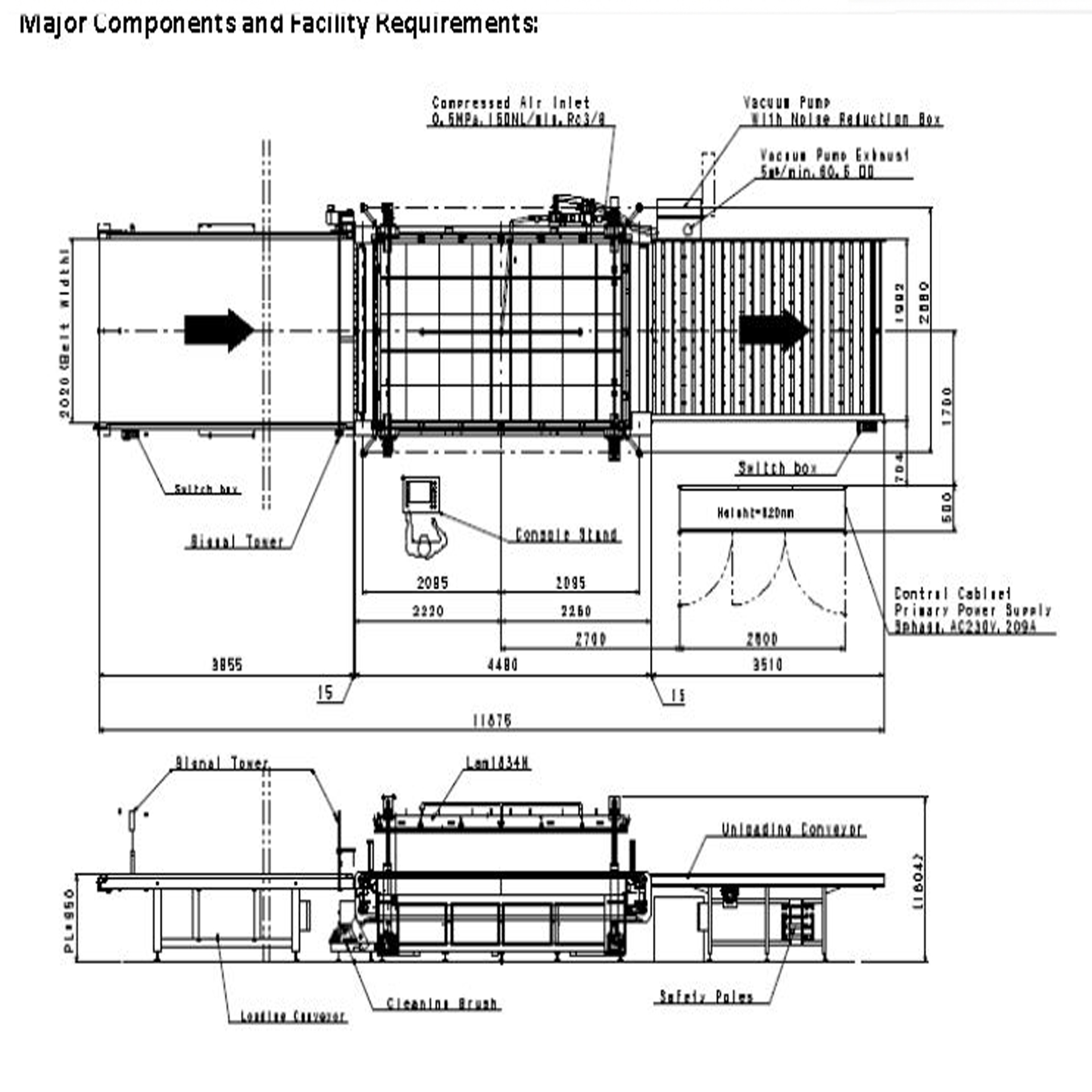

With 1.8 m x 3.4 m lamination area

LEYBOLD SCREWLINE SP250 Vacuum pump, 7.3 kW

Power belt in-feed conveyor

Power roller exit conveyor

PLC Operators control

Digital product documentation and operations manual

Cable size: 100 mm² (96.3-117.2 mm²)

Tightening torque: 45 nm

Terminal size: M12

Compressed air: >0.5 MPa, 150 NL/min

Inlet connection: Rc 3/8" Female fitting (Air panel)

Maximum thickness of solar modules: 15 mm

Vacuum system:

OERLIKON / LEYBOLD SV300 Rotary vane vacuum pump

Exhaust speed: 5666 L/min (60 Hz)

Noise reduction box

Vacuum pressure: <133 Pa

Pumping speed: Within 2 min to reach 133 Pa

Pressure sensor:

Upper chamber: KEYENCE AP-C31

Lower chamber: CANON / ANELVA Crystal gauge

Vacuum exhaust: Exhaust outlet

Vacuum pump: φ 60.5 OD (NW50)

Pressing control:

Pressing force: Maximum 0.1 MPa

Pressing speed: Slow, medium, fast

Heating system:

Heater type: Electrical sheathed heater

Temperature control: PID control, (4) Zones individual control

Operating temperature: Up to 180°C

Temperature uniformity: <±5°C (Between 100°C to 160°C)

Heating speed: <30 min (from 30°C to 150°C)

Temperature sensor: (3) Thermocouples

Control

Spear

Overheat detection

Chamber lifting system:

Driving method: (4) Electrical cylinders driven

Control system: Encoder feedback

Middle position moving stroke: 275 mm For automatic cycle

Fully opened position: 435 mm For manual operation

Moving speed:

Middle position to fully closed position: <15 Sec

Fully opened position to fully closed position: <20 Sec

Loading / Unloading:

Pass line: 950 mm (F.L.)

System cycle time: <60 Sec

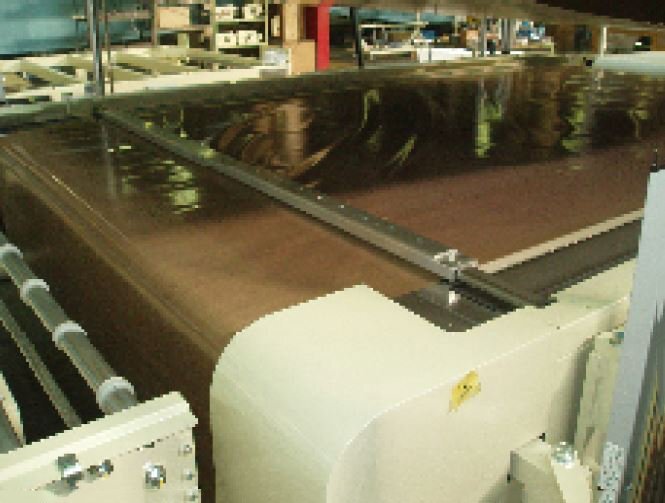

Laminator lower belt conveyor:

Transfer method: Belt transfer system

Transfer speed: 15 m/min

Maximum load: 50 kg

EVA Removing brush unit: EVA Dust tray

Loading conveyor:

Type: Belt conveyor (Heat resisting belt)

Driving method: Inverter controlled electric motor

Belt width: 2020 mm

Work detector: Photo-electric sensor detects the head of solar module

Unloading conveyor:

Type: Roller conveyor

Driving method: Inverter controlled electric motor

Module lift-up system

Work detector

Safety system:

Light curtains

Mechanical lock (Upper chamber)

General:

Working temperature: 0°C-55°C

Storing temperature: -25°C-75°C

Working humidity: 5-95% RH

Storing temperature: 5-95% RH

Working altitude: <2000 m

Over-voltage category: Category III

Pollution degree: Degree 3

Operating system:

Computer hardware: A-Series PLC

Touch screen: Color display, 10"

Does not include:

Additional sensor

Positive cooling

Built-in heater

Thermometer

Power supply: 230 VAC, ± 10 %, 3 Phase, 50/60 Hz, 209 A

2008 vintage.

NISSHINBO 1834N is a packaging machine designed to reduce human resources interventions in order to guarantee an efficient and consistent flow of materials. The machine is designed to handle various types of objects efficiently and quickly. It is a continuous track-type packaging machine that includes different modules that can be operated autonomously and can connect to other machines. Its high speed and accuracy ensure that there is minimal material wastage. By reducing the number of people handling the products, the machine helps reduce the risk of human error and improve production efficiency. 1834N offers a range of features that make it an effective packaging solution. It is a fully automated machine that does not require manual interventions as it is connected to peripheral equipment. It can be operated throughout the packaging process and used to detect various types of errors. It also recognizes product characteristics, such as size, shape, and weight, and then adjusts the motion of each item as it is processed. These features enable it to produce consistent packaging results. In addition, NISSHINBO 1834N has advanced sensors that can detect the size, shape, and weight of materials that are to be packaged. It can also recognize products that should not be packaged and remove them from the line. This helps to ensure that products are free from defects and are suitable for packaging. The machine is also designed for easy maintenance and can be operated with minimal downtime. It is equipped with an LED display that provides helpful information about the current status of the machine and any potential issues. It also includes a toolbox that allows for easy access to all components. 1834N is an efficient and cost-effective solution for companies looking to automate the packaging process. Its key features and advanced technology can help to improve accuracy and speed up the production process. This reduces the risk of errors and ultimately improves customer satisfaction.

There are no reviews yet