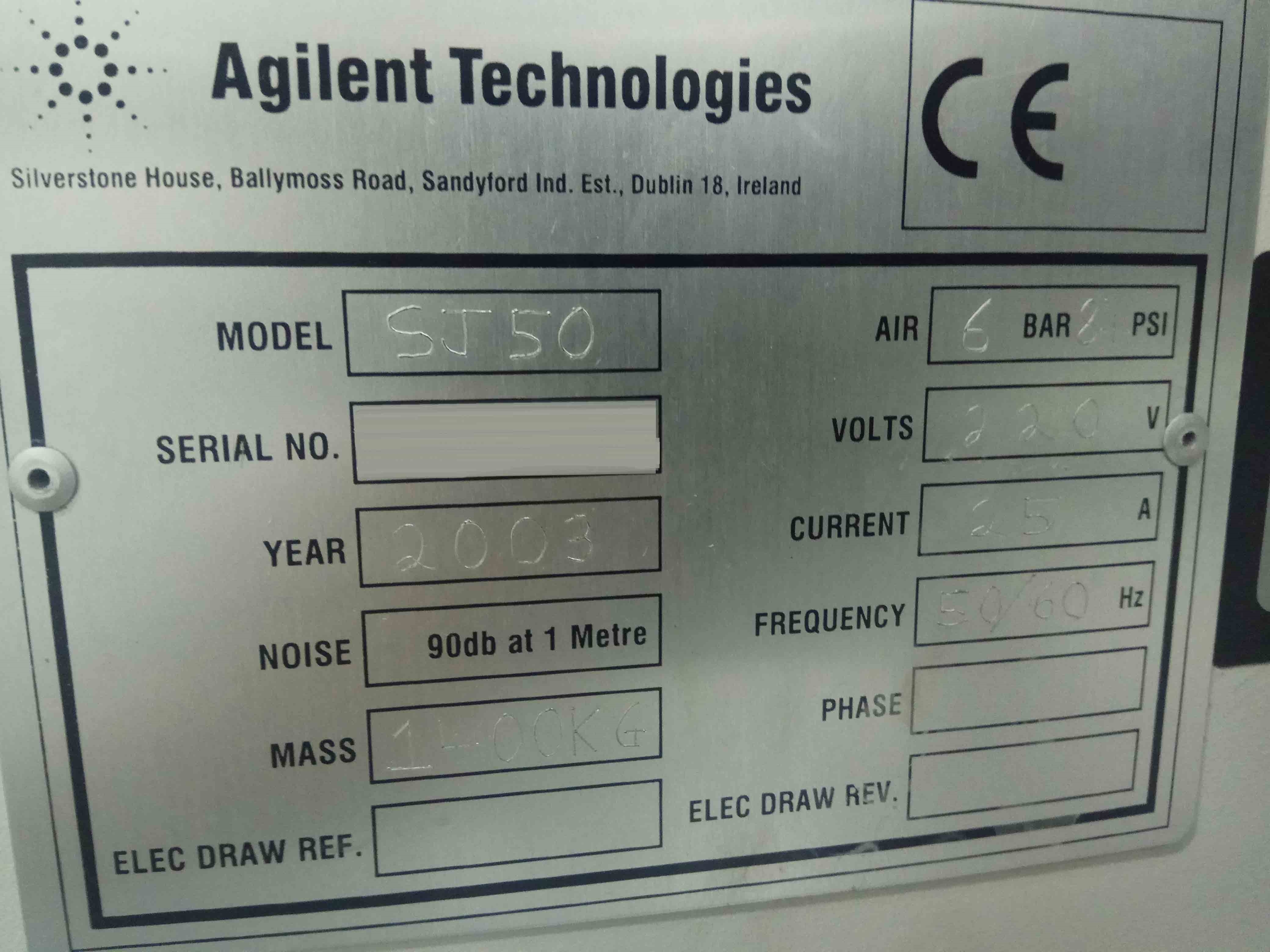

Used AGILENT / HP / HEWLETT-PACKARD / KEYSIGHT SJ50 #9208808 for sale

URL successfully copied!

Tap to zoom

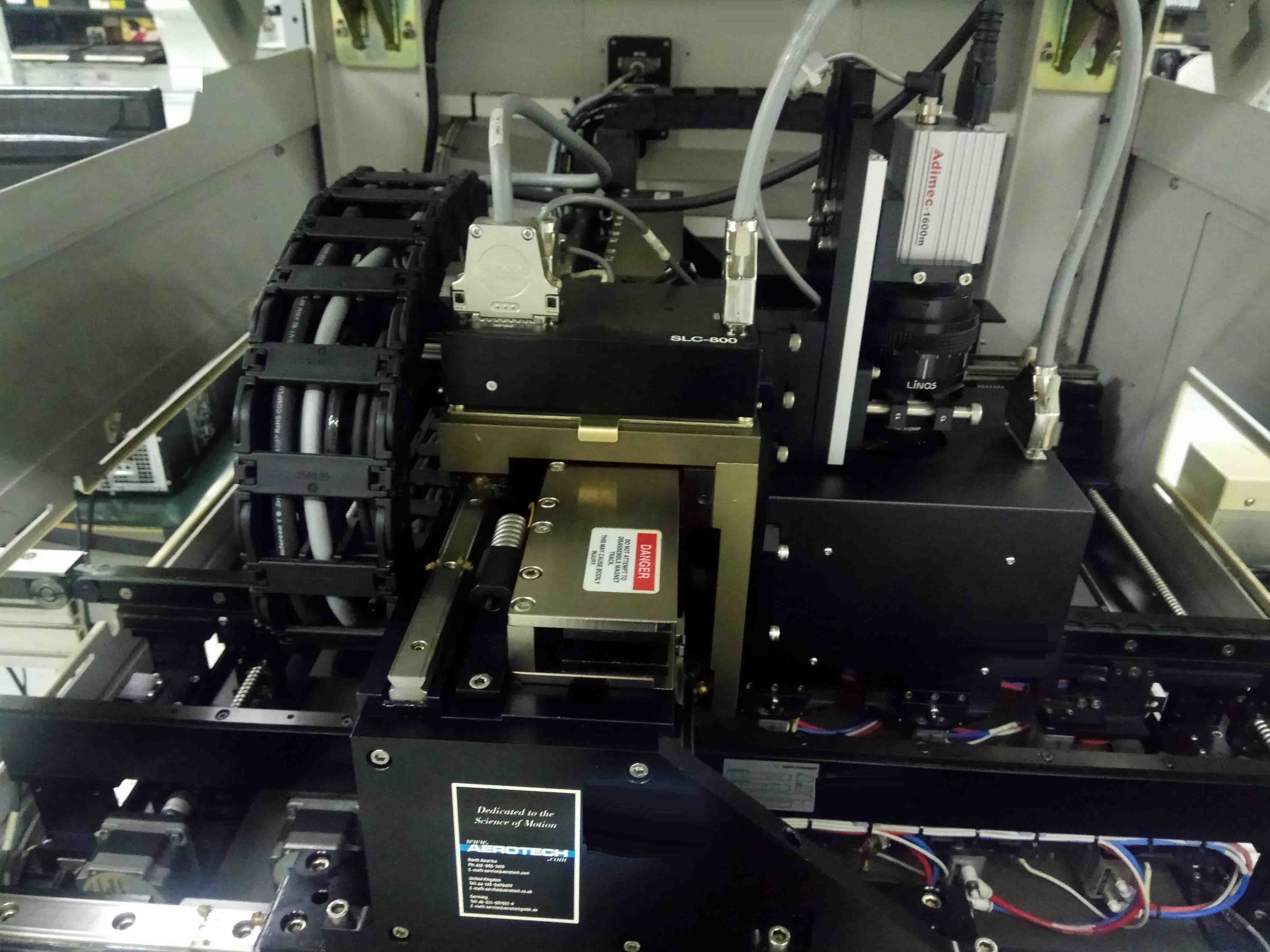

AGILENT / HP / HEWLETT-PACKARD / KEYSIGHT SJ50 is a fully automated pc board assembly and manufacturing equipment designed for high speed, quality controlled manufacturing and assembly of pc boards. The system includes a self-training, pick-and-place machine, a multi-headed AOI (Automatic Optical Inspection) machine, and an addition of precision pick-and-place parts placement machines for any size board. The unit is designed to rapidly place components ranging from 0201s to large BGA and connectors up to 50mm in size. HP SJ50 pick-and-place machine uses a self-training technology, which determines the best placement of components on the board, based on the design data file. It also has an automatic tool recognition, where the placement head automatically recognizes the package size of the components for faster and more accurate placements. The machine is also capable of dynamically changing speeds for different types of components in order to ensure high quality placements at a high speed. The AOI machine is equipped with a multi-head mode, allowing it to inspect multiple sections of the boards quickly. It has the ability to detect and classify multiple faults, including soldering, placement and component verification, which helps to ensure quality manufacturing. The machine also utilizes a vision based algorithm to identify defects like missing components and reversed components and also to detect excess solder or incorrect solder shape and size. AGILENT SJ-50 tool is designed for fast and efficient production with high quality assurance. It also comes with options for 3D X-ray pre-verification of closely spaced components, allowing the machine to detect and identify faults, regardless of their orientation. The asset also allows for real-time data collection, allowing for immediate analysis and prompt remedies to ensure continuous production. HP SJ-50 is ideal for high-accuracy and high-speed assembly of pc boards. As a fully automated model, it reduces the risk of human error, increases efficiency and improves quality control. With its built-in options for inspection and fault detection, it helps to ensure that the manufactured pc board will be of the highest quality. Its self-training capability and dynamic speed control ensure that the machine will quickly and accurately place components of a variety of sizes and configurations without compromising on speed and quality.

There are no reviews yet