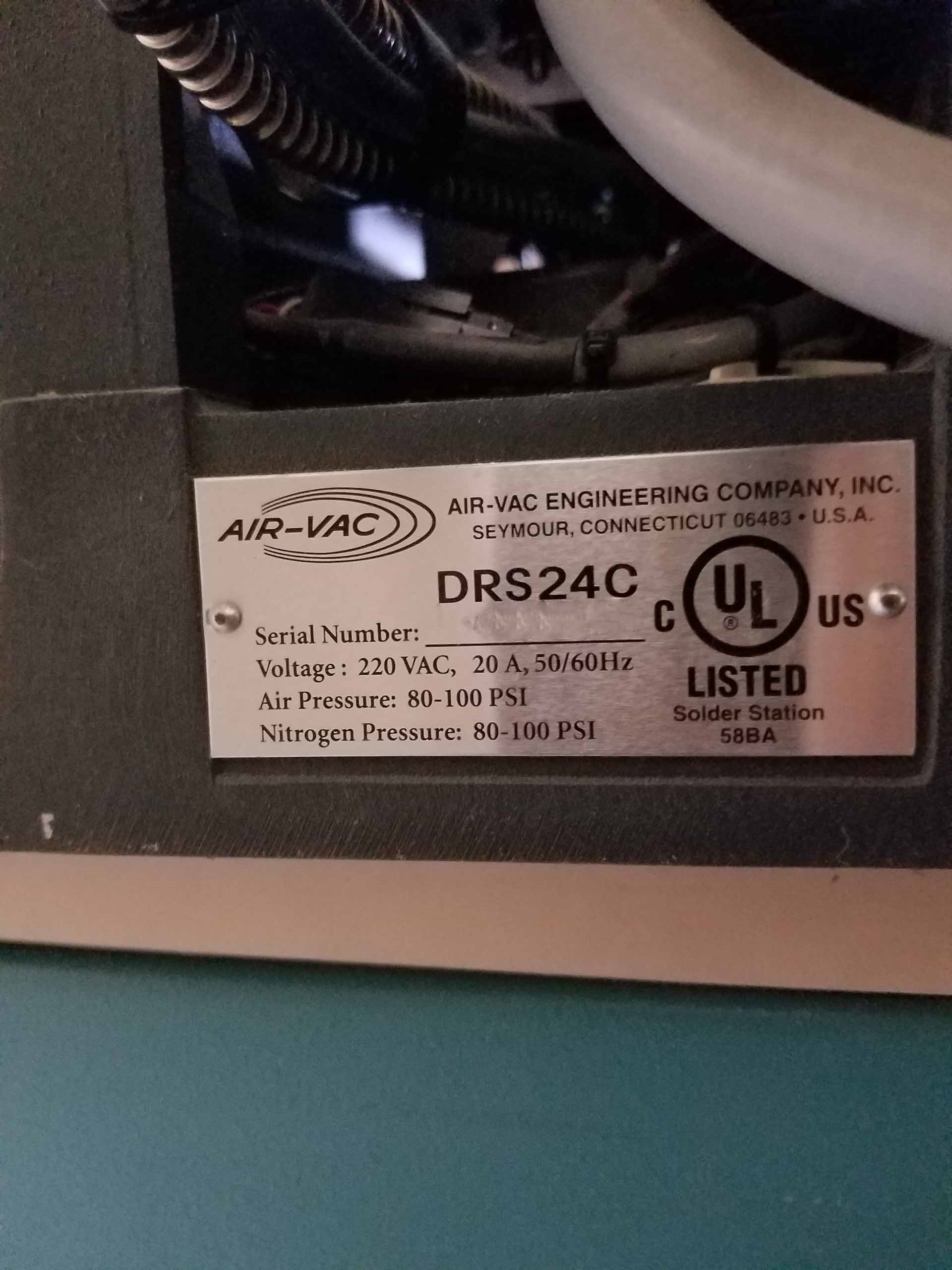

Used AIRVAC / ZEVAC DRS 24C #9204242 for sale

URL successfully copied!

Tap to zoom

AIRVAC / ZEVAC DRS 24C is a comprehensive, state-of-the-art PC board assembly and manufacturing equipment designed to meet the long-term manufacturing needs of today's technology-driven design and production environments. The system consists of a suite of high-performance components,including a dual-zone vacuum extraction unit, ultra-precise device placement tools, a highly accurate solder paste inspection machine, an advanced component placement camera, and a comprehensive test tool. The dual-zone vacuum extraction asset of ZEVAC utilizes two independent control zones to ensure precise handling and orientation, ensuring that all components are placed in the correct position on the target PC board. The vacuum extraction model also features a programmable control equipment that allows for easy and rapid selection of process recipes for different components. The ultra-precise device placement tools featured in AIRVAC are designed to precisely place components on the target PC board in the blink of an eye. Utilizing the latest in vision technology, the device placement system can be quickly programmed and controlled to place small and large components accurately and reliably. Furthermore, the device placement tools can accommodate components of different sizes and shapes, ensuring compatibility with standard components. AIRVAC / ZEVAC solder paste inspection unit is designed to deliver reliable inspection results by detecting defective components and contaminated solder paste. Utilizing high-resolution cameras and sophisticated software algorithms, it can detect a wide range of defects, such as insufficient or excessive solder paste, broken solder joints, missing component parts, and incorrect lead pitch. In addition, ZEVAC features an advanced component placement camera that can accurately capture images of the components to be placed on the PC board. The camera can be programmed to select components of different sizes, eliminating manual searches and saving time. This camera is also capable of identifying and correcting common errors in component placement. Finally, AIRVAC is equipped with a comprehensive test machine that can efficiently manage the various stages of production. This tool allows for valuable data to be gathered and shared in real-time, providing an effective means of troubleshooting and resolving issues. This array of advanced features makes AIRVAC / ZEVAC an ideal solution for reducing costs and delivering superb precision when manufacturing and assembling PC boards.

There are no reviews yet