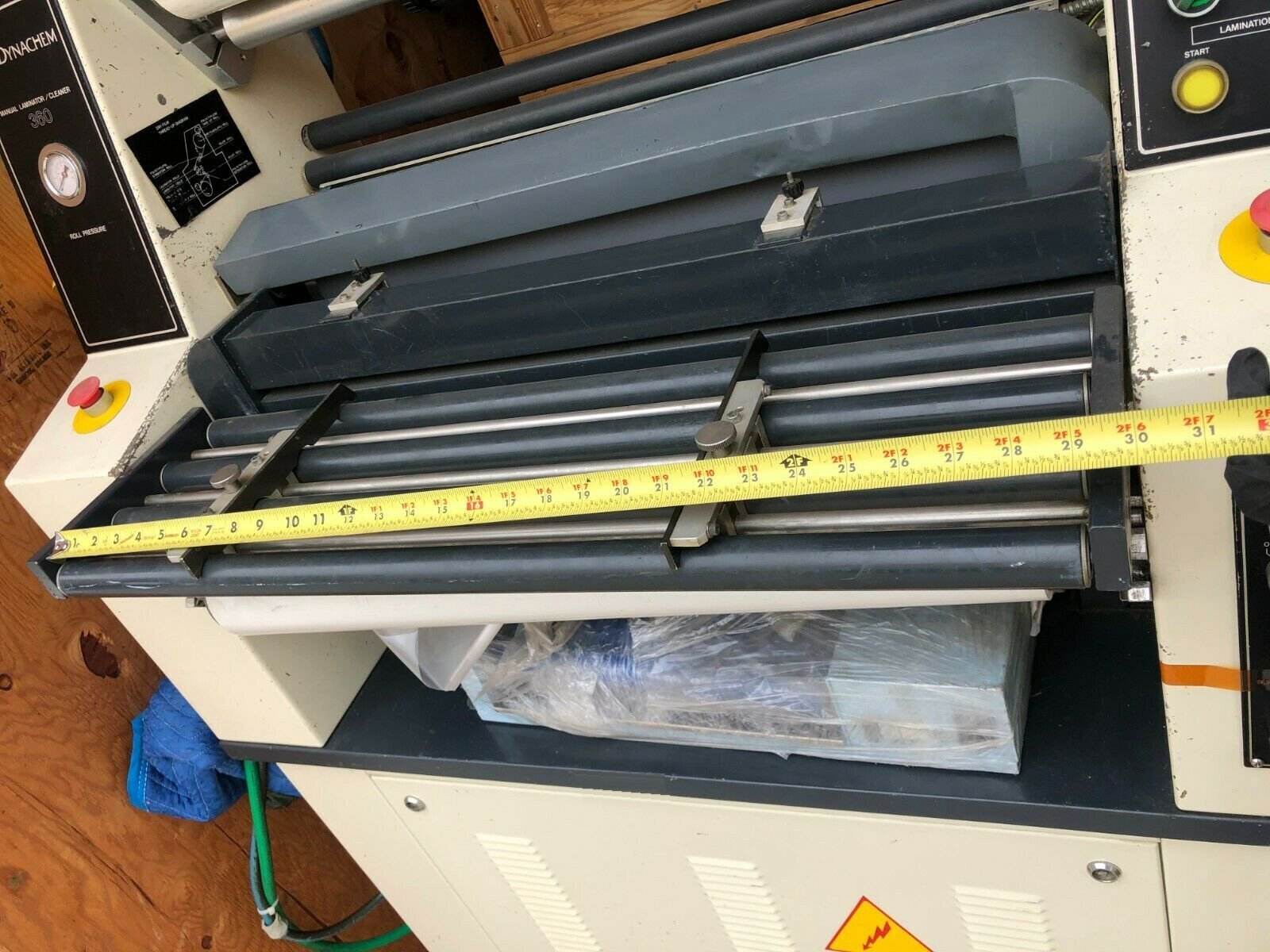

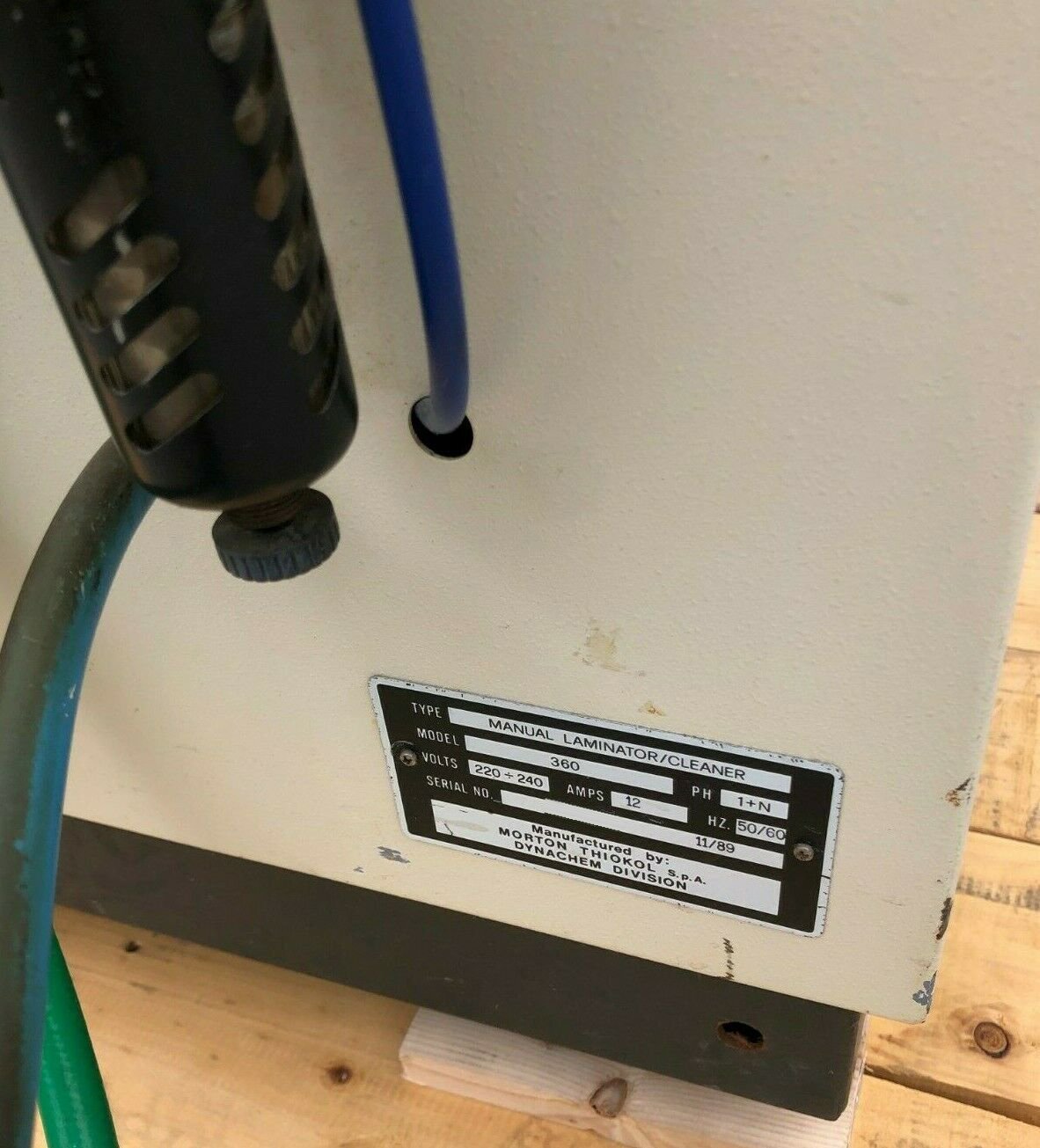

Used DYNACHEM 360 #9312547 for sale

URL successfully copied!

Tap to zoom

ID: 9312547

Manual laminator

Thickness panel sizes up to 635 mm

Rolls driven

Anti-static system

Easy dry film loading and alignment

Completely controlled by PLC

Provided with 3/6 in adapters

Oil-less compressed air system

Powerful vapor exhaust system

Lateral cutting capability.

DYNACHEM 360 is a revolutionary new PC Board Assembly and Manufacturing Equipment, designed to provide customers with a comprehensive, cost-effective solution to the increasingly complex needs of today's electronic component assembly and manufacturing processes. The system's cutting-edge technology boasts of a highly capable design that allows customers to customize the process according to their own unique needs. Utilizing 3-D imaging technology combined with virtual assembly, it enables users to accurately render and simulate assembly processes. The 3-D virtual environment drastically simplifies the management and tracking of product builds, ensures efficient traceability of components, and helps reduce overall errors within the assembly process. 360's modular architecture makes it easily adaptable to any existing or future production lines. The unit can be connected to SMT (Surface Mount Technology) manufacturing equipment, THT (Through Hole Technology) assembly processing, and CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) systems. This state-of-the-art technology ensures smooth transition between components of the entire manufacturing procedure. It also facilitates efficient resource management and reduces overall process lead times. The machine provides additional value-added features such as an inventory management tool, barcode scanner and BarTender printer. This allows users to track, manage, and store detailed manufacturing data which can be used to guide future production cycles. Furthermore, DYNACHEM 360 also incorporates a powerful defect reporting and analysis asset which provides detailed reports of production defects. Overall, 360 is an innovative and highly resourceful PC board assembly and manufacturing model. By providing customers with a complete package, it allows them to gain maximum return on their investment. It is flexible, easy to maintain, and provides an extensive array of features which reduce overall manufacturing costs and lead times. Therefore, this equipment is an ideal choice for customers looking for a reliable and cost-effective solution to their electronic component assembly and manufacturing processes.

There are no reviews yet