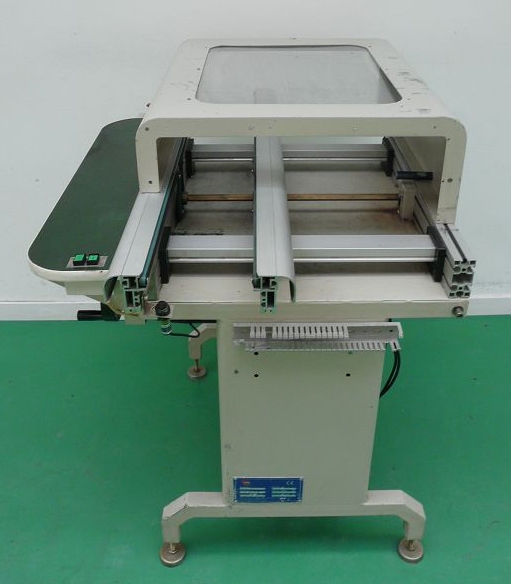

Used FOLUNGWIN FL-BC-1035A #9246203 for sale

URL successfully copied!

Tap to zoom

FOLUNGWIN FL-BC-1035A is a pc board assembly and manufacturing equipment designed for quick assembly and testing of printed circuit boards. It features a robotic gantry-type motion system, a programmable logic control (PLC) unit, and a variety of tools for automated material handling, drilling, and soldering. The machine can assemble a variety of PCB sizes and complexities from very small assemblies up to larger assemblies with many components. The robot gantry motion tool consists of an articulated arm driven by servomotors that moves along a predetermined path to pick up components from a selection array. The process is designed for speed and accuracy, allowing the asset to reliably assemble complex assemblies quickly and with repeatable accuracy. The PLC model is used to control the equipment as a whole, as well as the individual components. It allows the user to program different operations for each component, including the speed of the robotic gantry and the parameters for the automated drilling and soldering. This makes it possible to easily adjust the system for different types of components and assemble different boards. The unit also features a variety of tools for automated material handling, drilling and soldering. The machine is designed to handle a variety of components, from through hole parts to SMT components. It is also able to adjust for temperature differences when soldering, allowing for higher quality solder joints. The tool also includes automatic feeding and vision control, making it easier to inspect PCBs. Finally, the asset includes a quality control model to monitor the production process and ensure high-quality end-products. Data can be collected through the PLC equipment to track the performance of the system, and the data can be used to optimize the unit and ensure the assembly quality. Overall, FL-BC-1035A is an efficient and reliable pc board assembly and manufacturing machine that can be used to quickly and reliably assemble and test a variety of printed circuit board sizes and complexities. The tool is designed for maximum speed and accuracy, and can quickly and easily adjust for different components and assemblies. With its quality control asset and data gathering capabilities, it guarantees a high standard of end-products.

There are no reviews yet