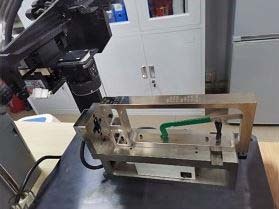

Used FUJI NXT #9360622 for sale

URL successfully copied!

Tap to zoom

FUJI NXT is a complete PC board assembly and manufacturing equipment that is capable of automating the most complicated and labor intensive aspects of circuit board production. The system combines advanced PC board manufacturing and assembly solutions designed for a wide range of applications. NXT is designed to reduce labor and overhead costs while increasing accuracy and throughput. The unit's features are tailored towards production automation, including simplified maintenance and setup. FUJI NXT machine includes an inline robotic tool that can handle multiple tasks, such as component placement, soldering, and rework. It is also capable of more sophisticated tasks such as optical and x-ray inspection. The asset utilizes powerful vision technology, such as machine vision and 3D imaging, to accurately detect components and ensure proper placement during assembly and soldering. NXT also offers an extensive range of process capabilities, including high-speed precision assembly, pick and place technologies, 3D imaging, and automatic component feeding. Through the use of these technologies, higher throughput rates can be achieved, resulting in reduced costs, and improved process reliability and repeatability. The model is equipped with advanced motion control features, including high-speed motion control servo motors, and an extensive library of motion profiles. This allows operators to create and adjust process parameters, such as optimal speed, accuracy, and control precision. FUJI NXT also features a fully integrated data management equipment. It allows for the collection and analysis of process data, and helps to ensure that information is stored and retrievable for future use. Additionally, alarms, warnings, and diagnostics are offered through the system to help identify any problems that may arise throughout production. In conclusion, NXT unit is a complete PC board assembly and manufacturing machine that offers numerous benefits to manufacturers. Its advanced features, such as robotic automation, vision technology, high-speed motion control, and data management provide increased process reliability and repeatability, while reducing labor and overhead costs.

There are no reviews yet