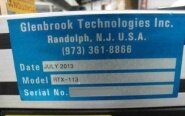

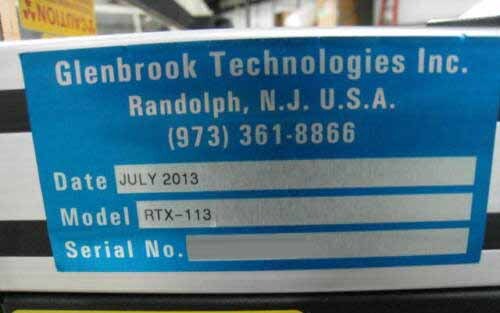

Used GLENBROOK TECHNOLOGIES RTX-113 #9174717 for sale

URL successfully copied!

Tap to zoom

ID: 9174717

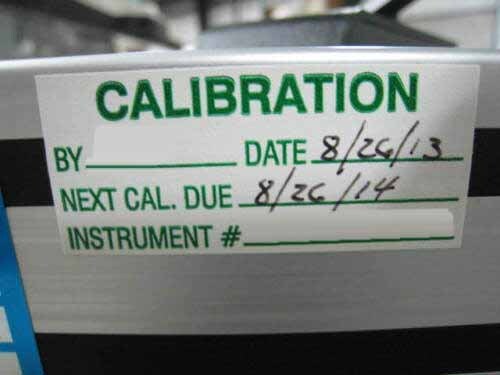

Vintage: 2013

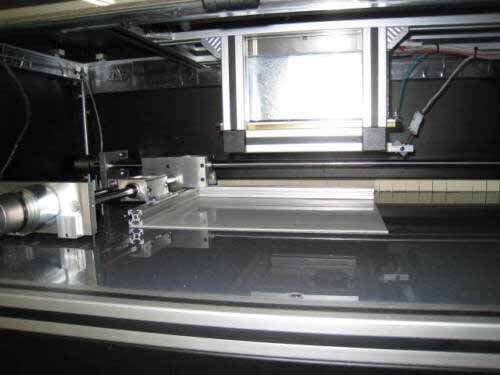

X-Ray inspection system

Recursive average: (8) Frames

Image magnification: 15x

Image processing software: GTI-5000

With USB frame grabber

Motorized X-Y positioner:

Image processing software: GTI-5000

USB Frame grabber

Frame average: 2-256

Includes:

80 kV X-Ray tube

Power supply and controls

XRTV High sensitivity x-ray camera

Auto-BGA analysis

Voltage: 110 V

2013 vintage.

GLENBROOK TECHNOLOGIES RTX-113 PC Board Assembly and Manufacturing Equipment is a state-of-the-art, production-level quality machine capable of delivering high-accuracy printed circuit board (PCB) assembly and fabrication. GLENBROOK TECHNOLOGIES RTX 113 boasts a wide range of features that enable businesses to quickly and easily produce high-quality parts with precise results. RTX-113 offers an ultra-compact design that packs a large array of components into a footprint much smaller than comparable systems. The embedded design makes for an improved system performance that ensures smooth operation with high returns on investment. The GTX-113 utilizes a sophisticated Mix-and-Match Technology that allows users to configure their workflow for maximum optimization and optimal cost-efficiency. RTX 113 is also equipped with advanced quality assurance systems, such as Advanced Metrology for precise part placement, Automated Optical Inspection (AOI) for pin-by-pin accuracy, and Integrated X-Ray Inspection (IXI) for defect-free parts. GLENBROOK TECHNOLOGIES RTX-113's advanced motion control unit uses a powerful microprocessor to provide ultra-fast speed and accuracy. It employs highly reliable delta-style robot arms to handle intricate and delicate parts with precision and consistency. Additionally, GLENBROOK TECHNOLOGIES RTX 113 offers a wide range of support services, such as complete installation, setup, and validation to ensure quick and easy deployment into any production environment. The included flexibility and scalability features provide versatility for any level of complexity. RTX-113 features a large variety of features to improve the assembly process, such as an ultra-high speed feeder machine for faster production, a unique nozzle tool to reduce product waste, a powerful Vision Positioning Asset, and an auto-rework model for solder removal and replacement. RTX 113 is one of the most powerful and reliable printed circuit board assembly systems available, capable of handling complex and intricate boards with precision and consistency. It is the perfect platform for businesses looking to produce high-quality parts with maximum efficiency and cost-effectiveness.

There are no reviews yet