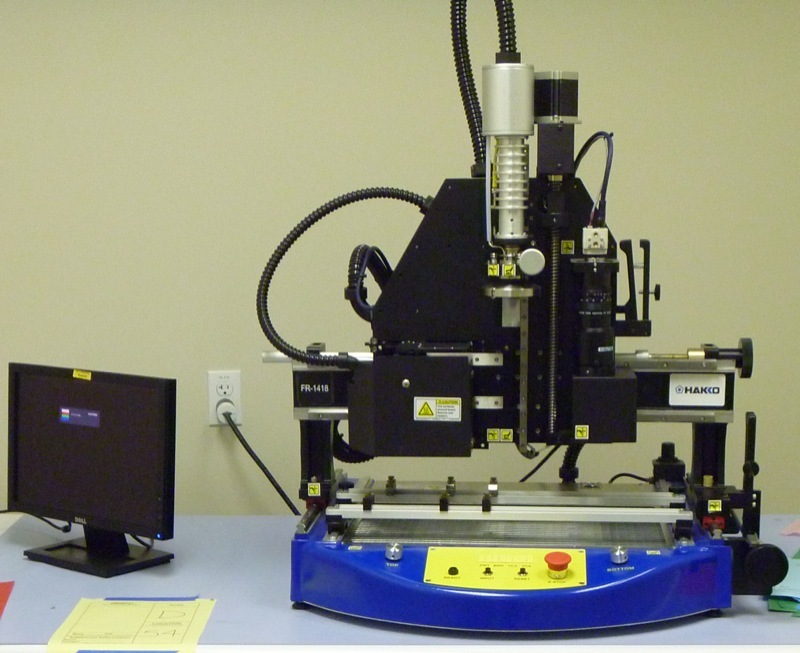

Used HAKKO FR-1418 #9009231 for sale

URL successfully copied!

Tap to zoom

ID: 9009231

SMD rework system

Single zone preheat (10 x 12")

Automated-Z with PC control system

120 V system

1 kW top heating element

Includes accessories:

(2) Heater, lamp, bottom IR, 500 W, part no. 222-510

(3) Thermocouple, type K, 36 AWG, part no. 222-512

Calibration, optics, tip, part no. 222-514

Calibration, optics, plate, part no. 222-515

HMI software and workstation, part no. 222-540:

HMI software

Workstation computer with flat panel monitor

Video capture card

Includes option:

Kit air preparation package, filter/regulator and hose, part no. 999-216-01

Nozzles:

Standard nozzle kit, part no. 222-503:

(6) standard square nozzles: 14, 18, 22, 26, 30, and 34 mm

Vacuum cups and fittings:

(3) Vacuum cup, 9 mm DIA, part no. 222-530

Fitting, vacuum cup, 9 mm dia, part no. 222-531

(3) Vacuum cup, 12 mm dia, part no. 222-532

Fitting, vacuum cup, 12 mm dia, part no. 222-533

(3) Vacuum cup, 5 mm dia, part no. 222-524-01

(3) Vacuum cup, 8 mm dia, part no. 222-513.

HAKKO FR-1418 is a reliable, automated PC board assembly and manufacturing equipment. It is designed for high-volume production of high-tech mobile devices and other consumer electronics products. It is capable of assembling PCBs of different sizes and densities. FR-1418 consists of three main components- a pick and place robotic cell, an assembly line, and a conveyor. The pick and place cell is designed to quickly and accurately pick and place components on PCBs of various shapes and sizes. It is equipped with a vision system to identify the location of each component, and the robot can place them with precision with a high success rate. The assembly line is designed to route and mount the components to the PCBs with the highest level of accuracy. It also serves to perform any additional tests and inspections necessary prior to mounting the components. Lastly, the conveyor is used to transport PCBs from the assembly area to the loading area. HAKKO FR-1418 is also capable of supporting complex print and programming operations. It includes a multi-functional high-speed printer for printing labels, company logos, and PCB information. It also includes a programmable unit for programming the data required for various tasks. Other special features include track and trace capabilities to record production data and a user-friendly graphical interface to allow for easy data entry and retrieval. Addtionally, FR-1418 offers customer support and maintenance services. The machine is designed with safety mechanisms to prevent accidental operation, and it is equipped with sensors and alarms to alert the operator of any errors or malfunctions. The customer service team is also available to provide remote assistance and technical advice. Overall, HAKKO FR-1418 provides a reliable, automated solution for high-volume PCB assembly and manufacturing. Its advanced features and support services make it an ideal option for busy production facilities. With FR-1418, you can be sure that your PCB assemblies and electronic devices will be produced with the highest level of quality and accuracy.

There are no reviews yet