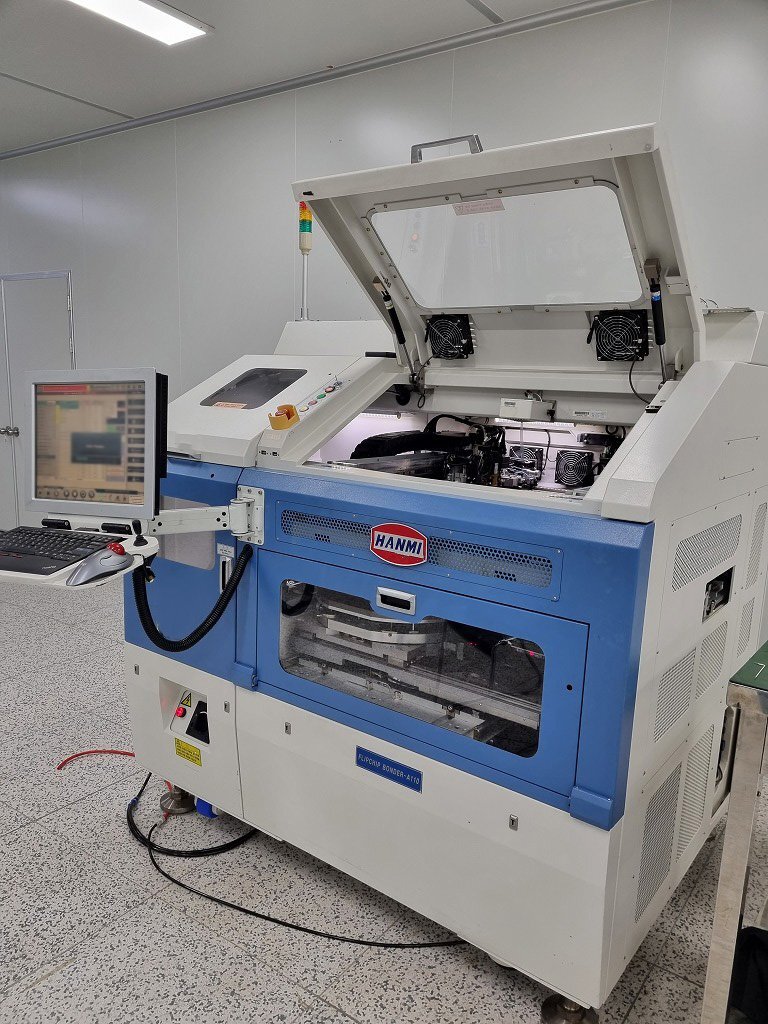

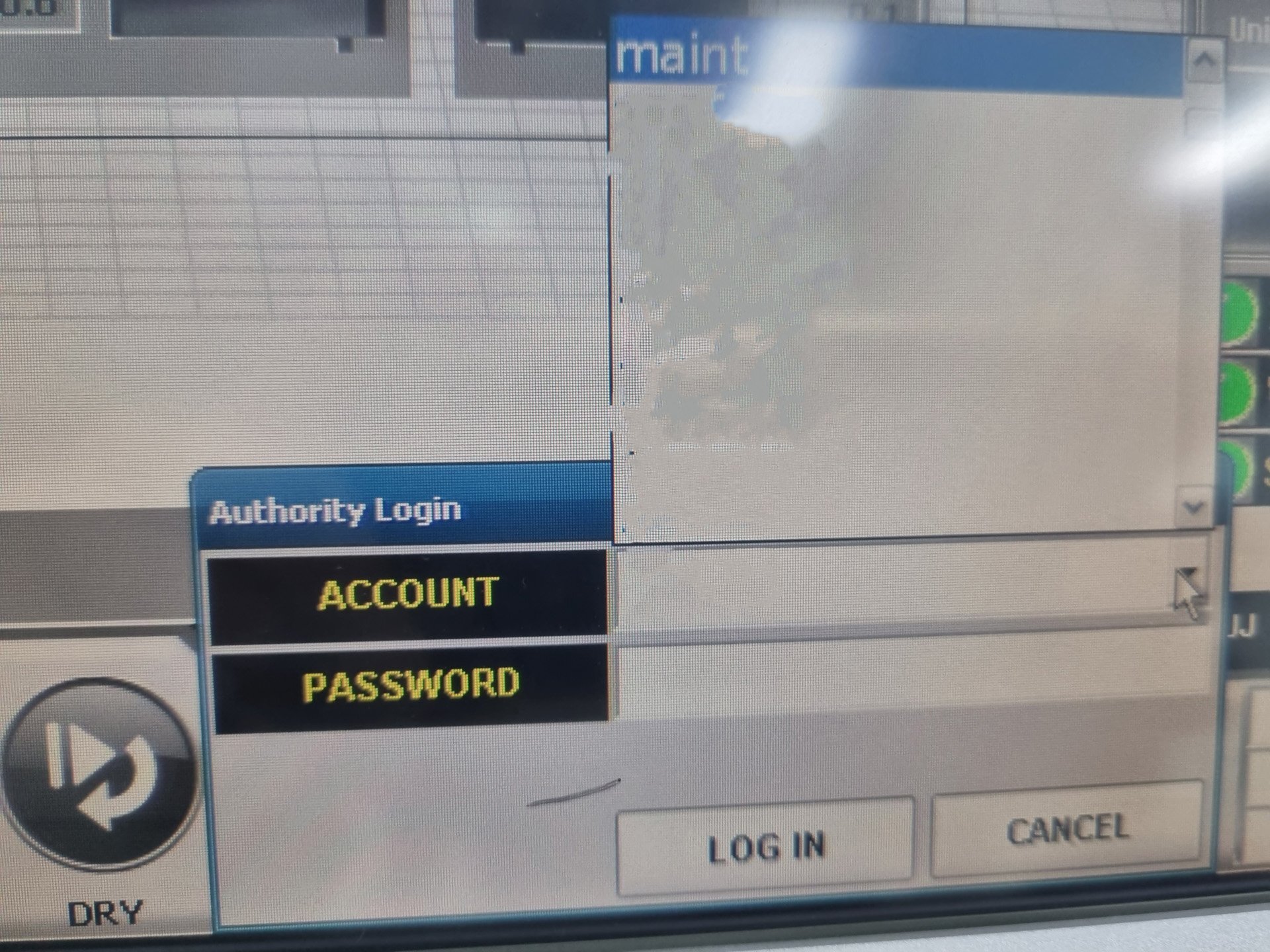

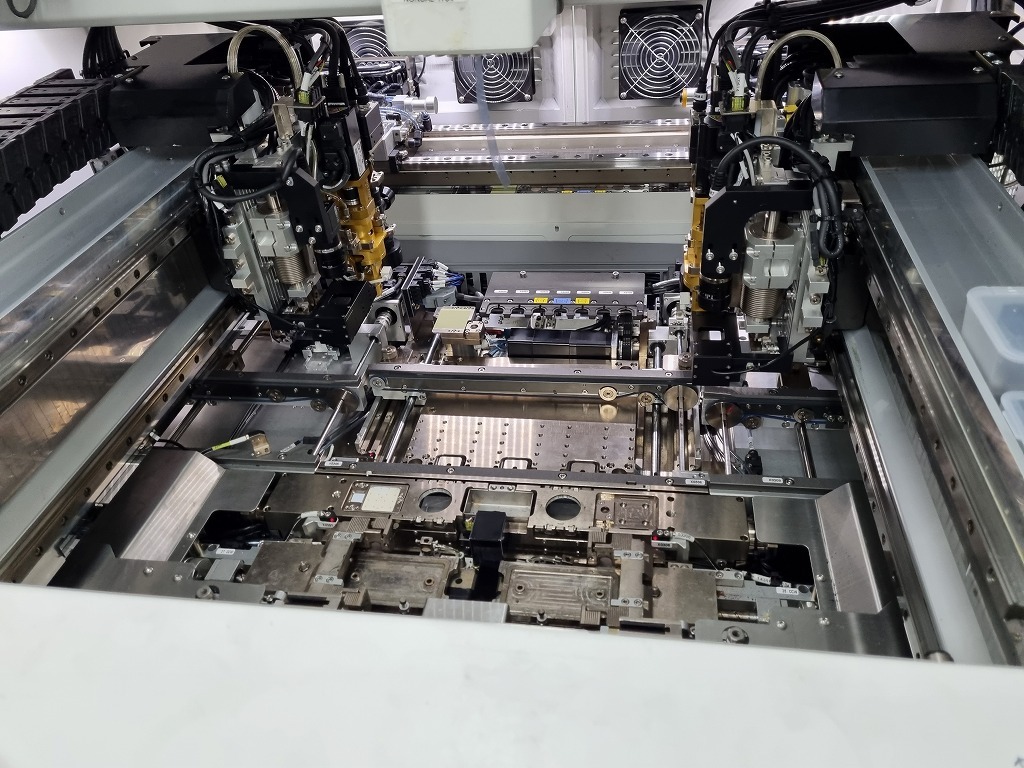

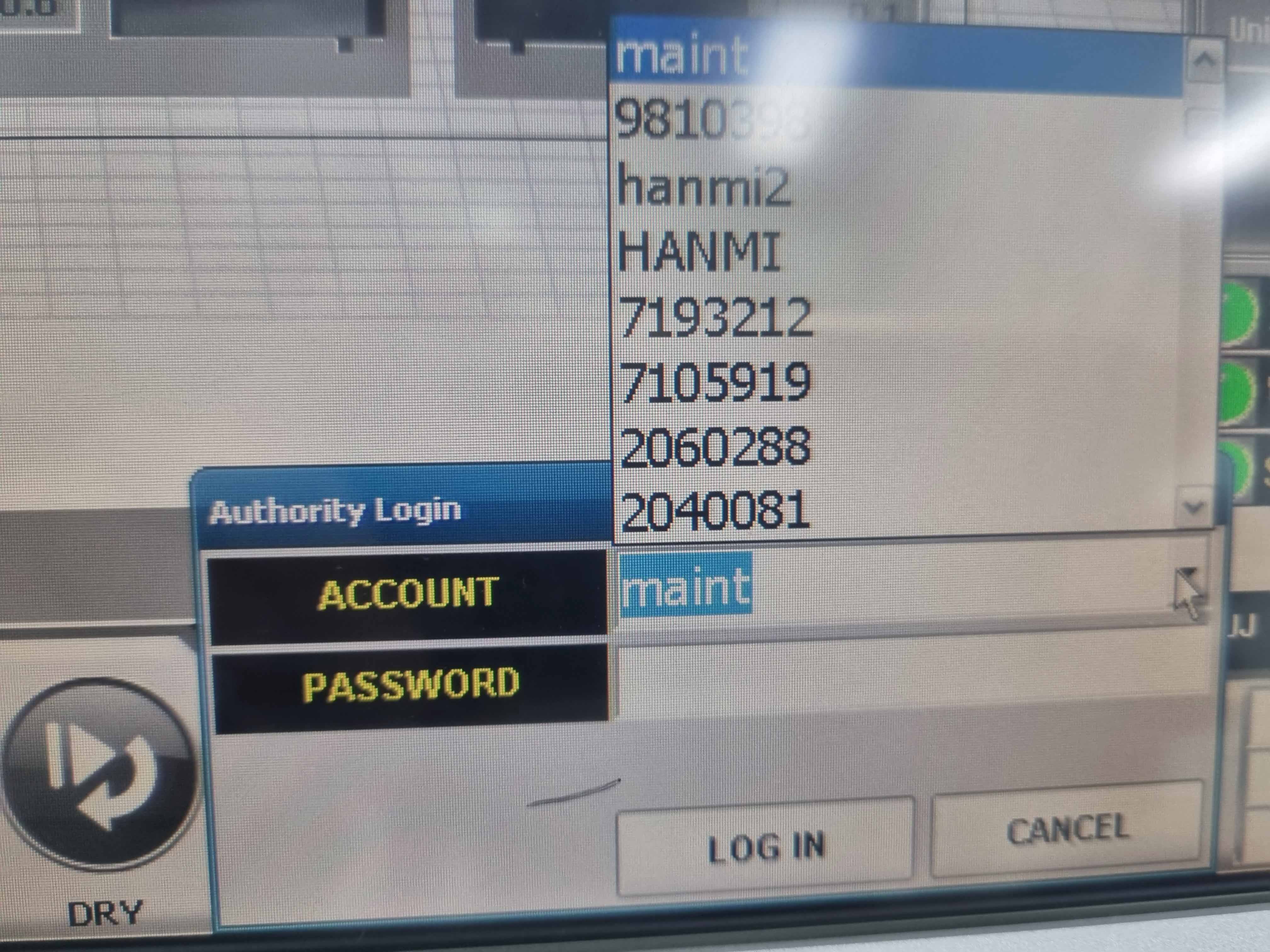

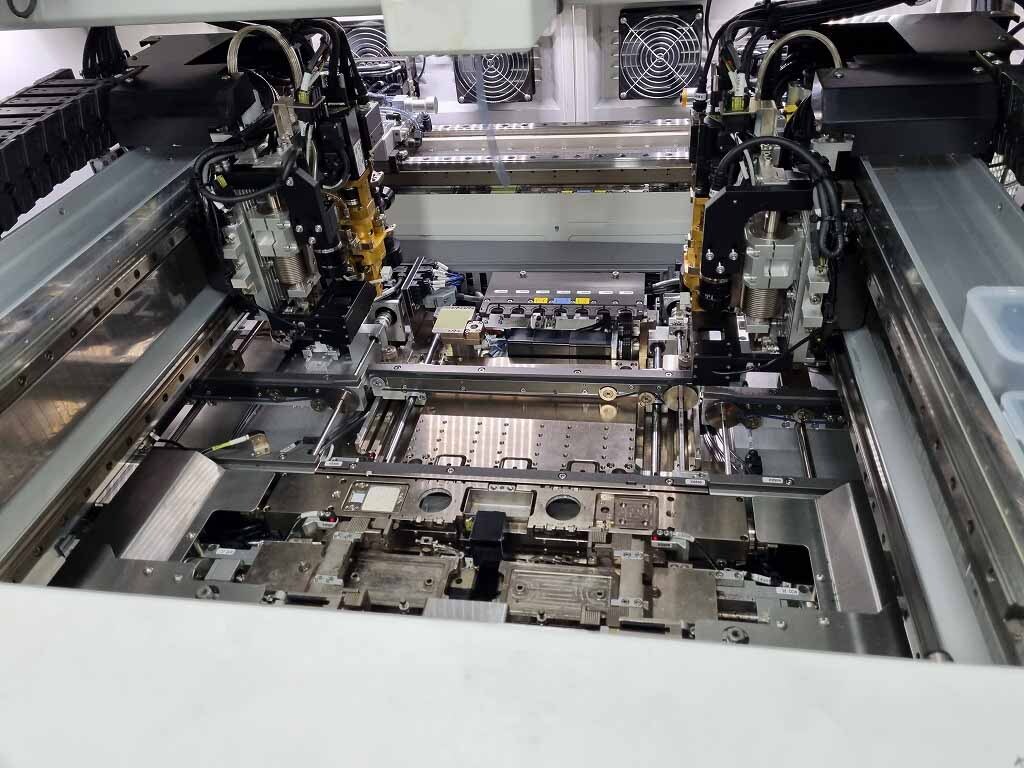

Used HANMI A110 #293641231 for sale

URL successfully copied!

Tap to zoom

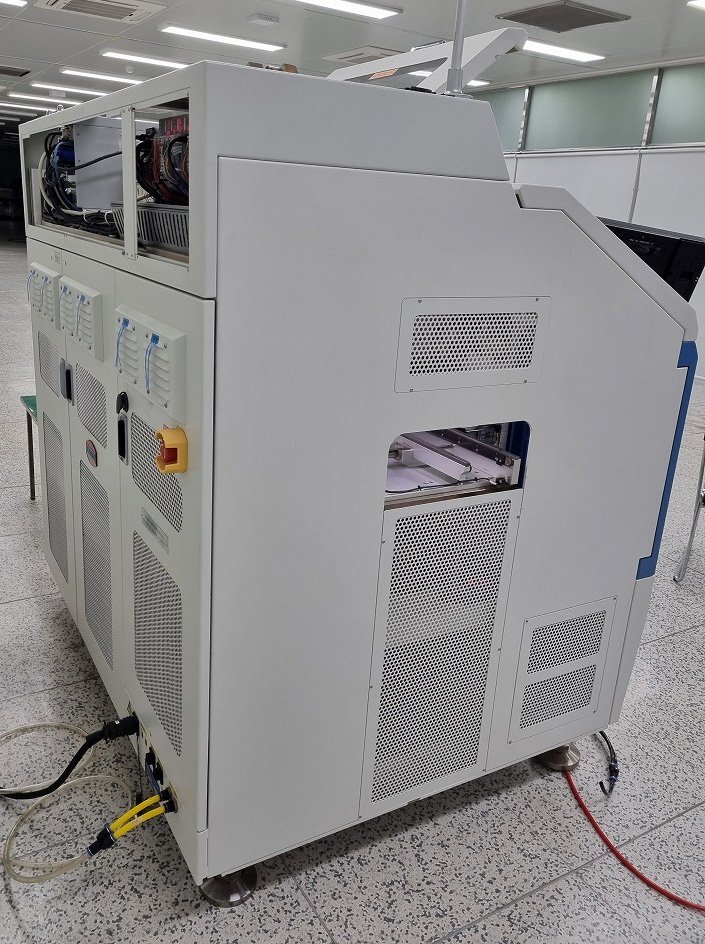

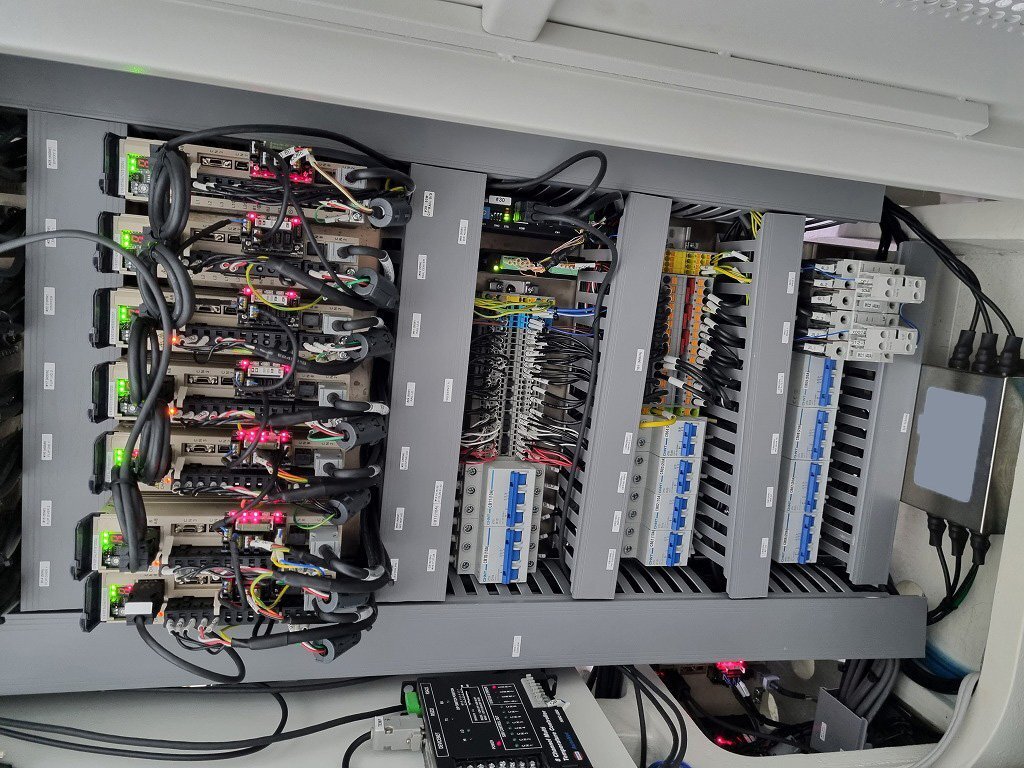

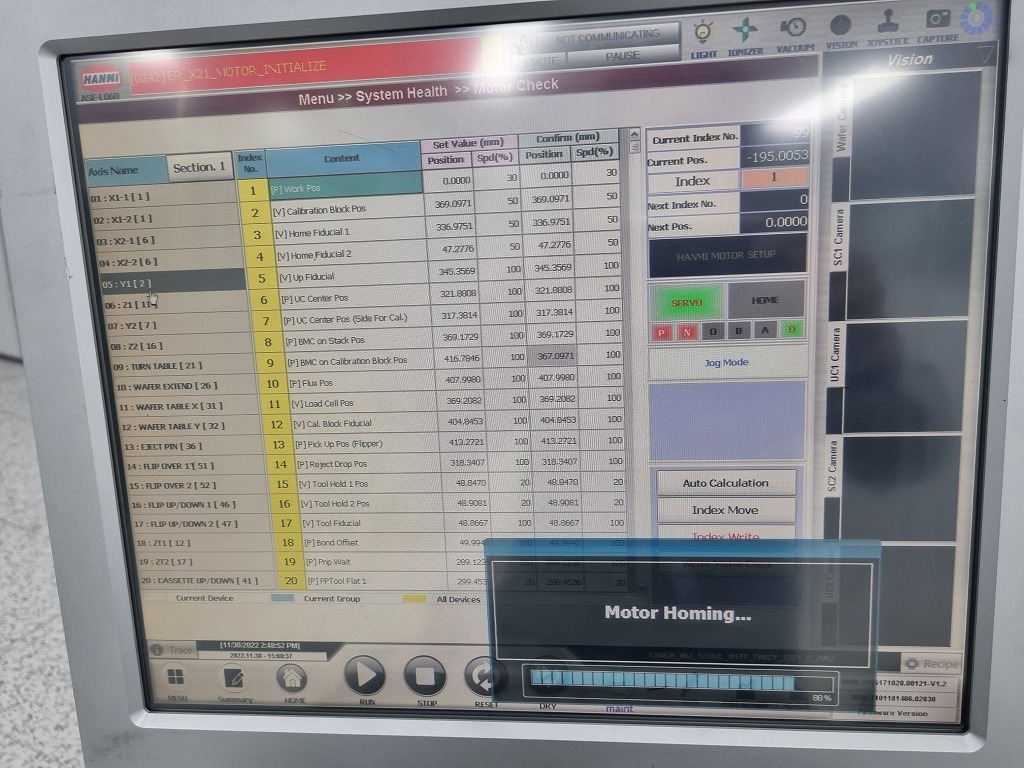

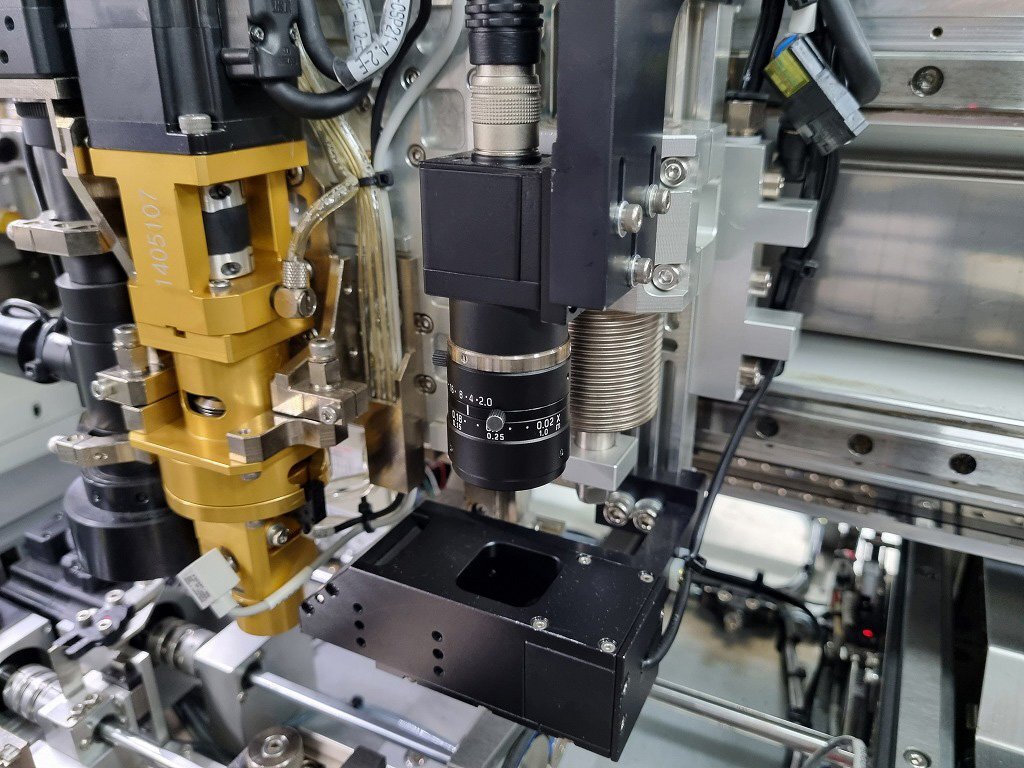

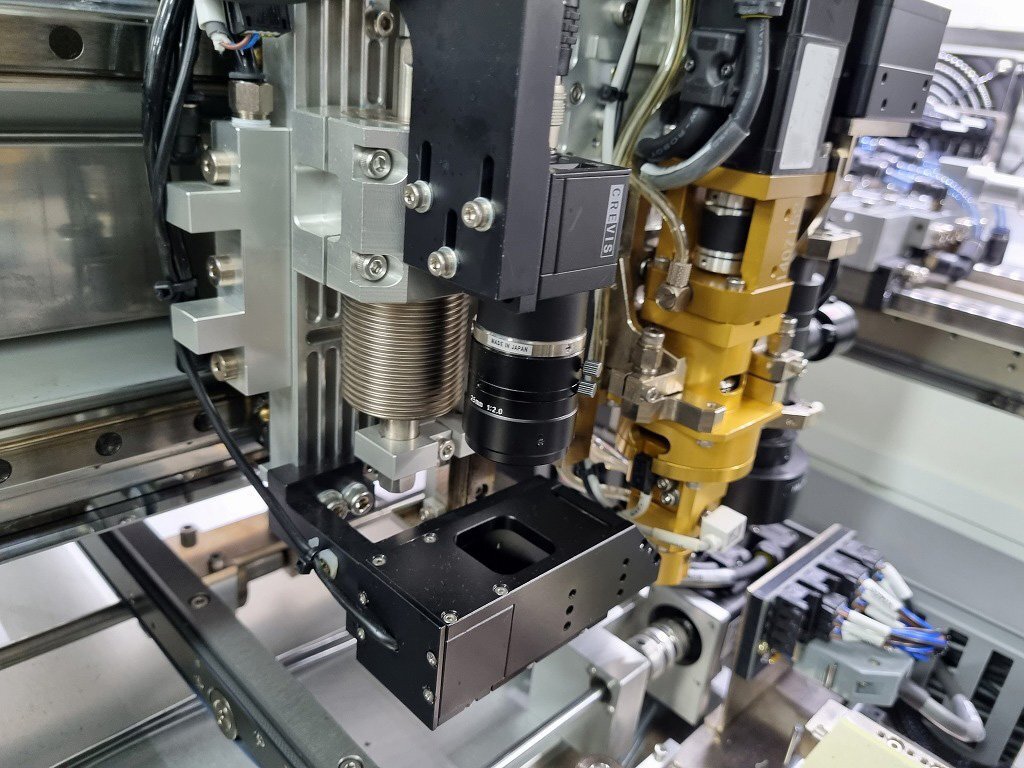

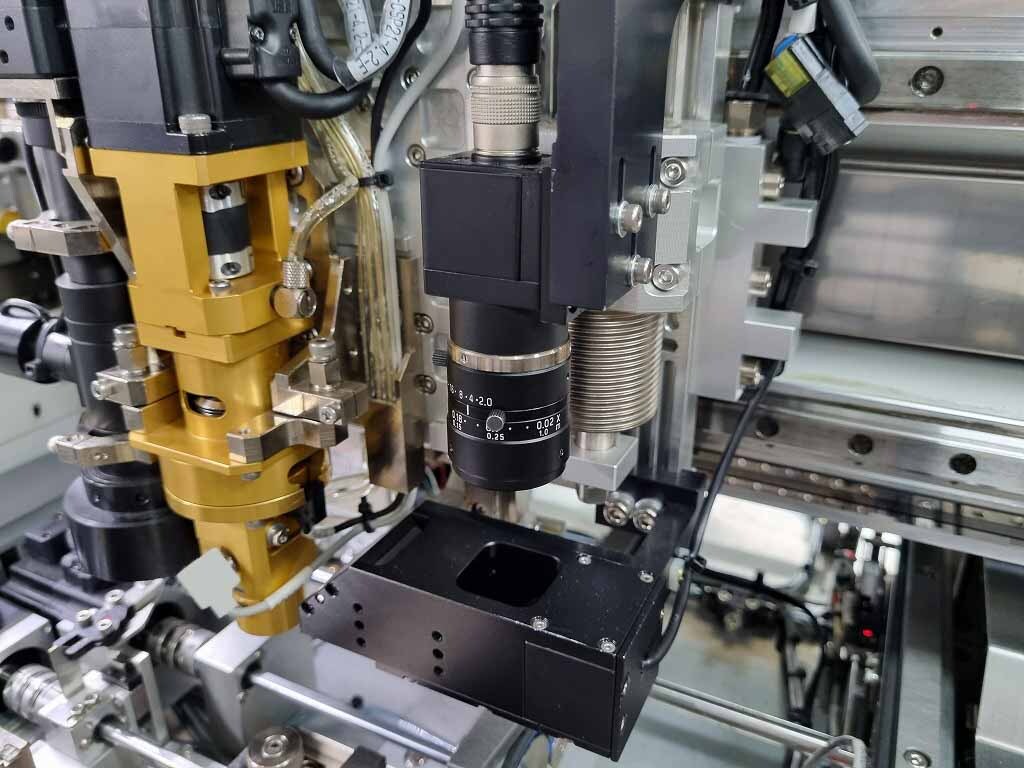

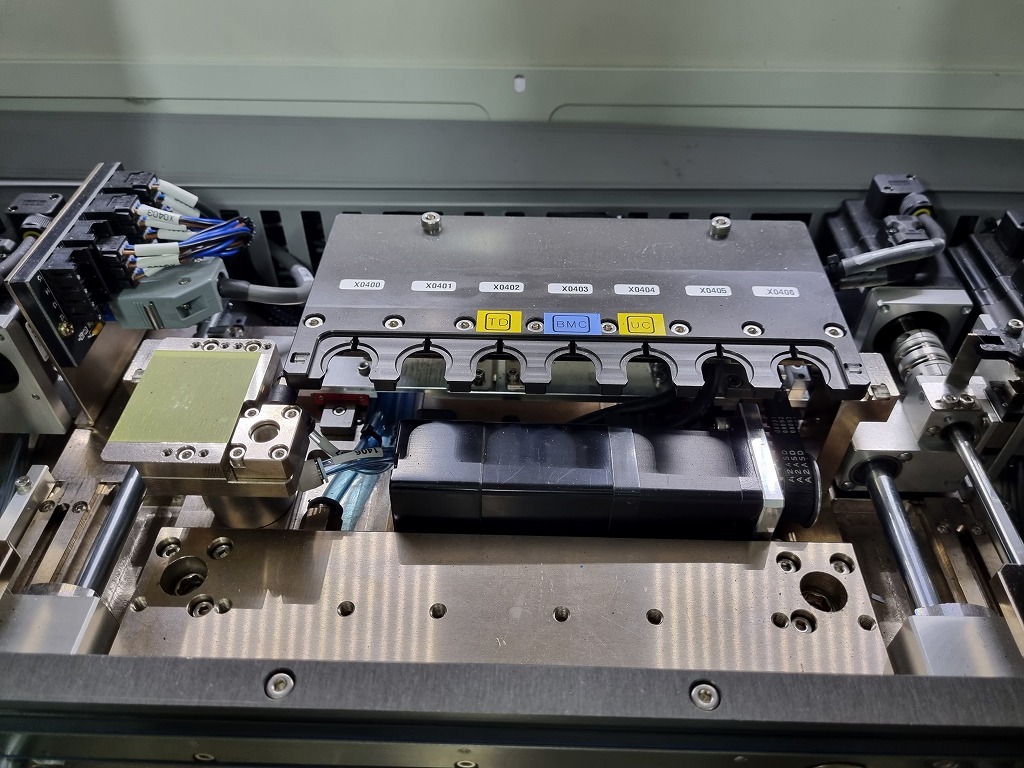

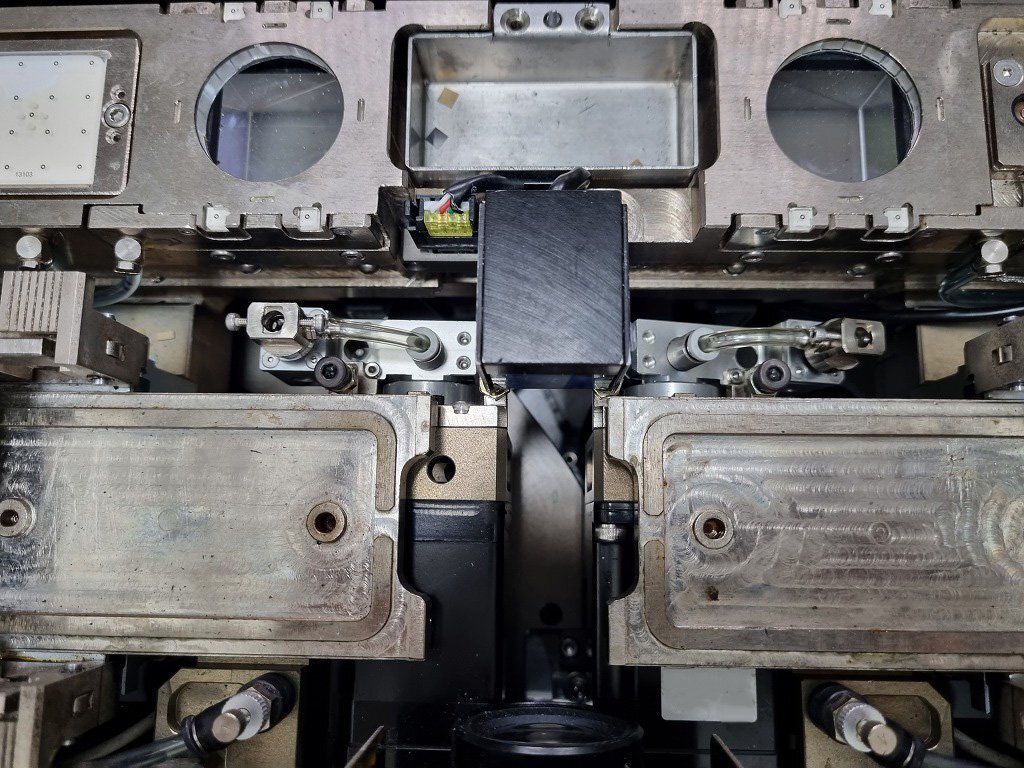

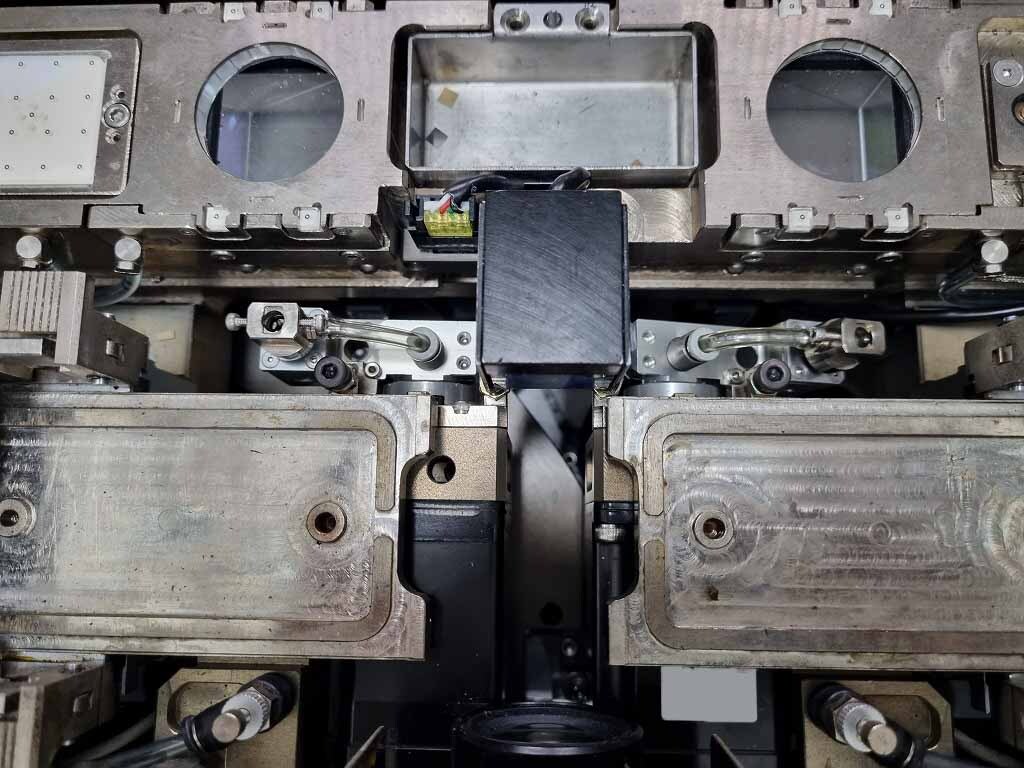

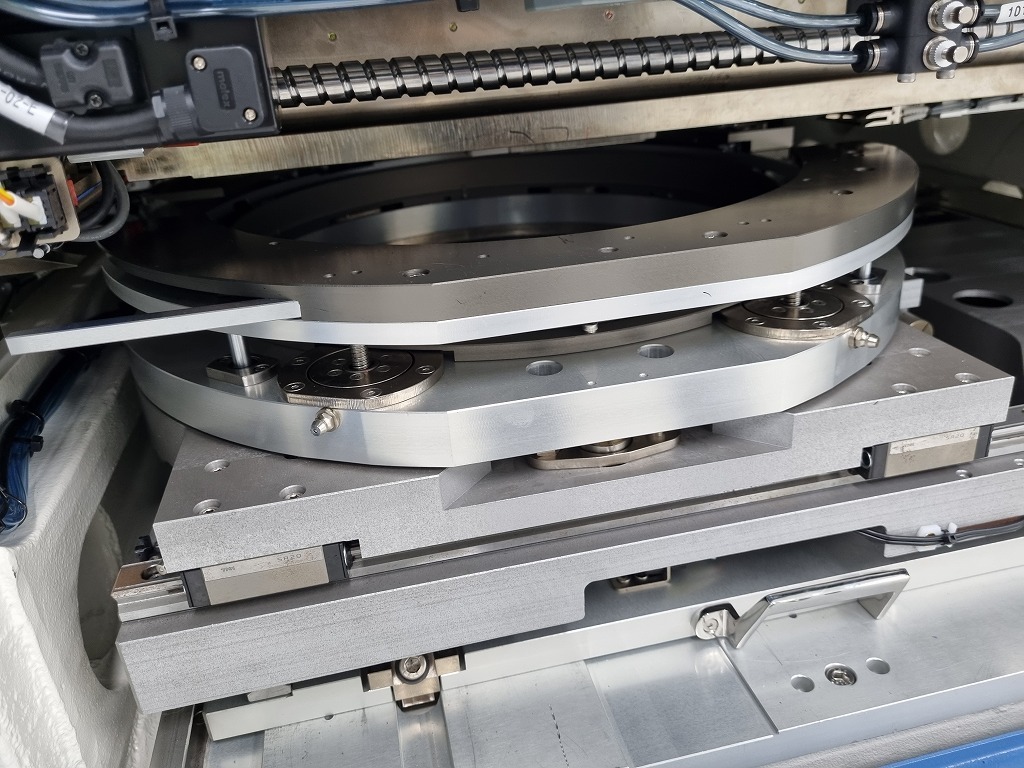

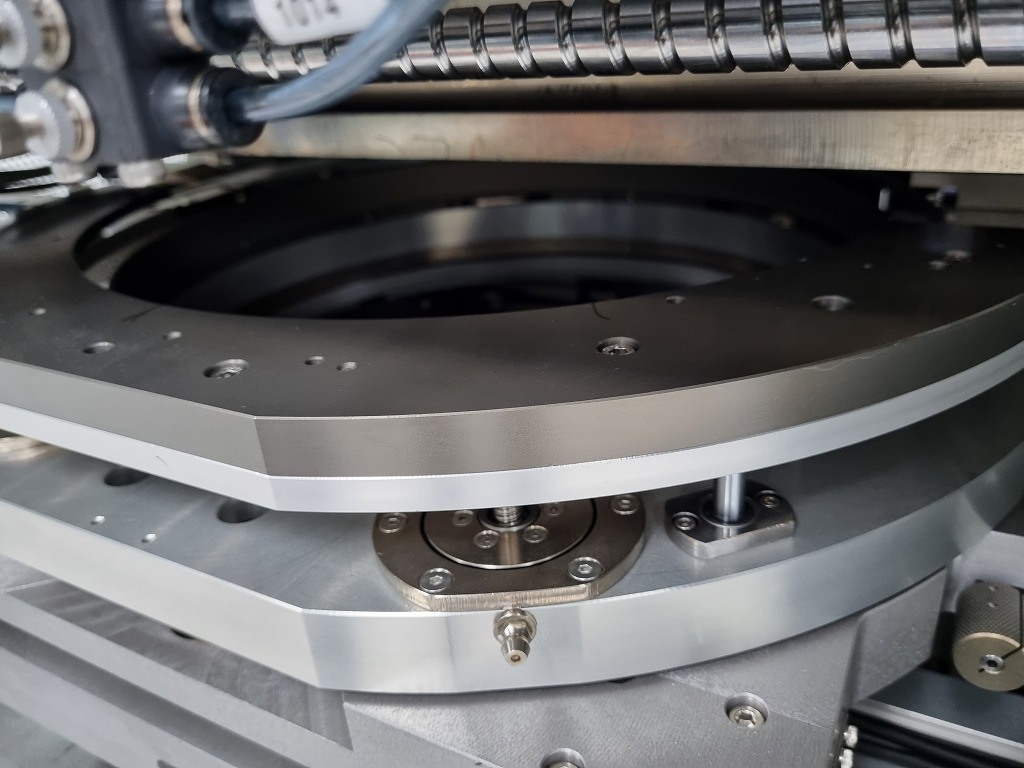

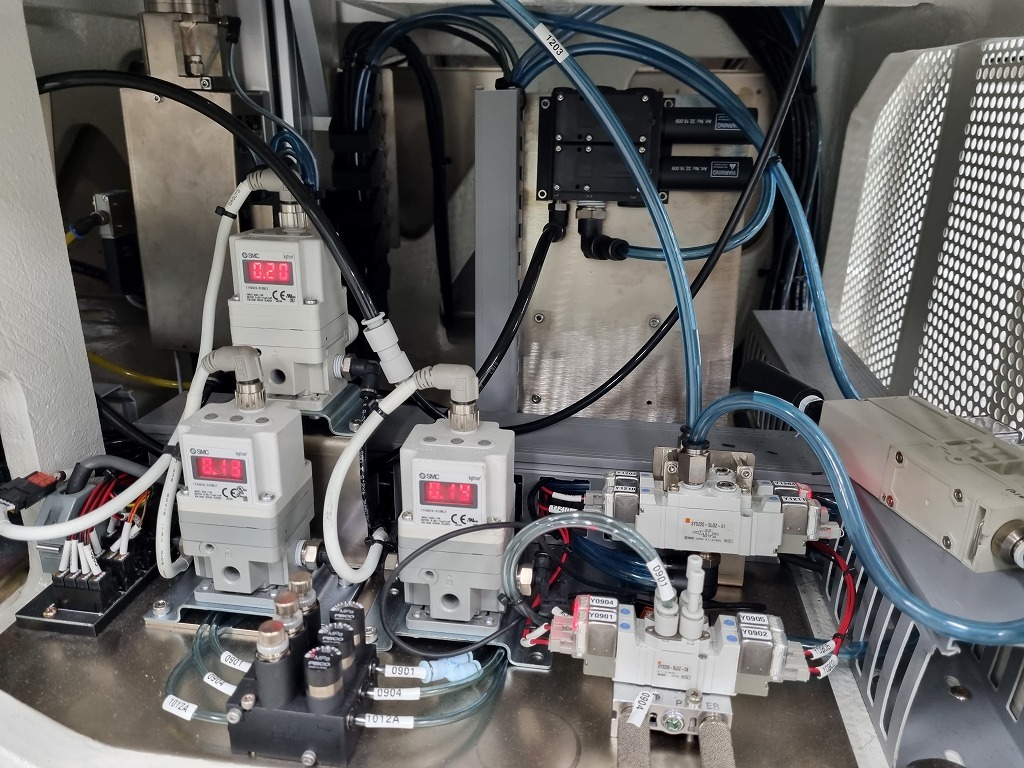

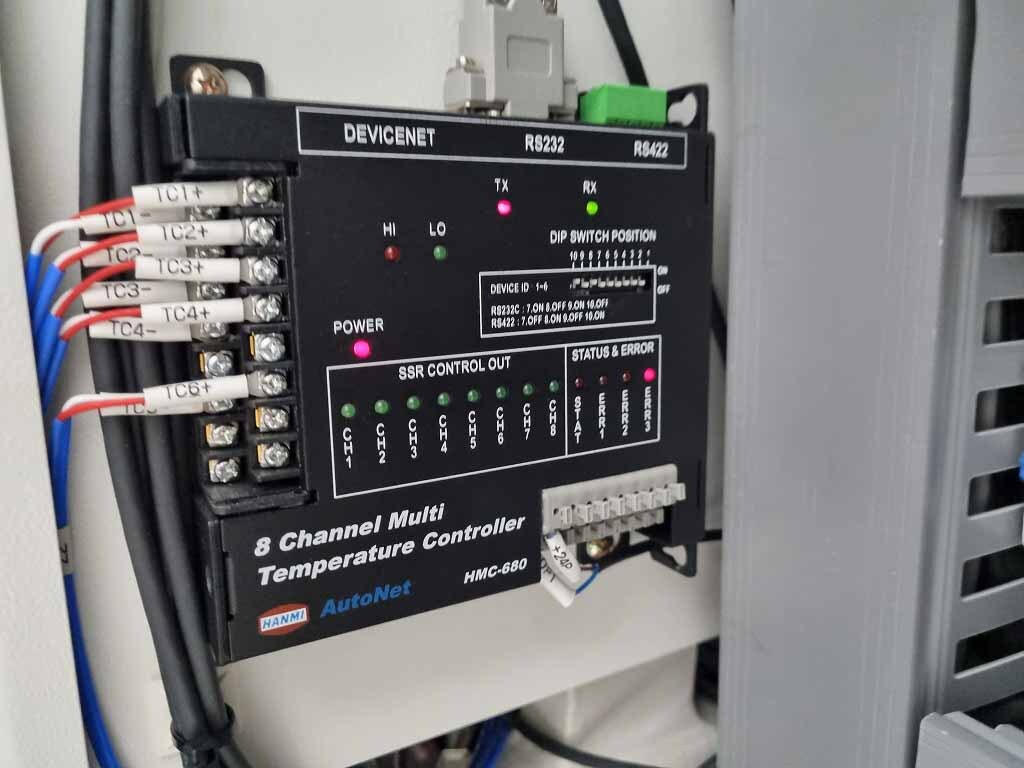

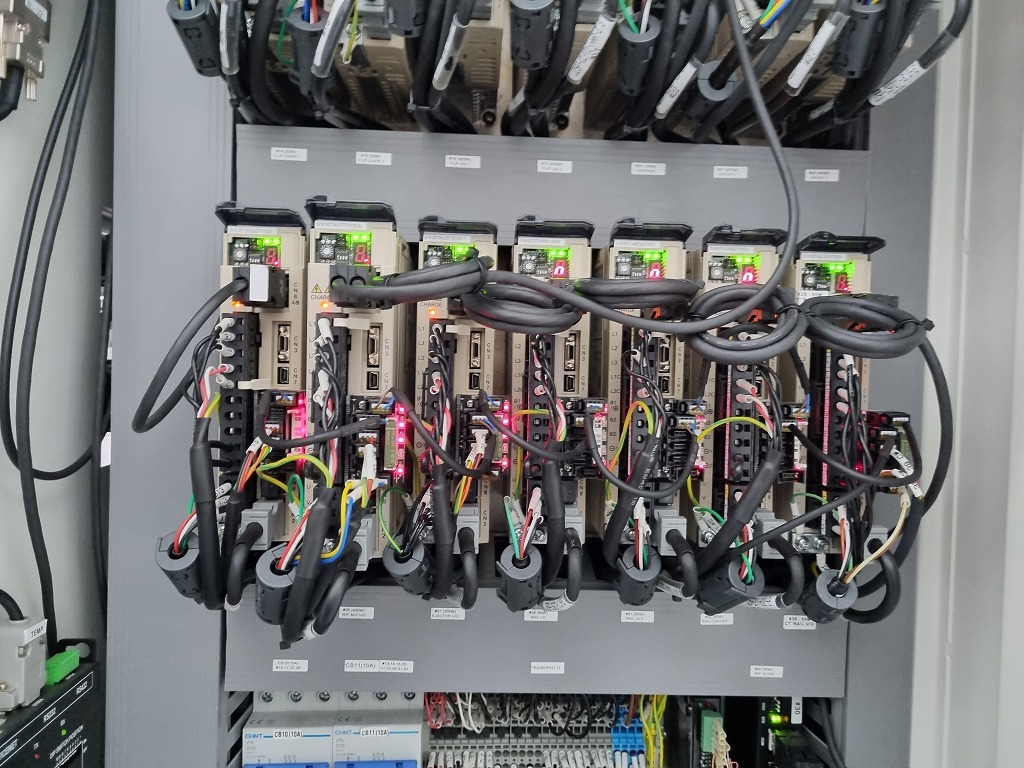

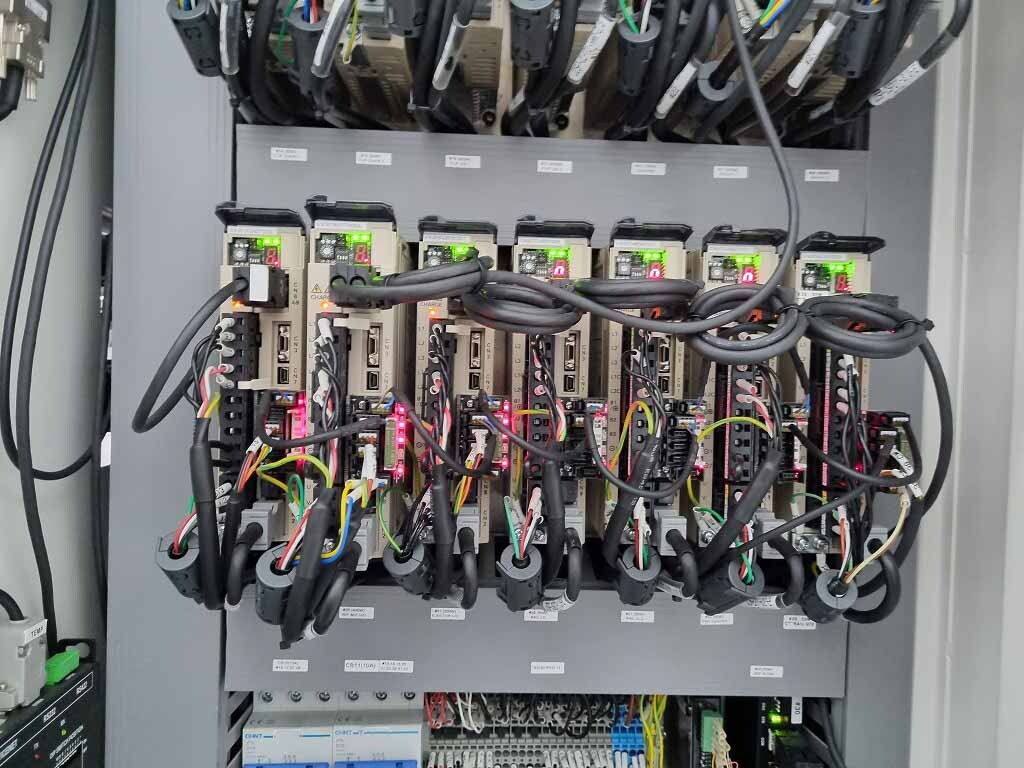

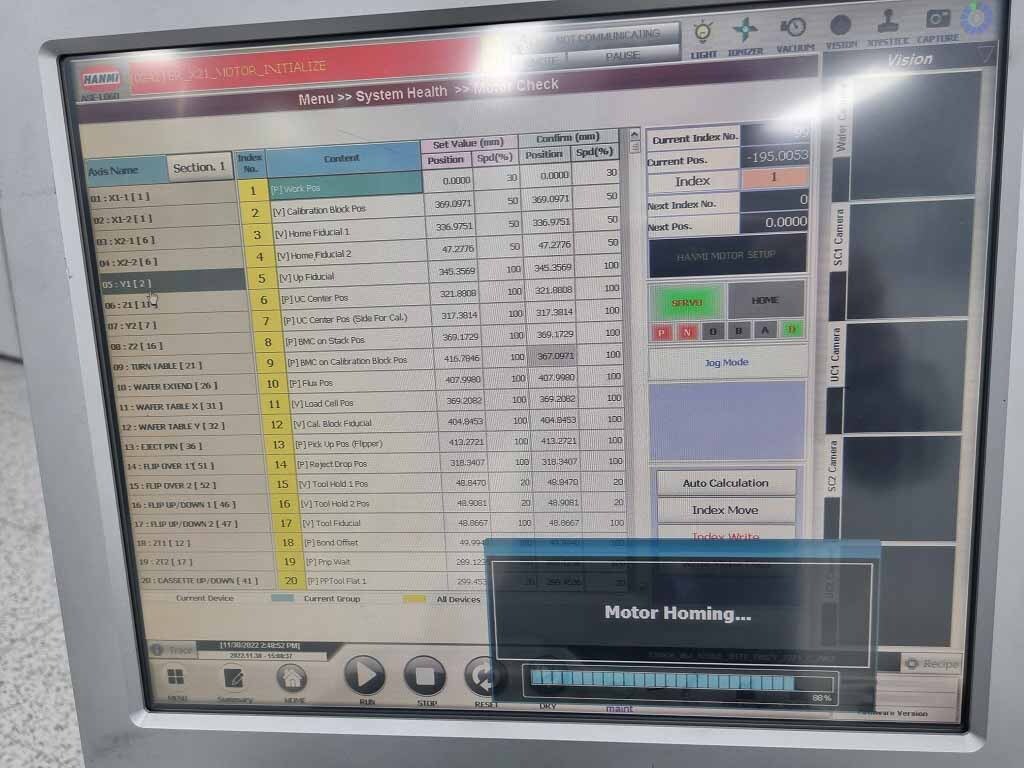

HANMI A110 is a specialized equipment designed for pc board assembly and manufacturing. It uses advanced pick-and-place technologies to accurately place components onto PCBs, allowing for quick and efficient production. The main components of the system are the placement head, pick-up head, tray feeder, and conveyor belt. The placement head is designed to precisely place each component onto the PCB, with consideration for component orientation, height, and distance. The pick-up head is used to lift components from the supply tray and place them onto the placement head. The tray feeder is an automated unit which replenishes the supplies of components for the pick-up head. The conveyor belt allows the board to smoothly move through the production process, and be quickly moved to the next station. A110 also offers a range of additional features to further improve efficiency. The vision alignment machine is designed to accurately detect component orientations even for complex packages, as well as ensure that all components are accurately placed. The laser measurement tool is used for precise measurement of surface-mount components, and helps to ensure that these components are placed correctly. In addition, the asset also offers auto nozzle compensation to adjust the nozzle position and height for different components, and auto nozzle pressure detection to ensure the proper level of pressure is being applied when placing components. To ensure a high level of flexibility and production capacity, the model can be equipped with multiple types of nozzles and tool heads. Further, the equipment offers a range of integration options, enabling it to be adapted to various conveyor systems, components, and PCBs. This also allows the system to be easily integrated into most production lines. HANMI A110 is a reliable and highly accurate unit for pc board assembly and manufacturing. Its advanced features offer greater flexibility and efficiency, and it can be easily integrated into a wide range of production line configurations.

There are no reviews yet