Used INLINE SMT WO-460 #119175 for sale

URL successfully copied!

Tap to zoom

ID: 119175

Vintage: 2009

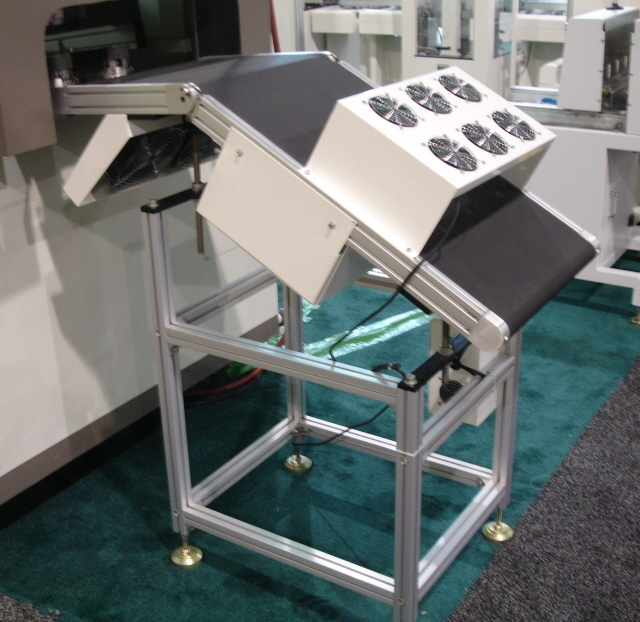

Wave offload conveyor

Variable speed

18" width ESD belt

Cooling fans

Extended length model WO-460-EXL available

120 V, 1 phase, 50 / 60 Hz

2009 vintage.

INLINE SMT WO-460PC Board Assembly and Manufacturing Equipment is an advanced, automated solution for assembling, testing, and manufacturing printed circuit boards (PCBs). This system is designed for high-precision, SMT-based circuit board production. Its modular design enables the operator to build, configure, and modify the unit to fit specific production needs. INLINE SMT WO-460 includes a number of advanced features, such as a modular design, advanced software, and multiple operating modes. Its modular design allows for the addition of peripherals as production requirements evolve and change. Advanced, intuitive software is included, making it easy to configure the machine, set up procedures, and monitor each step of the production process. Multiple operating modes are selectable, including manual, semi- automatic, and full-automatic operations. Additionally, the tool is capable of simultaneously testing each PCB for quality, ensuring only the highest-quality printed circuit boards are delivered to the customer. The asset's assembly line consists of a number of interconnected conveyors that move printed circuit boards from station to station. As a board enters a station, it is guided into place by programmed rollers and pressed into contact with built-in test probes. After being tested, it is automatically moved to the next station for additional inspection and/or assembly. Once all assembly/testing steps are complete, a built-in camera verifies the board's placement and orientation. Once verified, a finishing station packages the board for shipment. This advanced PCB assembly model includes an array of specialized inspection solutions such as automated optical inspection and X-ray imaging. Automated optical inspection (AOI) uses advanced optical technology to assess the quality of components, soldering, and other features of the assembled circuits. X-ray imaging checks for structural and electrical problems hidden beneath the components. WO-460 is an advanced solution for PCB assembly and manufacturing due to its modularity and powerful software. Its intuitive design and easy-to-use software make it ideal for prototyping and small-scale production. Additionally, its high-resolution cameras and automated inspection tools make it ideal for high-precision production, ensuring only the highest-quality products are produced.

There are no reviews yet