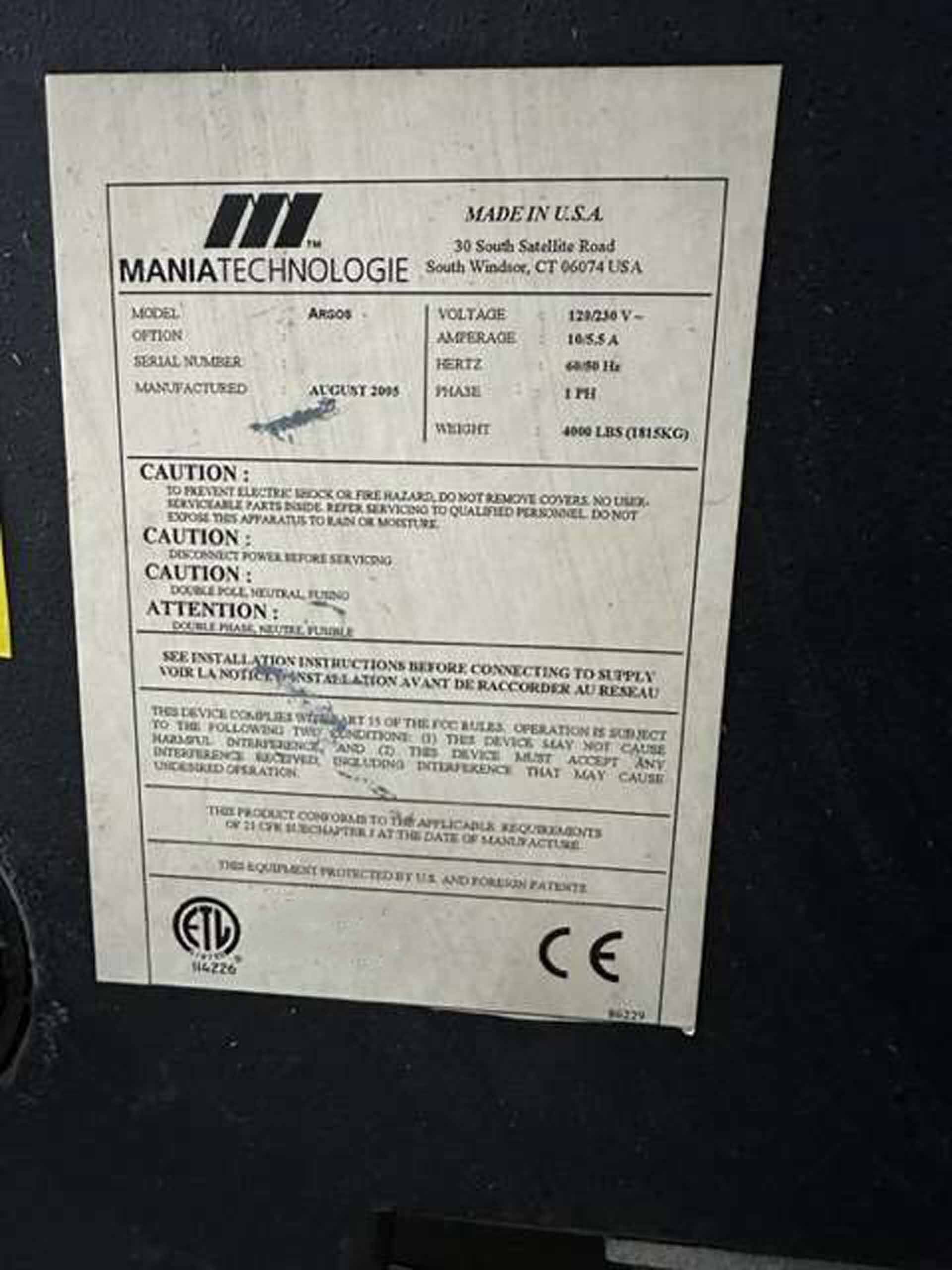

Used MANIA Argos #293653734 for sale

URL successfully copied!

Tap to zoom

MANIA Argos is a PC board assembly and manufacturing equipment designed to monitor and report on PCB production processes and assembly activities with the highest accuracy and precision. Argos system provides real-time performance data of the entire production line, including the movement of components, solder paste stencils, reflow ovens, pick-and-place machines, and more. By monitoring the whole production line with this unit, companies can quickly identify areas where the process needs to be improved, reduce scrap and defects, and improve yields. The machine is composed of four major parts: a management server, an edge board controller, an assembly station, and an inspection station. The management server stores information on production runs, monitors production statistics, and runs automated analysis and reporting functions. The edge board controller is responsible for machine control and reporting, communication with the edge devices, and command exchange with the assembly and inspection stations. The assembly and inspection stations both use cameras and vision systems to monitor and report on the assembly process. In addition, MANIA Argos tool is designed to be quickly and easily scalable, allowing users to easily add new assembly and process stations. Argos also offers a variety of production activity logging and alerting capabilities. It can log process statistics such as temperature readings, machine parameters, machine status, and cycle times for compliance and debugging purposes. It also provides automated alerts in case of excessive errors or when process parameters exceed set thresholds. Additionally, the asset can generate reports based on production data, allowing companies to easily track production trends and identify areas for improvement. MANIA Argos model allows for maximum process control and traceability. It is a powerful production management and optimization tool, allowing companies to achieve their manufacturing goals of high yields and part quality. It is the perfect solution for companies that require a robust equipment to monitor and report on their PCB production processes and assembly activities.

There are no reviews yet