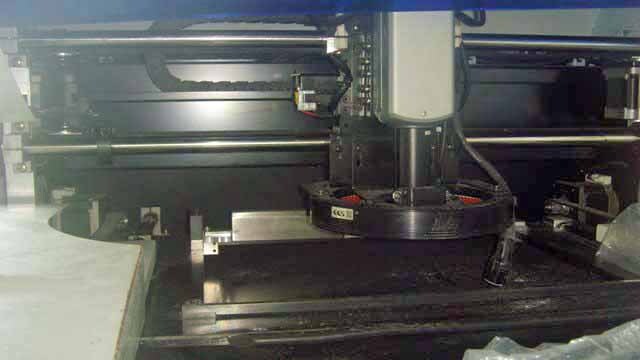

Used MARANTZ M22X #9076265 for sale

URL successfully copied!

Tap to zoom

MARANTZ M22X is an advanced pc board assembly and manufacturing equipment designed to facilitate the efficient and accurate manufacture of printed circuit boards at a production facility. This system offers users a series of features including an automated pick and place machine for loading components onto boards, a soldering machine for attaching the components, and a quality assurance function to guarantee board accuracy. The unit boasts several additional features that make it a reliable and cost-effective solution for PC board manufacturing. M22X Automatic Pick and Place Machine is a highly efficient and precise component loader featuring advanced operator control settings such as manual placement for quick loading as well as automated placement for consistently repeatable loads. The machine is equipped with a range of advanced components handling features, including a dedicated vision machine for identifying component codes and a pneumatic probe tool for placing components onto boards accurately and quickly. Component pick-up and placement are accurately and consistently integrated together, enabling the automated asset to effectively reduce both error rates and component placement time. MARANTZ M22X Soldering Machine is built to eliminate operator fatigue and improve efficiency. This unit is equipped with an adjustable working platform, automated soldering parameters, and an embedded vision model to assure precision when soldering components to boards. The high-precision soldering platform ensures accurate soldering and its ergonomic design reduces operator fatigue. Soldering Machine performance is further enhanced with MARANTZ Solder Stress Analyzer built into the unit. This analyzer produces a Solder Stress Evaluation Report for accuracy verification. M22X Quality Assurance function offers the assurance that boards are defect free when leaving the workstation, through basic visual inspections and more advanced automatic monitoring. Operators are notified when components are loaded inaccurately and boards are automatically rejected if components are discovered to be unsuitable. Additionally, integrated temperature sensors and resistance sensors monitor component performance to detect any potential issues that may affect the board's performance. MARANTZ M22X is designed to optimize production and reduce equipment downtime by making it easier for operators to load more accurate boards and reduce labor costs. The system is highly versatile and effective, and can be easily set up and configured to suit a wide range of operating requirements. In turn, this ensures that M22X remains a reliable and cost-effective solution for PC board production.

There are no reviews yet