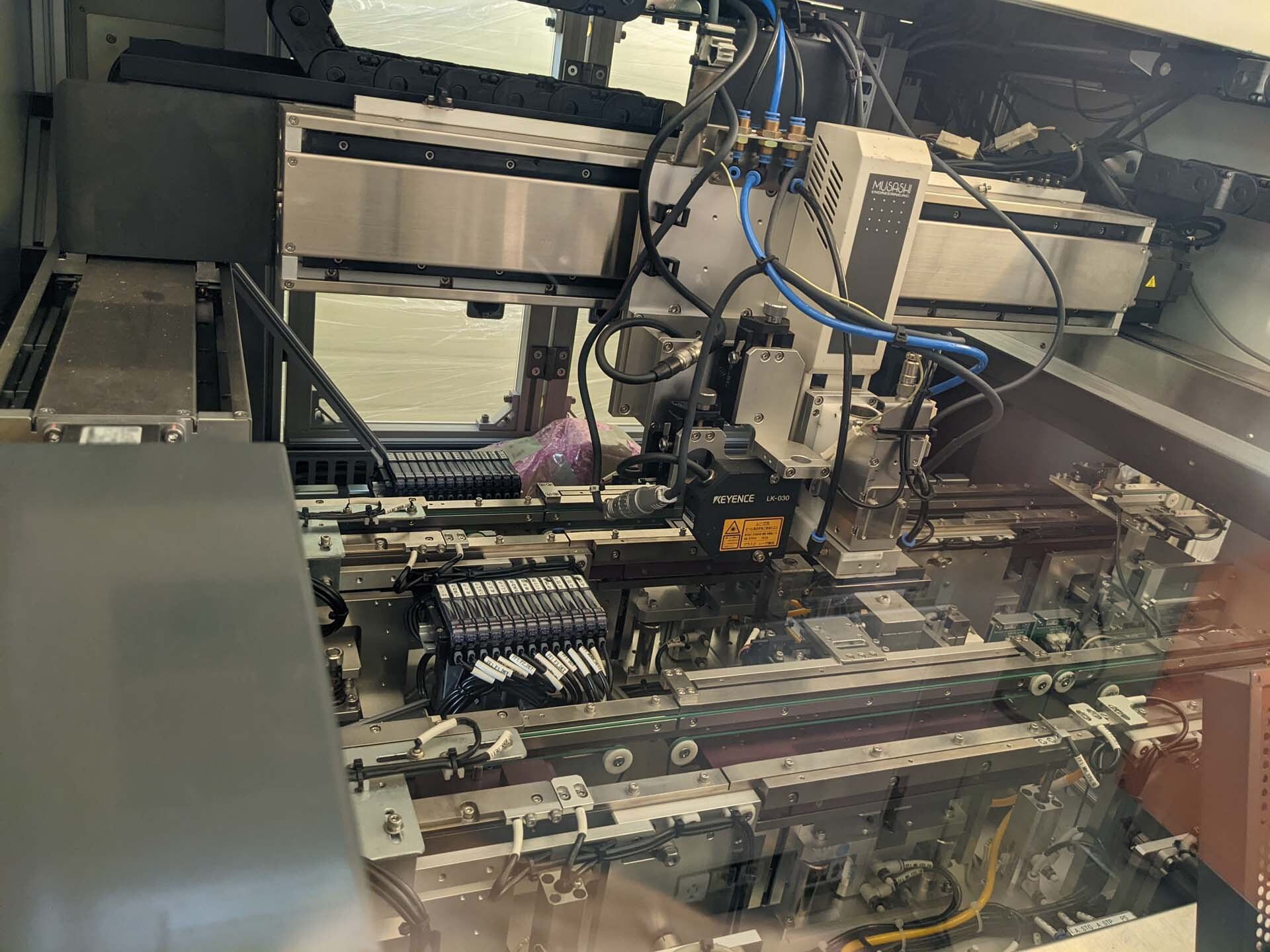

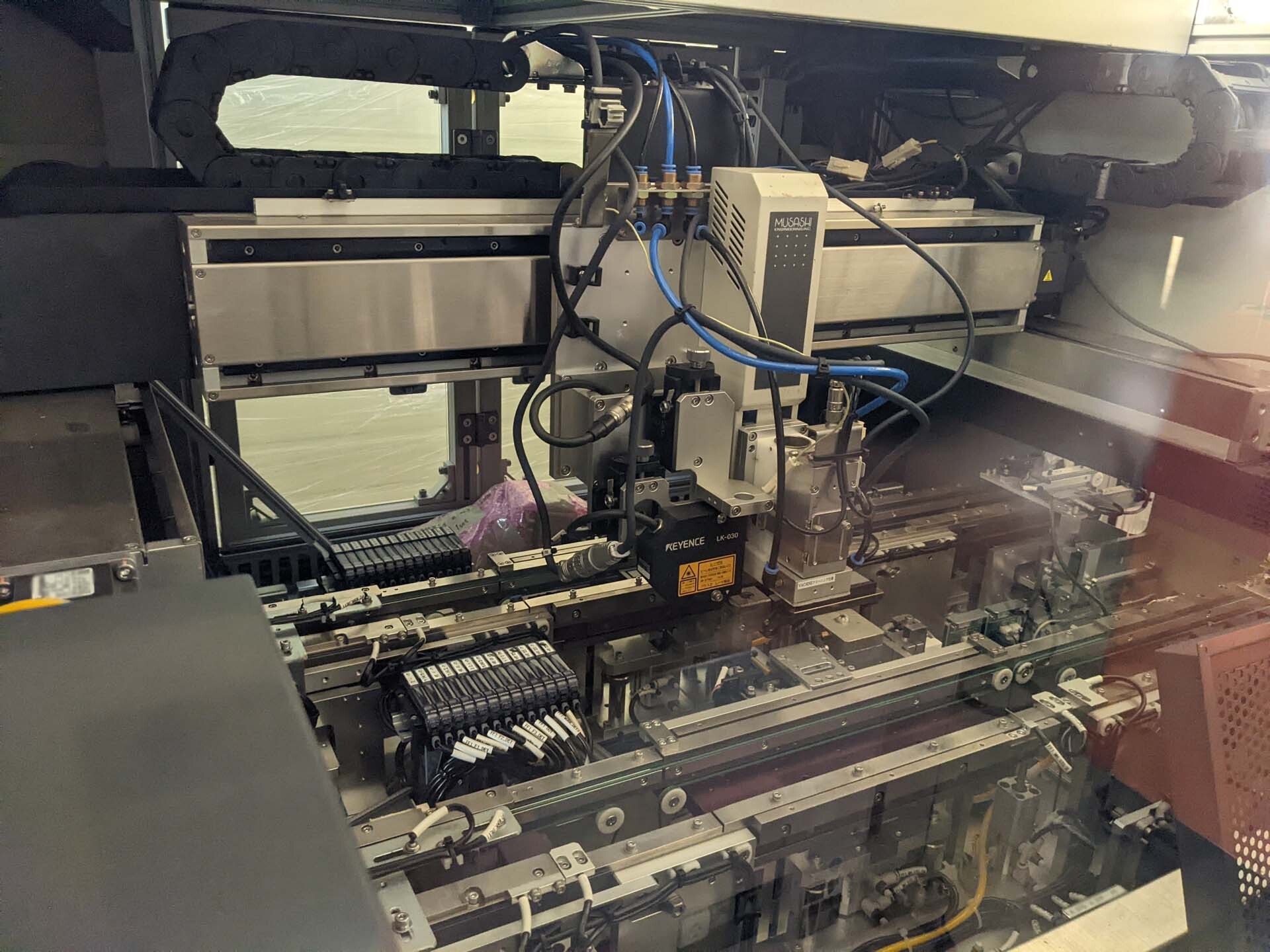

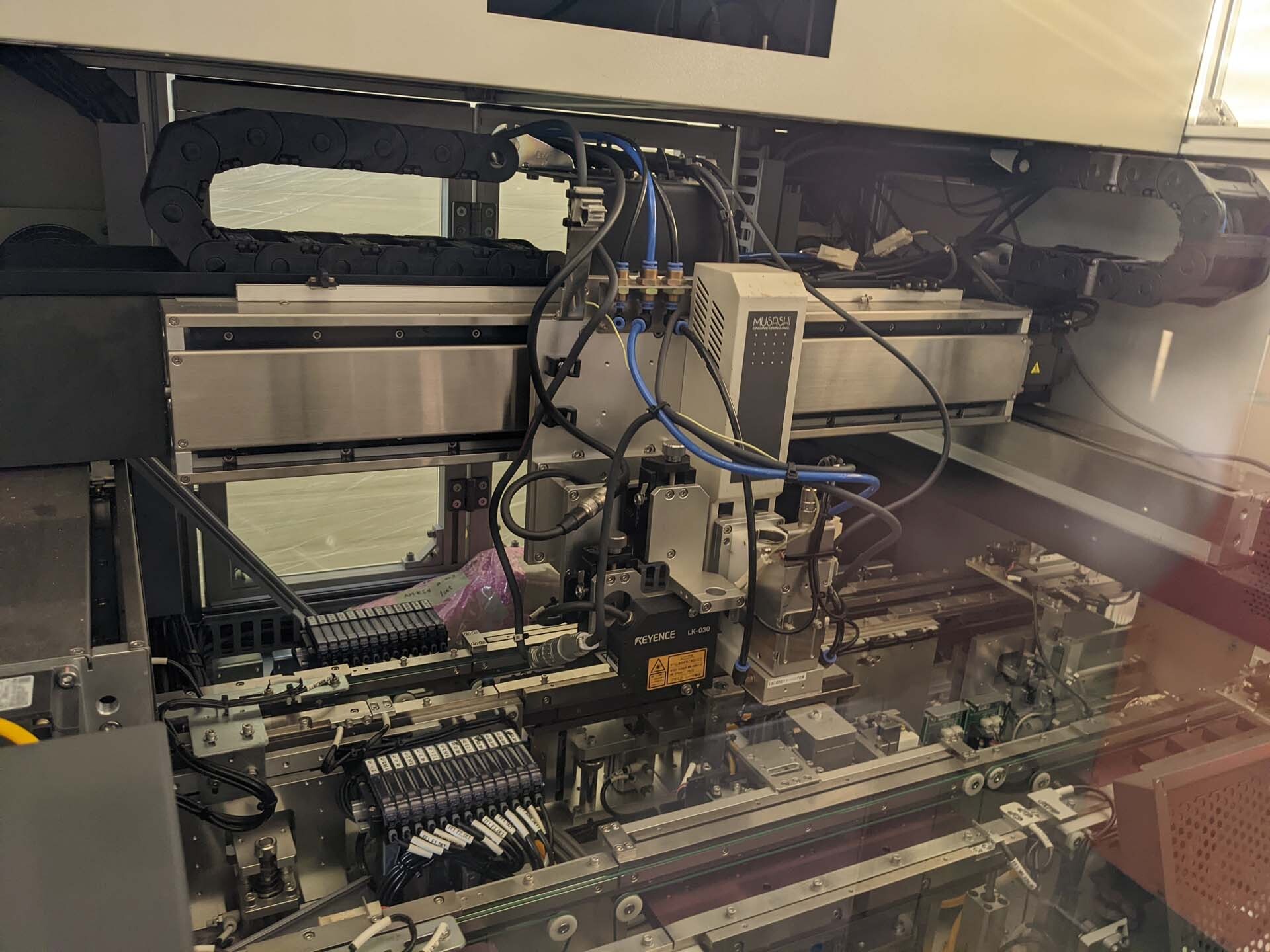

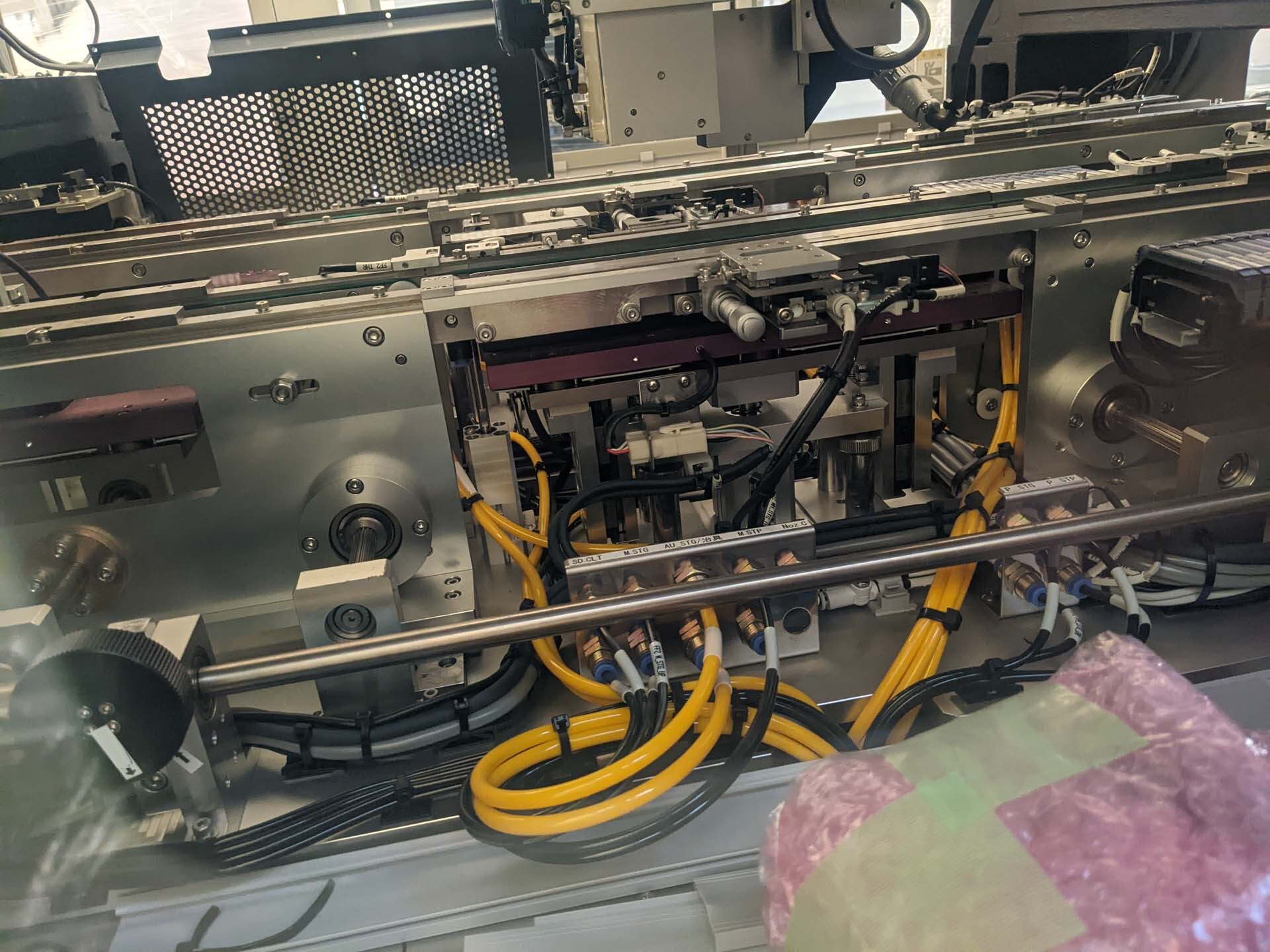

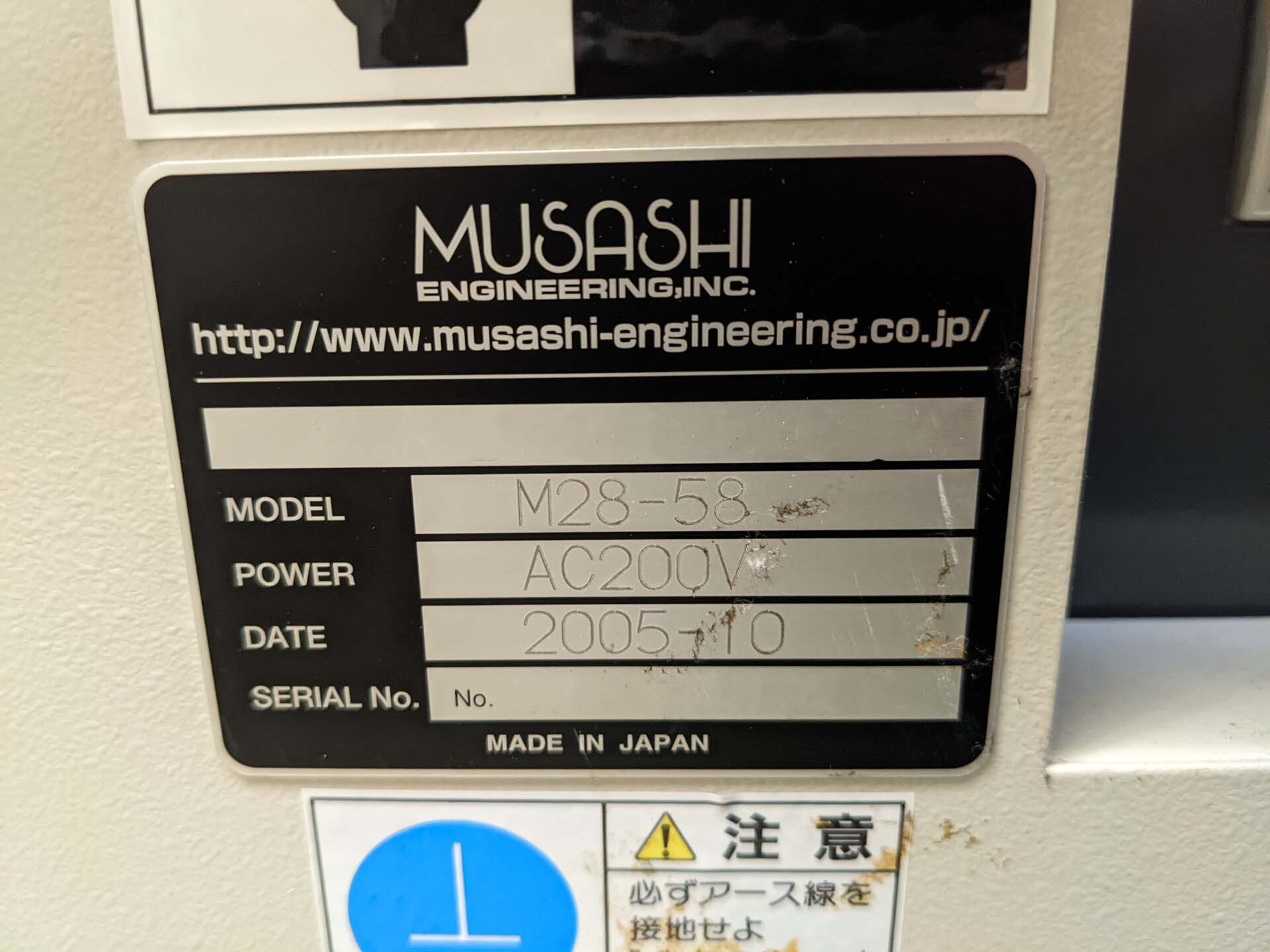

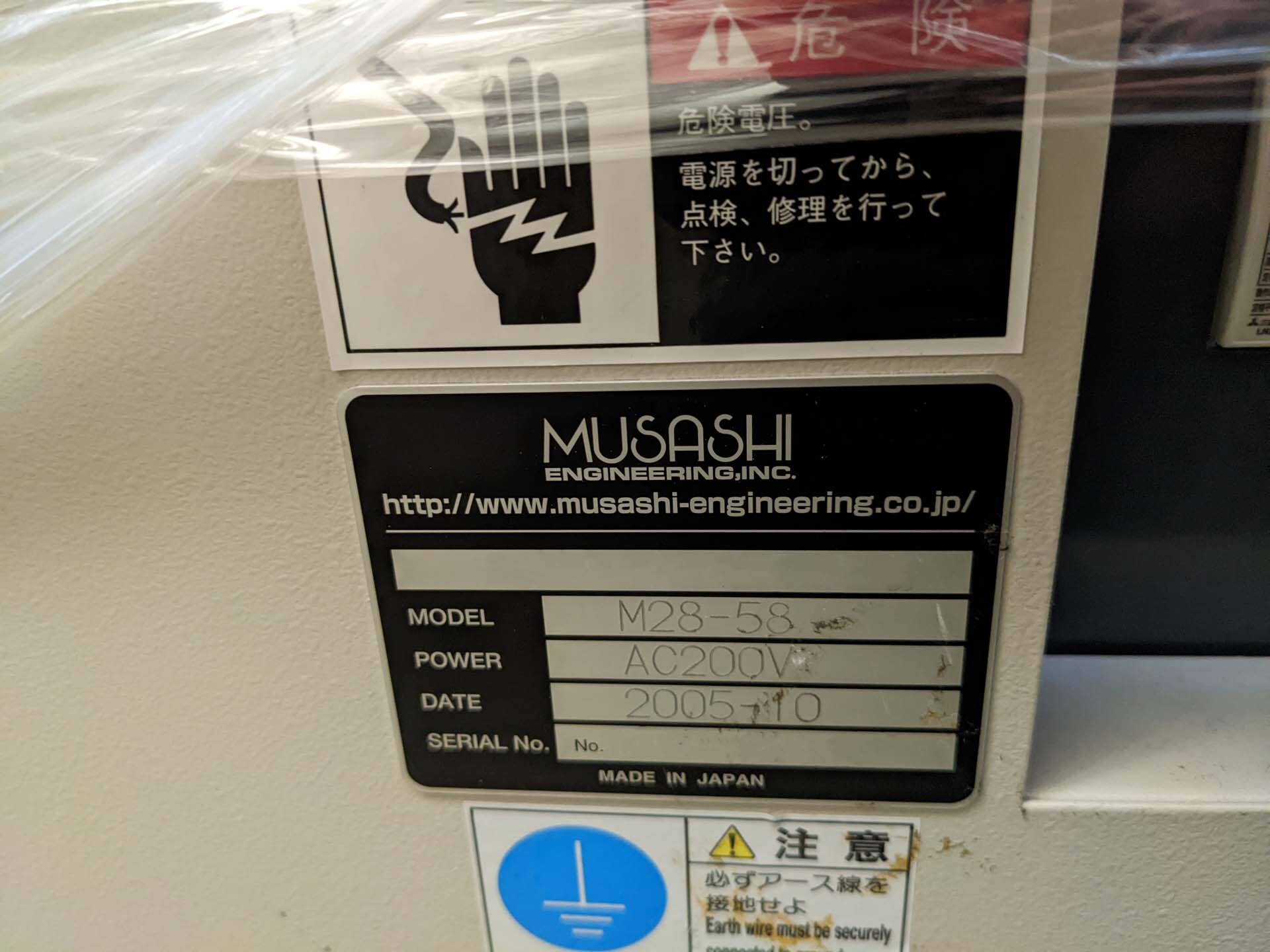

Used MUSASHI ENGINEERING FAD 2200D #293634930 for sale

URL successfully copied!

Tap to zoom

MUSASHI ENGINEERING FAD 2200D is a highly advanced, automated PC board assembly and manufacturing equipment. It offers precision accuracy and is designed to produce high-yield electronic components and assemblies. FAD 2200D is a fully functional automated work cell, offering a variety of component placement, soldering, and production capabilities. The system utilizes the latest in machine vision technology to align and manipulate components and assemblies within the ergonomic X-Y-R positioning stage. It is powered by a precision multi-axis drive-train and servo-controlled linear actuators, allowing for precise placement and soldering of component packages. MUSASHI ENGINEERING FAD 2200D performs component assembly and placement utilizing pick-and-place heads with speeds up to 200mm/sec, allowing for a large component production capacity. An integrated Component Selector Station (CSS) provides the necessary component feeding capability, and is capable of conveying components from various storage formats including tape and reel and trays. The unit is designed to easily integrate into any existing electrical manufacturing process and is capable of carrying out a broad spectrum of operations including component mounting, soldering, visual inspection, thermal profiling, and subassembly validation. The robust machine design ensures processes reliably to high quality standards, while helping to maximize the efficiency of production processes. In order to increase production accuracy, FAD 2200D is equipped with an automated production machine consisting of an Electrical Screen Printer, an Enhanced Vision Tool (EVS), a Conformal Coating Station, and an In-Circuit Test asset. The Electrical Screen Printer is capable of printing high resolution screen printing, which is necessary for precise component placement and assembly. The Enhanced Vision Model provides precise component placement and inspection which helps optimize production yield. The Conformal Coating application equipment helps to ensure reliable connection throughout the board and protects components from corrosion. Finally, the In-Circuit Test system allows for real-time verification of electrical connectivity and quality assurance of the finished assembly. In conclusion, MUSASHI ENGINEERING FAD 2200D is a powerful, reliable, and reliable automated PC board assembly and manufacturing unit. It offers a variety of component production capabilities, precision accuracy, and enhanced quality assurance through integrated vision and inspection capabilities. It is a reliable addition to any electronics manufacturing process.

There are no reviews yet