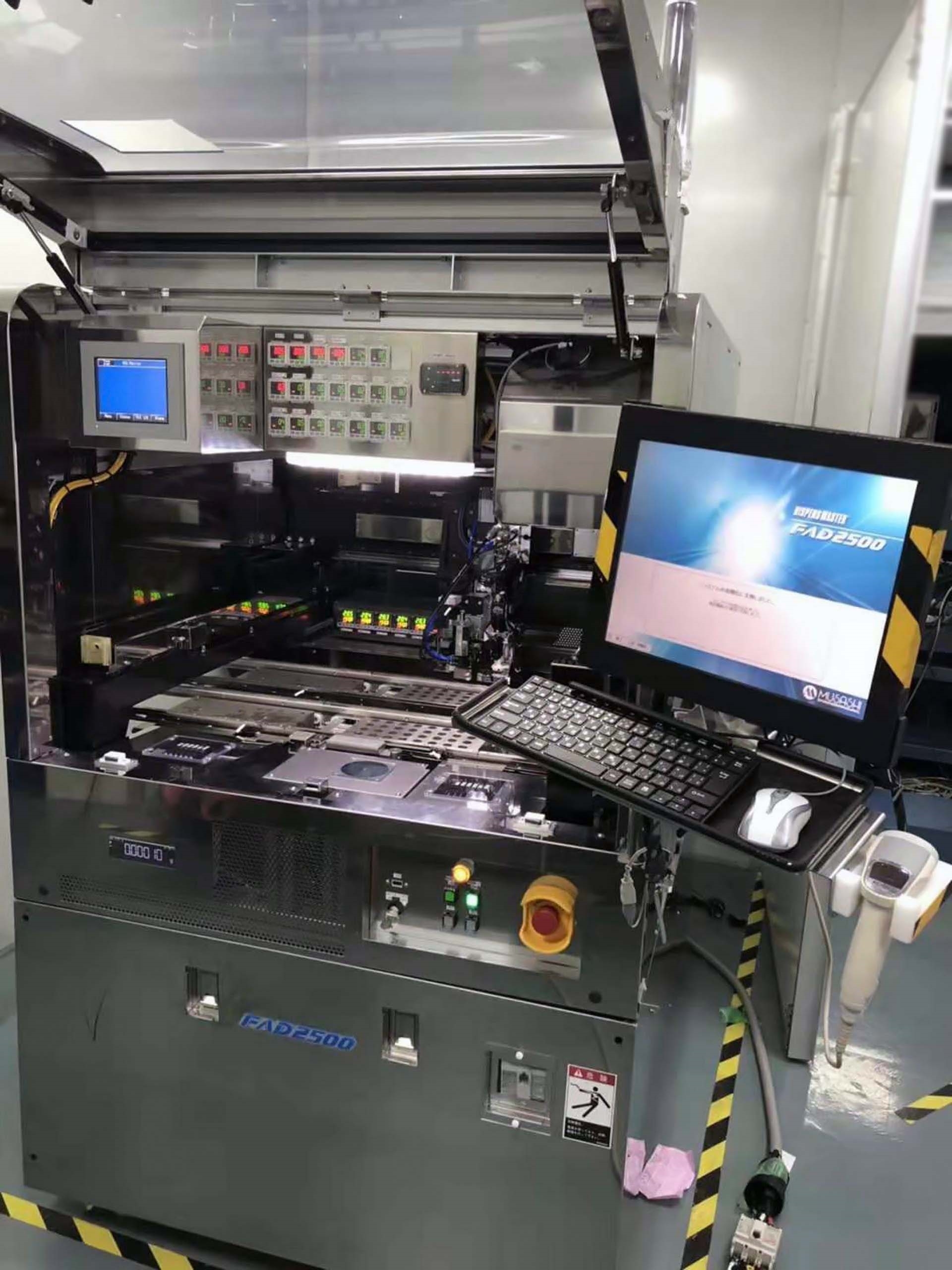

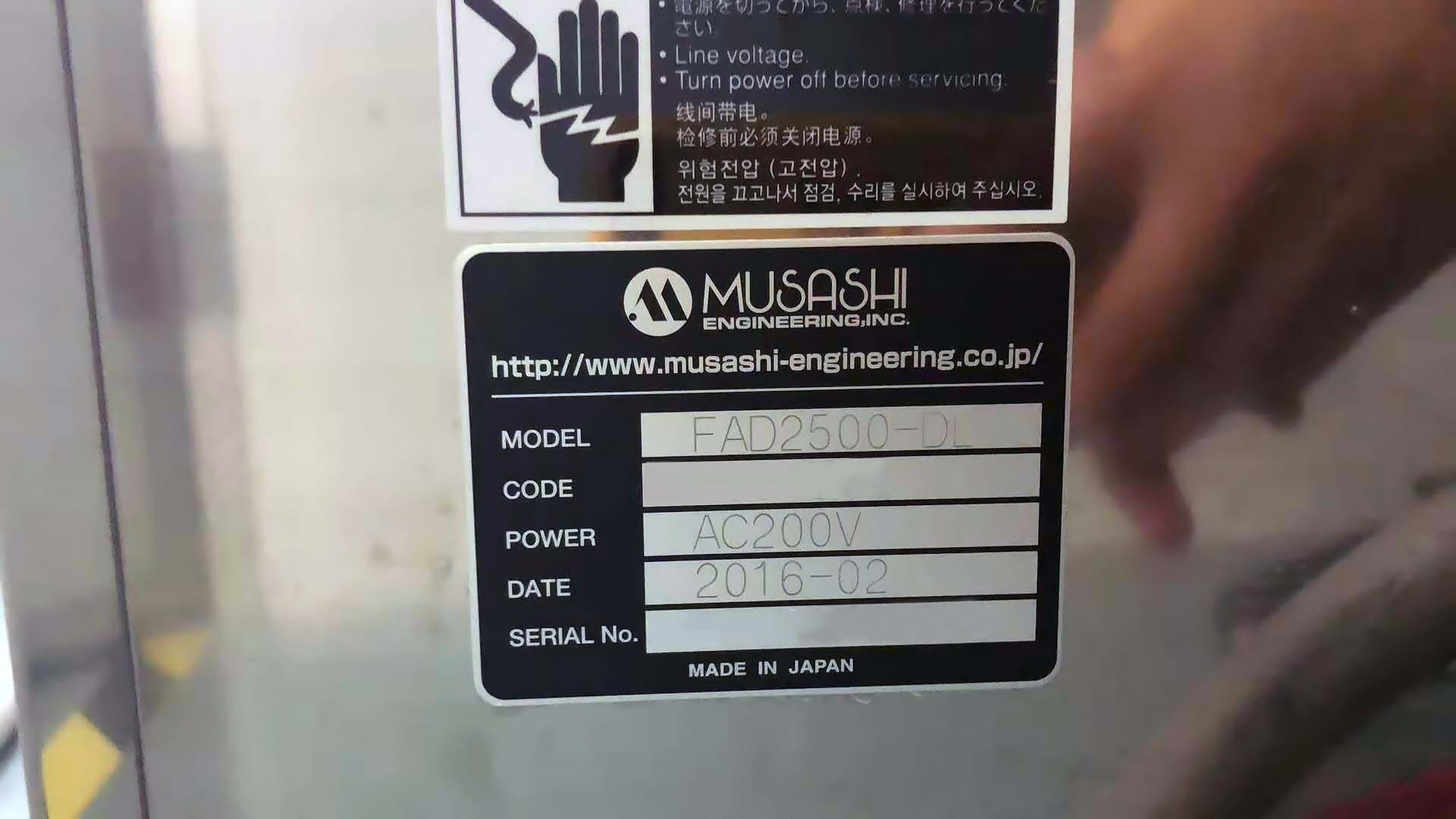

Used MUSASHI ENGINEERING FAD 2500 #9255267 for sale

URL successfully copied!

Tap to zoom

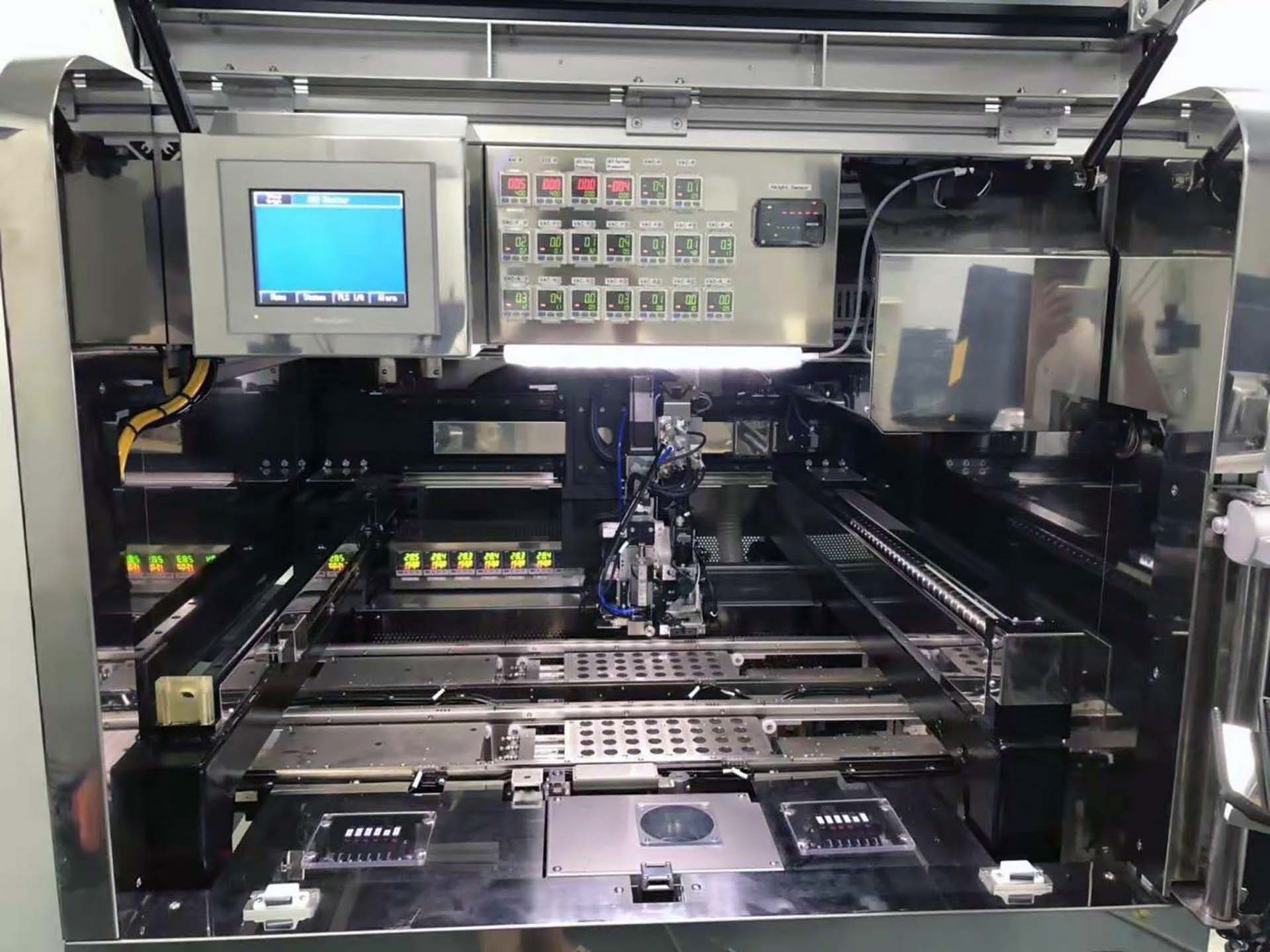

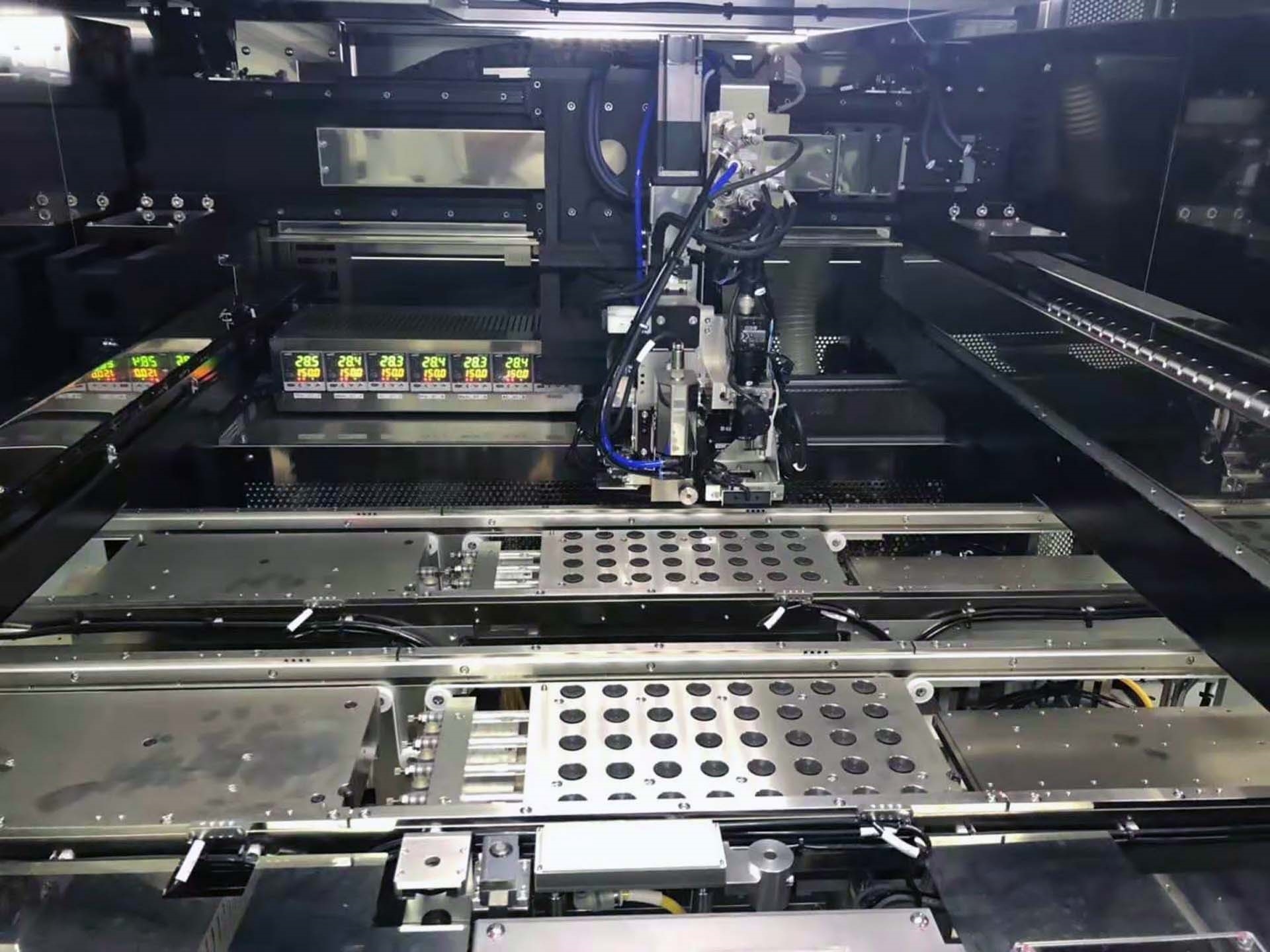

MUSASHI ENGINEERING FAD 2500 is a multi-station mixed model flow assembly equipment designed for use in pc board assembly and manufacturing. The system offers a high-speed, automated set-up using a combination of SMT, Through Hole, and Selective Soldering components in complete assemblies. The unit utilizes a FANUC M710 robot for component feed and placement, coupled with a Yamaha YV100XG pick-and-place head. The FANUC M710 is capable of high acceleration and deceleration speeds, as well as precise positioning, making it ideal for high-speed assembly. The Yamaha YV100XG pick-and-place head has a high-resolution two-camera machine for accurate component recognition, allowing for speeds up to 30,000 CPH (components per hour). The tool can run components ranging from very small-sized 0201 chips and 01005 resistors to larger 12mm x 12mm parts. The board size capabilities are up to 330mm x 330mm. The machine is capable of quick setup and tool-less changeover. It also has an optically-guided fiducial vision asset for rapid board registration. The model is designed with state-of-the-art proprietary IR technology for reflow and wave solder systems, as well as a 3-zone infrared module for lead-free soldering processes. It also features a vacuum nozzle equipment for increased placement accuracy. The system is capable of producing quality printouts following the assembly process; even for the most complex designs. The output file format can be easily integrated into any other CAD systems. The unit also provides static analysis, failure analysis, and quality testing for every assembled pc board. FAD 2500 is designed for efficient production of high accuracy pc board assemblies to meet the most complex assembly requirements. Its high-speed, accurate pick-and-place capabilities coupled with its range of components make it ideal for pc board assembly production.

There are no reviews yet