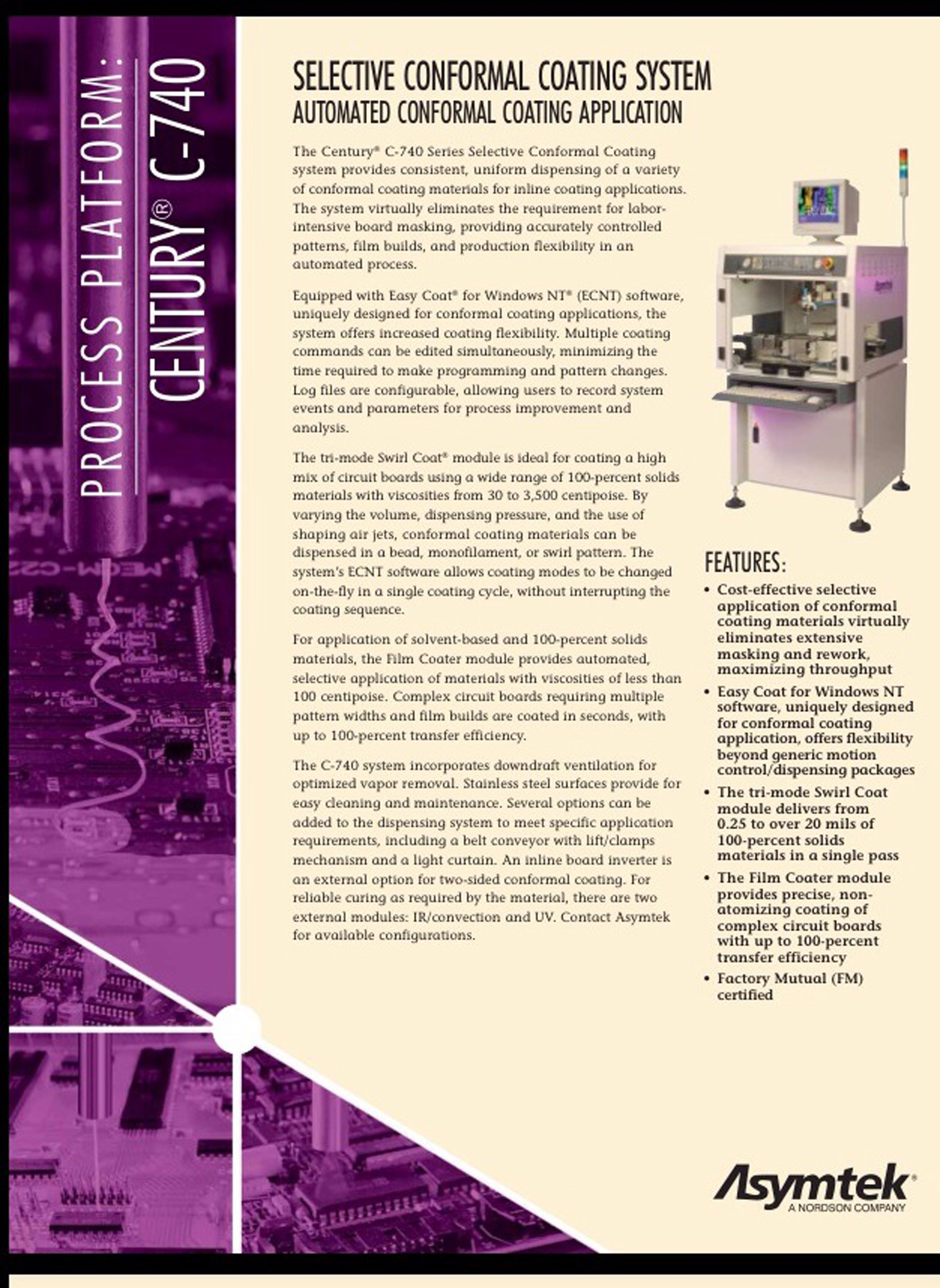

Used NORDSON / ASYMTEK C 740 #9245225 for sale

URL successfully copied!

Tap to zoom

ID: 9245225

Vintage: 2006

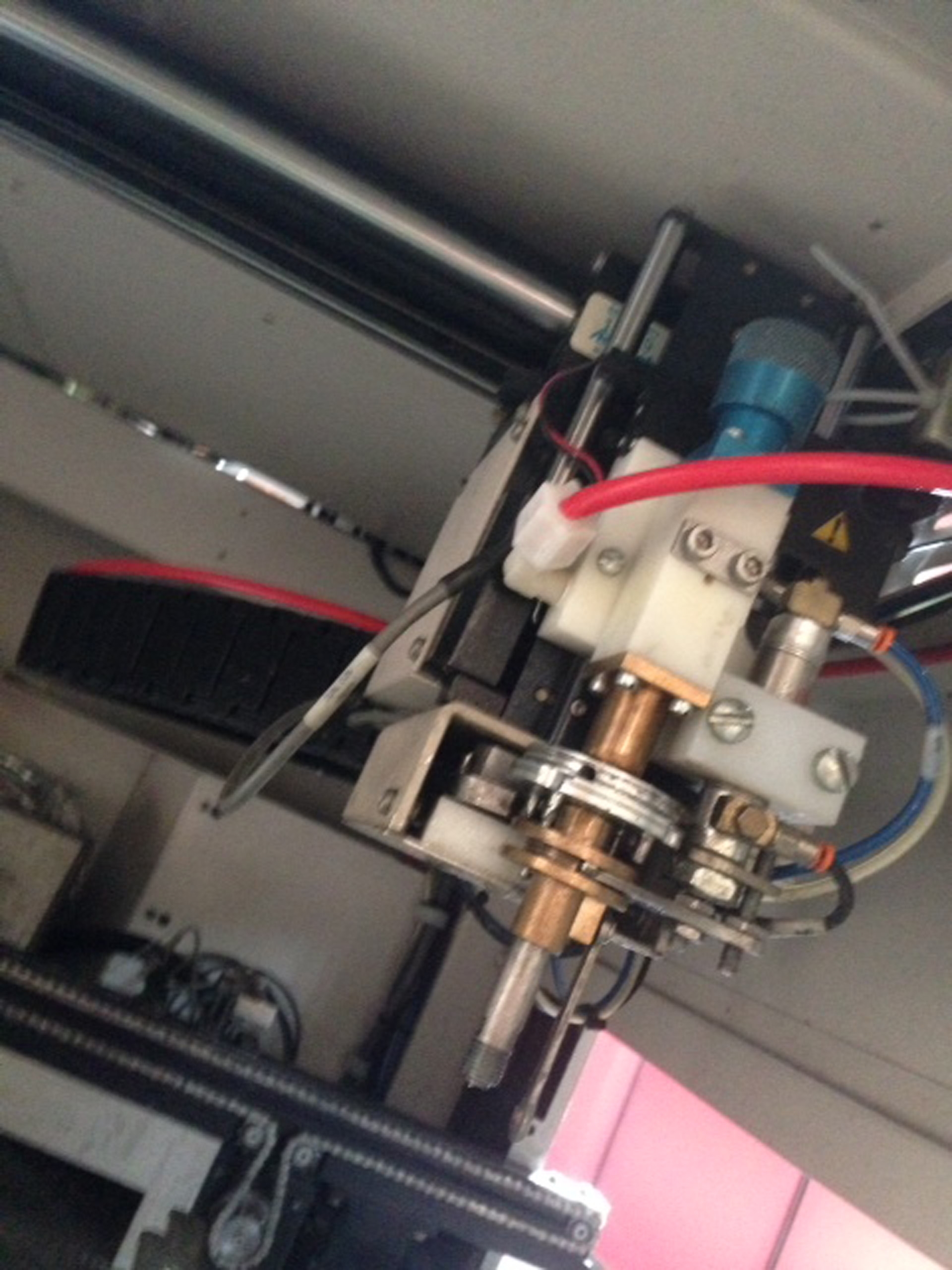

Conformal coating machine

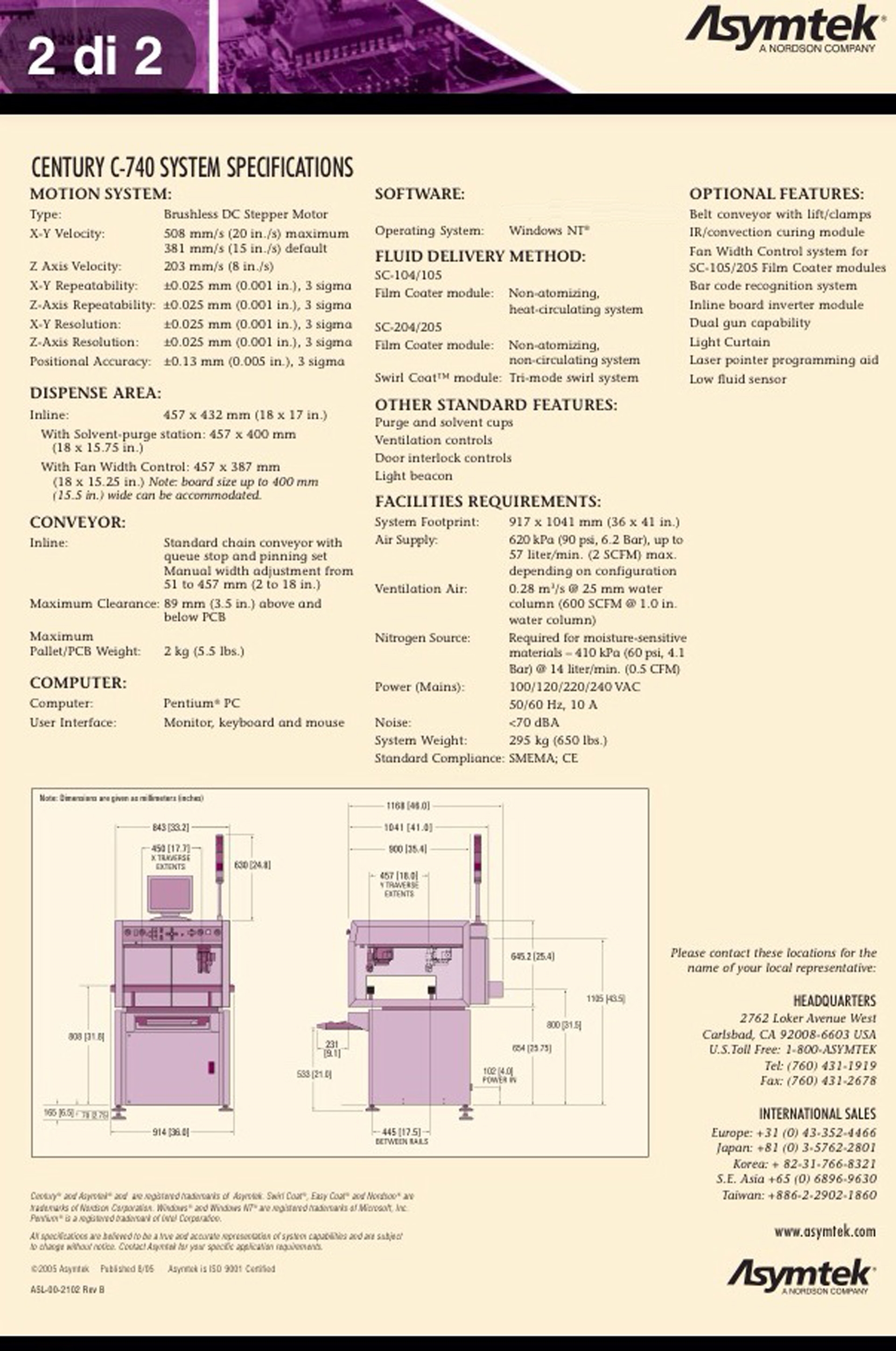

Motion system:

X-Y Velocity: 508 mm/s (20"/s) Maximum, 381 mm/s (15"/s) default

Z Axis velocity: 203 mm/s (8"/s)

X-Y Repeatability: ± 0.025 mm, 3 σ

Z-Axis Repeatability: ± 0.025 mm, 3 σ

X-Y Resolution: ± 0.025 mm, 3 σ

Z-Axis resolution: ± 0.025mm, 3 σ

Positional accuracy: ± 0.13, 3 σ

Dispense area:

Inline: 18" x 17"

Conveyor:

Inline: Standard chain conveyor 2"-18"

Computer: Pentium PC

User interface: Monitor, keyboard and mouse

Operating system: Windows NT

Fluid delivery method:

SC-104/105 & SC-204/205:

Film coater module:

Non-atomizing

Non-circulating system

Swirl coat module: Tri-mode swirl system

Other standard features:

Purge and solvent cups

Ventilation controls

Door interlock controls

Light beacon

Facilities requirements:

System footprint: 36" x 41"

Air supply: 620 kPa (90 psi, 6.2 bar)

Ventilation air: 0.28 m³/s @ 25 mm Water column

Nitrogen source:

Required for moisture-sensitive materials: 410 kPa (60 psi, 4.1 bar)

Noise: < 70 dBA

Standard compliance: SMEMA, CE

Power supply: 100 / 120 / 220 / 240 VAC, 50/60 Hz, 10 A

2006 vintage.

The NORDONNORDSON / ASYMTEK C 740 is an automated pc board assembly and manufacturing equipment, designed for high speed and accuracy in small to medium sized batch production runs. The system features a dual lane design, with automated assembly and production of PC boards on each lane. The first lane is a production solution lane, which features an industrial grade robotic arm for precise routing and placement of components, an automated soldering equipment for accurate and reliable bonding, and a noise inspection station for proper soldering quality control. The second lane is a test solution lane, which includes an in-circuit test station and an automated optical alignment unit for accurately checking finished boards and ensuring proper component orientation. The NORDONNORDSON C 740 also features an intuitive, easy-to-use graphical user interface, along with powerful, integrated software for programming, optimizing, and troubleshooting assembly and production processes. The machine also comes with a smart feeder tool, allowing for quick and efficient setup and changeovers of component kits. Additionally, the asset offers advanced fault detection and reporting capabilities, allowing for easy and timely repair of any malfunctions or faults that may occur during production. The NORDONASYMTEK C-740 can also be easily integrated with existing factory automation systems, or used as a standalone assembly and manufacturing model. Overall, the NORDONC 740 is a high performance, automated pc board assembly and manufacturing equipment that is capable of providing cost-effective, high quality, reliable, and consistent production of small to medium sized batch runs. It is designed for quick setup and changeovers of component kits, easy programming and optimizing of the assembly and manufacturing processes, and advanced fault detection and reporting capabilities. The system is ideal for any type of pc board production, offering maximum production efficiency and flexibility.

There are no reviews yet