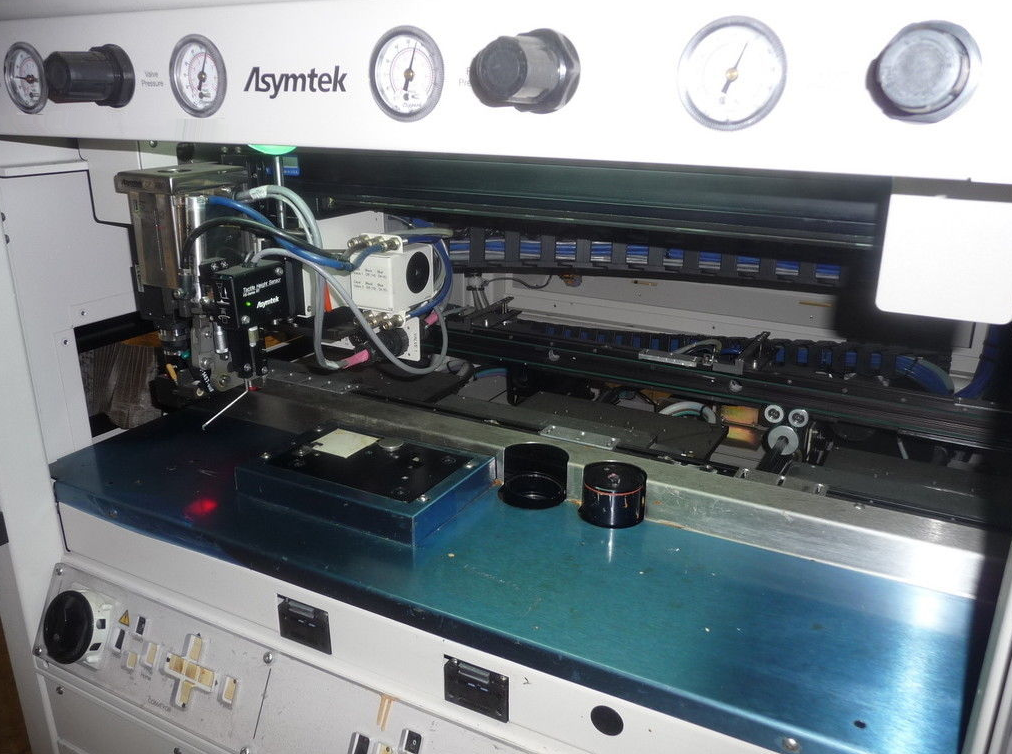

Used NORDSON / ASYMTEK M-620 #9101915 for sale

URL successfully copied!

Tap to zoom

ID: 9101915

Vintage: 2001

Dispensing system

Fluidmove for Windows NT (FmNT)

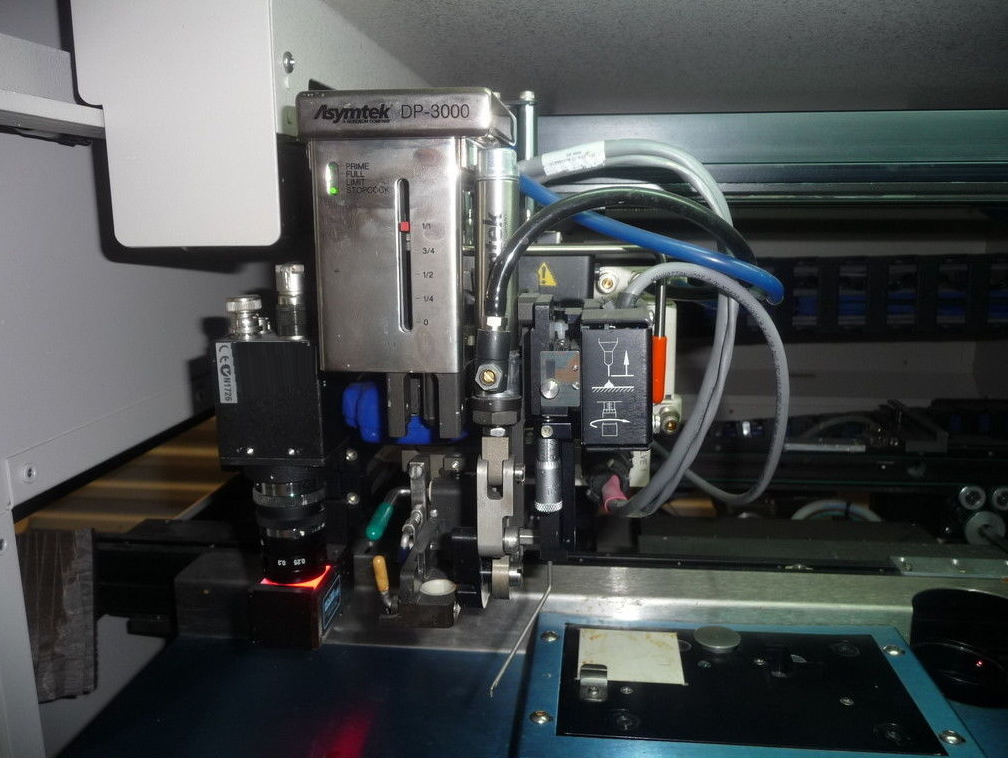

Needle sensor

Vision system and light source

Purge and weigh stations

Scale

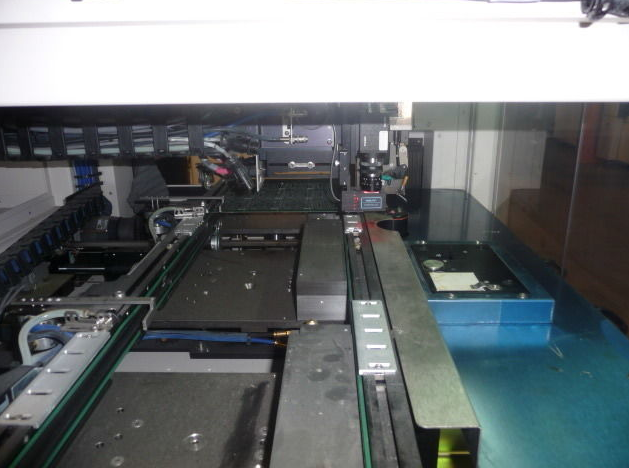

O-ring conveyor

Heaters

DP-3000 dispense valve

Needle heater

Conveyor:

SMEMA-compatible

O-ring style: pre-dispense, dispense, and post-dispense heat stations

Motorized width adjustment: 50.8 mm min. to 317.5 mm max

Conveyor speed: 254 mm/s max

Flow direction configurable: left-to-right (standard) or right-to-left flow

Carrier width: 266.7 mm max, 38.1 mm min.

Motion System

Brushless DC stepper motor

X-Y Velocity: 381 mm/s

X-Y Repeatability: ±0.025 mm, 3 sigma

Z-Axis Repeatability: ±0.025 mm, 3 sigma

Positional accuracy: ±0.13 mm, 3 sigma

Z Travel: 89 mm max

NER lighting

Needle not installed

Dispense Area:

DP-3000 Pump (single action)

355.5 x 269.1 mm

Volts: 110 / 120 / 220 / 240

10 Amp max, 47-62 Hz, single phase

2001 vintage.

NORDSON / ASYMTEK M-620 is a purpose-built solution for efficient and accurate pc board assembly and manufacturing. It is an ideal solution for small to medium volume production operations and prototyping. NORDSON M-620 provides a high-speed throughput and features a rigid machine frame construction for superior component placement accuracy. Its high accuracy placement and fast cycle time make it ideal for industries that require a high level of precision in their pc board manufacture, such as telecom, medical, automotive, and computer systems applications. The machine is designed with a dual-head gantry-style pick and place equipment with a traverse speed of up to 800mm per second. It has a placement accuracy of ±.001" for placement of 0603 parts. ASYMTEK M-620 features a compact design with a deep feeder pocket to accommodate components and boards of various sizes and angles. The deep feeder pocket also offers flexible board nesting and allows for quick access to components when changing product types. The machine is driven by a NORDSON PC control system with Windows-based software providing comprehensive process control, data collection, and product traceability. The user interface is intuitive and provides users with information on material/component status, placement program status, and performance reviews. The machine is equipped with a vision unit that monitors the placement of parts. It uses a Cognex Laser Vision Machine to provide real-time inspection of placed components. The vision tool also provides automatic recognition of component types and eliminates the need for manual rework. M-620 is a robust and reliable asset and operates with minimal maintenance. Along with its impressive accuracy and low-cost of ownership, NORDSON / ASYMTEK M-620 is an ideal solution for managing production lines that require high-quality, efficient and reliable mass production.

There are no reviews yet