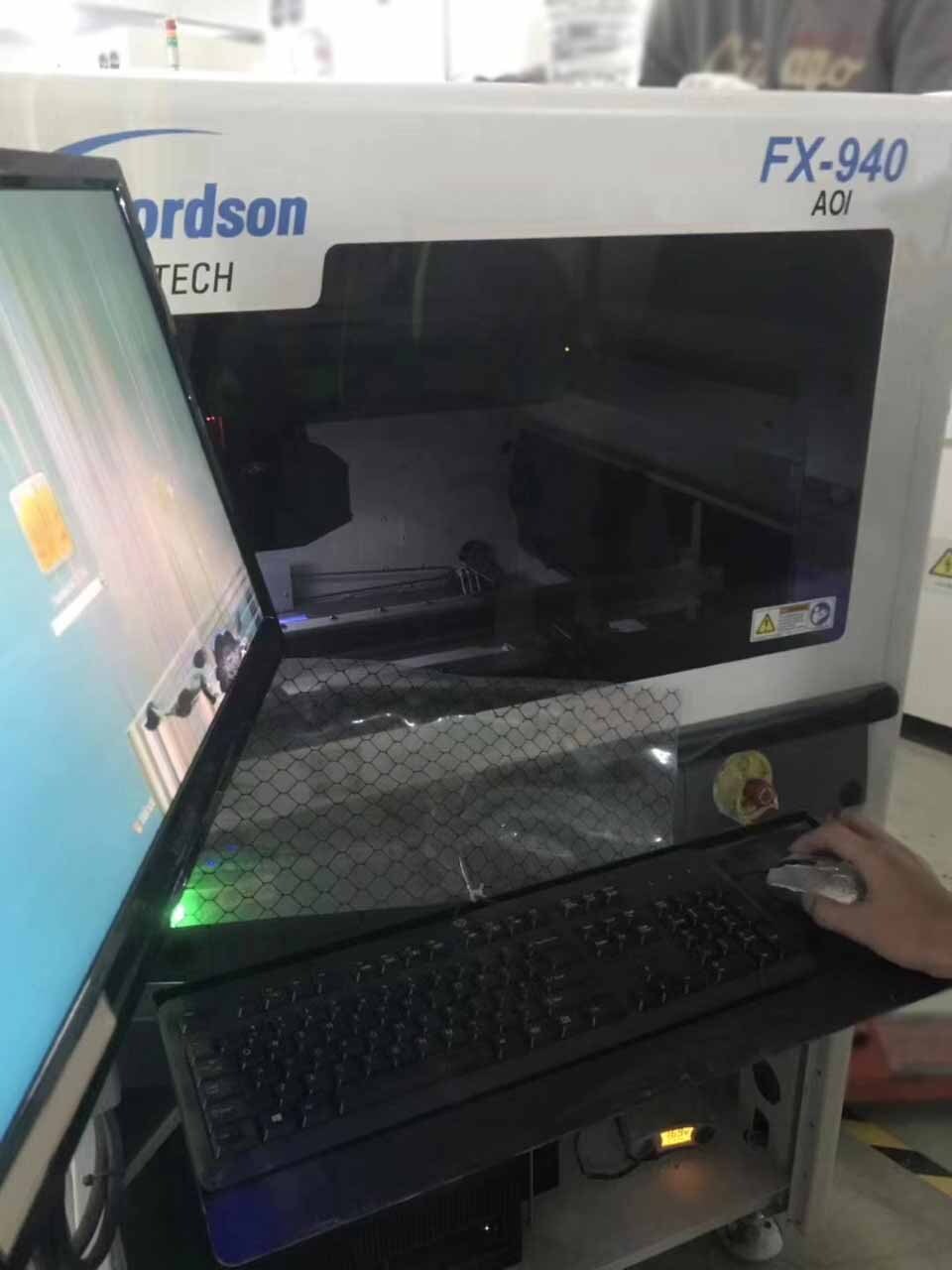

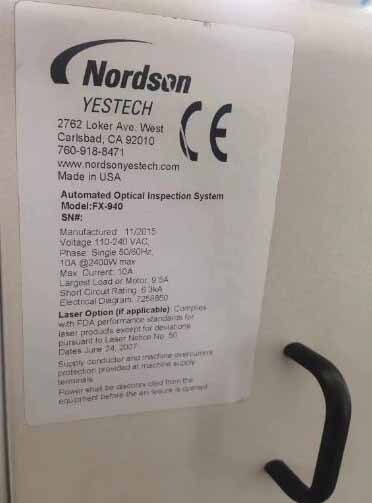

Used NORDSON / YESTECH FX-940 #293609668 for sale

URL successfully copied!

Tap to zoom

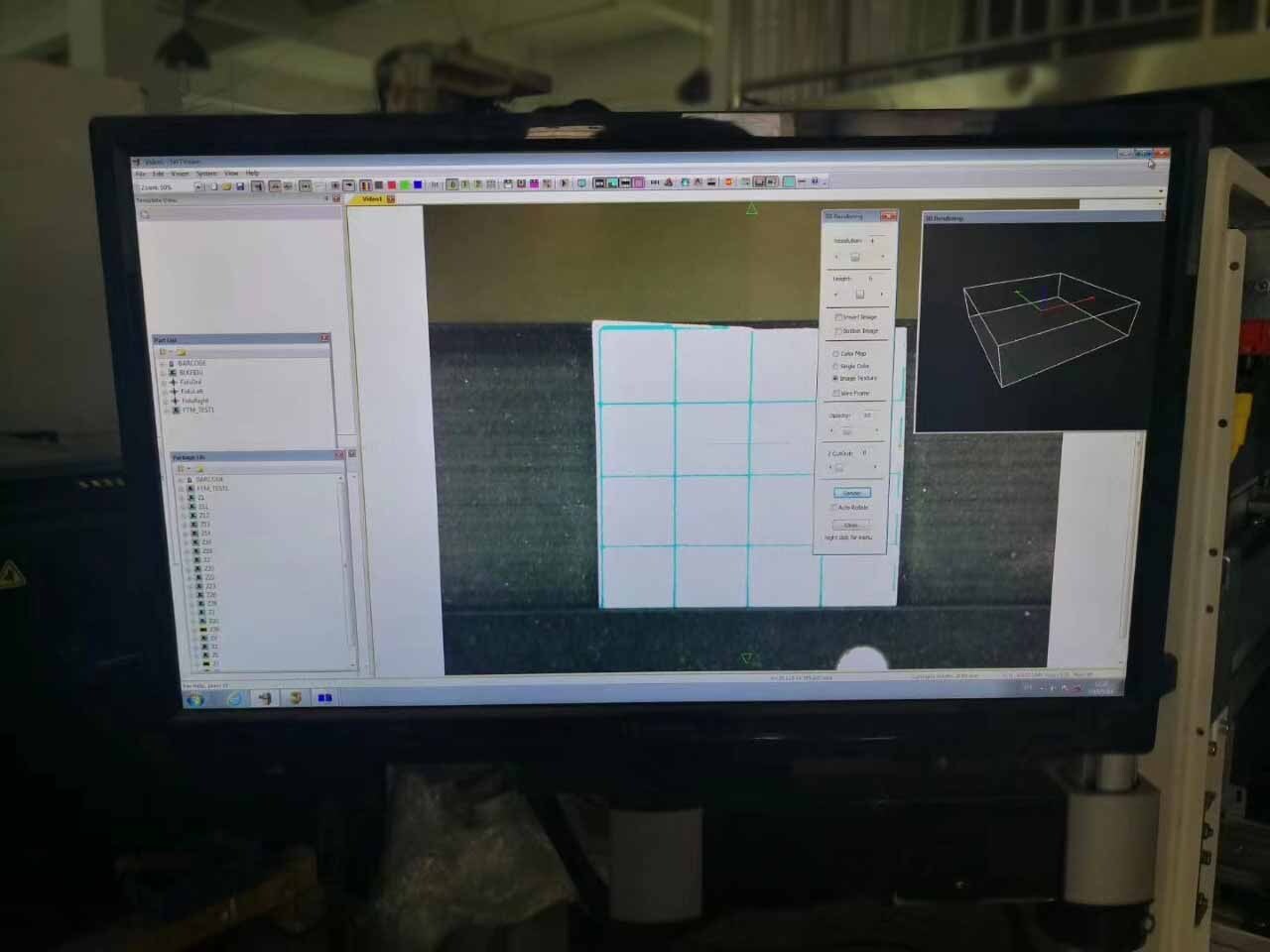

NORDSON / YESTECH FX-940 is a PC board assembly and manufacturing equipment that offers fast and precise automatic processing of boards up to 24 inches in length. This equipment operates through three main areas tuned to simultaneous high-capacity production: a machine, computer and operator control panel. NORDSON FX-940 machine area carries out the main production tasks for both through-hole and surface mount assembly operations. The computer area provides the capacity for the system to store data, providing the ability to store settings, retrieve sequence programs and review current settings. The controller area allows the operator to operate the unit, allowing them to review machine status, set up specified sequence programs, and make any changes necessary to the operation settings. YESTECH FX 940 offers precise handling of board materials and components, with ability to carry out optimal assembly functions for both conventional through-hole and surface mount devices. This productivity is achieved through the machine's 11-axis parallel motion units and dual material feeders. To ensure precise assembly, YESTECH FX-940 utilizes two shuttle based pick and place systems that can place components without fail. The feeder stocks provide up to 50 different feeder stocks of varying components, enabling versatile functions and rapid setup changes. FX 940 PC board provides precise mechanical alignment between the board and the components, reducing misfeeds. A vision tool assists in the accurate assembly of components of varying package sizes, by inspecting the mid-process components and verifying their accuracy. This also works in collaboration with a set of dual vision stations that further increase accuracy. FX-940 allows for an advanced inspection of up to 24 points with its fine pitch checking board, ensuring high- precision inspection. The asset also allows for easy and quick programming of sequence programs, with each program capable of simultaneous operation at differing speeds, creating a safe and efficient environment for production. For added control, it also allows for review current settings and data, with the ability to store settings for future access. It also allows for operator access audit trails for production data, helping improve traceability for products. Overall, NORDSON FX 940 is a fast and reliable model for production of PCB boards and components. Its accurate assembly capabilities, precision vision equipment, and dual material feeders make this an ideal option for PCB assembly and manufacturing.

There are no reviews yet