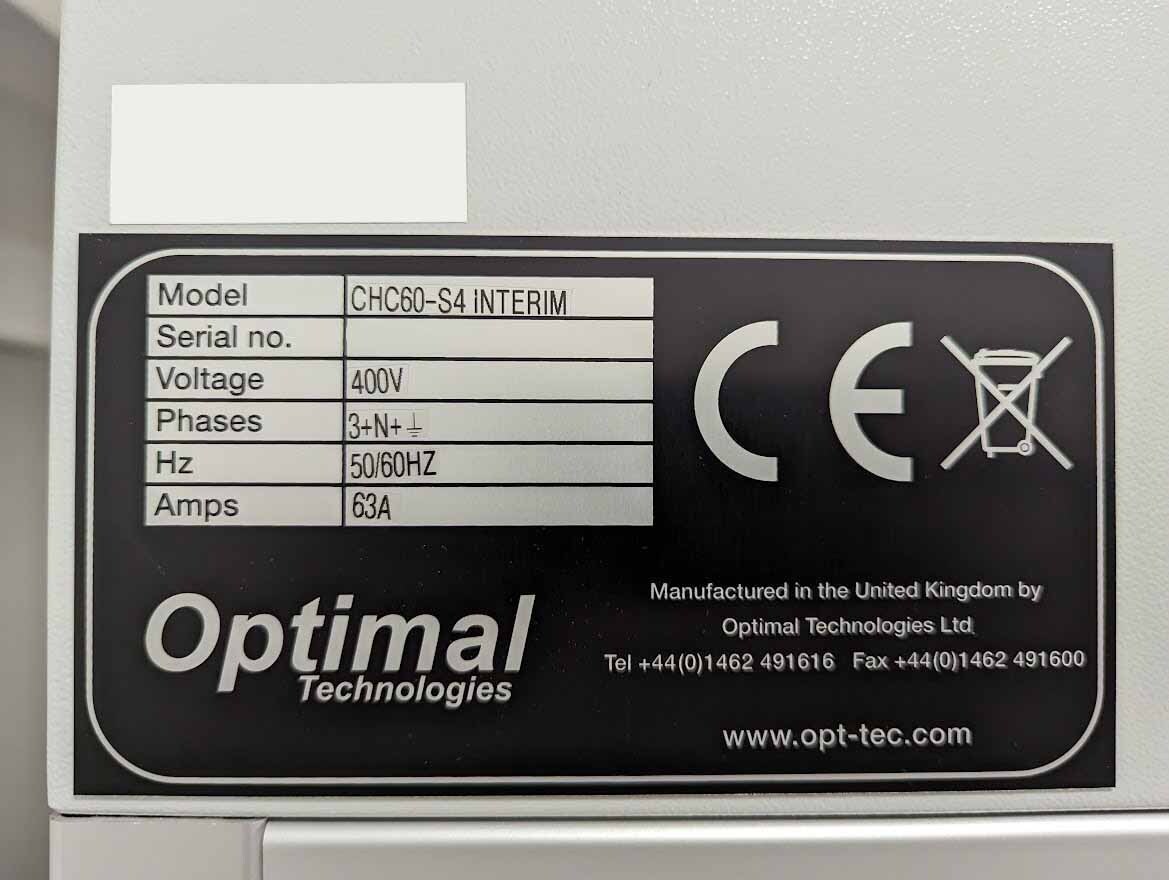

Used OPTIMAL TECHNOLOGIES CHC60-S4 INTERIM #293641096 for sale

URL successfully copied!

Tap to zoom

OPTIMAL TECHNOLOGIES CHC60-S4 INTERIM is a PC board assembly and manufacturing equipment designed for maximum flexibility and throughput. It is a two-stage process that begins with the placement of components on the board and then moves on to the soldering stage. The CHC60-S4 offers a range of advanced automation features, including high speed component placement, accuracy testing, automated component changeover, component rework, and automated soldering. The accurate placement of components on the board is achieved using intelligent component recognition, enabling component placement within .0125mm. Additionally, a rotary indexer increases the speed of component placement. The component testing component of the CHC60-S4 ensures that all components are operating within required parameters prior to soldering. This process is automated and provides the consumer with the highest possible level of assurance that the products meet all quality assurance requirements prior to emissions testing. The automated component changeover feature is one of the most advanced features of the CHC60-S4. The system is capable of automatically recognizing component placements and allowing these to be changedover in single preprogrammed operation. This feature is particularly beneficial in the assembly of complex components or parts that require multiple component placements or component changeover before soldering. The component rework feature enables the user to diagnose any component placement errors after component testing and then to make adjustments to ensure that the component placements do not affect performance. The component rework feature helps to ensure maximum component re-use and reduce component replacement costs. Finally, the CHC60-S4 includes an automated soldering unit. This process integrates a variety of elements such as preheaters, solder coverage, detection of shorts and opens, and solder inspection. The accuracy of the automated soldering process is achieved through an advanced voltage sensing machine that monitors the status of the soldering process and ensures that the board is alighted and soldered correctly each time. CHC60-S4 INTERIM tool is designed for maximum throughput and flexibility; it offers advanced automated features for component placement, accuracy testing, component changeover and rework and automated soldering. This asset ensures that all components are operating within their parameters to ensure maximum performance and a reduced cost of production.

There are no reviews yet