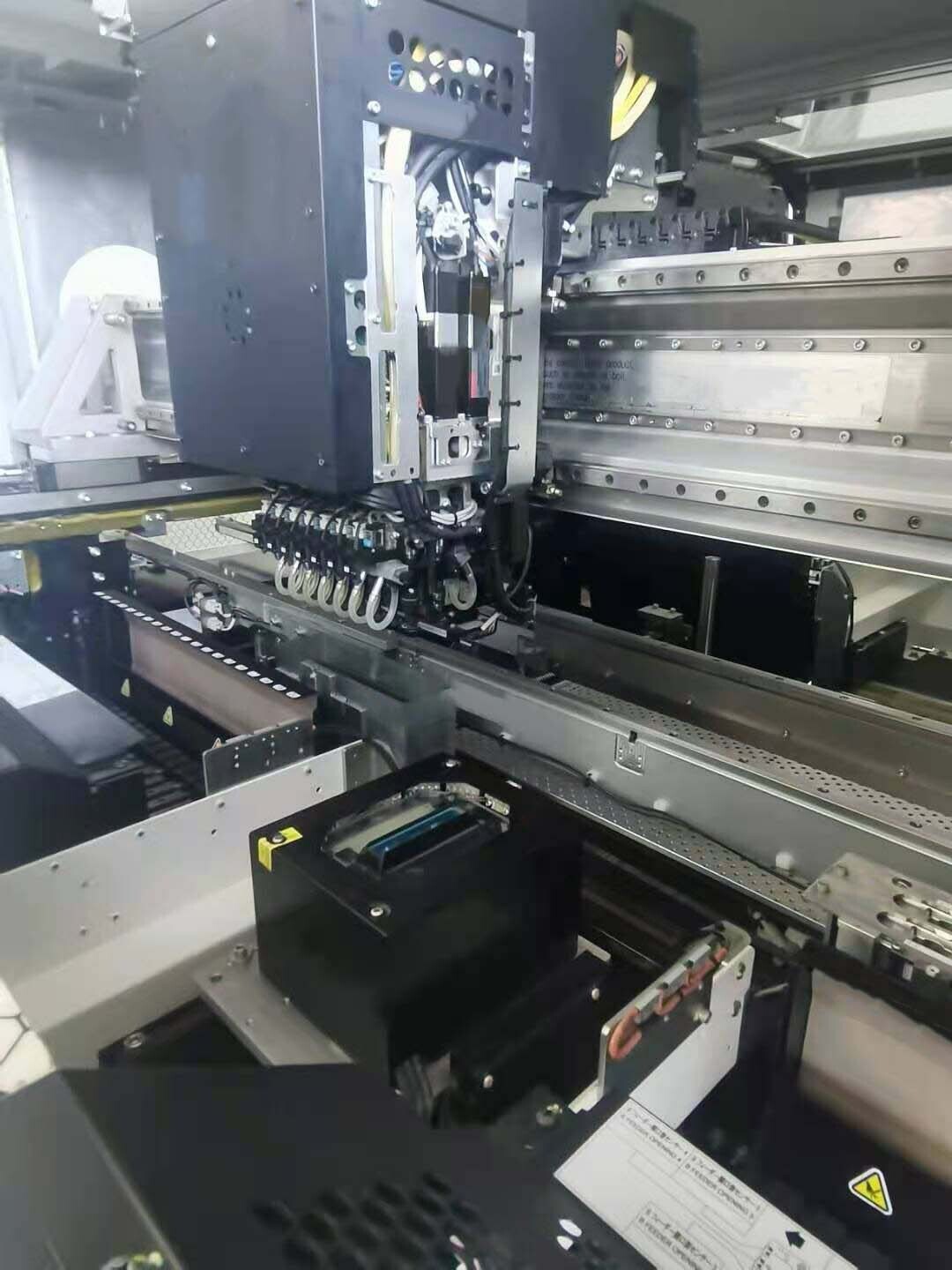

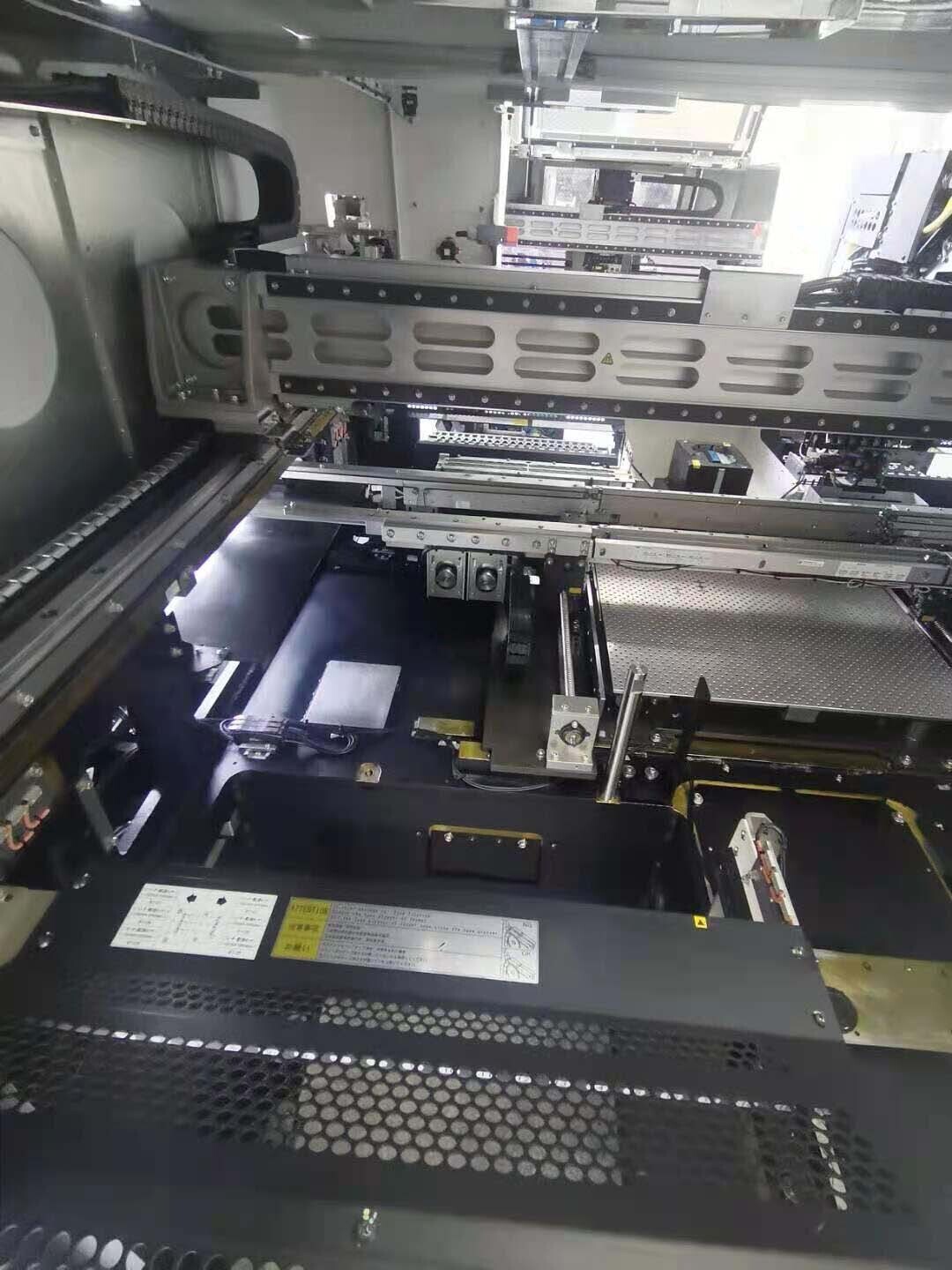

Used PANASONIC AM100 #9283496 for sale

URL successfully copied!

Tap to zoom

ID: 9283496

Pick and place machines

Substrate replacement time

Substrate dimensions: L 50 mm x W 50 mm ~ L 510 mm x W 460 mm

Placement speed:

35,800 Cph (0.1006 seconds / chip)

12,200 Cph (0.295 seconds / QFP port below 12 mm)

Mounting accuracy:

± 40 µm / chip

± 50 µm / QFP Port < 12 mm

± 30 µm / QFP Port 12 mm ~ port 32 mm

Taping bandwidth: 8~56 / 72 / 88 / 104 mm

Tape rack: 160 Varieties

Pallet feeder: 120 Varieties

Braid 8 mm, double braid rack (Small reel)

Rod:

Tape braiding rack: 20 Varieties

Tray feeder: 15 Varieties

Tray:

Pallet feeder: 20 Varieties

(2) Manual tray: 20 Varieties

Component size:

(3) 0402 Chips

L 120 mm x W 90 mm / L150 mm x W 25 mm

Model no: NM-EJM4D

2014-2017 vintage.

PANASONIC AM100 is a high-performance, PC board assembly and manufacturing equipment which features a set of highly advanced capabilities that enable the efficient and accurate production of PCBs. This system comes equipped with a variety of specialized equipment and software, giving users the ability to conduct various types of advanced operations including mounting, surface coating, soldering, and testing. One of the key features of PANASONIC AM 100 is its automated conveyor unit. This machine includes an automated shuttle conveyor, allowing boards to be moved through a wide range of production processes. It also features an integrated automatic Component Placement Tool (CPS) which uses a robotic arm to precisely place components onto the PCB. This asset also supports the use of step-and-repeat fixtures which enables users to quickly and reliably place components in various locations on the board. AM100 also has automated surface coating capabilities, providing users with a choice between two processes—electroless copper plating and electrochemical (silver) plating. This model is further equipped with options for whole-board soldering and lead-free soldering, allowing users to choose between different modes based on their needs. The equipment also comes with a powerful microscopy feature, which allows users to examine and evaluate PCBs at multiple levels of zoom such that they can easily spot potential problems. This system is further equipped with an inspection assistant feature which helps to identify issues with soldering. AM 100 is also highly compatible with a wide range of software programs, from commercial CAD programs to advanced PC Board Layout and Design programs, that can be used within the unit to create incredibly complex designs. This machine also supports a wide range of test and simulation features that enable users to quickly and accurately identify potential issues with the PCB. Overall, PANASONIC AM100 is an advanced PC board assembly and manufacturing tool which is ideal for a wide variety of businesses and organizations. This asset offers users a comprehensive set of capabilities that enable advanced manufacturing of PCBs, allowing users to quickly and easily create highly complex and accurate boards.

There are no reviews yet