Used SAKI BF-942 #9254865 for sale

URL successfully copied!

Tap to zoom

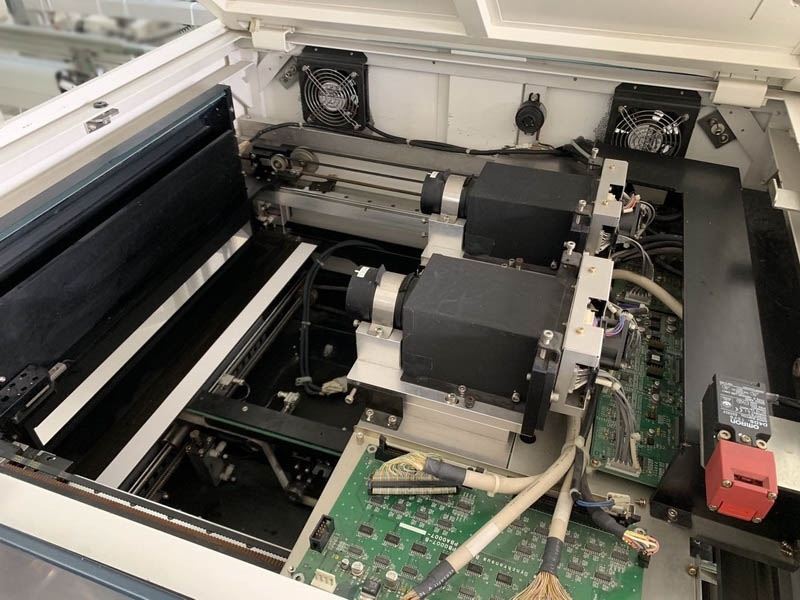

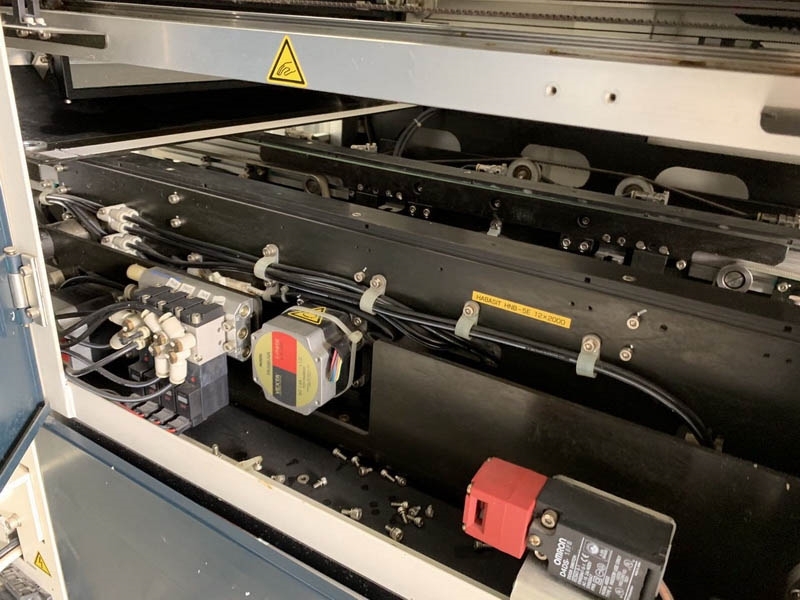

SAKI BF-942 is a PC Board Assembly & Manufacturing Equipment that provides a complete and comprehensive solution for all PCB Assembly & Manufacturing production lines. This system utilizes a range of advanced and precision mechanical and vision components to manufacture PCBs accurately and quickly, making it an efficient and reliable way to assembly and manufacture boards. The core components of the unit include a pick-and-place machine, a die-bonding and soldering station, a component-loading tray and associated software. The pick-and-place machine enables the insertion of components onto printed circuit boards, and is capable of a precision of 0.2 mm. This machine can handle a wide range of PCBs with different size and shape components, and is equipped with an advanced vision-machine that can detect misalignment and inaccurate placement for precise execution. The die-bonding and soldering station is pivotal for the precision and accuracy of the entire tool and ensures accurate and secure placement of components on the PCB. The station includes a variety of modules that further increase the speed and accuracy of the asset, including vibration tools, high-resolution inspection cameras and powerful lighting systems. The component-loading tray is a key component of the model as it stores components that are ready to be loaded onto the printed circuit boards. It is equipped with a programmable control equipment that can accurately and quickly calculate the exact number of components that are needed for each board. The system is further enhanced with the support of powerful software. This software tracks the location and inventory of parts, controls and monitors the pick-and-place machine, monitors the speed, accuracy and quality of the die-bonding and soldering station, and stores data for a complete traceability. BF-942 is a highly efficient and reliable unit that increases productivity and accuracy of PCB assembly and manufacturing lines. It incorporates a variety of advanced mechanical and vision components that are able to produce PCBs with high precision and reliability. With the support of powerful software, the machine creates complete traceability and offers complete fabrication visibility.

There are no reviews yet