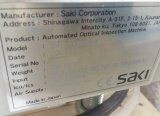

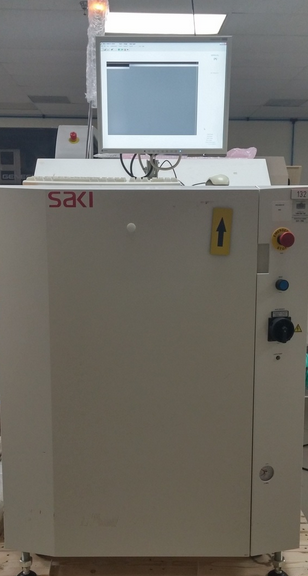

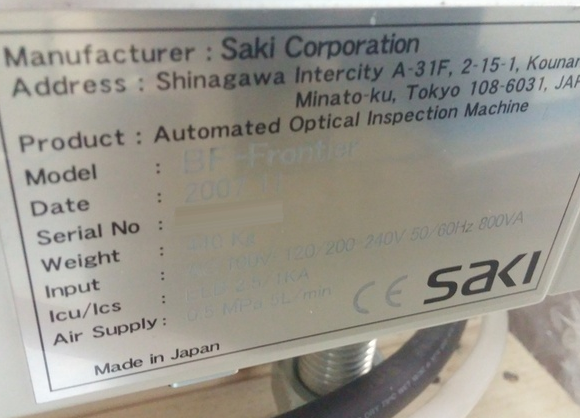

Used SAKI BF-Frontier #9083900 for sale

URL successfully copied!

Tap to zoom

ID: 9083900

Vintage: 2007

Inline AOI system 18x20"

18 micron down to 0201

Color AOI inspection

Multicolor Coaxial LED lighting

SMT and thru hole inspection

Glass plate calibration tool

Manuals

2007 vintage.

SAKI BF-Frontier is a comprehensive PC board assembly and manufacturing equipment that is designed to automate, simplify, and speed up the process of assembling printed circuit boards. It is a versatile system that can be adapted to meet the specific needs of any PC board manufacturing process. At the heart of BF-Frontier is its advanced robotic motion control unit. The robotics provide fast, precise motion and minimize the need for manual labor. It provides repeatable motion control, making sure that each component is placed in the exact same place each time. This ensures consistent outcomes and reduces the chance of human error. SAKI BF-Frontier is also equipped with automatic vision inspection and machine learning capabilities. This allows the machine to analyze the PCBs and ensure that all components are properly placed and functioning correctly. This powerful feature helps ensure a higher level of quality control and reduces the number of defects that pass through the production process. The tool is designed to be easy to operate and offers a variety of features including multi-axis motion, high speed swapping, flexible component placement, precise motion control, and a high speed data exchange platform. In addition, it is highly configurable and can be tailored to meet the demands of any PCB assembly. BF-Frontier offers many benefits to PCB manufacturers, including increased production speeds, increased accuracy and repeatability, improved quality control, and reduced labor costs. Additionally, SAKI BF-Frontier is a reliable and cost-effective solution for short-run production and prototype manufacturing. Overall, BF-Frontier provides a top-tier automated solution for any PCB assembly process.

There are no reviews yet