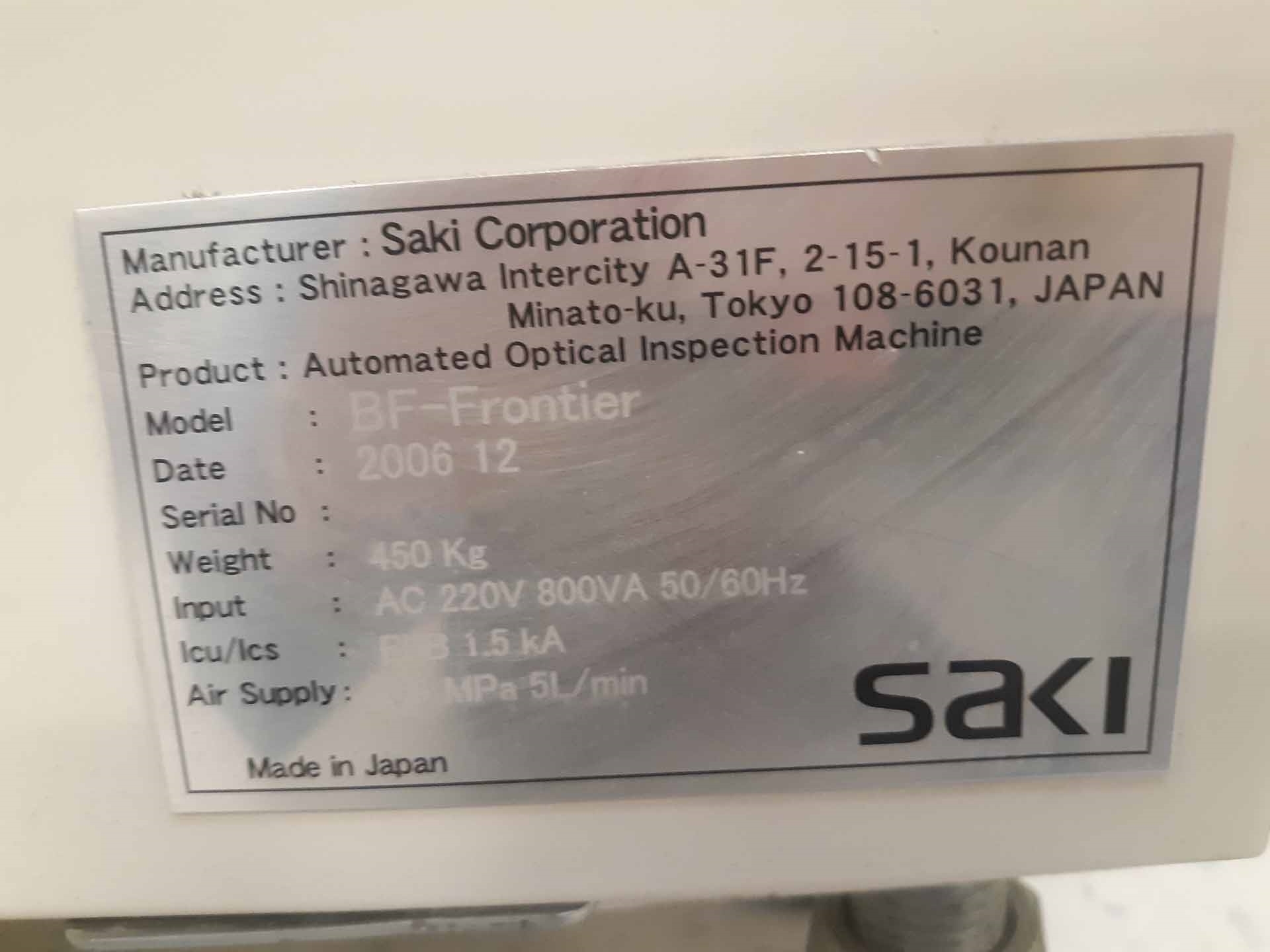

Used SAKI BF-Frontier #9263057 for sale

URL successfully copied!

Tap to zoom

ID: 9263057

Vintage: 2006

Inline Automatic Optical Inspection (AOI) system

Operating system: Windows XP (Pentium based)

Transfer: Left to right

Fixed front rail

SMEMA Auto width conveyor

Power supply: 110 VAC

2006 vintage.

SAKI BF-Frontier is a PC board assembly and manufacturing equipment that is capable of producing printed circuit boards in high volumes with a guaranteed quality. It has a variety of features and benefits that are designed to help streamline production and reduce costs. The system starts with material handling via BF-Frontier's automatic feeders that can be configured to specialize in components such as surface-mount and through-hole components. With its configurability, setup times are decreased, which helps minimize production time. Automatic placement machines then take the components precisely and accurately from the feeders before dispensing them on the board. A user can customize board layouts and enable or disable features such as glue printing, component recognition, and coating. The whole process is integrated into one production line, which drastically reduces time, cost, and potential errors. The unit also excels in quality assurance. It features a multi-inspection machine that constantly checks the accuracy of the assembly process and placements. This allows for higher quality end products. Additionally, the tool helps protect against the type of defects that usually are brought on by impacts or mishandling of the boards. A general inspection of the boards also can be done with SAKI BF-Frontier's vision-based inspection asset, which is able to check, locate, and measure defect conductors, components, and many other objects. Improvements and upgrades can be made to this model in order to ensure that it remains effective and efficient. This includes looking into software upgrades as well as hardware upgrades. The more up-to-date these features are, the higher the efficiency of the equipment and the better it is able to perform. Overall, BF-Frontier is a PC board assembly system that is designed to help manufacturers efficiently and accurately produce printed circuit boards. It features multiple configurable features and benefits, offering multiple inspection systems to ensure quality and increased protection.

There are no reviews yet