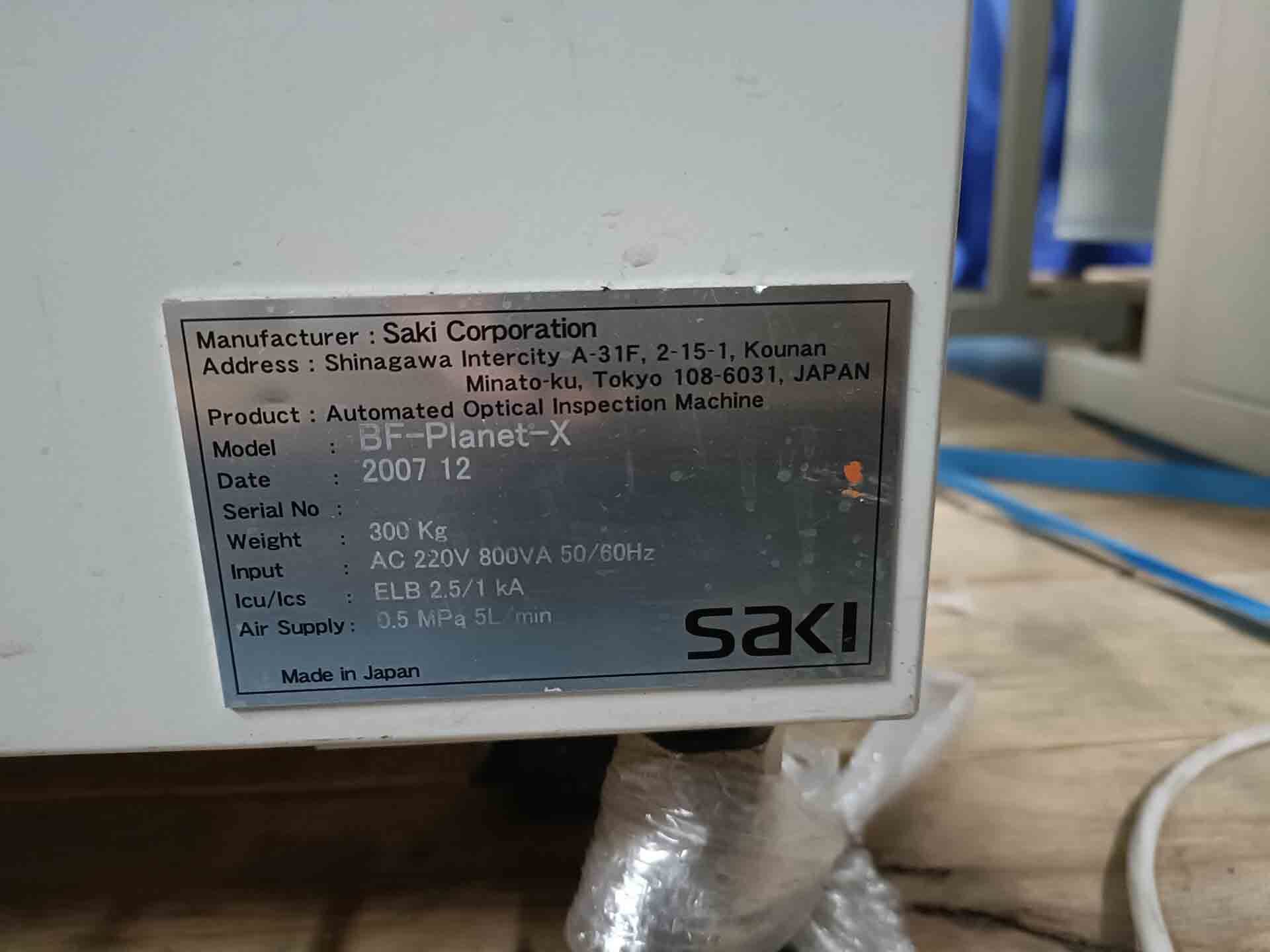

Used SAKI BF-Planet-X #9364786 for sale

URL successfully copied!

Tap to zoom

SAKI BF-Planet-X is a commercial PC board assembly and manufacturing equipment designed for high throughput and flexibility. It utilizes a combination of feeders, machines, test stations, and conveyors to provide an automated process from component placement to quality assurance. The system's main components include various placement machines for SMD and TH components, including a Giusto HP Placer for high-accuracy surface mount devices; a SAKI Flex Placer for odd-form parts; and a pair of SakiBF-R2E Pick-and-Place machines for rapid area array, BGAs, and CSPs. Multiple test stations provide the tests required to ensure the absence of defects in the printed circuit boards (PCBs). A SAKI Infinity 3D AOI inspects boards in both 3-D and 2-D layered perspectives, for accurate visual inspections of solder joints and other characteristics. The unit also has several ancillary machines that provide additional functionalities necessary for a complete assembly. Examples include nut/bolt/washer supplier systems for feeding fasteners into pallets to ensure boards will not become detached; an Electrolux soldering robot for efficient solder application; a vertical reflow oven for heat treatment; an Omron NJ-101 soldering robot for precise leaded-component placement to reduce the labor of manual assembly; and various cleaning systems to ensure the boards are free from flux residues and other contaminants. The machine has onboard memory that allows for a variety of customized settings to meet the specific needs of each assembly job. This includes adjustments to temperature, air flow, speed, vision, placement accuracy, and other parameters to ensure a uniform result. Everything in the tool is controlled by an automated process scheduler that monitors media, machines, and processes. This lets each project be handled smoothly and efficiently with no stoppage in production. In summary, BF-Planet-X asset is a PC board assembly and manufacturing model that streamlines production and improves turn-around time. With its combination of machines and processes, coupled with automated control, it has become an integral part of production lines that need reliable assembly and testing of PCBs.

There are no reviews yet