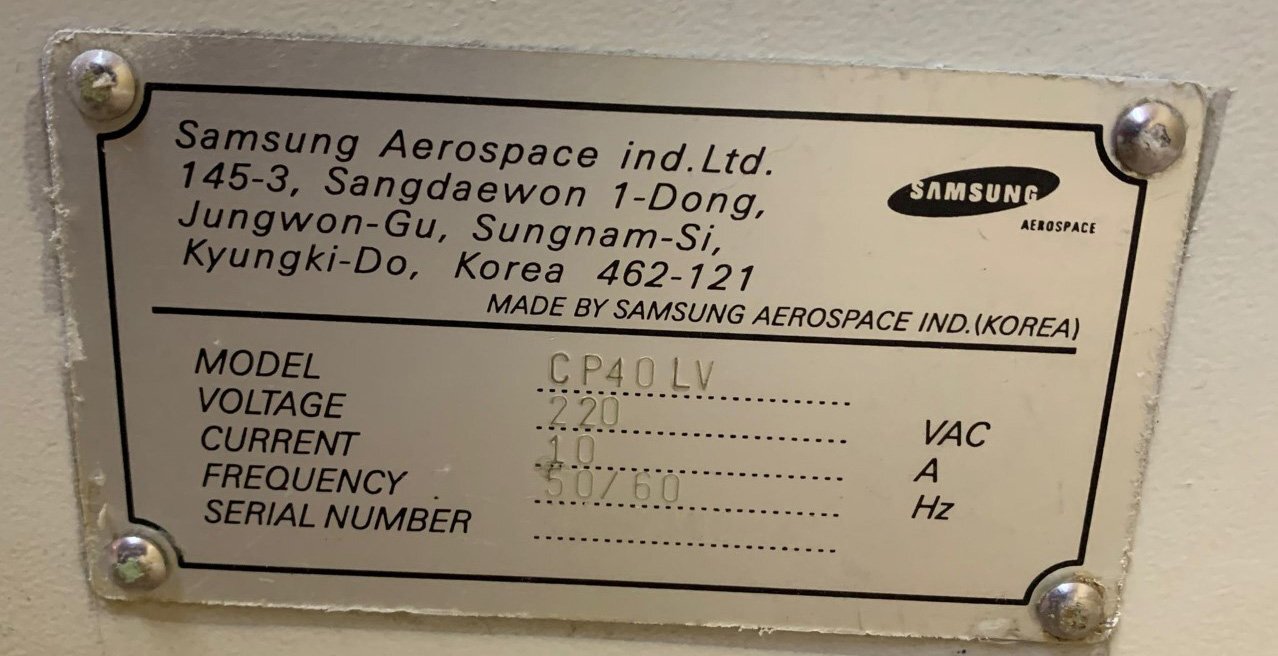

Used SAMSUNG CP-40LV #293615305 for sale

URL successfully copied!

Tap to zoom

SAMSUNG CP-40LV is a PC board assembly and manufacturing equipment designed to meet the production needs of small and large businesses alike. The machine boasts of a wide range of features that allow users to produce high quality printed circuit boards (PCB) in a cost-effective and reliable manner. The system includes a high-performance 6-axis robot with an intuitive control program. The robot is capable of carrying out a wide range of operations such as component pick-up, placement, and soldering. This ensures efficient production and fewer errors. The unit also features integrated visual recognition and tracking, which enables it to identify components with accuracy and precision. SAMSUNG CP40LV also offers numerous additional features that help to ensure quality assurance and accuracy. For example, it is equipped with both optical and laser recognition systems, which enable it to detect errors and irregularities in placed components. The machine also features sophisticated thermal inspection capabilities for detecting faulty soldering and other mistakes. CP 40LV is designed with a wide range of flexibility and convenience features. For example, it features a user-friendly interface and can be easily programmed to operate according to a user's specified needs. It is also equipped with an intelligent and automated feeder tool that can feed components in any quantity and orientation. In addition to superior performance and accuracy, CP-40LV is equipped with a variety of safety measures to ensure the safety of employees during operation. The asset is equipped with a robotic arm with safety plates that prevent accidental contact and injury. The model also has a locking mechanism that prevents unauthorized access and removal of components. Overall, SAMSUNG CP 40LV is a reliable and highly efficient PC board assembly and manufacturing equipment. It has easy-to-use features that make it suitable for use in high-volume production environments. It also has high production accuracy and reliability with its optical recognition and tracking capabilities. Furthermore, its safety features make it ideal for use in hazardous manufacturing environments.

There are no reviews yet