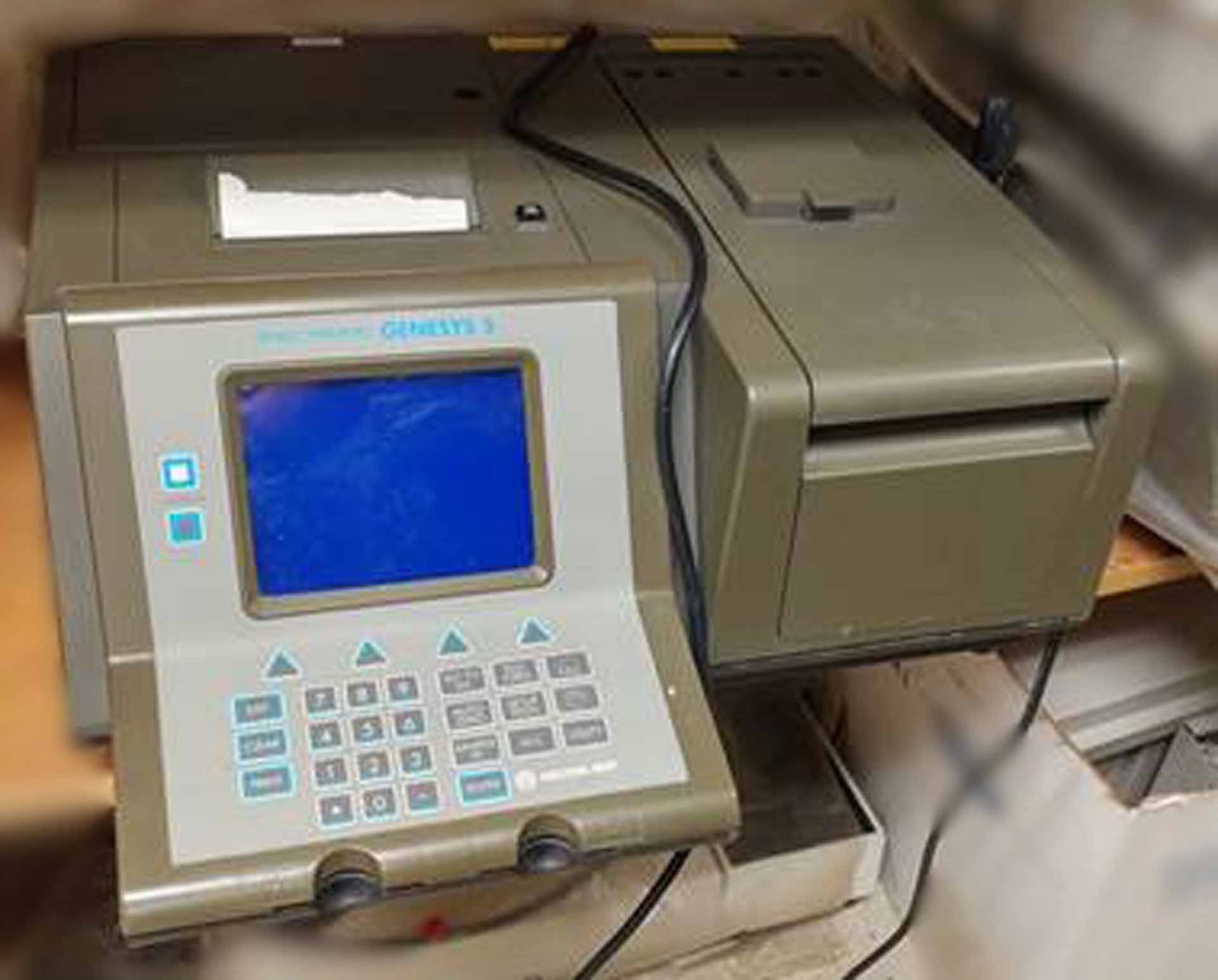

Used SPECTRONIC GENESYS 5 #9135919 for sale

URL successfully copied!

Tap to zoom

ID: 9135919

UV-Visible spectrophotometer

Part no: 336001

Motorized sample holders

Built-in printers

Softcards

Water jacketed cell holders

Spectral slitwidth: 5 nm

Optical system: Split-beam, dual detectors

Display: Graphic, backlit monochrome LCD Screen

Display range: - 0.3 to 4.0 A

Photometric readout: Absorbance and % transmittance

Range: - 0.1 to 3.0 A, 0 to 125 %T

Noise: ± 0.001 A at 220 and 340 nm at 0 A

Drift: ± 0.002 A/hour at 340 nm

Stray radiant energy: 0.05%T at 220 nm and 340 nm

Scan speeds: 300 nm/min (1pt/1nm) or 900 nm/min (1pt/3nm)

Slew speed: 27,000 nm/min

Standard cell holder: 8 Position, instrument controlled

Standard interfaces: RS-232C and Centronics ports

Accuracy:

± 0.003 A From 0 to 0.3 A

± 1% Reading from 0.3 to 2 A

± 2% Reading from 2A to 3 A

Power requirements: 115 V, 50/60 Hz; 230 V, 50/60 Hz.

SPECTRONIC GENESYS 5 is a PC board assembly and manufacturing equipment designed for small to medium volume production. It provides user-friendly operation and maximum flexibility in board assembly and test. It combines automatic component placement and piece-part supply and tests in a single, integrated package. It has a high-resolution touch-screen graphical user interface (GUI) and Windows-based operating system (OS), making it easy to program and operate the unit. The machine provides high-uniform component placement accuracy, with precision placement in X, Y and rotational axes, and an advanced oven temperature control tool that ensures optimal component drying and curing for clean assembly. It can house up to 20 different reels, allowing for a wide range of components to be placed with no manual intervention, and can process up to 8500 parts per hour in high-precision operations. The asset has two functional modules for optimal performance: the Automatic Component Placement Station (ACPS), and the Scheduling/Supervision Station (SSS). The ACPS has two feeders, an X/Y multi-nozzle dispenser and a camera with a built-in detection model to ensure quality consistency. It also has a variety of functions, such as placement variation for short component layering and high-precision alignment and placement of carbon film components. The SSS is used to schedule production based on the individual needs of client applications. It can also be used for manual operation control and monitoring of the entire operation, such as setting up pick and place cycle times, and can be customized for each product. The equipment also has an advanced board testing system and a special function for surface-mount component testing. It is capable of both static and dynamic tests, including inspection of soldering quality, high-speed tests, and the test accuracy can be monitored at all times. GENESYS 5 is a versatile, efficient and reliable unit to help manufacturers streamline their assembly and manufacturing processes. Its highly sophisticated automation combined with user-friendly operation makes it an excellent choice for medium volume production.

There are no reviews yet