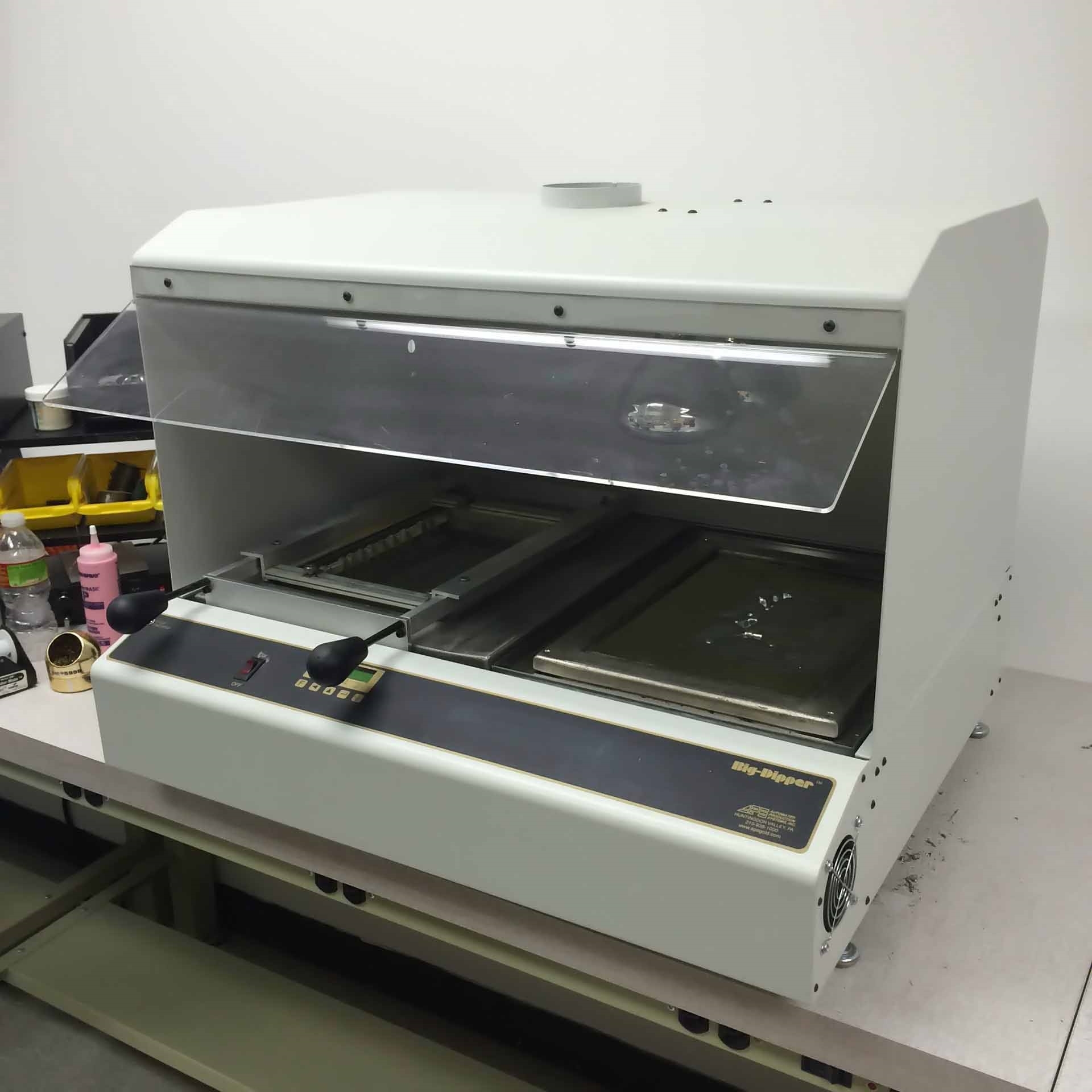

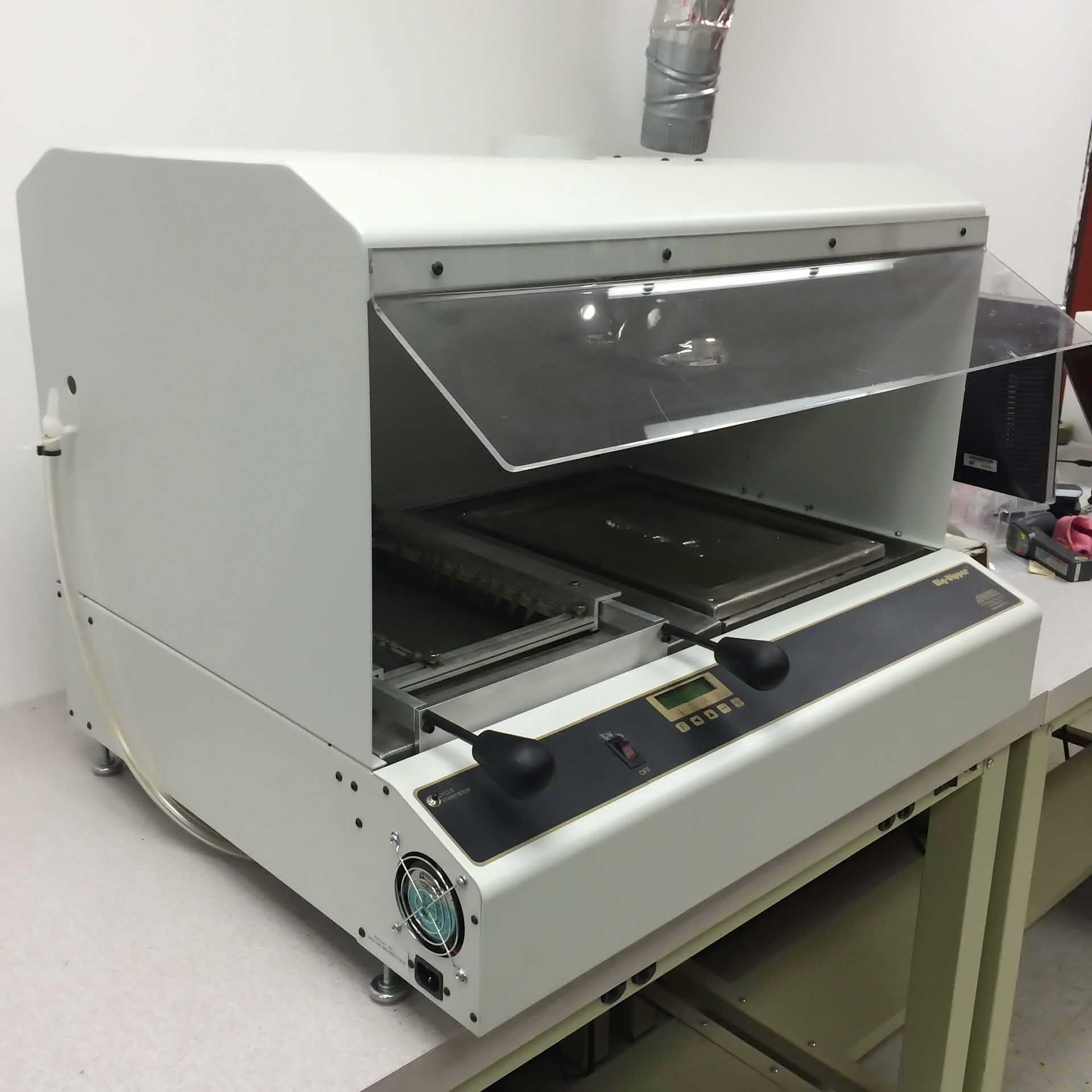

Used APS / AUTOMATED PRODUCTION SYSTEMS Novastar #9214645 for sale

URL successfully copied!

Tap to zoom

ID: 9214645

Vintage: 2007

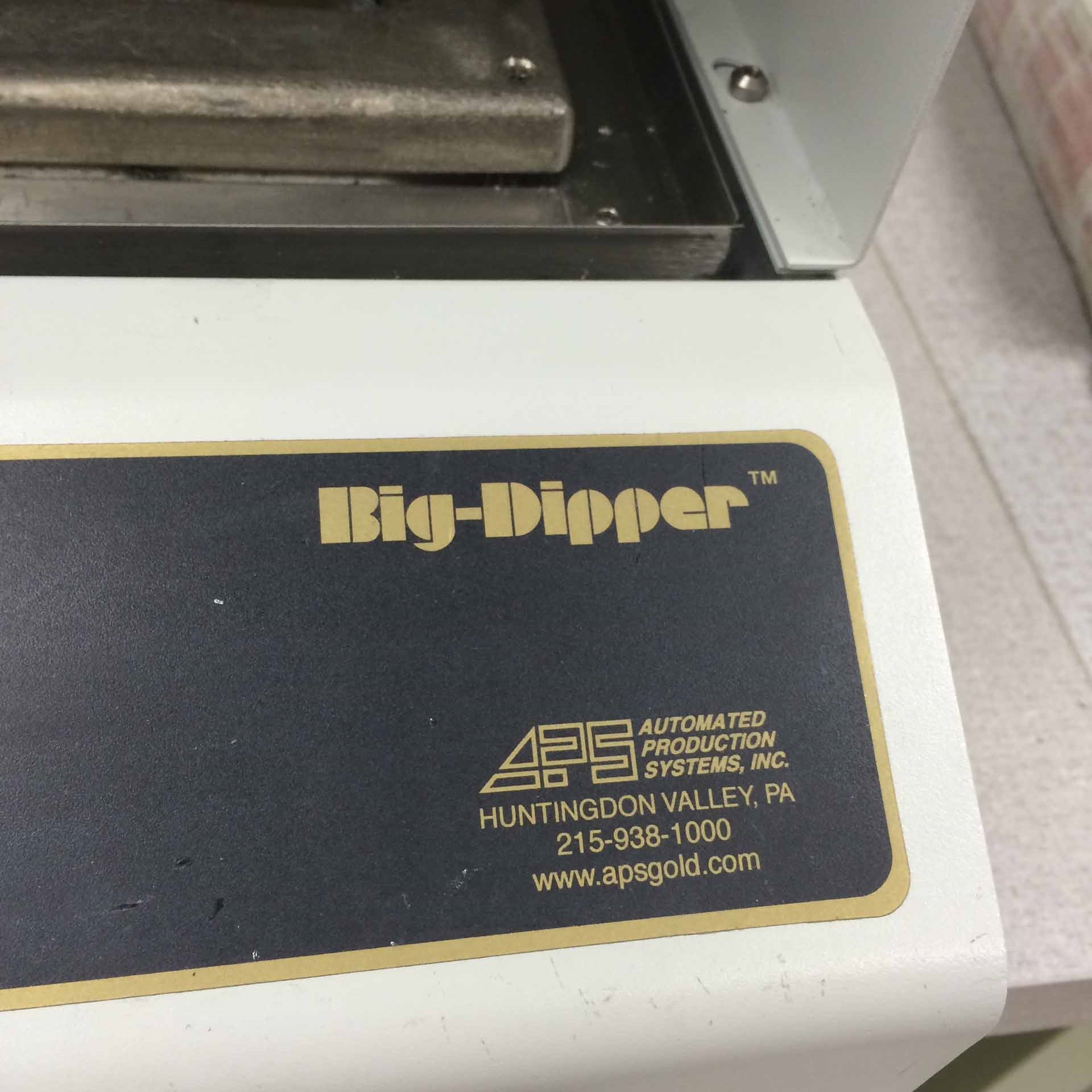

Gold big dipper

Includes:

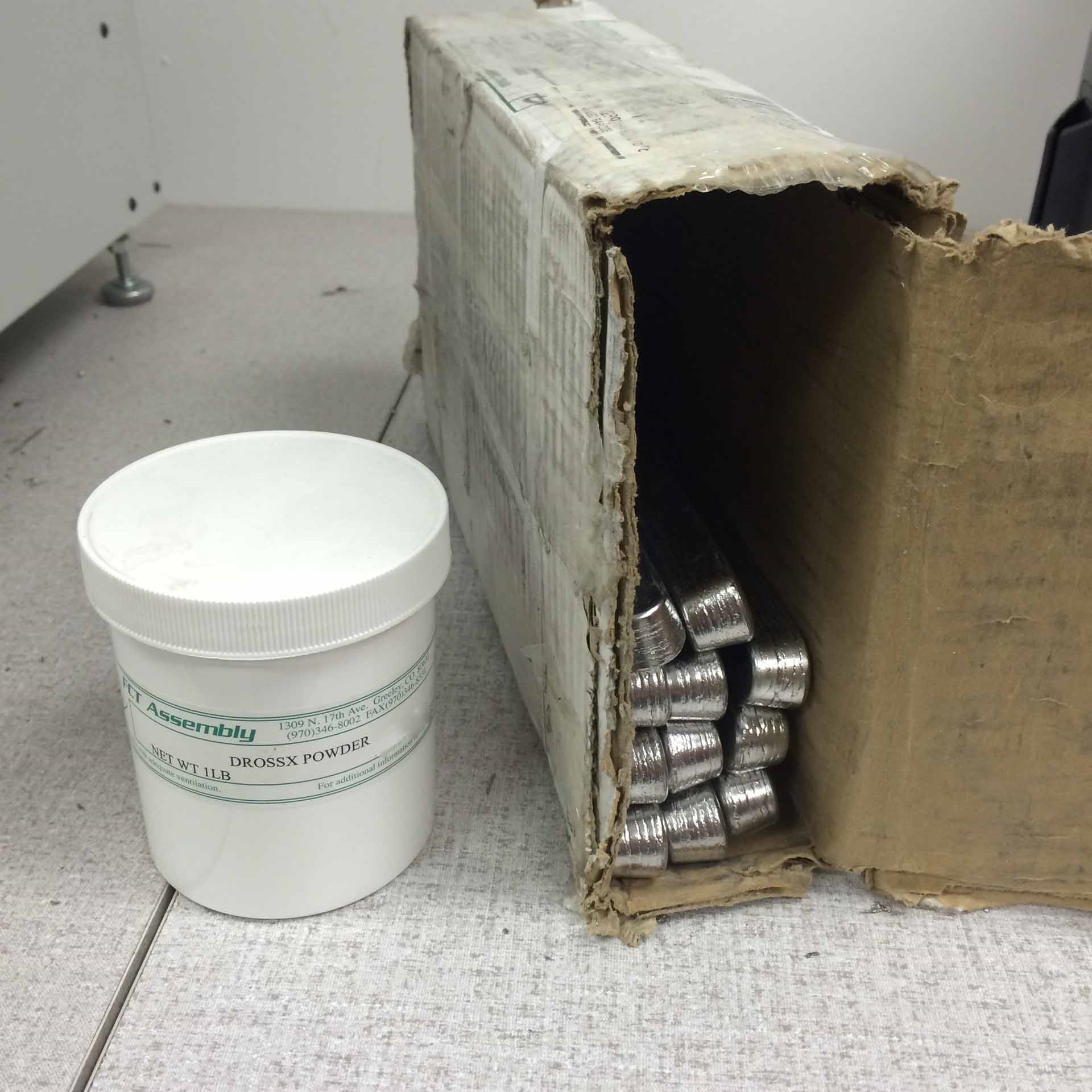

Dross-X de-drossing agent

Lead-free capable

Tin / Lead solder: ~30-40 lbs

Power cord

Dross removal tool

Heat lamps per flux manufacturer to aid in flux activation

Maximum solder temperature: 275°C (527°F)

Maximum solder temperature lead free model HT: 350°C (662°F)

Solder capacity: ~50 lbs

Maximum board size: 8” x 11.375” (203 x 290 mm)

Warm-up time: ~50 min

Power: 120 VAC, 60 Hz, 10 A

2007 vintage.

APS / AUTOMATED PRODUCTION SYSTEMS Novastar from APS (AUTOMATED PRODUCTION SYSTEMS) is a PCB solder machine that is designed for high-speed, medium- to high-volume production. APS Novastar is an integrated assembly solution designed to provide users with a high-throughput and highly flexible machine. The equipment features an advanced motion control system, feeders for automatic and precise parts placement, and a powerful vision unit. AUTOMATED PRODUCTION SYSTEMS Novastar features a large-capacity solder pallet which enables users to store up to 800 different PCBs on any product loaders at any given time. The large pool of feeder modules in Novastar offers an array of different feeder types including single-lane modules, multi-lane modules, and other components. The Modular-FlexBoard Feeder's in this machine offer high-speed metal insert feeders and its separate lanes and flexible hookup technology make parts changeover easier. The fast and precise vision tool of APS / AUTOMATED PRODUCTION SYSTEMS Novastar allows it to detect, measure, and place newly primed components accurately. APS Novastar provides an ergonomic working environment with a low noise level, minimal dust, and comfortable working temperature. This asset also ensures user safety with its solid frame and a full range of safety features. AUTOMATED PRODUCTION SYSTEMS Novastar offers flexible maintenance access and integrated self-diagnosis functions. Additionally, it offers an integrated profile and HotSpot solution offering accurate temperature profiling and control with a single repair station. In terms of process flexibility, Novastar is capable of running multiple batches at increased throughput levels. The machine is also suitable for a range of processes such as Pb-free lead-free soldering, mixed technology soldering, pin-and-lay, pin-in-hole, pin-in-paste, and more. The model guarantees product conformity, as it allows users to standardize their production process to IPS. APS / AUTOMATED PRODUCTION SYSTEMS Novastar is also fully compatible with the latest generation of fluxes. APS Novastar from APS / AUTOMATED PRODUCTION SYSTEMS is a unique fully automated PCB solder machine specially designed for high-speed, medium to high-volume production. It is an integrated assembly solution that features an advanced motion control equipment, feeders for automatic and precise parts placement, a powerful vision system, a large-capacity solder pallet, Modular-FlexBoard Feeder's, flexible maintenance access, integrated self-diagnosis package, a HotSpot solution and a range of other features that offer a user with an ergonomic working environment, product conformity and process flexibility.

There are no reviews yet