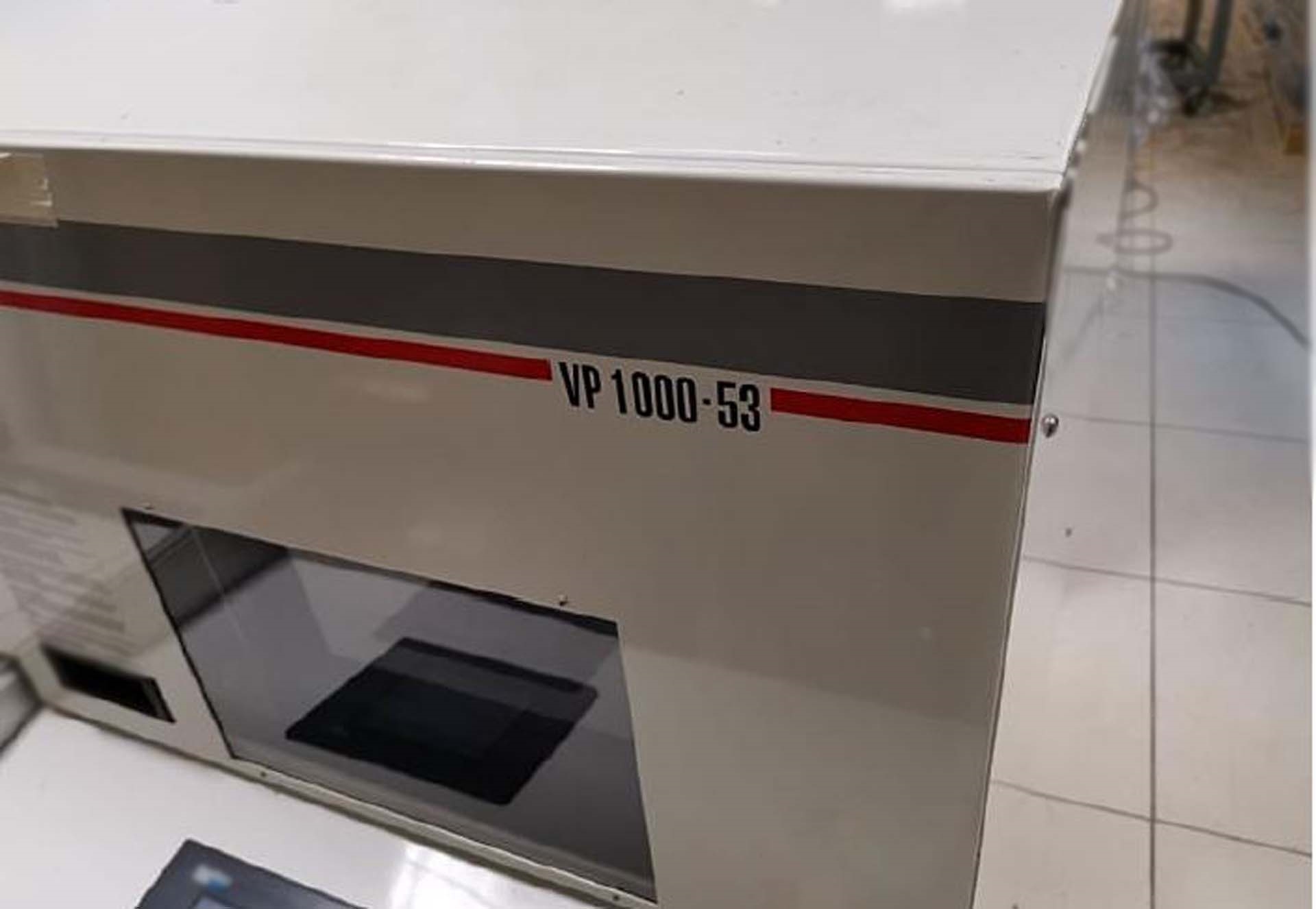

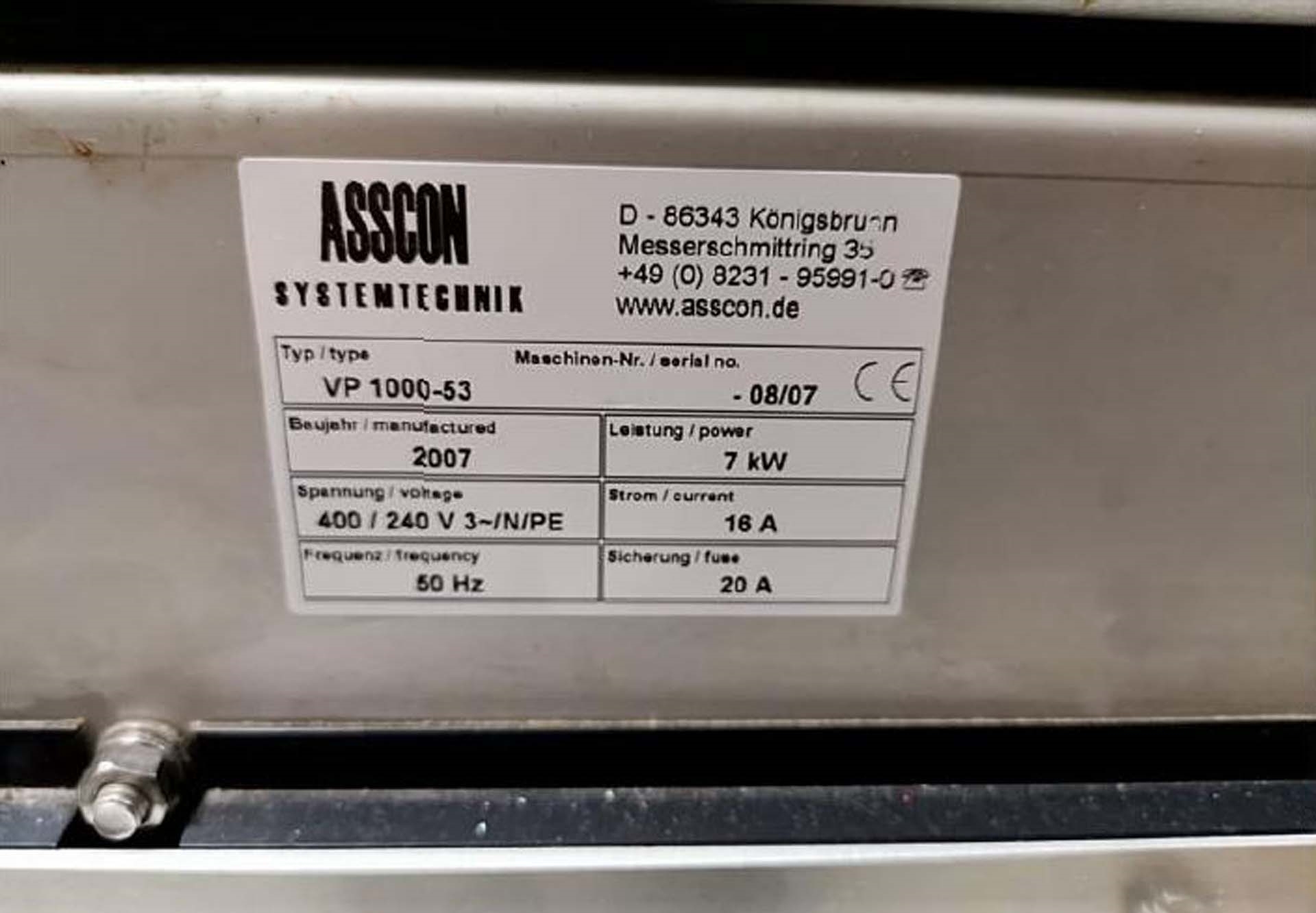

Used ASSCON VP 1000-53 #9233960 for sale

URL successfully copied!

Tap to zoom

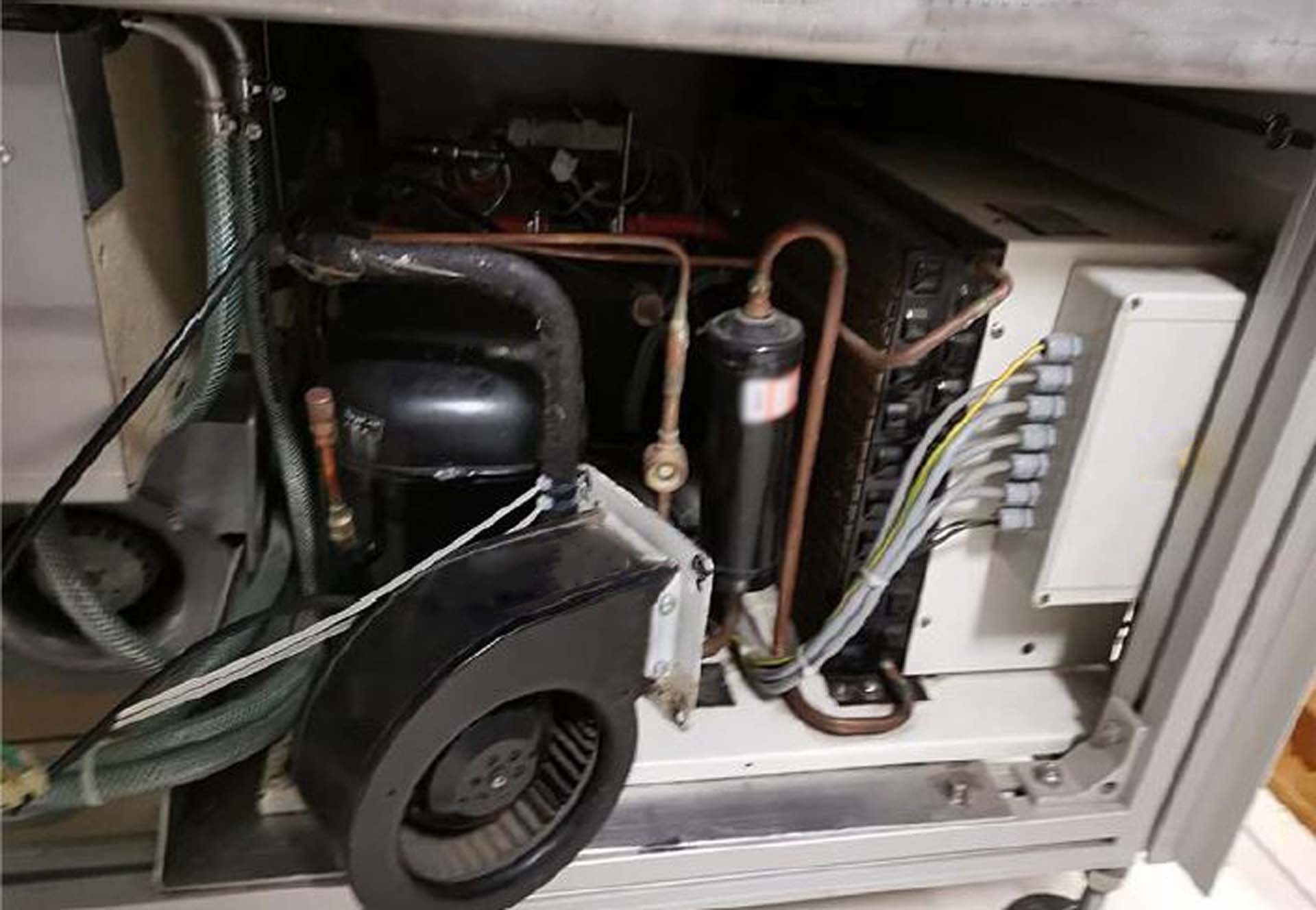

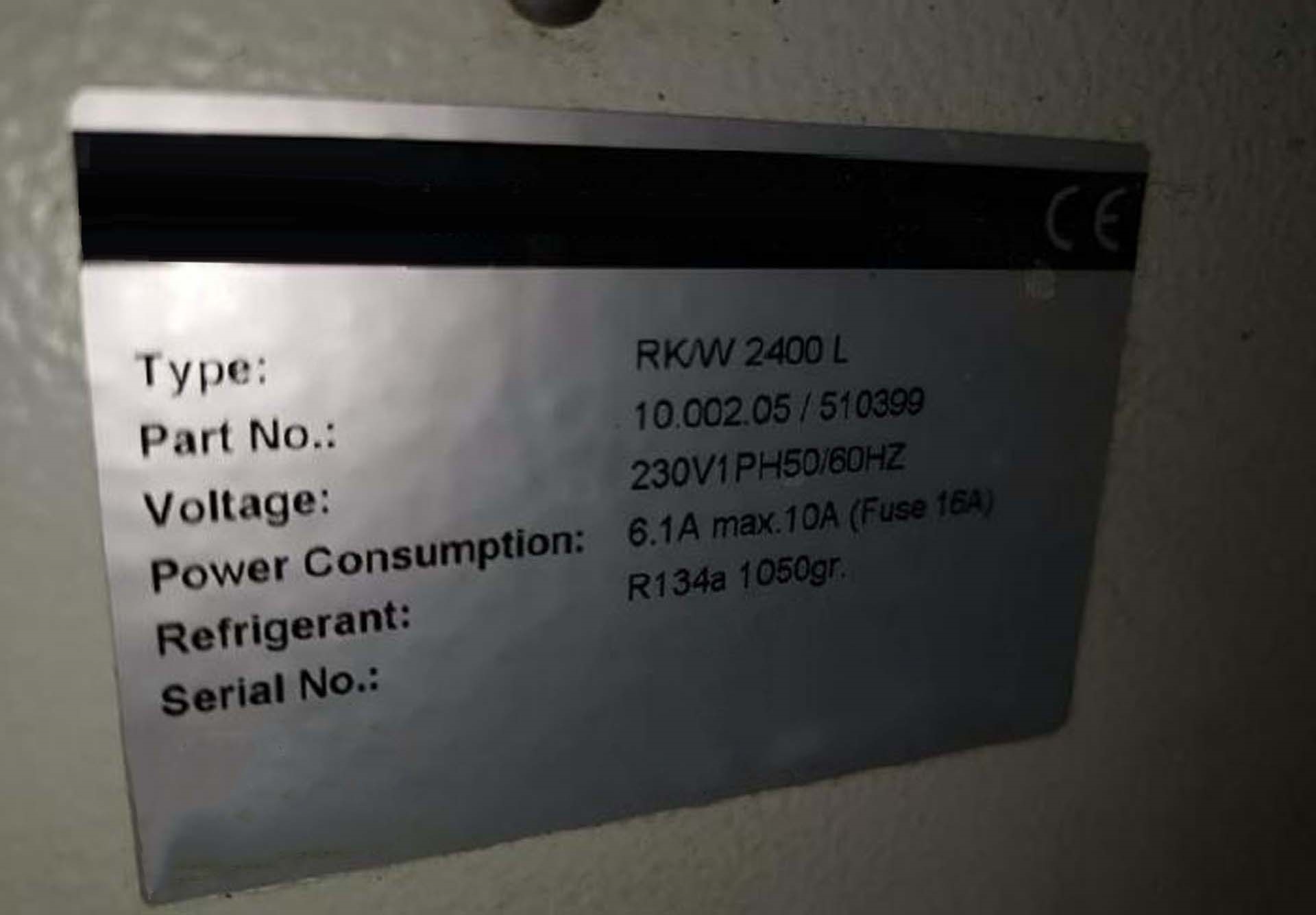

ASSCON VP 1000-53 is a fully automated precision soldering machine designed for applications in the PCB assembly industry. This machine is equipped with a high-precision, low-thermal-impact soldering robot, allowing for increased accuracy and productivity. The soldering robot is able to work with various sizes of solder wires, allowing variations in the solder joints as well as different profiles. The robot is driven by an advanced computer-controlled equipment, allowing for very precise and reliable operation. VP 1000-53 utilizes a three-zone furnace that provides rapid heating of solder at temperatures up to 750°C (1382°F). This is done through a stepped approach, where the solder is preheated, then further heated in consecutive zones. Additionally, the furnace is segmented into two separate sections, allowing for simultaneous processing of two PCBs. The machine is also equipped with an automated pre-placement system that accurately aligns and applies solder paste on the PCB. This unit reduces manual labor and prevents damage to solder paste that can occur during manual application. This also allows for improved consistency in the solder paste application, resulting in higher soldering quality. The machine also has an optimized vision machine that allows for precise detection of PCB components. This tool ensures that components are correctly aligned and placed on the PCB, reducing the risk of potential bridging or shorts. Additionally, the vision asset is also used to detect surface-mount components, ensuring the copper tracks have been accurately placed before soldering. Finally, ASSCON VP 1000-53 has a unique 'chip-off' detection model. This equipment is able to detect and alert of any potential component chips during soldering, preventing defects and ensuring high product quality. In conclusion, VP 1000-53 is an automated precision soldering machine designed with various advanced features that enable increased accuracy, productivity, and product quality. The advanced furnace, pre-placement system, vision unit, and 'chip-off' detection machine all work together to provide reliable and effective PCB assembly operations.

There are no reviews yet