Used JT AUTOMATION WS-610 #9395325 for sale

URL successfully copied!

Tap to zoom

ID: 9395325

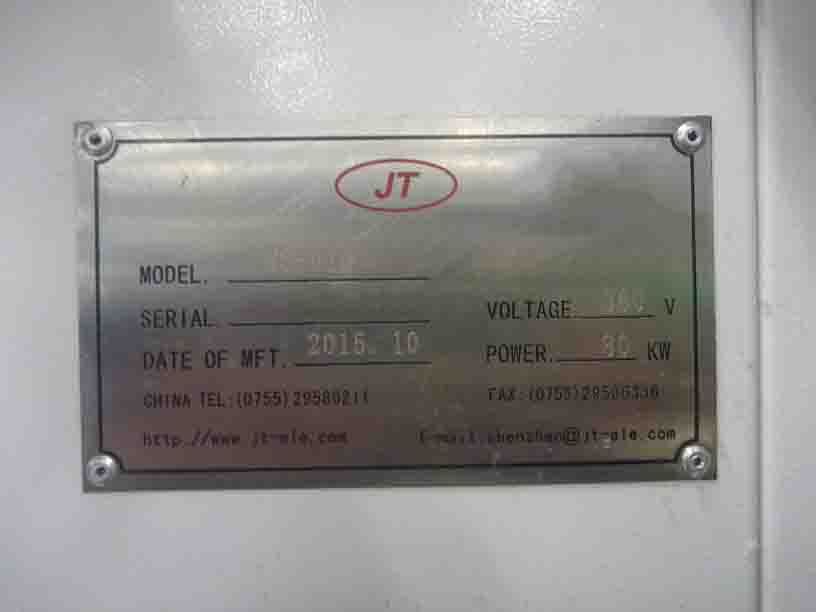

Vintage: 2015

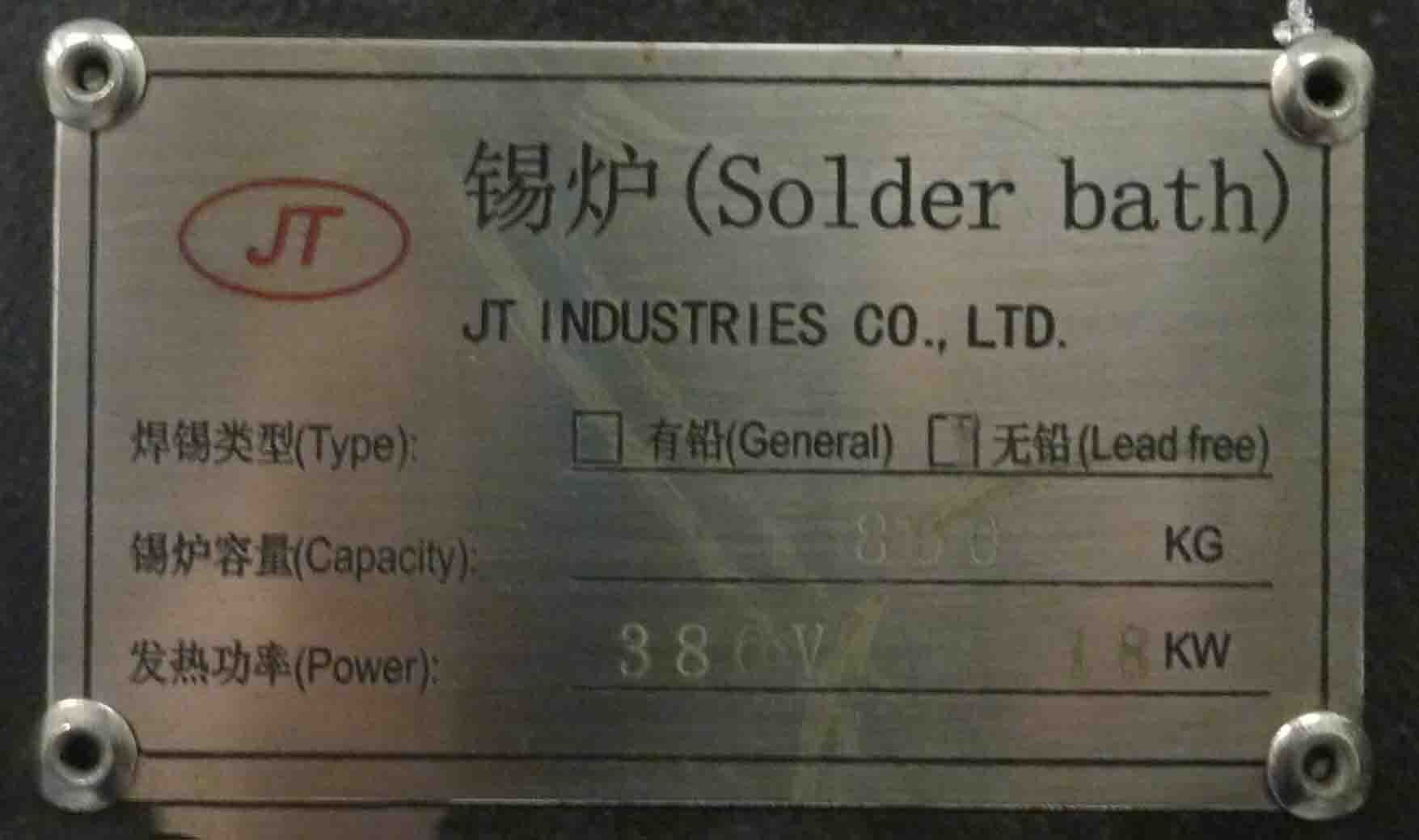

Wave solder machine

Maximum conveyor width: 610 mm

Finger conveyor

With auto width adjust: Left to right travel

Chip and delta wave

Integral spray fluxer module

BALVER Zinn SN100C Lead free solder

Supplied manuals included

JT AUTOMATION FS-610B Spray fluxer unit

Maximum conveyor width: 610 mm

Travel: Left to right

(6) Zones convection preheat:

(3) Bottom

(3) Top

2015 vintage.

JT AUTOMATION WS-610 is a next generation Fully Automated PCB Soldering Machine, designed for high volume production. The machine is equipped with advanced features such as self-learning and self-adjustment algorithms for improved Solder Paste Distribution (SPD), high speed Solder Motion Control (SMC) and advanced process monitoring capabilities. It also has a wide range of substrate and component type support. WS-610 supports a wide range of component types, including SMDs and Flip Chips, Leaded and Through-Hole devices, J-Leads, and common Interconnects. The machine has integrated Solder Paste Inspection (SPI) to ensure the highest quality of soldering for any of the supported components. This is combined with adjustable air pressure and nitric acid concentration that are specifically tailored for each substrate thickness. JT AUTOMATION WS-610 has an advanced feature set that enables streamlined operation and maximum production efficiency. It leverages an SMC module to ensure precise control of the machine's motion and ensure an accurate and repeatable process. It also has an automated process adjustment feature to reduce aberrations and waste between board assemblies, stepper and servo-controlled motion for improved accuracy, and feedback sensors to optimize the process during production runs. The Solder Paste Distribution (SPD) technology available on WS-610 ensures that the necessary amount of solder paste is applied evenly across the substrate. This is combined with the ability to adjust the pressure and amount of flux used for each application. It has a self-adjustment feature that can be used for fine-tuning the process for better results. The machine is equipped with a wide range of monitoring and diagnostic features that provide reliable process data. These include the monitored Solder Bath Temperature, Average Component Temperature and Solder Joint Conduction. It also provides real-time alarms and trends tracking for improved process control and improved component yield. In conclusion, JT AUTOMATION WS-610 is an advanced and versatile PCB Solder Machine that is developed to meet the demands of high-volume production. It is equipped with features to ensure a precise and repeatable process. The machine can be integrated into any existing or automated line for improved precision and process efficiency. It has advanced SPD, motion, monitoring and diagnostic features to ensure a reliable production process.

There are no reviews yet