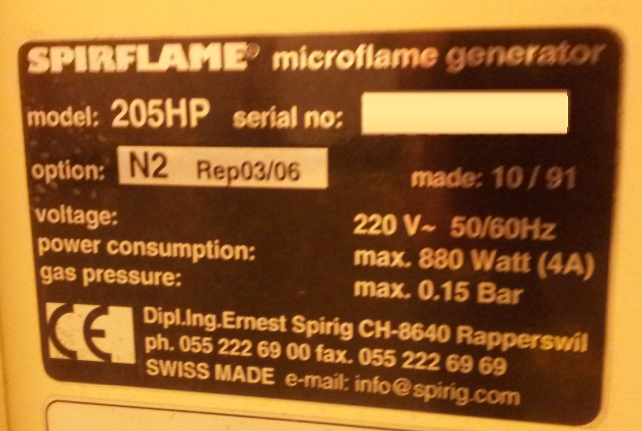

Used SPIRFLAME 205HP #9081697 for sale

URL successfully copied!

Tap to zoom

ID: 9081697

Vintage: 1991

Microflame generator

11.230 VAC

Watt input: 30 - 880 W dependent on gas generating rate

1991 vintage.

SPIRFLAME 205HP is a premium high-performance PCB (Printed Circuit Board) solder machine for production and prototyping that combines speed and accuracy. It has a small foot print making it ideal for high-speed, high speed prototyping, both in low-medium volume environments. 205HP is a hot bar machine that uses oppositional temperature control to improve throughput and minimize voids. The factory temperature can be set from 40°C to 250°C allowing for a wide range of different alloys and temperatures. The combination of hot bar technology and intelligent temperature control creates a reliable temperature profile across the entire board, resulting in a high-quality and consistent soldering. The temperature control also minimizes degradation of the solder joint over time. SPIRFLAME 205HP is a flexible machine with a wide range of process controls, including flux application levels, lead-free and low-temperature fluxes, nozzle configurations for fine-pitched components and multiple axes. It has a two-position head with the ability to move along the x, y single, rotating, and z axes for high-precision assembly. 205HP also features a intuitive 5.7" touch screen that provides fingertip control of the entire process. In addition to its core features, SPIRFLAME 205HP offers additional features for production and prototyping purposes. Some of the key features it provides include placement process commands, an integrated vision systems, and a nozzle sensor that can select the correct nozzle configuration depending on the PCB geometry. These features appeal to both low-volume prototypers and mid- to high-volume manufacturers who require quick turnarounds, high accuracy, and high-quality results. Overall, 205HP is a premium, high-performance PCB solder machine that combines speed, accuracy, flexibility and advanced control features. It provides quick turnarounds and high-quality results in both low- and high-volume production environments. Its temperature control, process control, and nozzle sensor make it a dependable source for accurate and consistent solder joints in every run.

There are no reviews yet