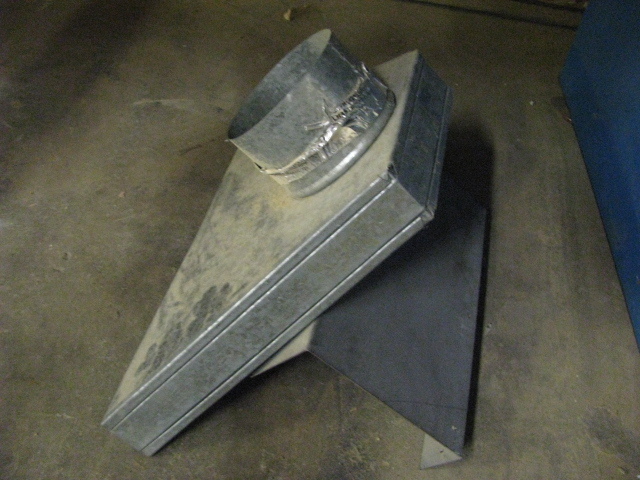

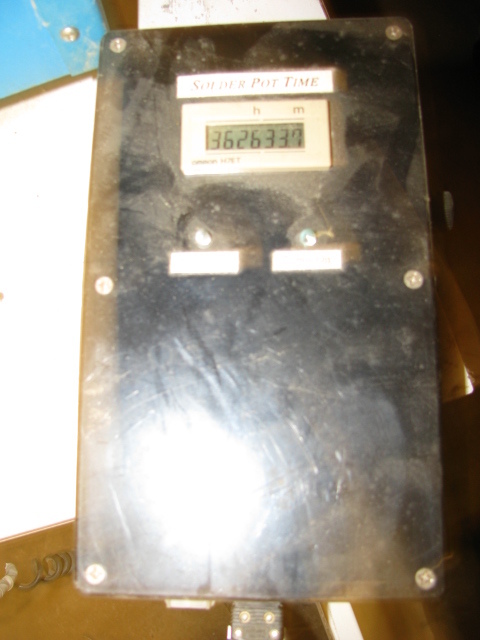

Used UNITDESIGN 210 #9012278 for sale

URL successfully copied!

Tap to zoom

UNITDESIGN 210 is a high-performance, cost-effective pick-and-place machine for printed circuit board (PCB) solder application. It is designed to provide faster, more accurate and reliable results than manual soldering. Featuring high-speed vision inspection capabilities, advanced process control, and on-site calibration, it is an ideal solution for high volume PCB manufacturing and assembly operations. 210 consists of a full vision inspection system, precision positioning, and high-speed soldering iron control. It can place components with a 0.10mm accuracy across its work area, making it highly suitable for complex, high density PCBs. This also ensures a high wire bond quality and reliability as well as reducing overall installation time. The vision inspection system helps to minimize solder wastage and still maintain excellent solder joints. It can identify faulty solder joints and can remove them before the entire board is assembled. This saves time and money, as well as increases the quality of the solders. UNITDESIGN 210 features an advanced process control system, which allows it to continuously monitor the temperature, pressure, and time during the soldering process. This allows it to ensure repeatable, high-quality results with every soldering operation. Additionally, operator safety is also enhanced as it is designed to automatically stop its operations should any safety limits be exceeded. The use of on-site calibration ensures that 210 delivers consistently efficient results. With this feature, the machine is easily calibrated on-site, saving both time and money by avoiding the need to send the entire machine off for calibration. Finally, UNITDESIGN 210 also offers the convenience of allowing components to be attached directly to the PCB substrate, eliminating the need for any external wiring harnesses. This feature further helps to reduce installation time and cost as the number of components to be wired is decreased significantly. In summary, 210 is a high-speed, precision pick-and-place machine for electrical board soldering application. It offers advanced features such as high-speed vision inspection, precise positioning, and advanced process control, allowing for reliable and repeatable performance even in high-volume solder operations. Its on-site calibration and direct component attachment also add to a cost-efficient production process. This makes the machine an ideal solution for PCB manufacturing and assembly operations.

There are no reviews yet