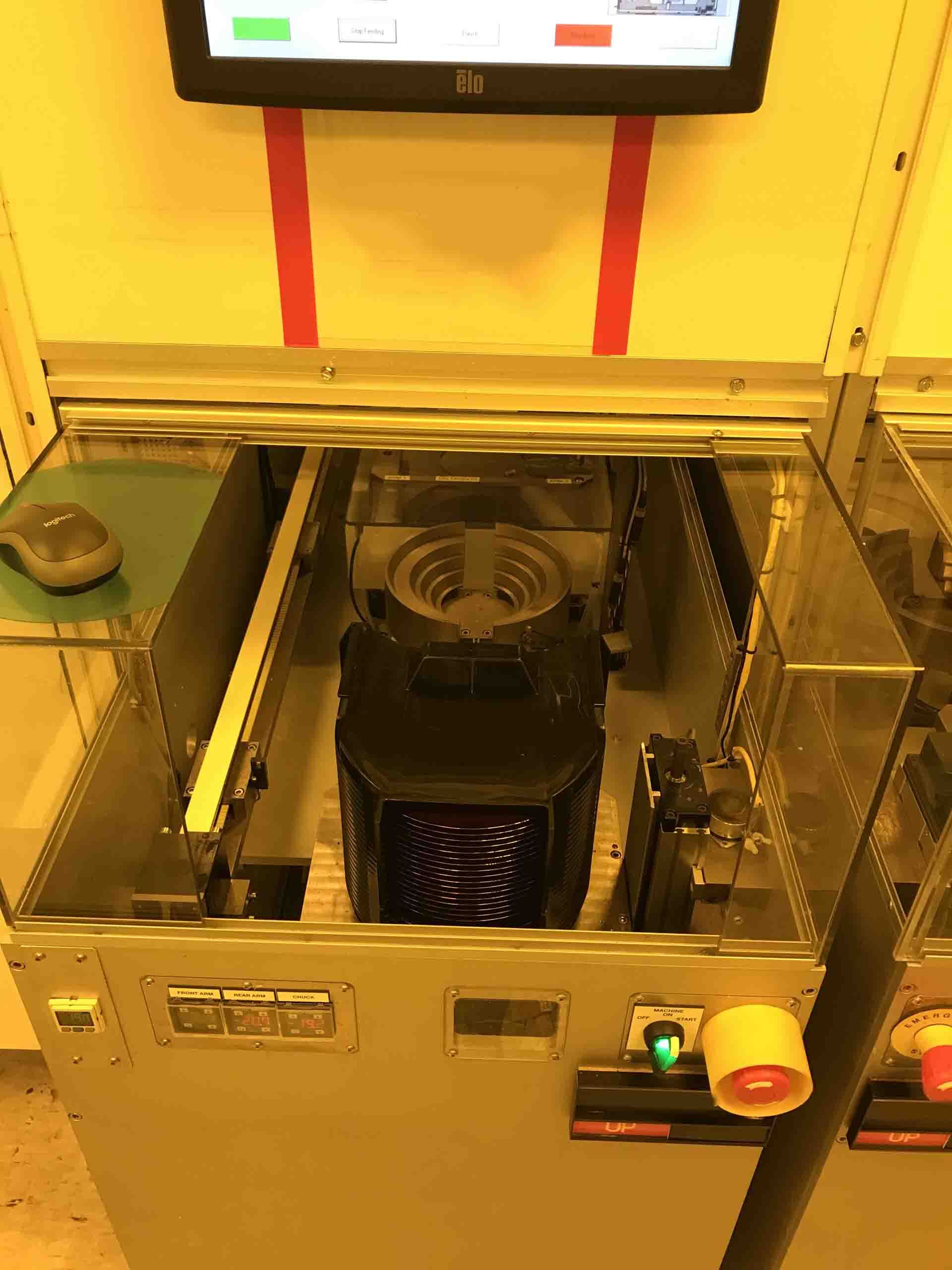

Used DELTA 5AQ #9395524 for sale

URL successfully copied!

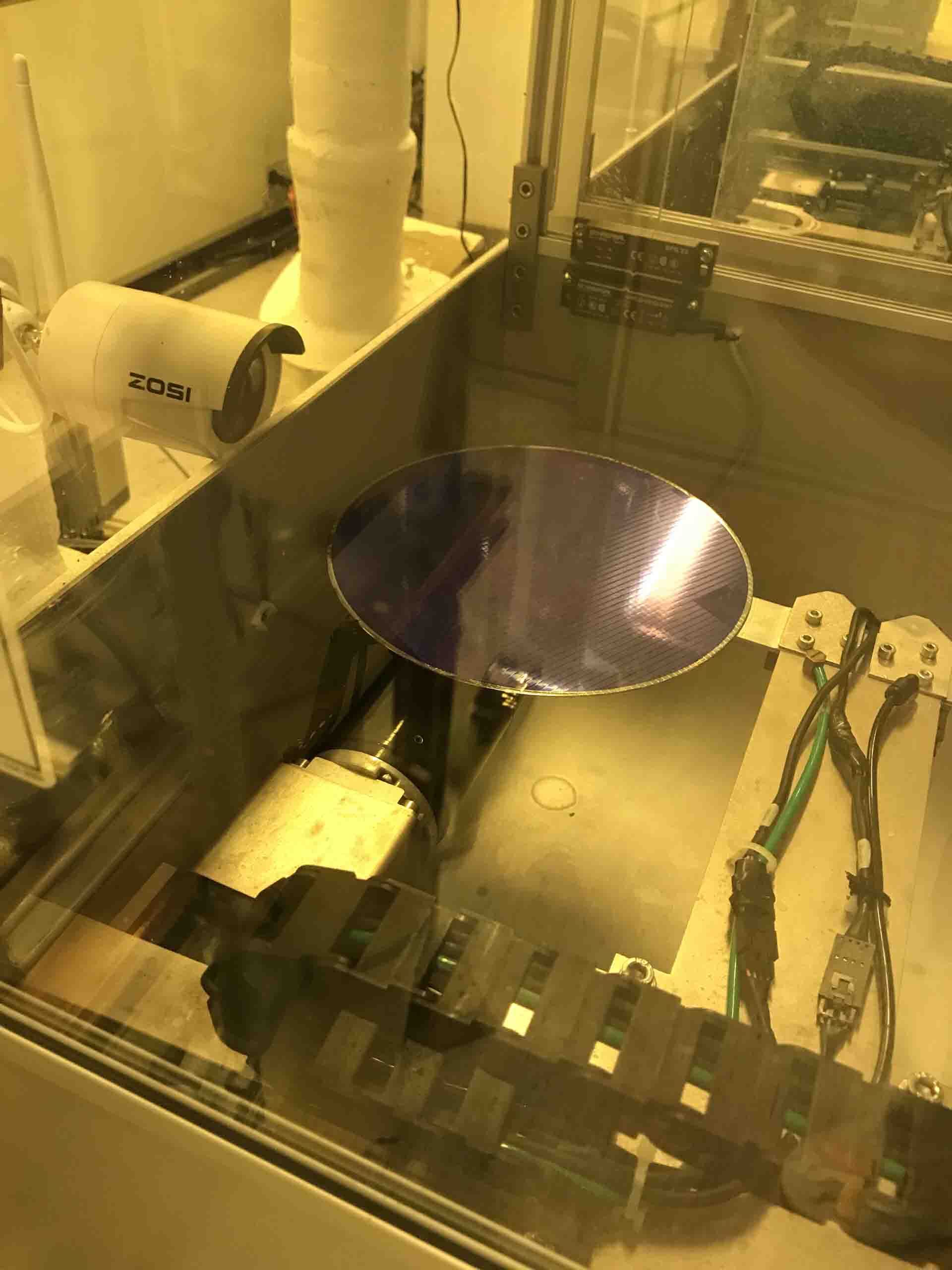

Tap to zoom

ID: 9395524

Wafer Size: 6"-8"

Vintage: 2005

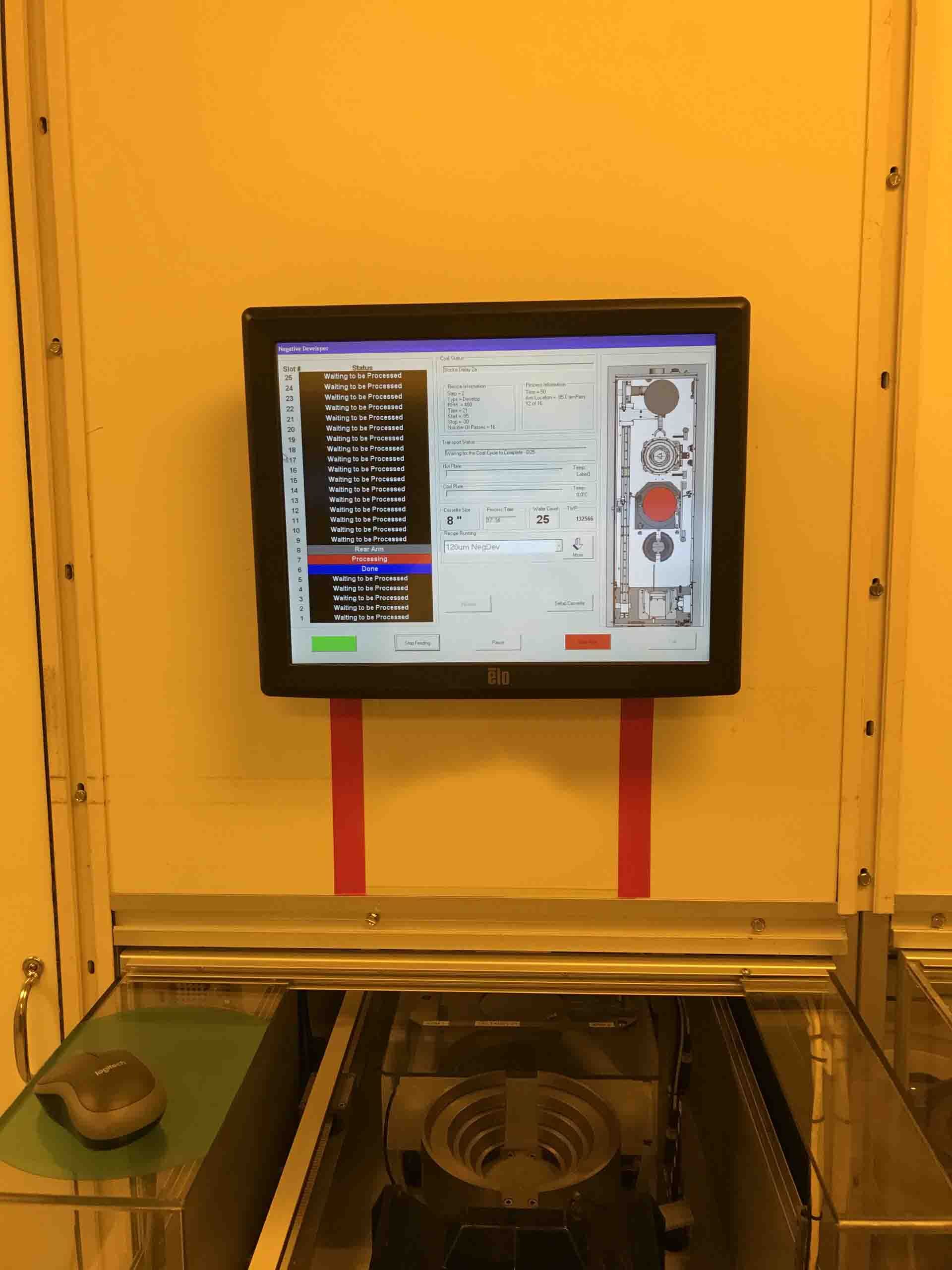

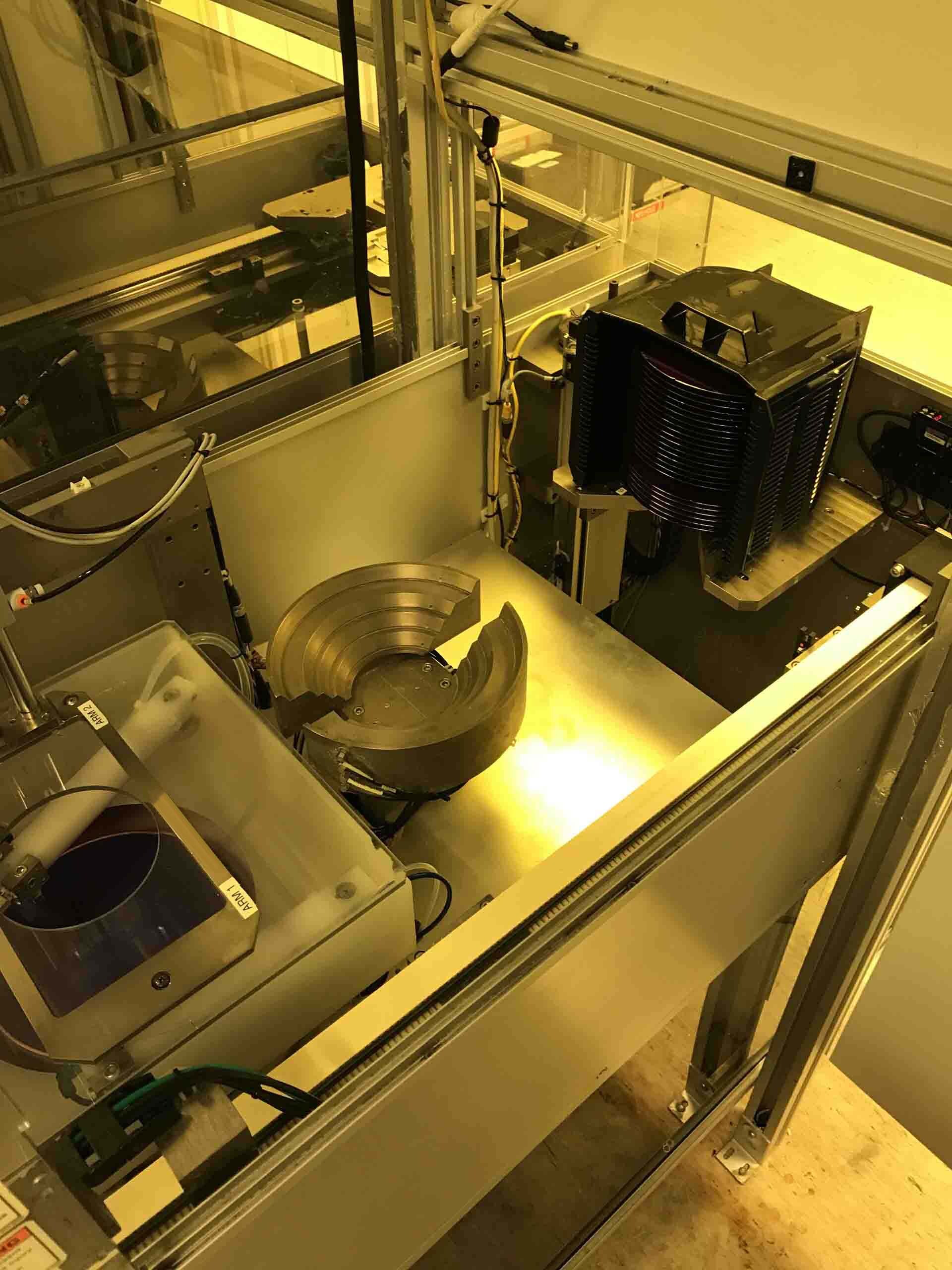

Developer system, 6"-8"

Puddle dispense arm for developer and N2

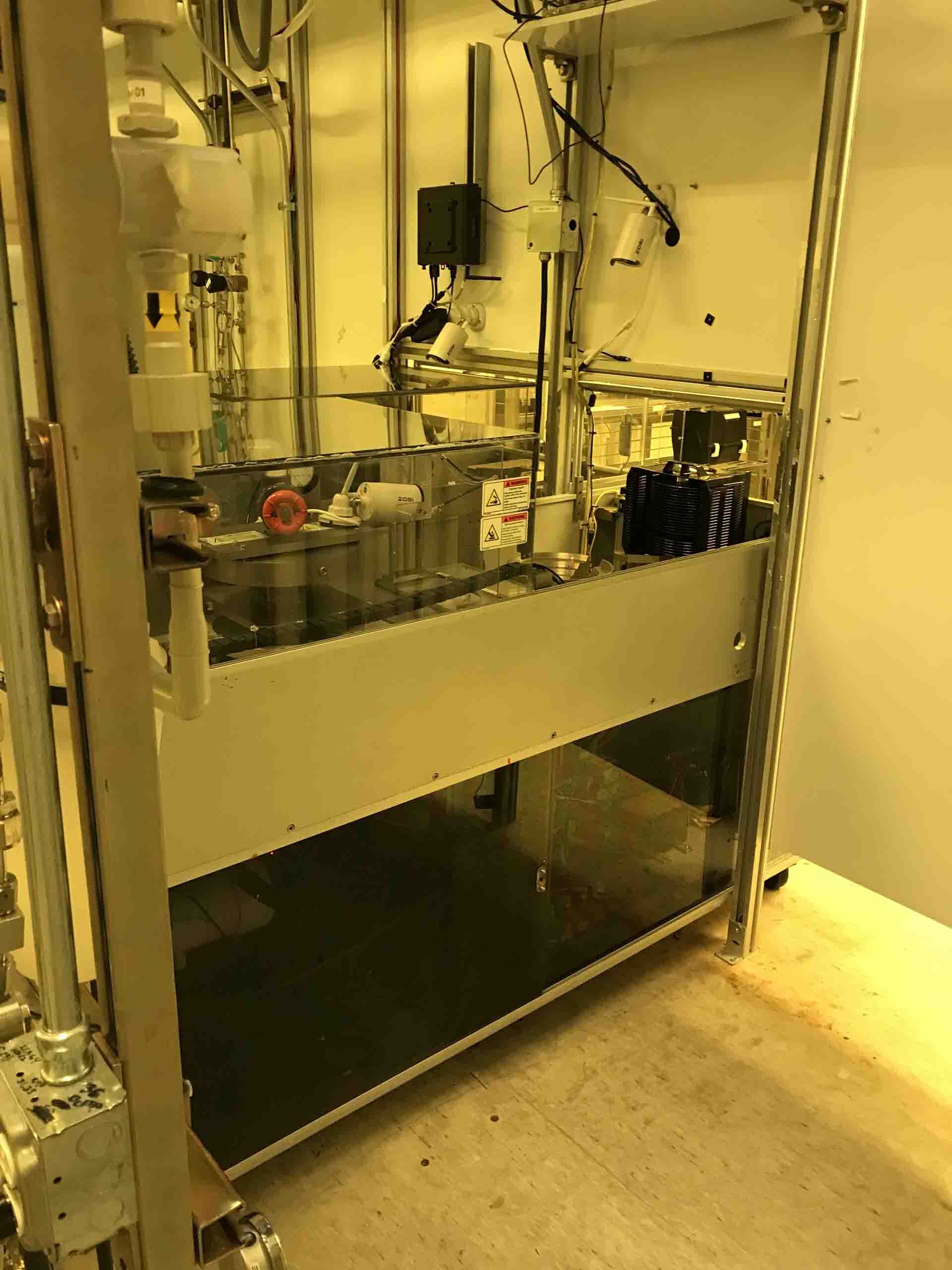

Spray arm for developer and DI dinse

Hotplate

THERMO SCIENTIFIC A25 Chiller

Video process monitor

PC

2005 vintage.

DELTA 5AQ equipment is a state-of-the-art photoresist system engineered for the clean production of microelectronic devices. This unit is specifically designed to help manufacturers better manage their processes, minimize defects and reduce costs. The machine offers a wide range of robust photoresist services that can support organizations that need to create high-quality microelectronic components. This includes processes such as masking, patterning, and lithography. It also provides a variety of advanced capabilities, such as pattern overlay inspection, vertical line scanning, and automated process monitoring. 5AQ is a three-component tool that consists of a development station, a processor, and an automatic wafer handler. All three components work together to ensure consistent and optimized processes. The development station is responsible for the service and batch-tuning of the photoresists used in the asset. It has a high-speed memory model, which allows for quick transfer of data and recipes. The processor contains multiple pumps and agitators, far-UV lamps, and spray guns that enable the full array of photoresist development and processing operations. It also has an intuitive user interface that guides users through the process. The processor also contains a self-cleaning equipment to maintain cleanliness and chemical stability. The automated wafer handler can handle a variety of wafer sizes and offers the highest throughput rate available. It uses advanced robotics and precision motion systems to accurately align and place substrates. The system is also equipped with a special-purpose docking station, which allows for easy exchange of substrates. In conclusion, DELTA 5AQ is an advanced photoresist unit designed to produce high-quality microelectronic components. It combines a powerful development station, a processor, and a reliable automated wafer handler to ensure consistent and optimized processes. The machine is fully automated and provides an easy-to-use user interface. With its cutting-edge features, this tool is the perfect tool for any organization that needs to produce high-quality microelectronic components.

There are no reviews yet