Used DELTA DI Wafer Cleaner #293628705 for sale

URL successfully copied!

Tap to zoom

ID: 293628705

Wafer Size: 6"-8"

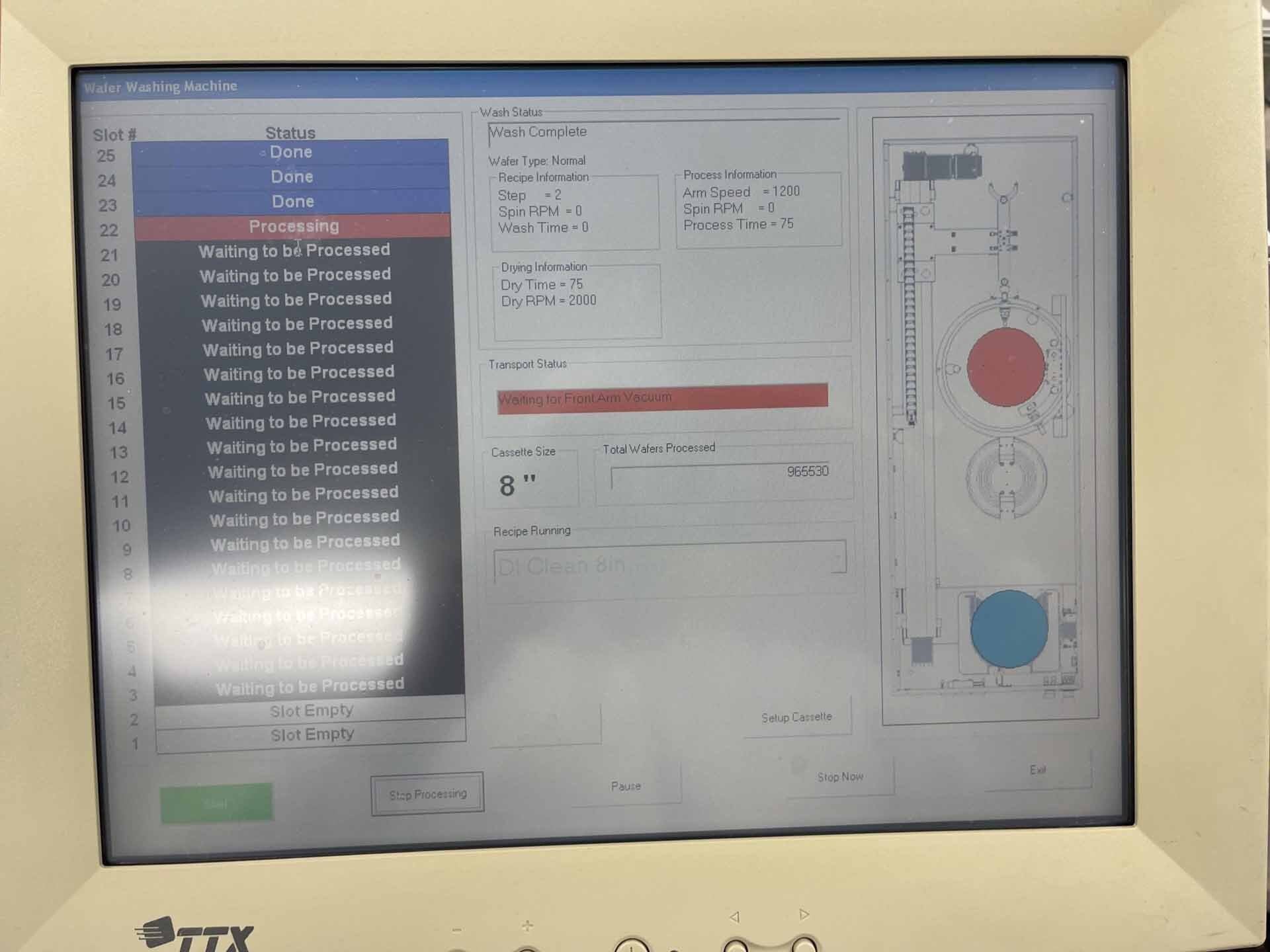

DI Wafer cleaner, 6"-8"

6" and 8" wafer cassette holder

Wafer centering station

Dual end effector

DI Spray arm

1" Drain

N2 Dry nozzle

Exhaust booster fan

PC.

DELTA DI Wafer Cleaner is a photoresist equipment that can be used to quickly and reliably remove layers of deposited materials, residues and contaminants from substrates such as semiconductor wafers, circuit boards and other thin-film carriers. The system utilizes patented technology to provide enhanced cleaning capabilities. The wafer cleaning process involves the use of a solvent-cleaning step and an ozone-based post-etch step. The solvent-cleaning step involves the use of an effective cleaning solution that is dispensed through a nozzle and allowed to coat the surface of the wafer. This solution is designed to quickly break down any residues left by the preceding etch or deposition process and provide a clean substrate for further processing. After the solvent-cleaning step has completed, the wafer is put through an ozone-based post-etch step. This step utilizes ozone (O3) to quickly break down and extra residue that may still remain, including organic compounds and some inorganic compounds. DI Wafer Cleaner is a robust and reliable machine that is designed to offer numerous advantages to its users. First, it is able to clean both sides of the wafer simultaneously, which can greatly reduce cycle time. Second, a "single-use" version of the cleaner is available, which eliminates concerns of cross-contamination by allowing each cleaning cycle to be performed with a fresh wafer. Third, the machine is designed to be quick and easy to use, making it an ideal choice for users who require high-quality results in a short period of time. Lastly, since the wafer cleaner is based on fully automated technology, it eliminates the need for manual processes. In summary, DELTA DI Wafer Cleaner is an excellent photoresist unit that is designed to quickly and reliably remove layers of deposited materials, residues and contaminants from substrates such as semiconductor wafers, circuit boards and other thin-film carriers. Its advanced cleaning machine and automated pre-programmed settings make it ideal for users who require high-quality results in a short period of time.

There are no reviews yet