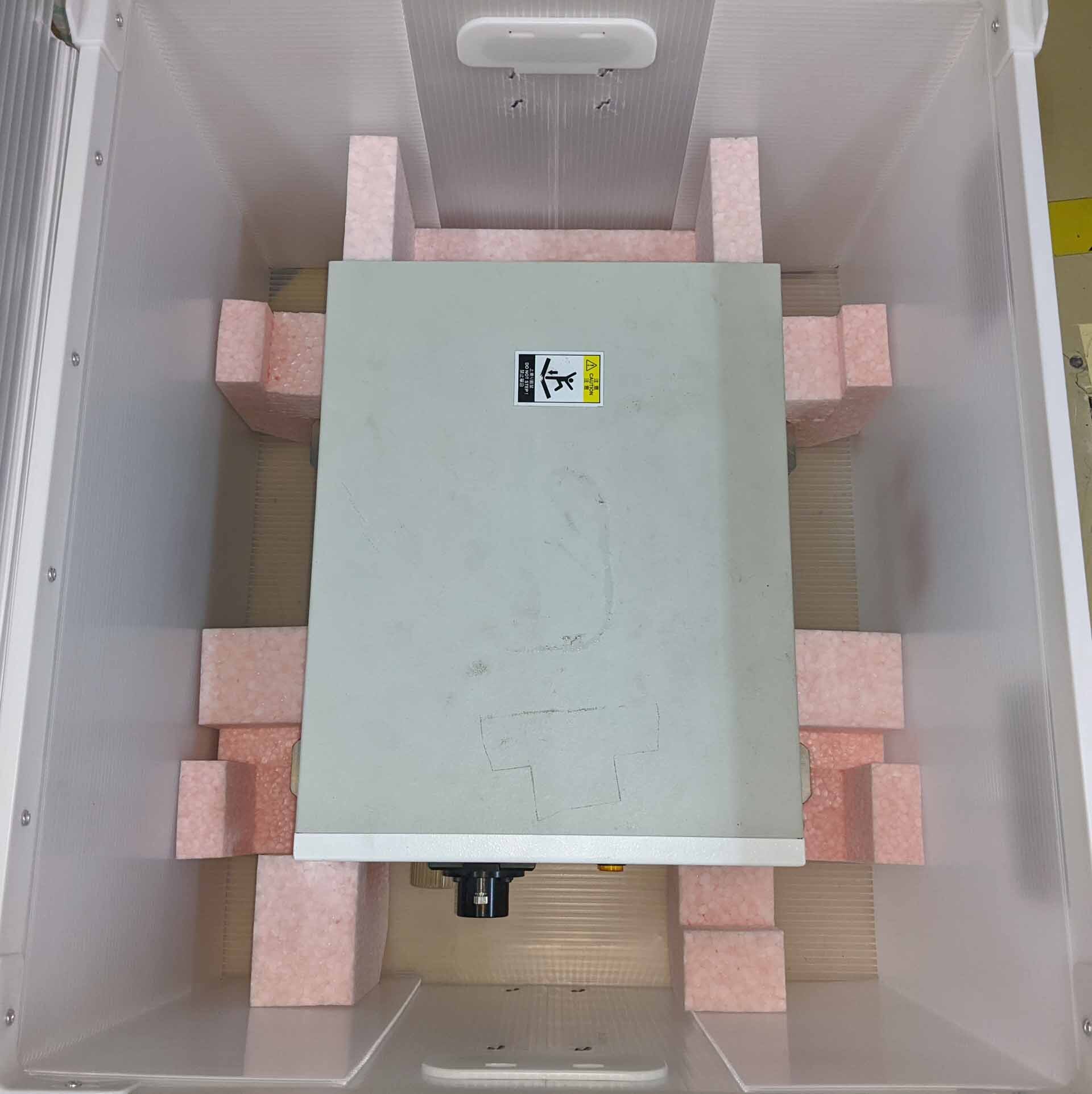

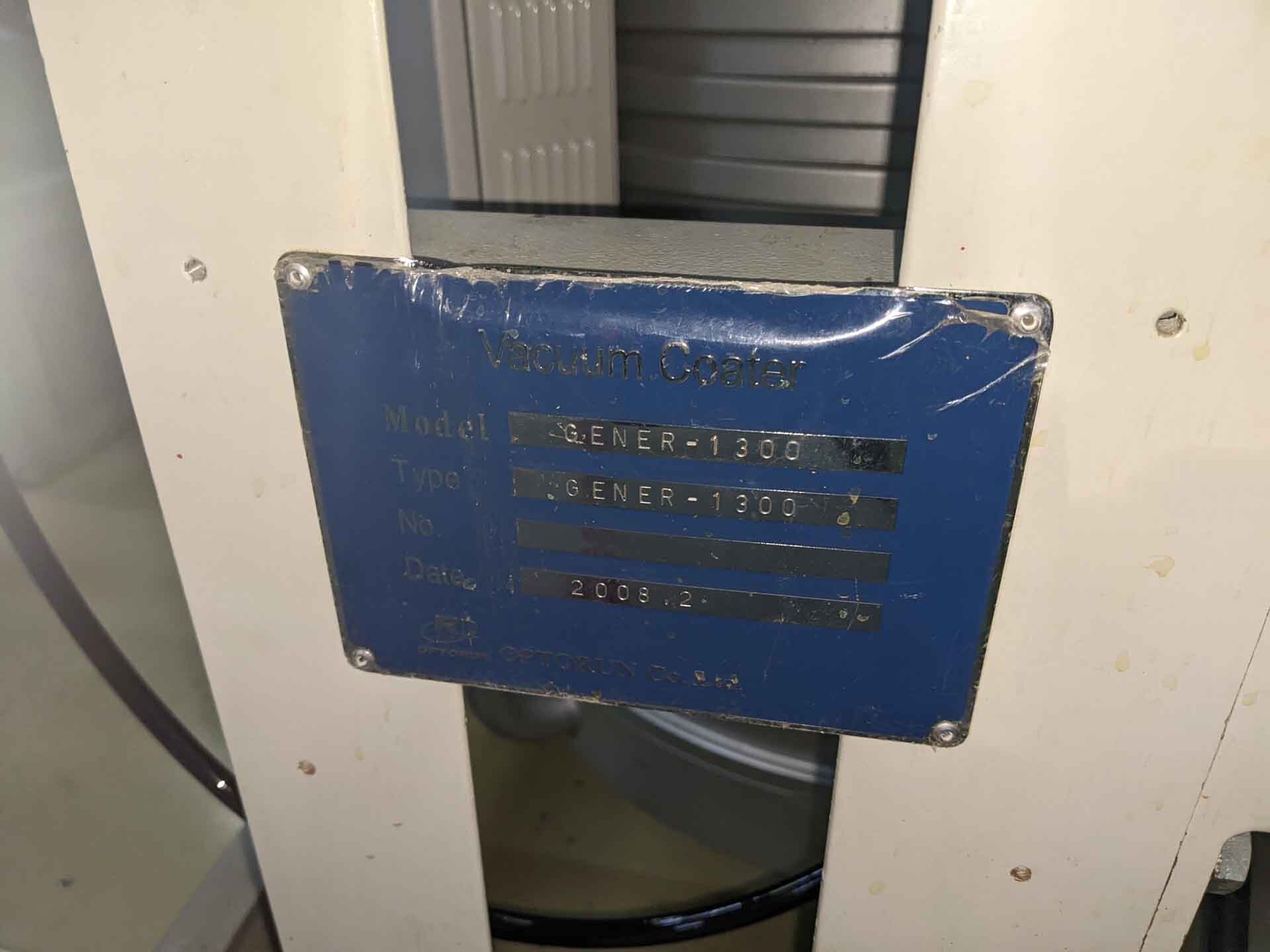

Used OPTORUN GENER-1300 #293615983 for sale

URL successfully copied!

Tap to zoom

ID: 293615983

Vintage: 2008

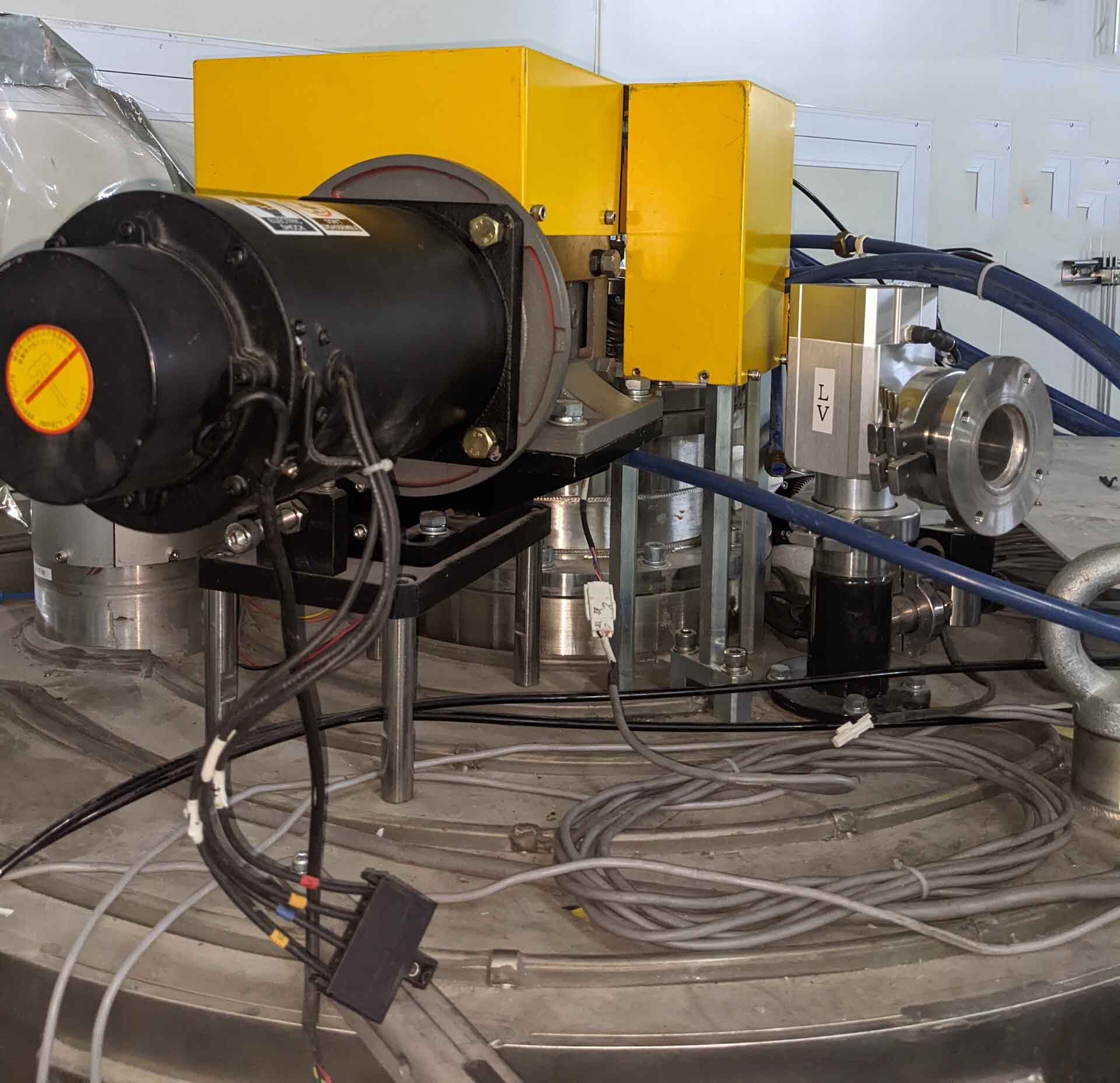

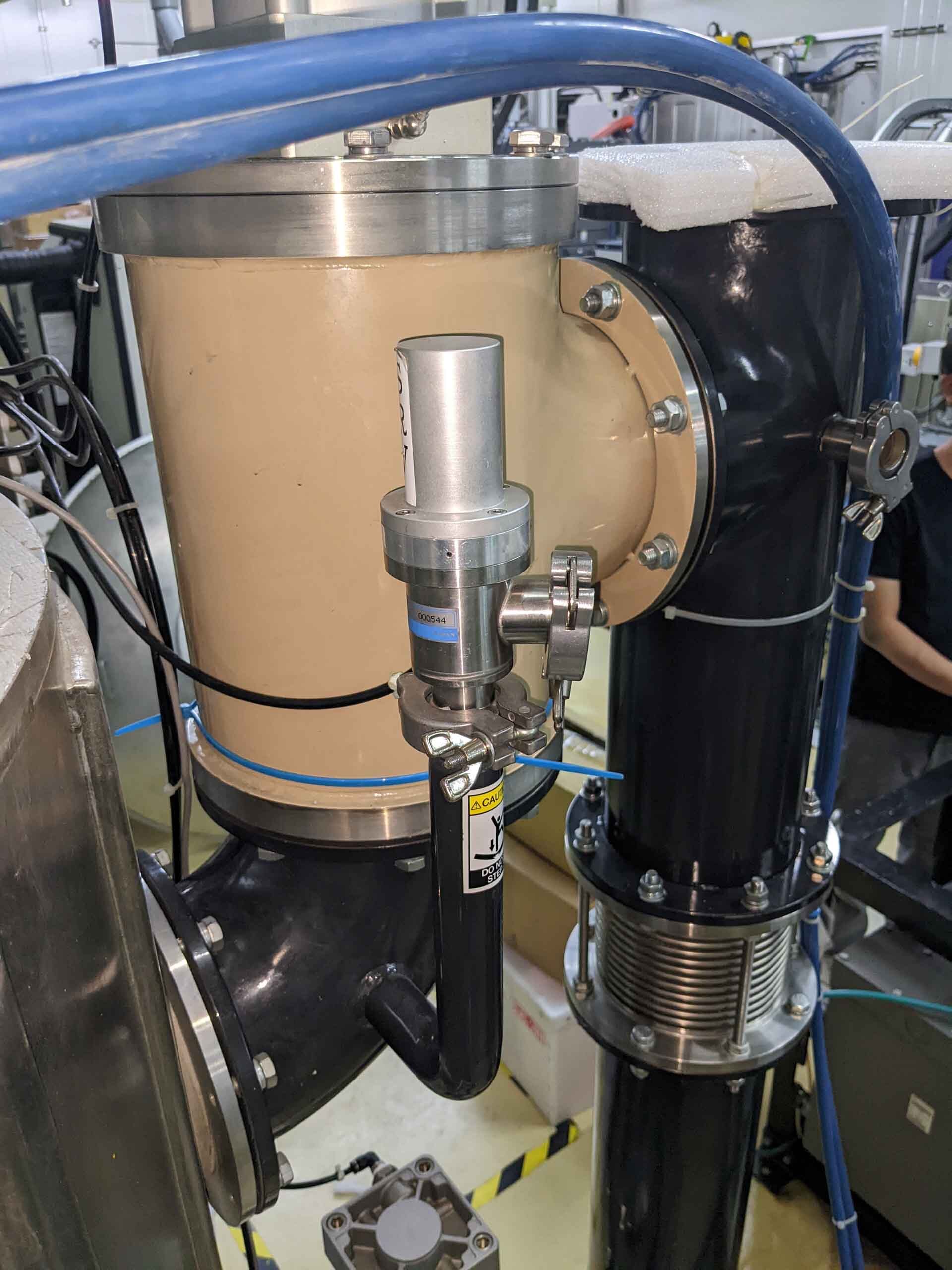

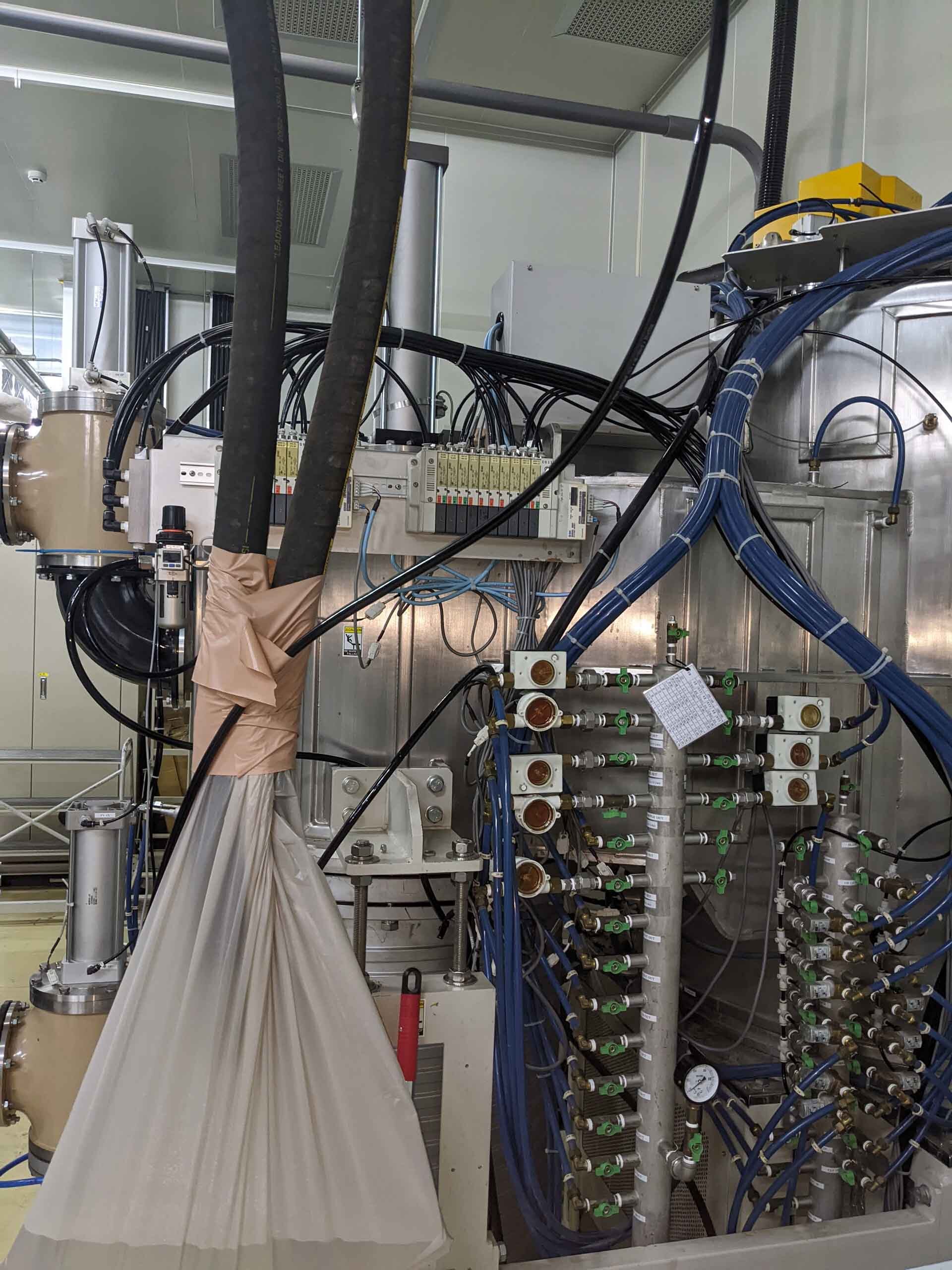

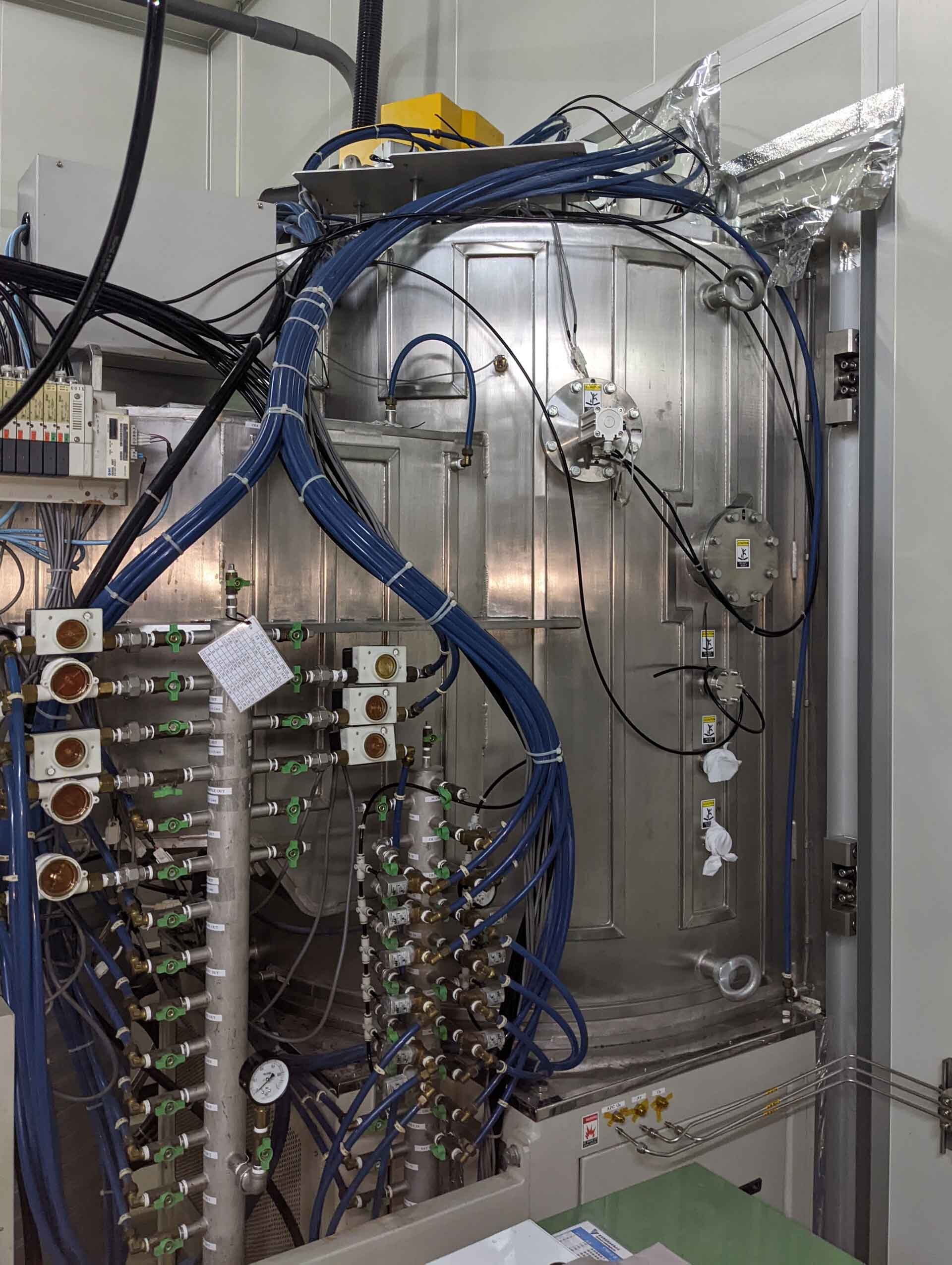

Vacuum coater

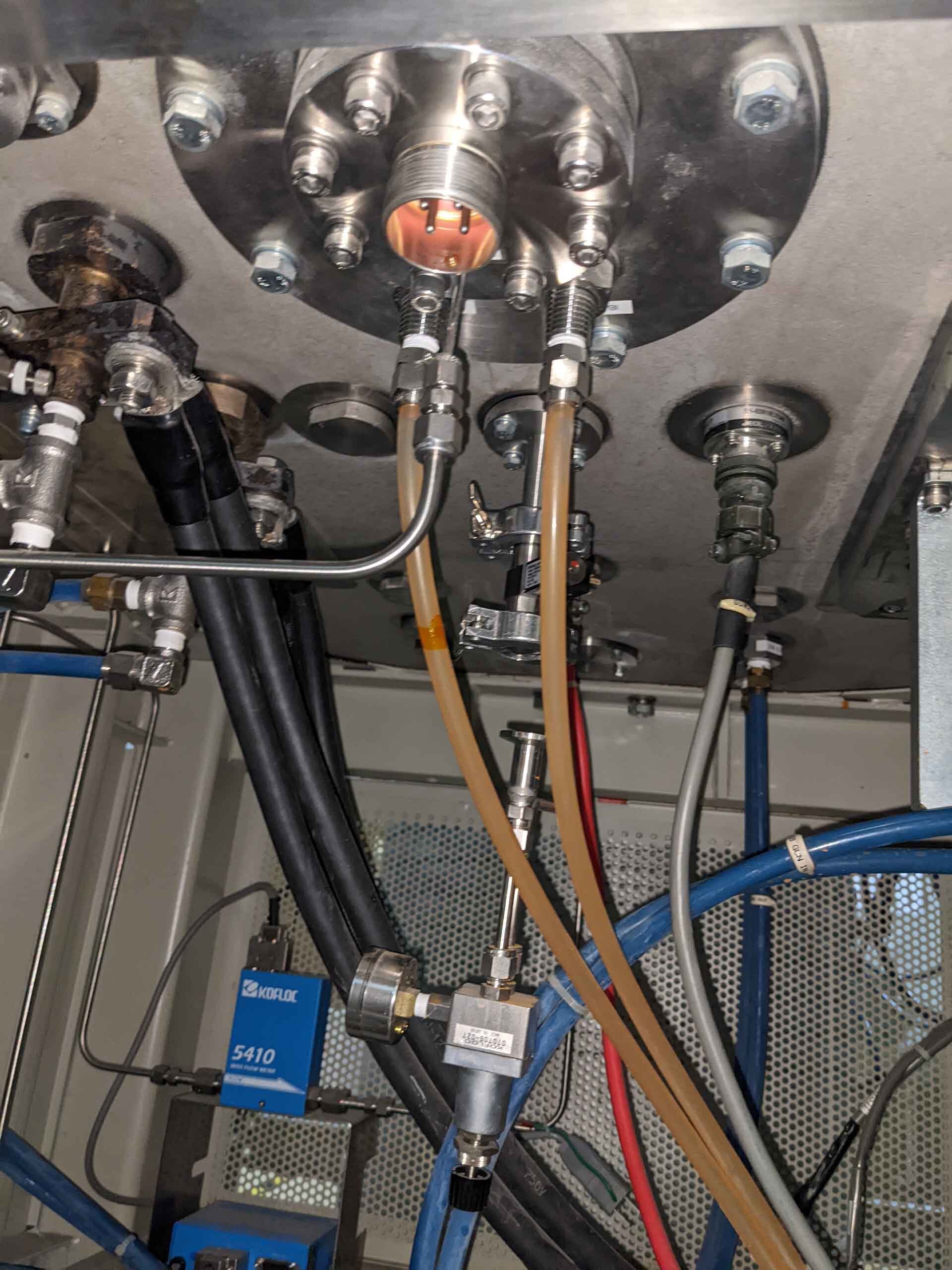

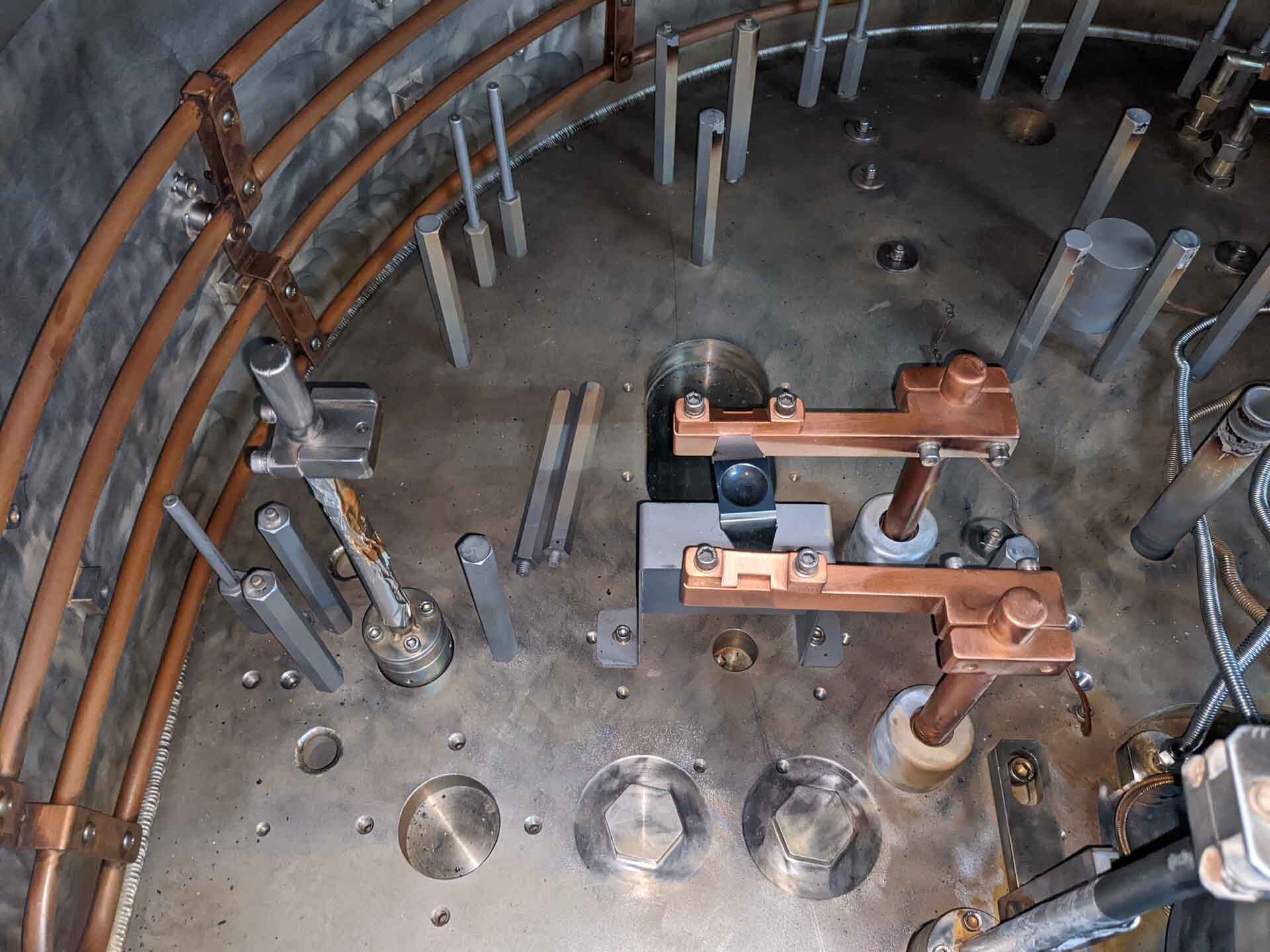

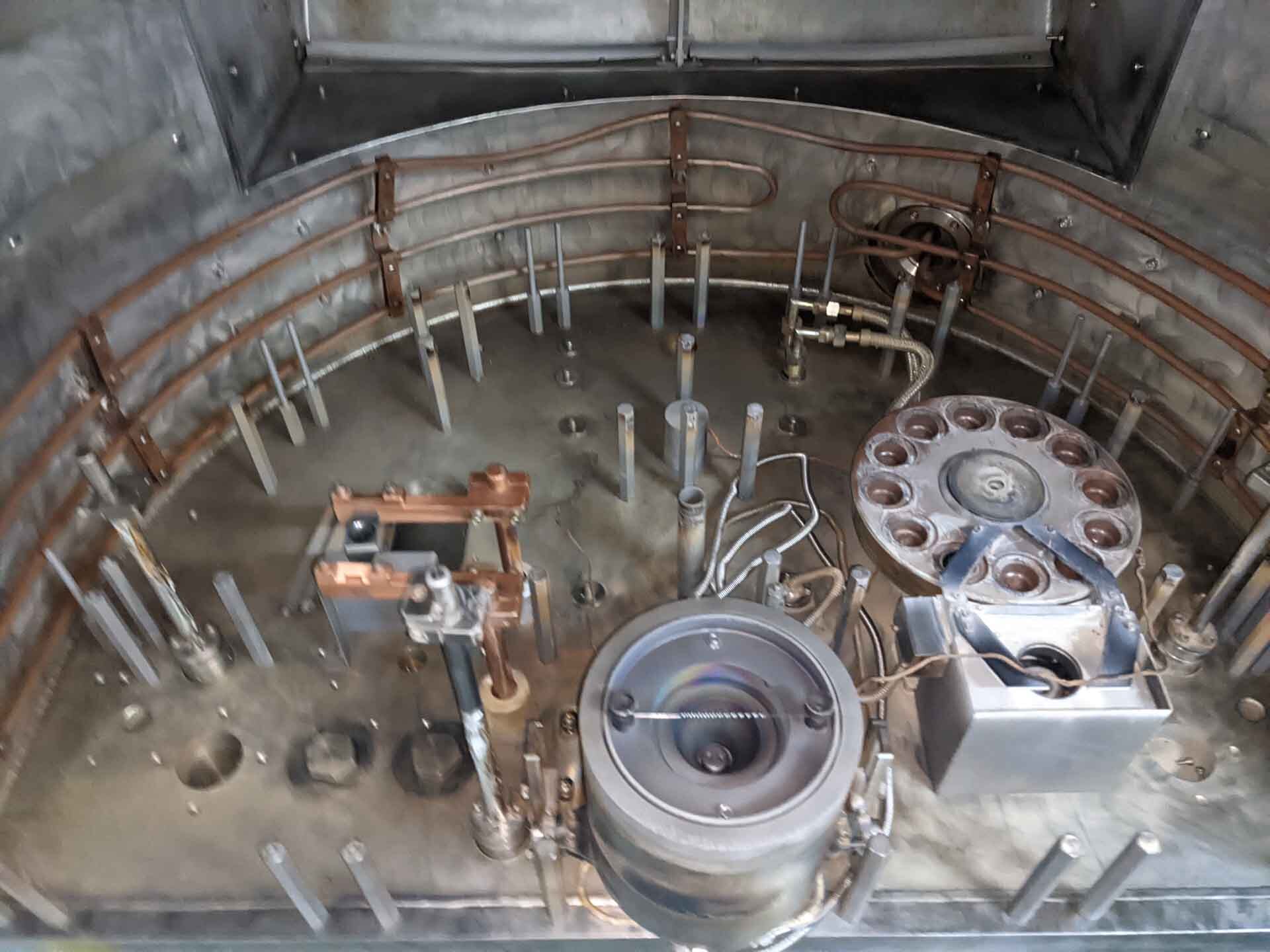

Chamber: φ1300 mm x 1500 mm

Dome: φ1200 mm (Spherical)

Low energy DC ion source (For plastic lenses)

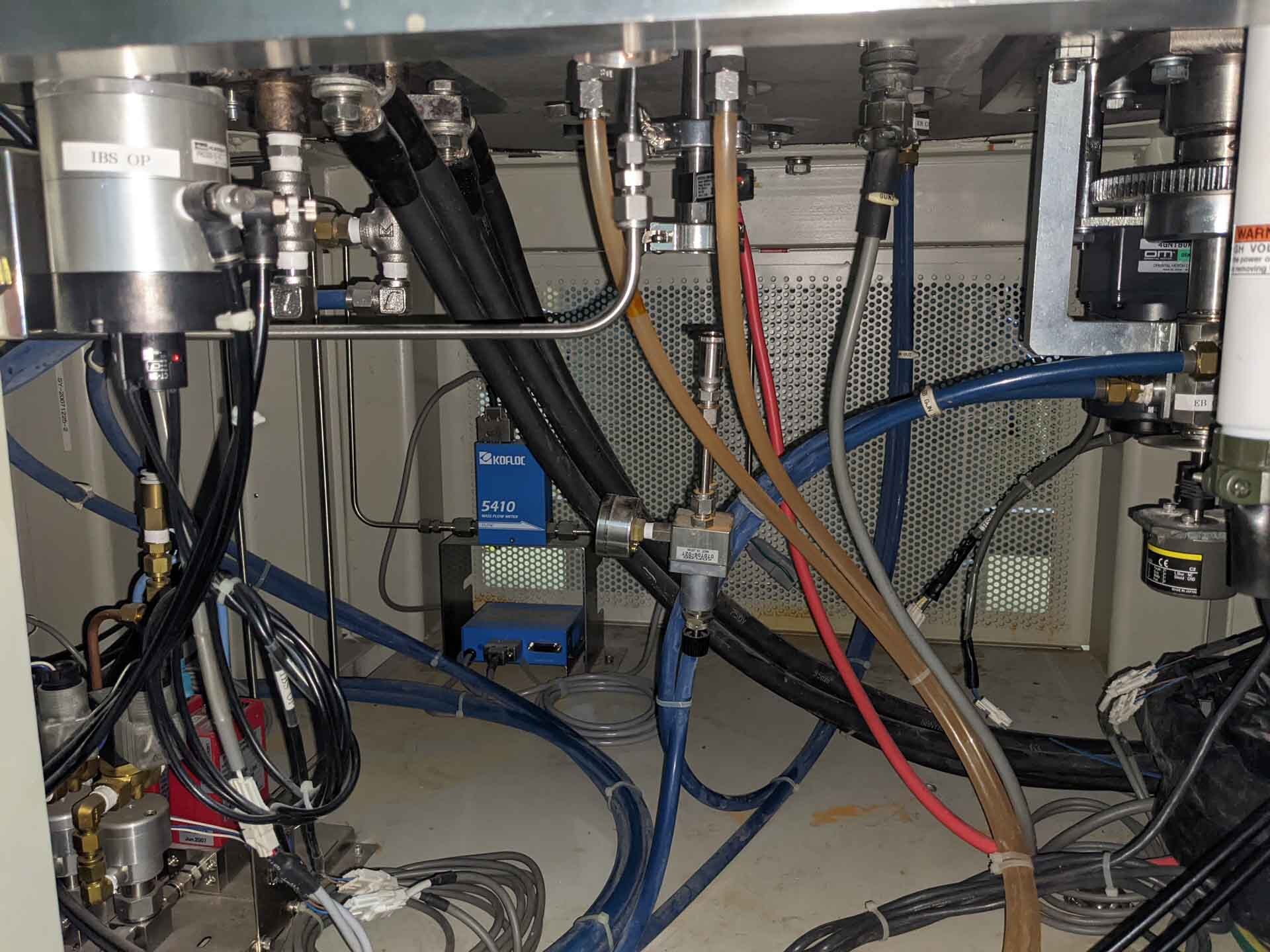

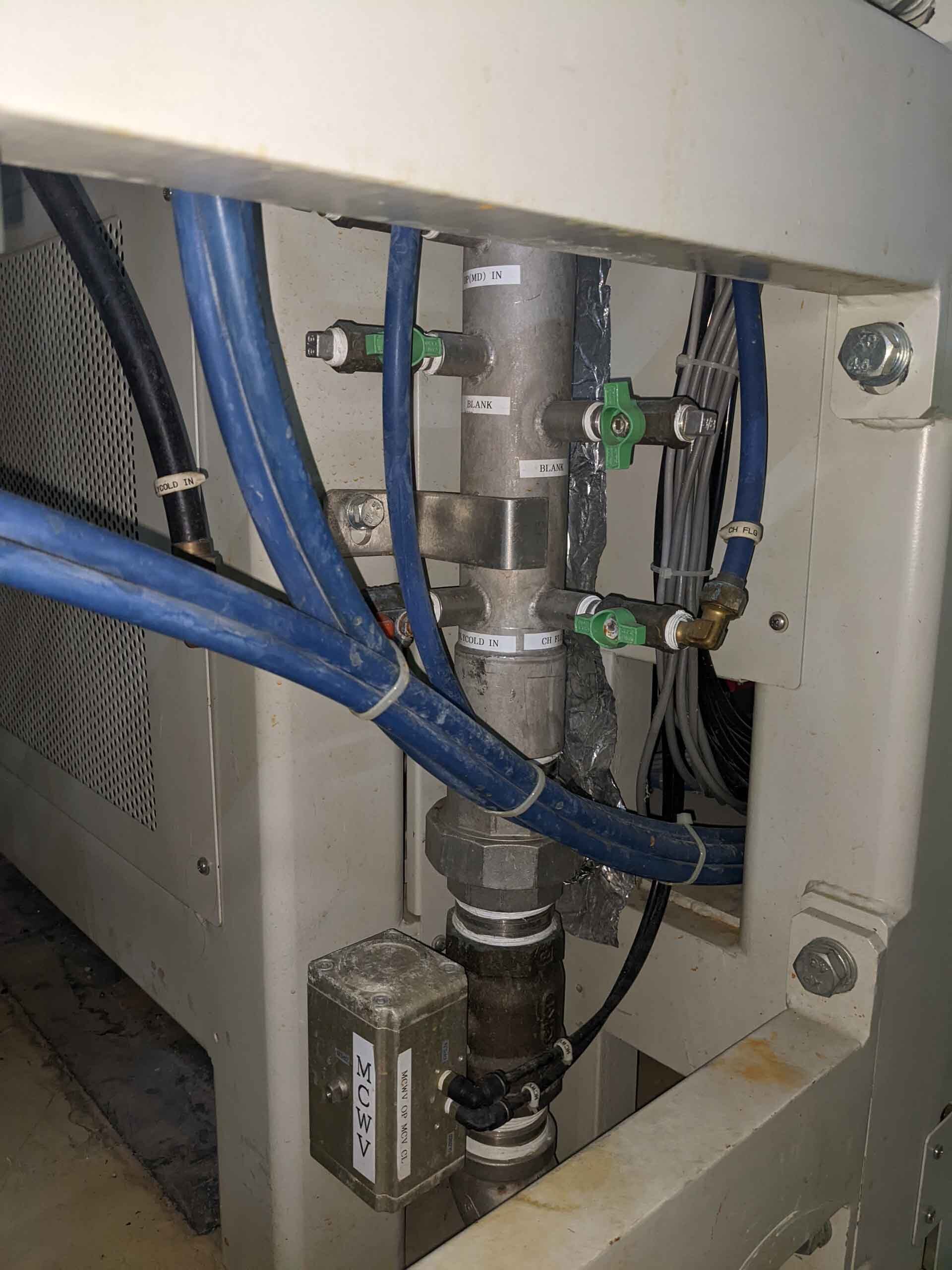

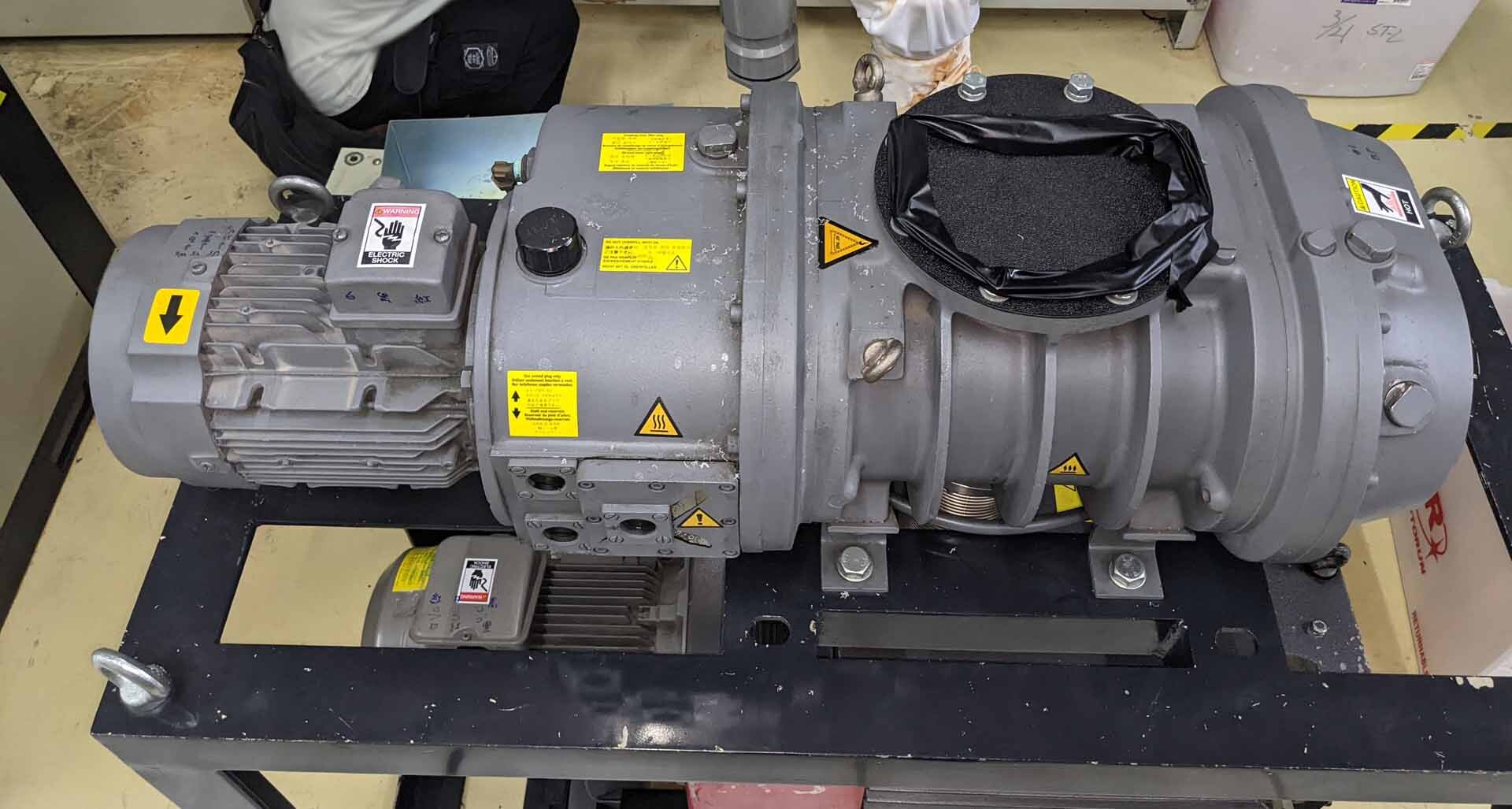

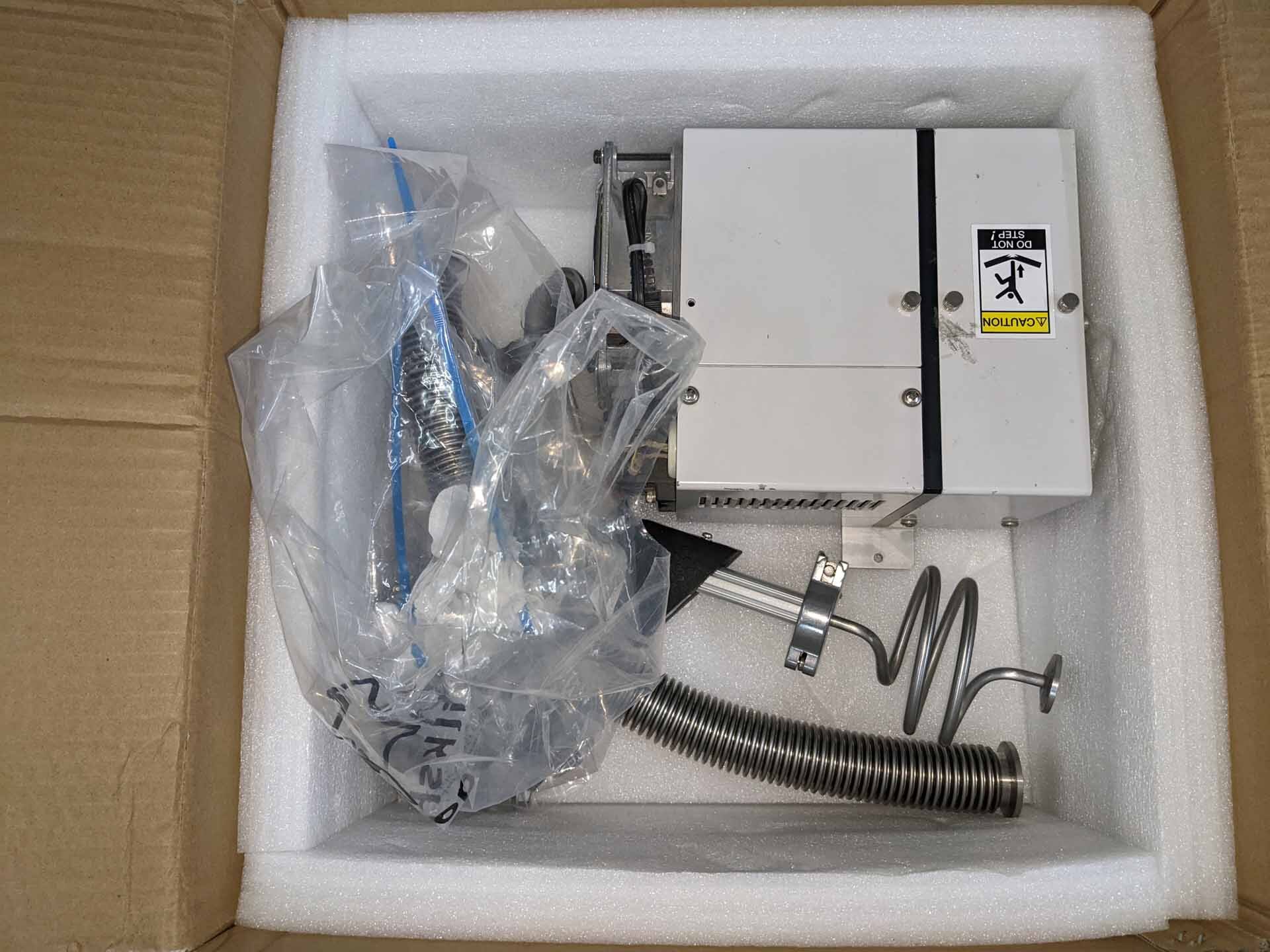

EDWARDS E2M285 Pump, 2010 vintage

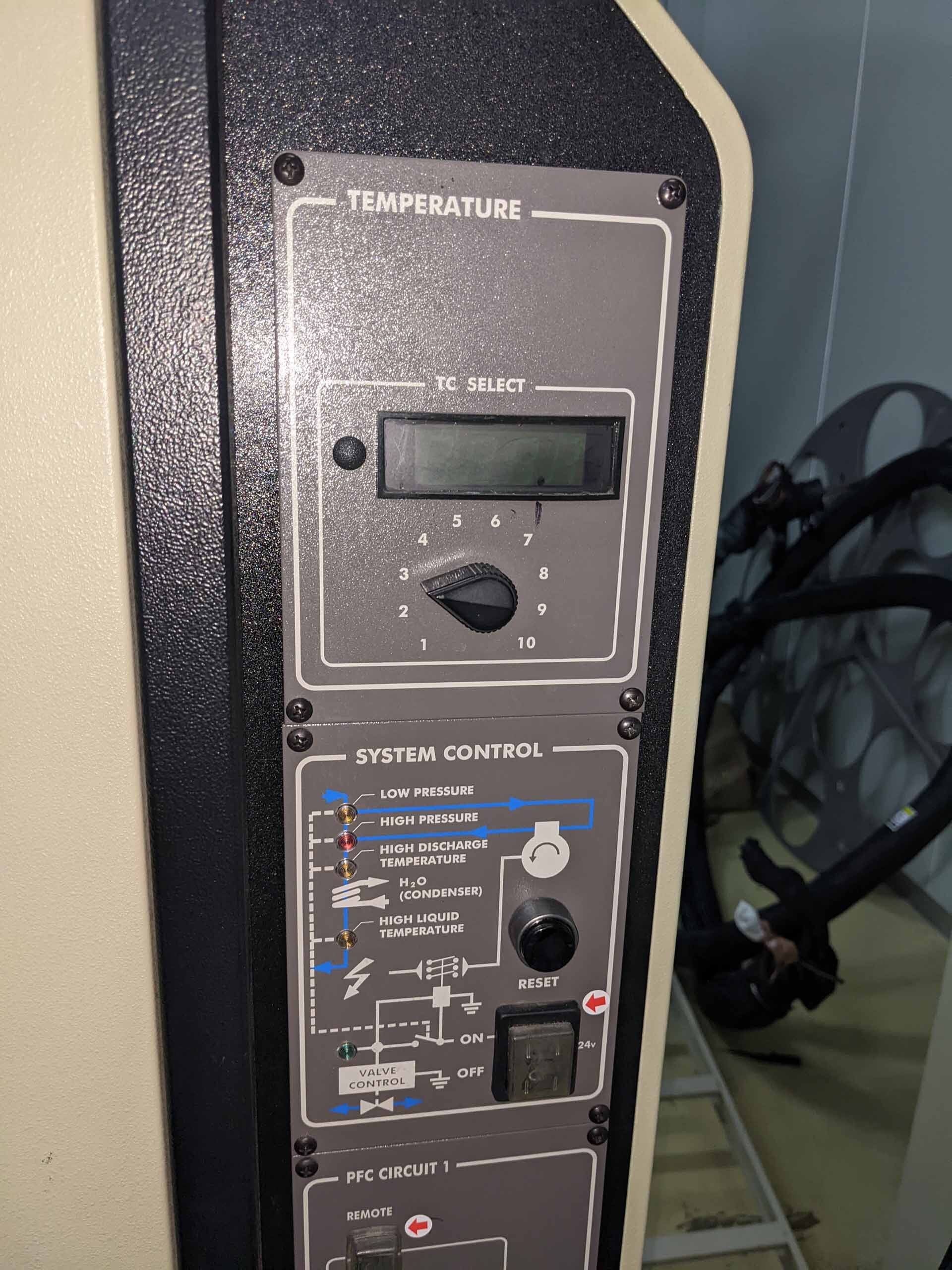

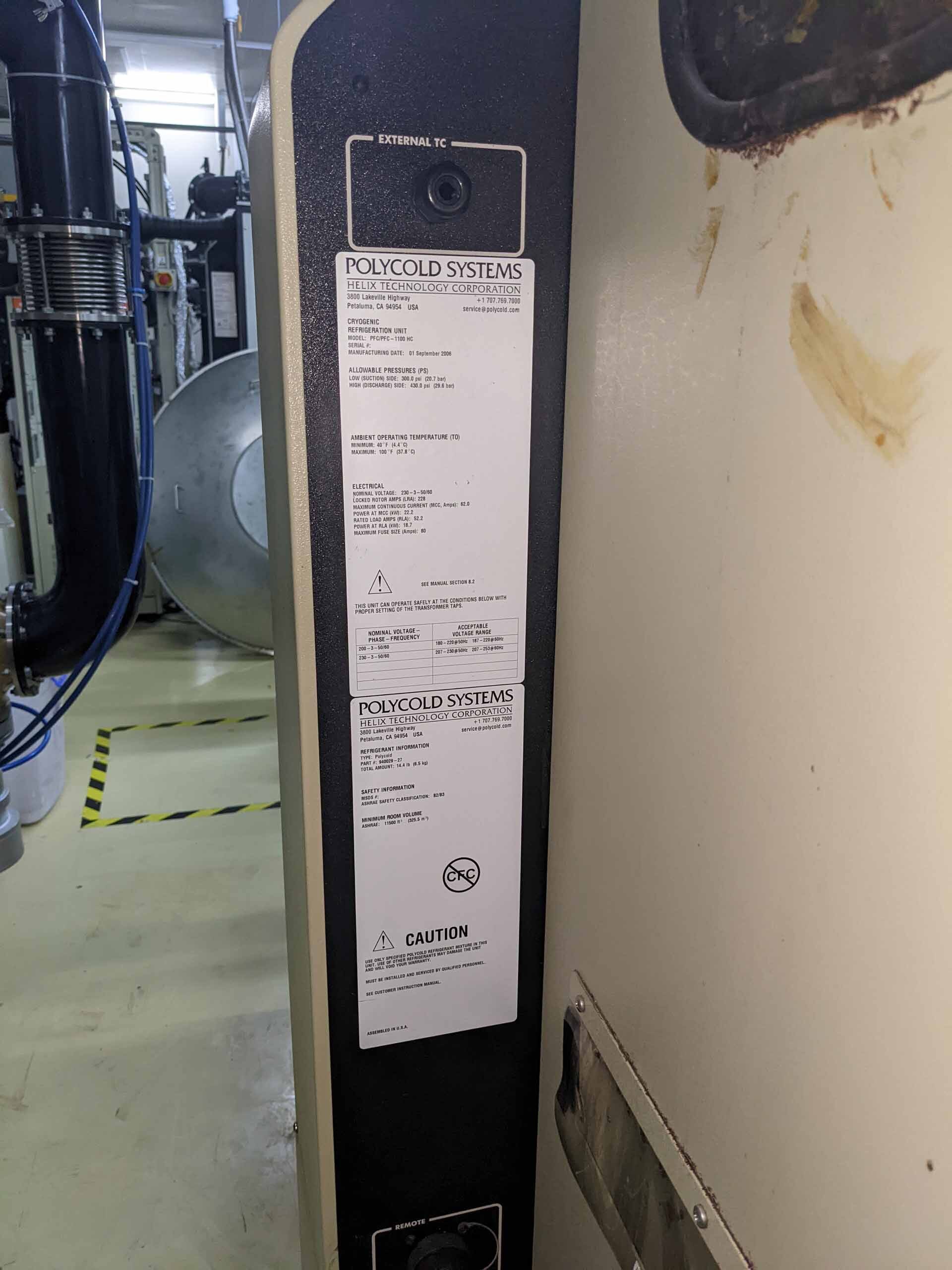

HELIX / POLYCOLD PFC-1000HC Chiller

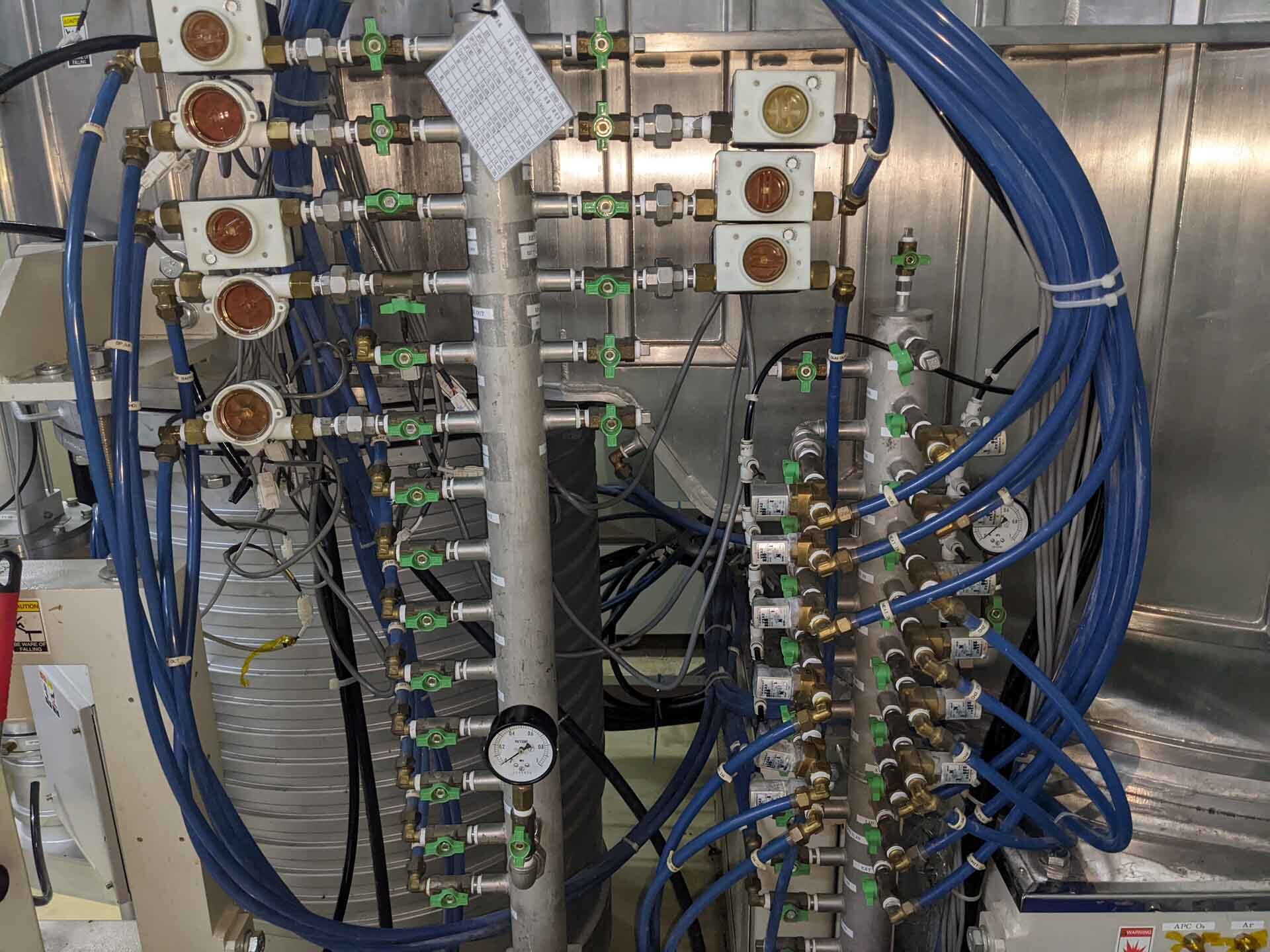

Exhaust system:

E2M275 + EH1200 Lu Type, 2010 vintage

DP + POLYCOLD, 28"

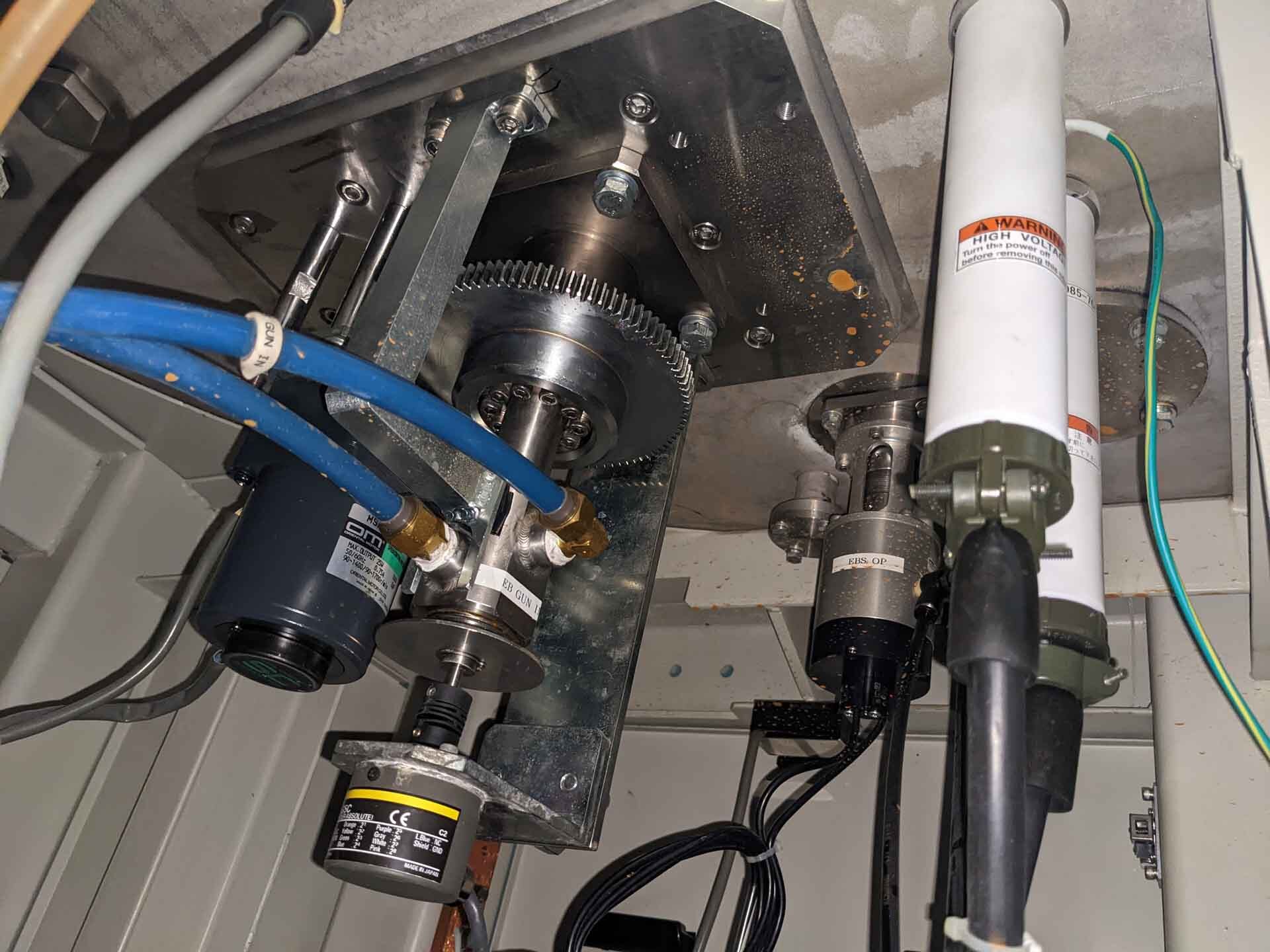

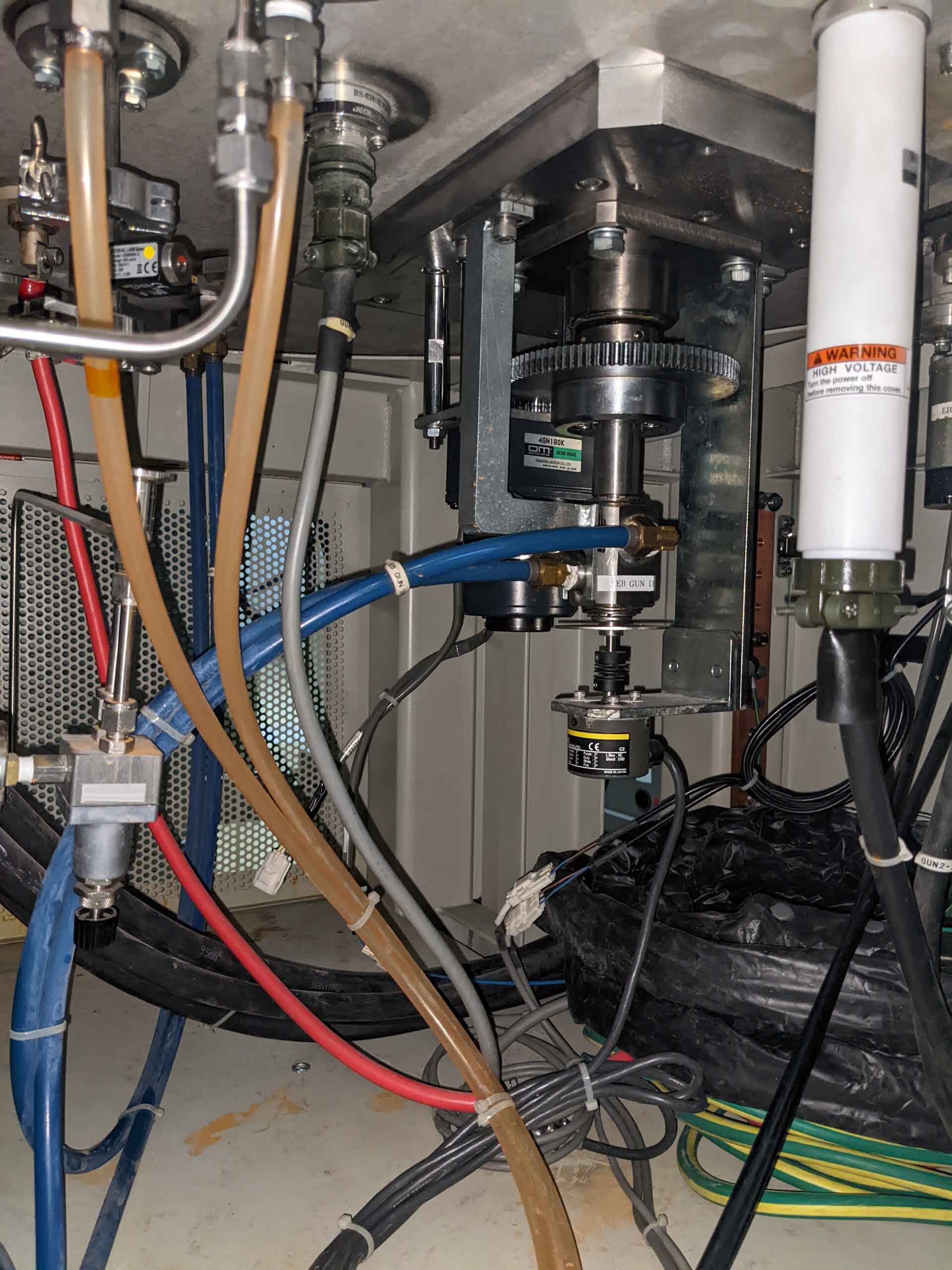

Evaporator:

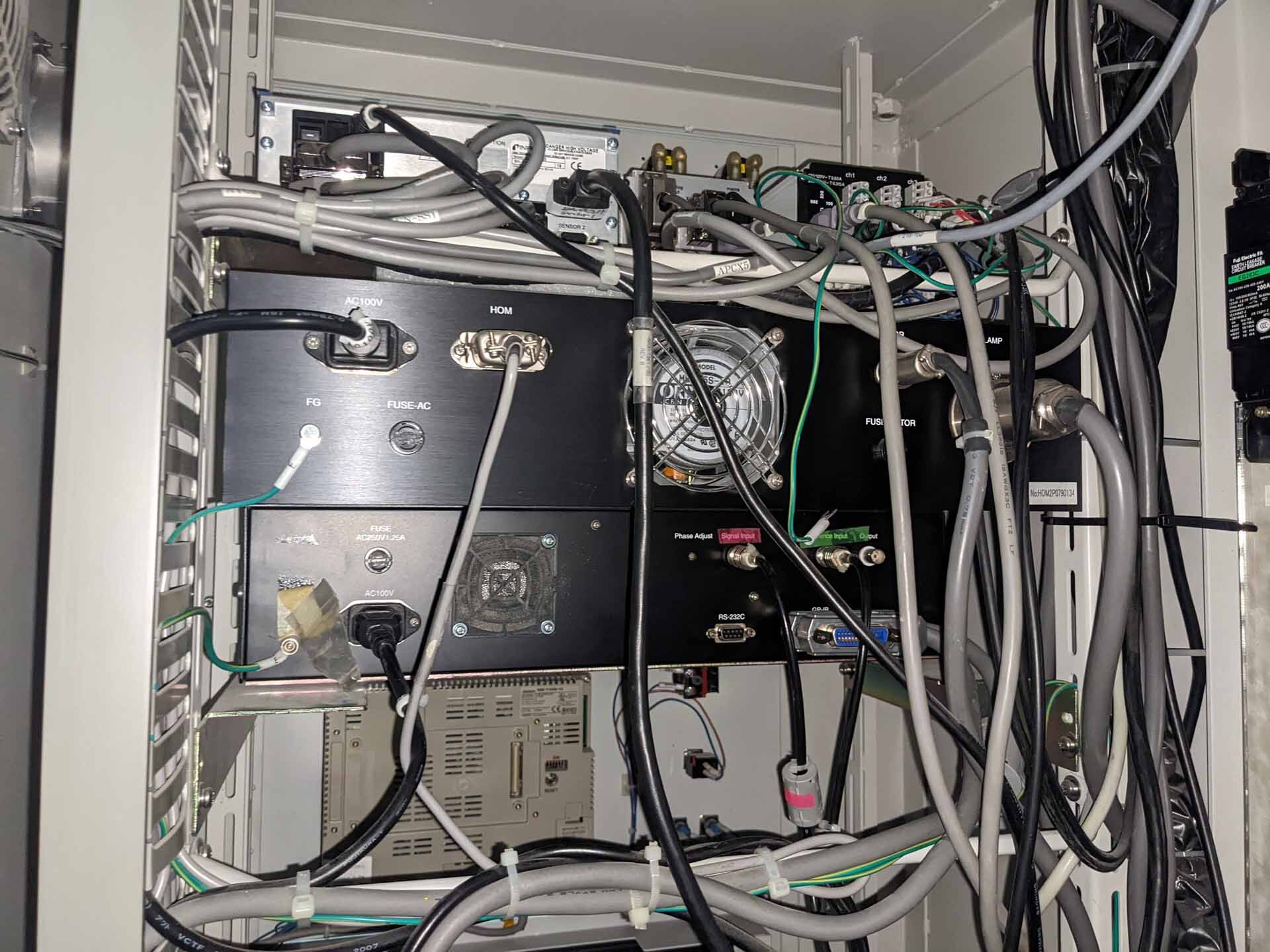

JEOL JST-10F E-beam power supply, 10kW

(2) Thermal resistance boats

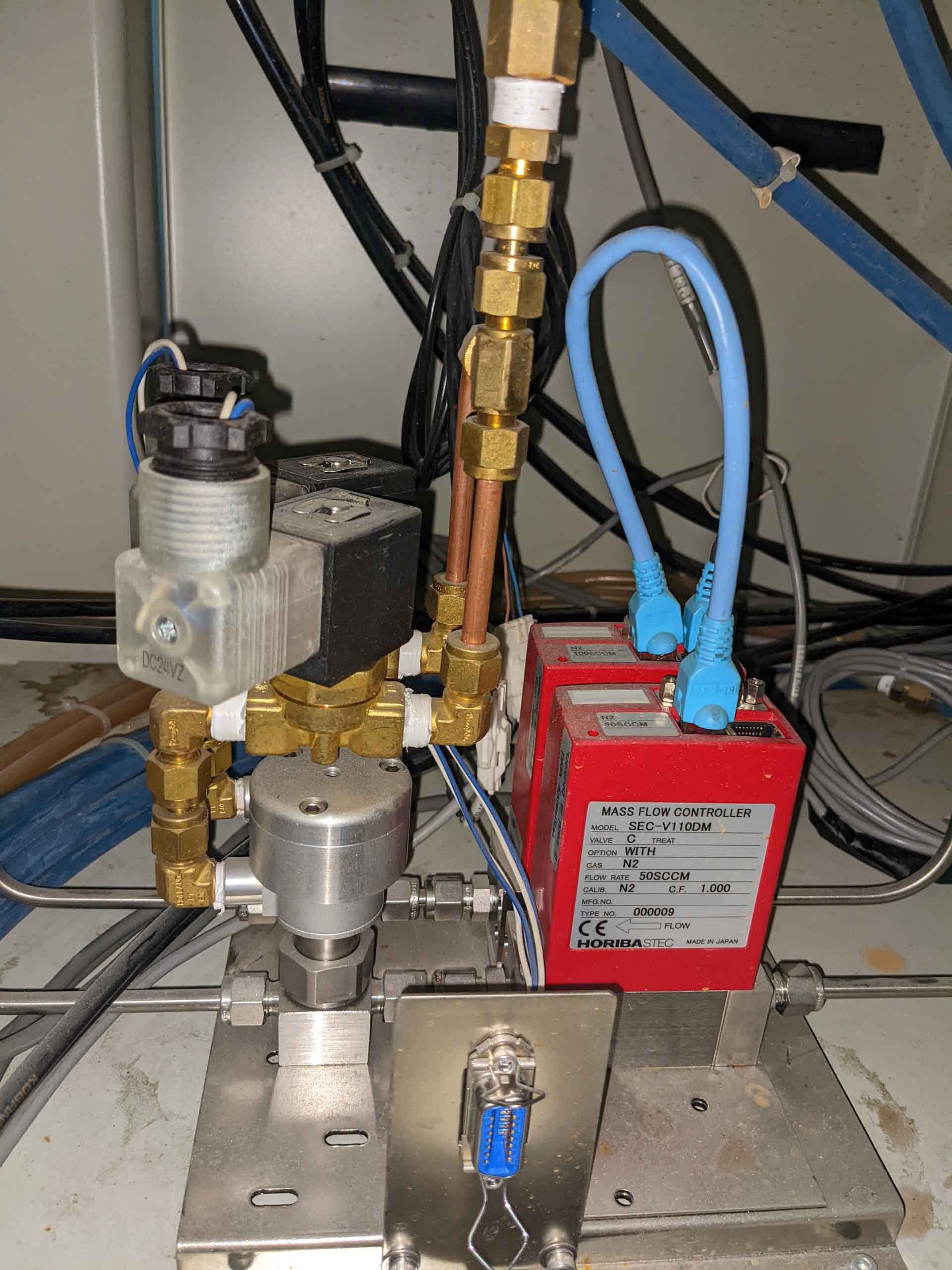

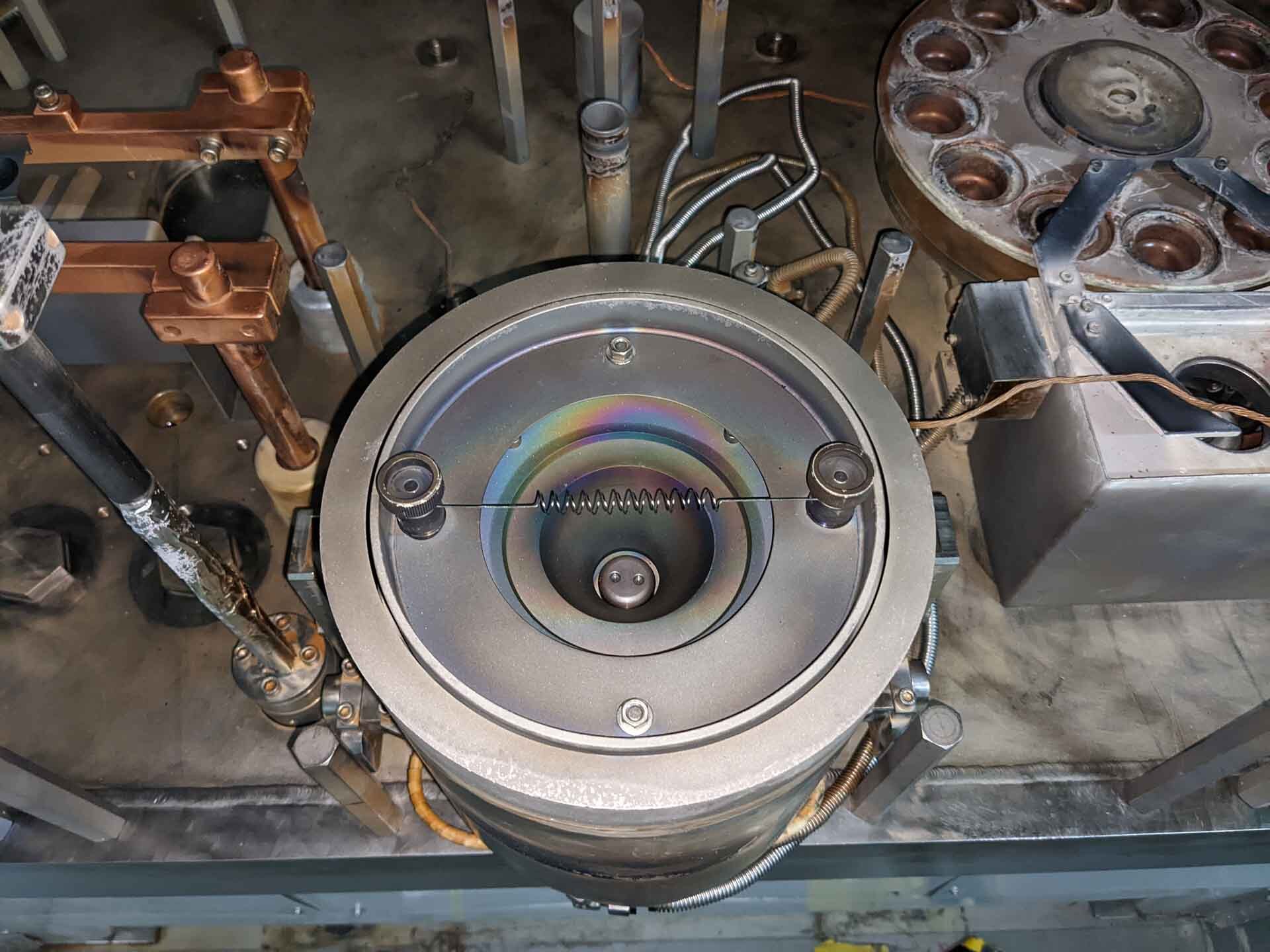

Film thickness control:

Optical monitoring

6-Points quartz monitoring

2008 vintage.

OPTORUN GENER-1300 is a photoresist equipment used to fabricate microcircuits, semi-conductors, MEMS devices, and other components used in the electronics and semiconductor industries. It utilizes advanced UV light, including UV lasers, to expose the photosensitive resist layer on a substrate. This resist is then used to define the circuit patterns and layouts on the surface of the substrate. OPTORUN GENER 1300 photoresist system can expose resists to light with a wavelength of 190-365 nm. The intensity and duration of the light exposure is controlled with a high-precision timing mechanism. The unit is broken down into four major components, each performing a specific task in the process. The first component is the lithography machine, which is responsible for exposing the resist surface to UV light. An optical head contains a laser that is focused and directed onto the surface of the substrate. This laser is moved along the surface of the substrate in a pre-programmed path and can be adjusted to expose different areas with different intensities and locations. The second component is the alignment stage, which assists in bringing the substrate into the proper position for the lithography machine and for aligning the surface for proper exposure. The alignment stage can be adjusted in three axes and can be programmed to perform various operations. The third component is the chemistry management machine. This component is responsible for controlling the pre-baked process, development process and post-treatment of the substrates. The pre-bake stages include soft-bake, resist coating, hard-bake, pre-etch, and post-etch. The development process involves post-treatment of the resist, including emphasizing solvent and developer selection, temperature, time and concentration. The fourth component is the track tool, which is responsible for loading and unloading the substrates into and out of the machine, as well as recording information about the exposed and developed substrates. In addition to the four major components, GENER-1300 photoresist asset is equipped with several safety features, including an optical safety shield. This safety shield protects the operator from any UV radiation emitted by the model and provides protection from potential eye injury. The equipment is also equipped with a temperature control system to ensure that the temperature in the machine remains within a given range during the entire operation process. Overall, GENER 1300 photoresist unit is an advanced machine designed to fabricate electronic components with accuracy and precision. The highly controlled environment and programmable functions allow for quick and efficient fabrication of circuit patterns and layouts. The safety features ensure that the tool is operated safely and responsibly.

There are no reviews yet