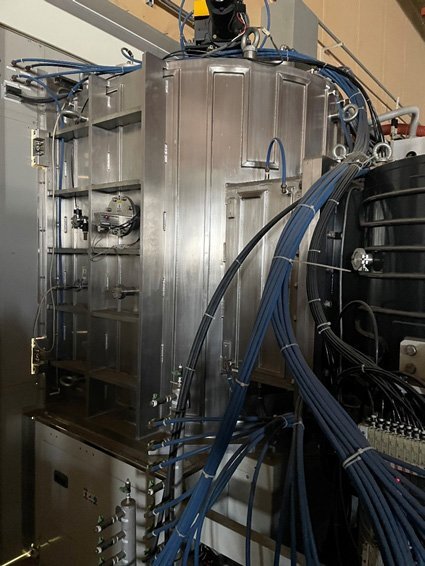

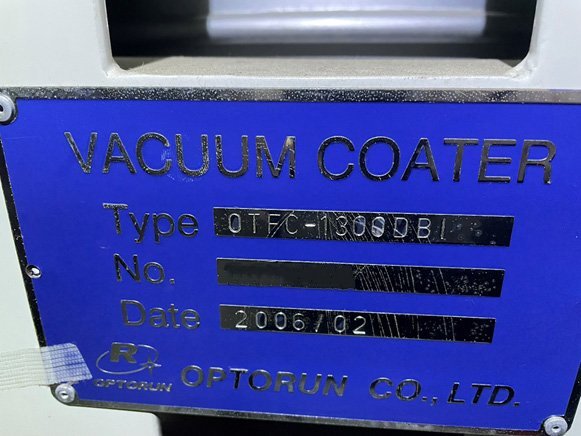

Used OPTORUN OTFC-1300DBI #293603058 for sale

URL successfully copied!

Tap to zoom

OPTORUN OTFC-1300DBI is a precision automated photoresist equipment that is used in a variety of commercial, research, and industrial applications. Photoresist is a type of light-sensitive polymer material that can be applied to a substrate surface and exposed to light to create permanent patterns or features. OTFC-1300DBI is a precision automated system that is designed to accurately fabricate intricate and fine patterns onto any type of substrate. OPTORUN OTFC-1300DBI enables users to perform high-volume photoresist jobs by providing reliable and repeatable results. The unit is designed to maintain consistent accuracy from job to job and can employ multiple process tracks for automated operations. When a substrate is loaded into OTFC-1300DBI, a low-radiation laser beam is used to scan the substrate surface and locate the exact width, depth, and position of the substrate pattern. The laser beam then moves in X, Y and Z axes to application stage where the photoresist is applied to the substrate. The photoresist is then exposed to ultraviolet light. This initiates a photocurable reaction, which hardens and sets the photoresist in exact alignment with the substrate according to the desired pattern. This process is rapid, reliable and repeatable is capable of creating intricate patterns and fine details. Additionally, the machine is equipped with an adjustable beam divergence, which ensures an even and consistent spread of the photoresist material across the substrate. Upon completion of the photoresist patterning process, the substrate can then move to the metering station where devices measure the finished features to ensure accuracy and compatibility with the project specifications. The finished photoresist can now be inspected according to customer requirements. Furthermore, OPTORUN OTFC-1300DBI is designed for flexibility and can handle different types of substrates and photoresists, allowing for increased process variable management. OTFC-1300DBI tool provides a reliable, repeatable and cost-effective solution for any substrate patterning application. This automated process can provide a number of advantages over traditional manual assembly, including improved accuracy, faster throughput, and reduced scrap. The asset is designed for ease of use and can be quickly set up and operated, facilitating on-demand manufacturing with minimal training.

There are no reviews yet