Used STEAG / MATTSON / AST Marangoni #9162787 for sale

URL successfully copied!

Tap to zoom

ID: 9162787

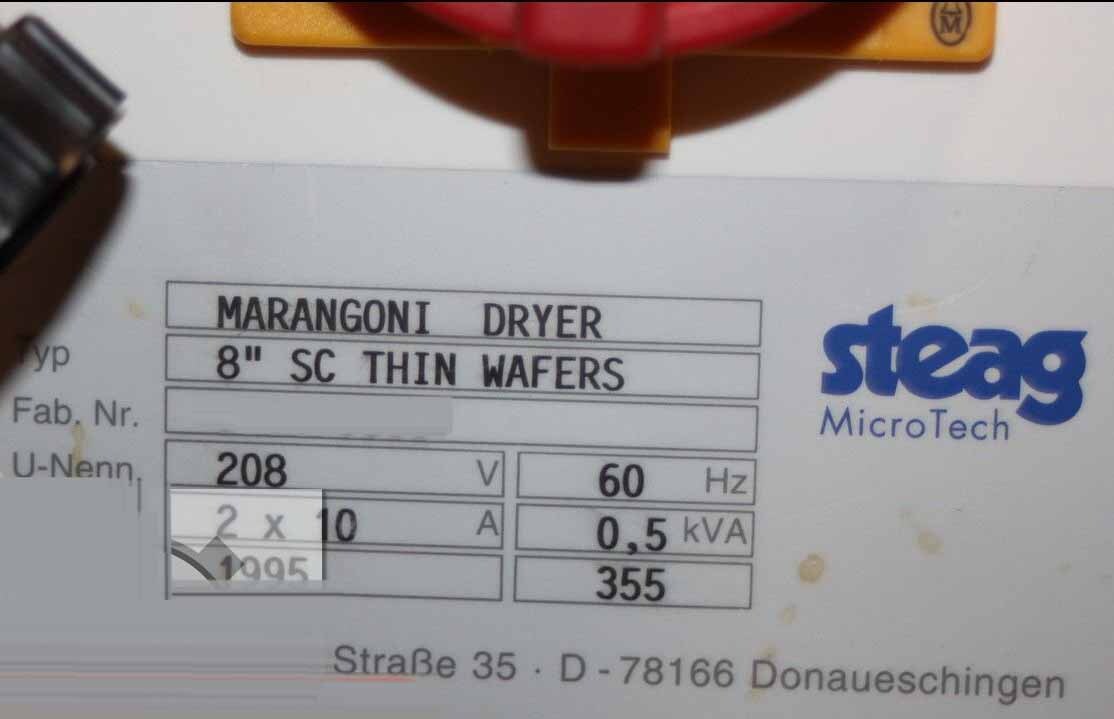

Wafer Size: 8"

Vintage: 1995

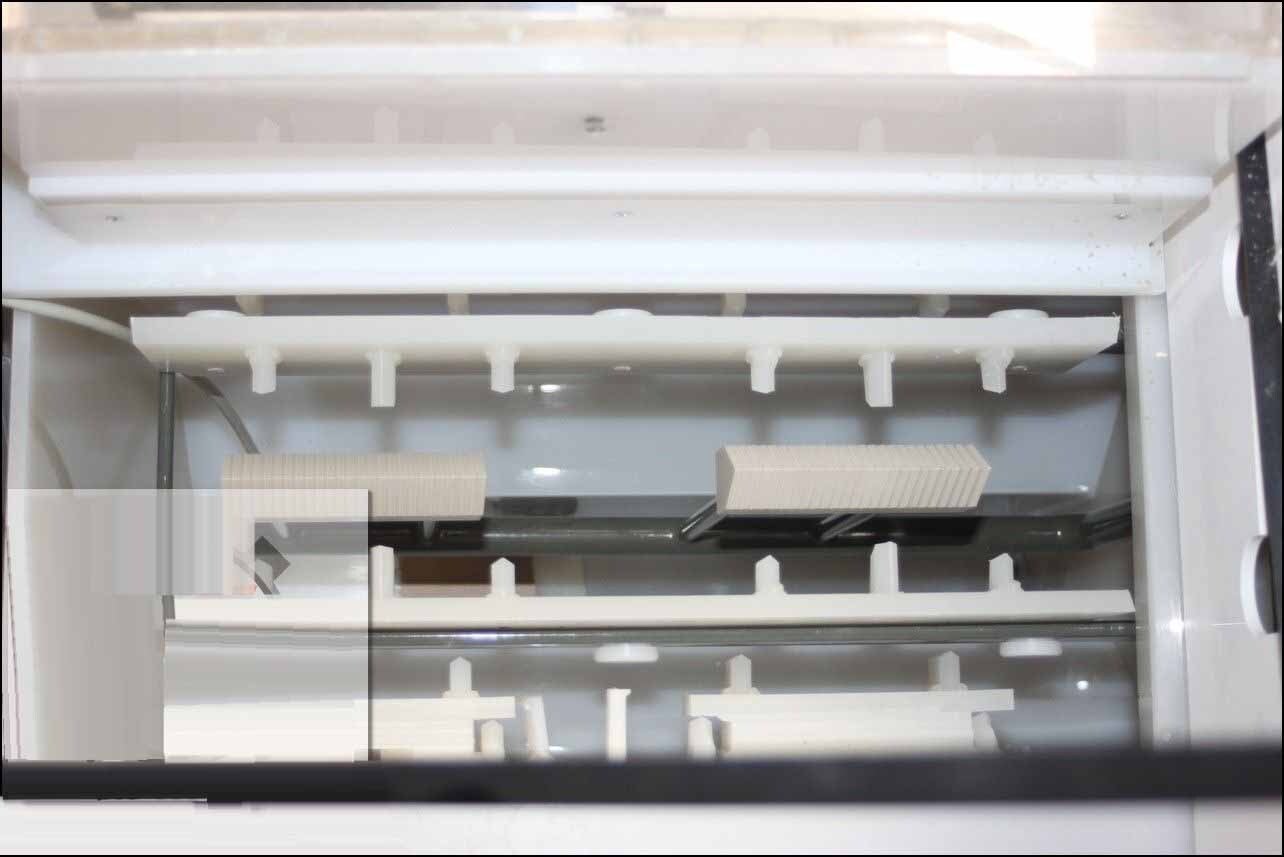

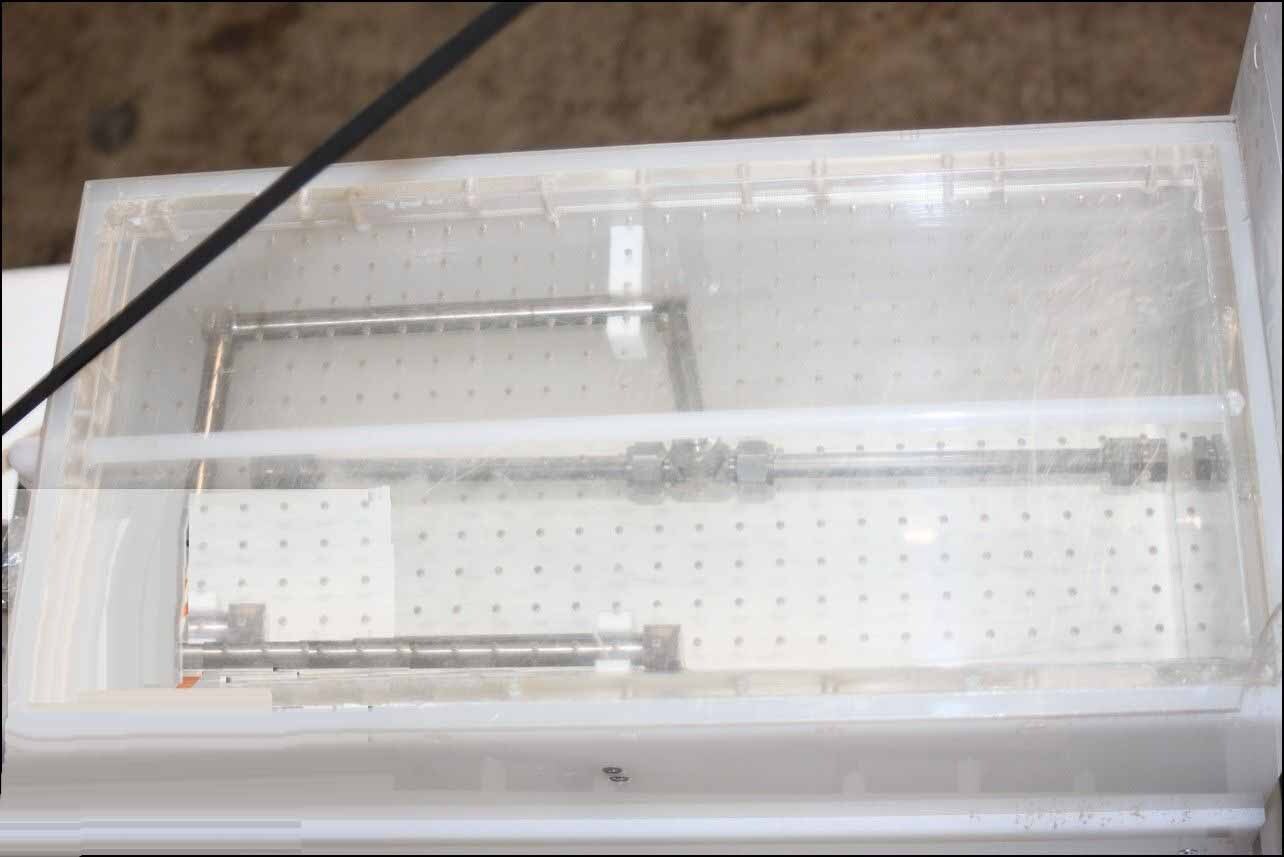

Dryer, 8"

SC Thin wafers: 2X10

1995 vintage.

STEAG / MATTSON / AST Marangoni equipment is a photoresist system which utilises AST Marangoni effect to transfer liquid-based chemical materials to a surface. This photoresist unit is suitable for a wide range of industrial processes, including cured-in-place-pipe (CIPP) relining, customised gasket sealing, tank lining, roof repair, and composite tankless bonding. The machine works by applying a layer of photoresist to the surface of a material which is then exposed to an ultraviolet (UV) light source. This causes a reaction effect, known as STEAG Marangoni effect, which pulls liquid materials onto the surface of the photoresist-coated material, allowing them to bond securely. The end result is strong and durable bonding or sealing around the edges of the material, providing a water, oil, and gas tight seal. Marangoni effect is dependant on a combination of surface tension and temperature differentials at the photoresist-coated surface. The surface tension forces the liquid material onto the surface, while the greater the temperature differential, the more aggressive the attraction of the liquid material is to the surface. As the photoresist tool is heated up and the temperature differential increases, the liquid materials are pulled towards the surface more aggressively. This makes it an ideal asset for high-volume industrial processes that require consistently strong and durable bonds and seals. MATTSON Marangoni model is also highly efficient as the amount of heat applied to the photoresist-coated surface is significantly lower than other systems, allowing for quick setup and application times. Additionally, the equipment is compatible with a wide range of materials, ranging from silica, natural rubber, epoxy, vinyl, polyesters and many more. STEAG / MATTSON / AST Marangoni system is an efficient, cost-effective photoresist unit which is suitable for a wide range of industrial processes requiring strong and durable bonds and seals. With its low setup and application times, it is one of the most popular systems in the market today.

There are no reviews yet