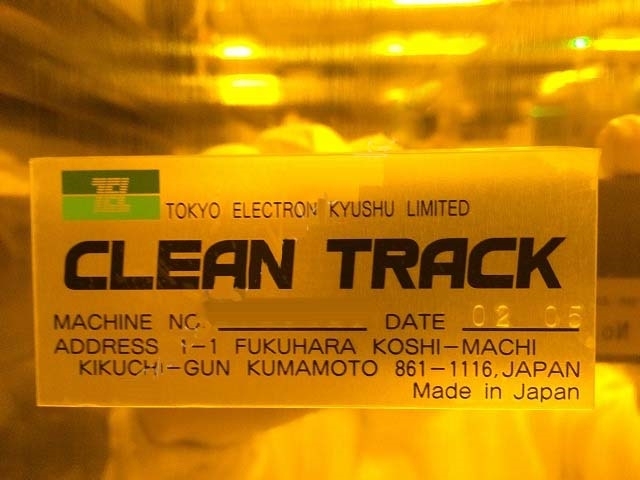

Used TEL / TOKYO ELECTRON ACT 12 #9290661 for sale

URL successfully copied!

Tap to zoom

ID: 9290661

Wafer Size: 12"

Vintage: 2002

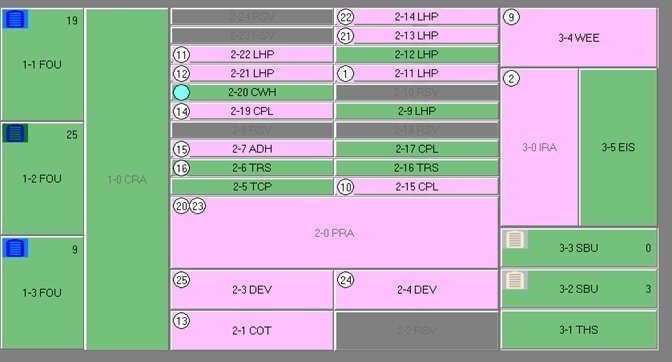

Coater / (2) Developer system, 12"

Track 1:

Single block

ADH

Track 2:

Resist reduction: RRC

Developer nozzle: H Nozzle

RDS Resist pump: 10 ml

Oven:

(3) CPL

(7) LHP

Does not include Hard Disk Drive (HDD)

2002 vintage.

TEL / TOKYO ELECTRON ACT 12, a photoresist equipment developed by TEL and marketed by various distributors around the world, is a cost effective yet advanced etching system designed primarily for semiconductor processing. The unit enables the accurate fabrication of complex patterns on substrates by controlling the deposition of photoresist. Photoresist is a type of light sensitive material which is applied to semiconductor components and other similar materials to structure them by etching or depositing additional layers. TEL ACT 12 machine is designed to be user-friendly, and offers broad process capabilities to accommodate a variety of processes, such as contact lithography, spin coating, mask aligning, and post-treatment steps. The tool includes several powerful hardware features to ensure accurate process control. These include a photoresist supply asset, wafer handling model, pattern generator, laser alignment, and an auto focus mechanism. The overall equipment features a large work area with high travel accuracy and high precision. The photoresist supply system is the heart of the unit, and allows for a consistent and uniform coating of photoresist on the substrate. It is also capable of adjusting the thickness of the photoresist layer based on the user's needs. The wafer handling machine provides accurate movement and positioning of the substrate, while the pattern generator enables the user to define the patterns to be etched. The laser alignment feature ensures precise placement of the patterns, and the auto focus mechanism ensures that the entire wafer is exposed to the same level of UV light exposure. In addition, TOKYO ELECTRON ACT12 tool includes an intuitive software control program that allows for the easy management and programming of process sequences. This makes the asset ideal for automated manufacturing operations. The software features a built-in library of process parameters that can be customized based on the process needs. It also includes safety features that alert the user to any errors or problems in the process. Overall, TEL ACT12 model is an excellent choice for anyone looking for a cost effective photoresist equipment with advanced process capabilities and ease of use. The system's robust hardware features ensure consistent and accurate process control, while its intuitive software control program enables smooth operation and maintenance.

There are no reviews yet