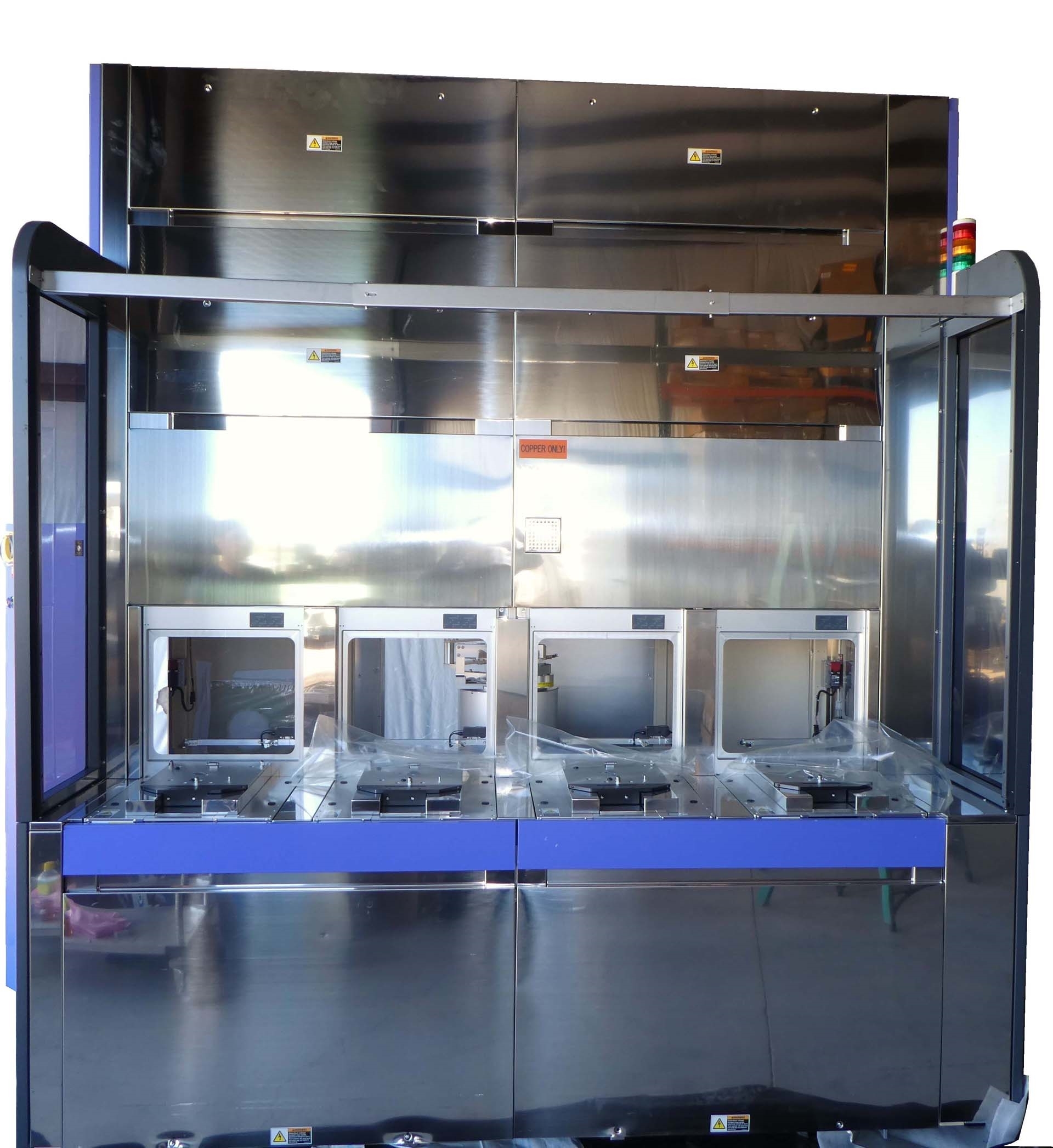

Used TEL / TOKYO ELECTRON Clean Track Lithius #9267420 for sale

URL successfully copied!

Tap to zoom

ID: 9267420

Wafer Size: 12"

System, 12"

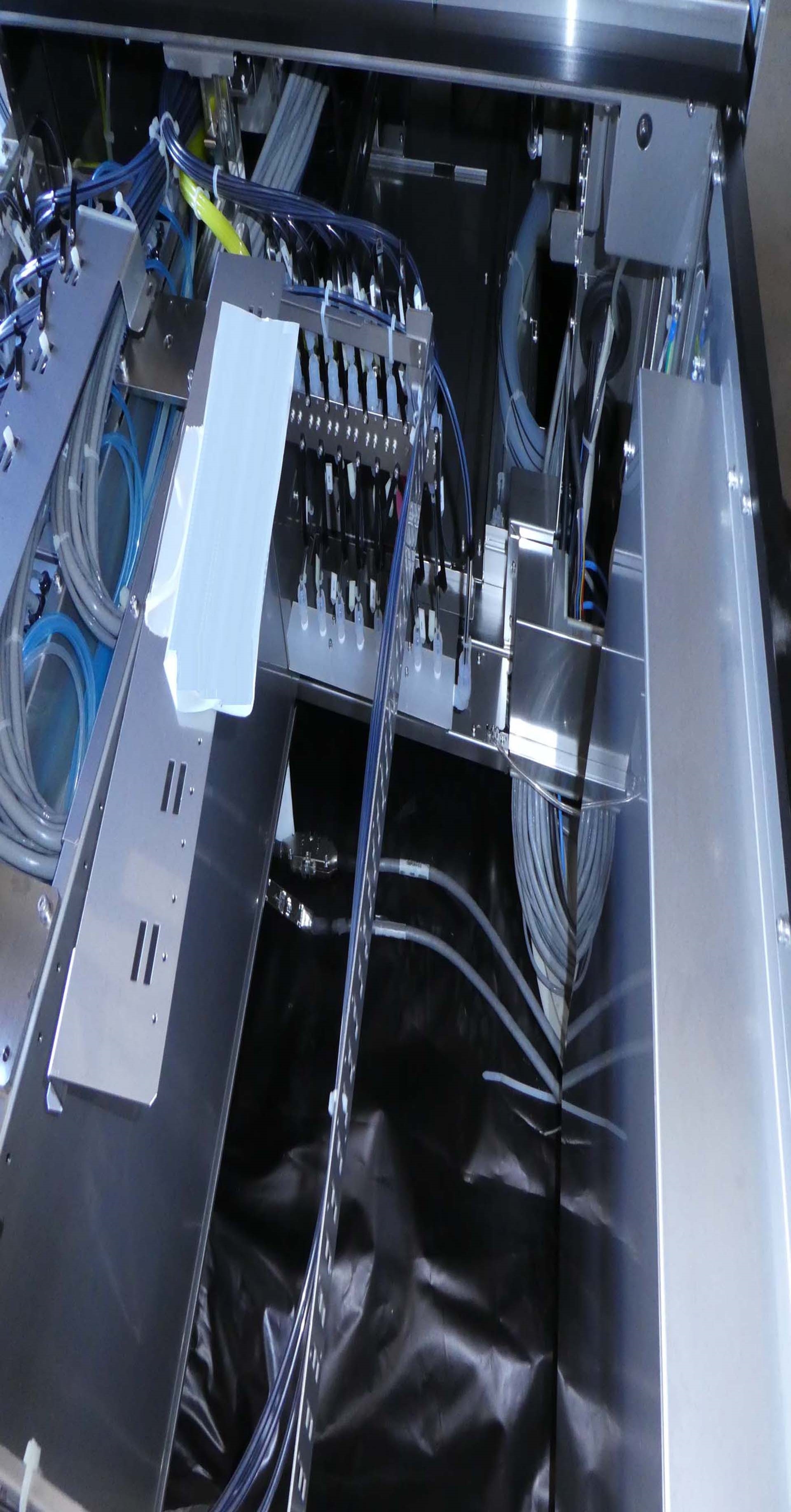

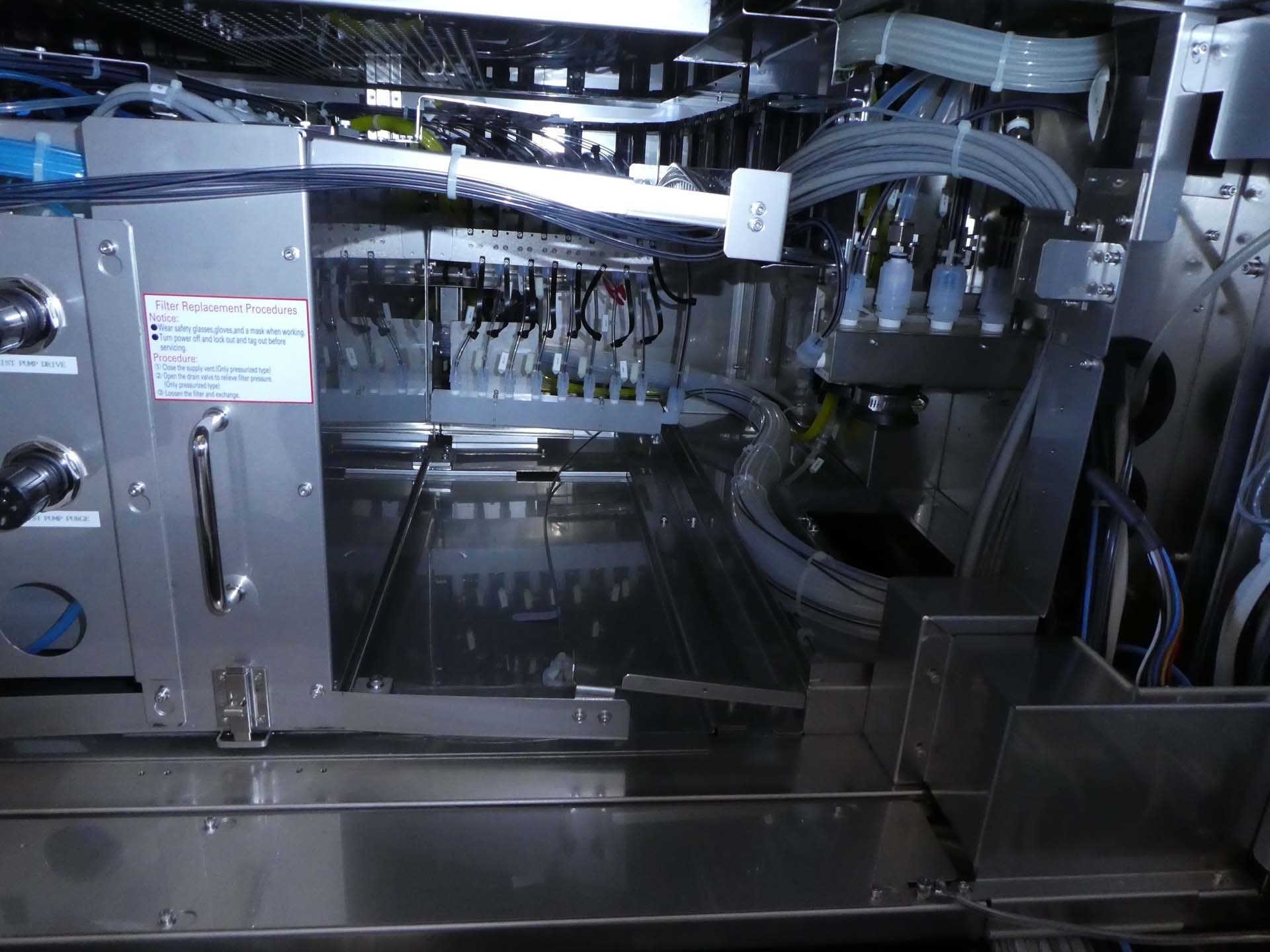

Cassette stage block

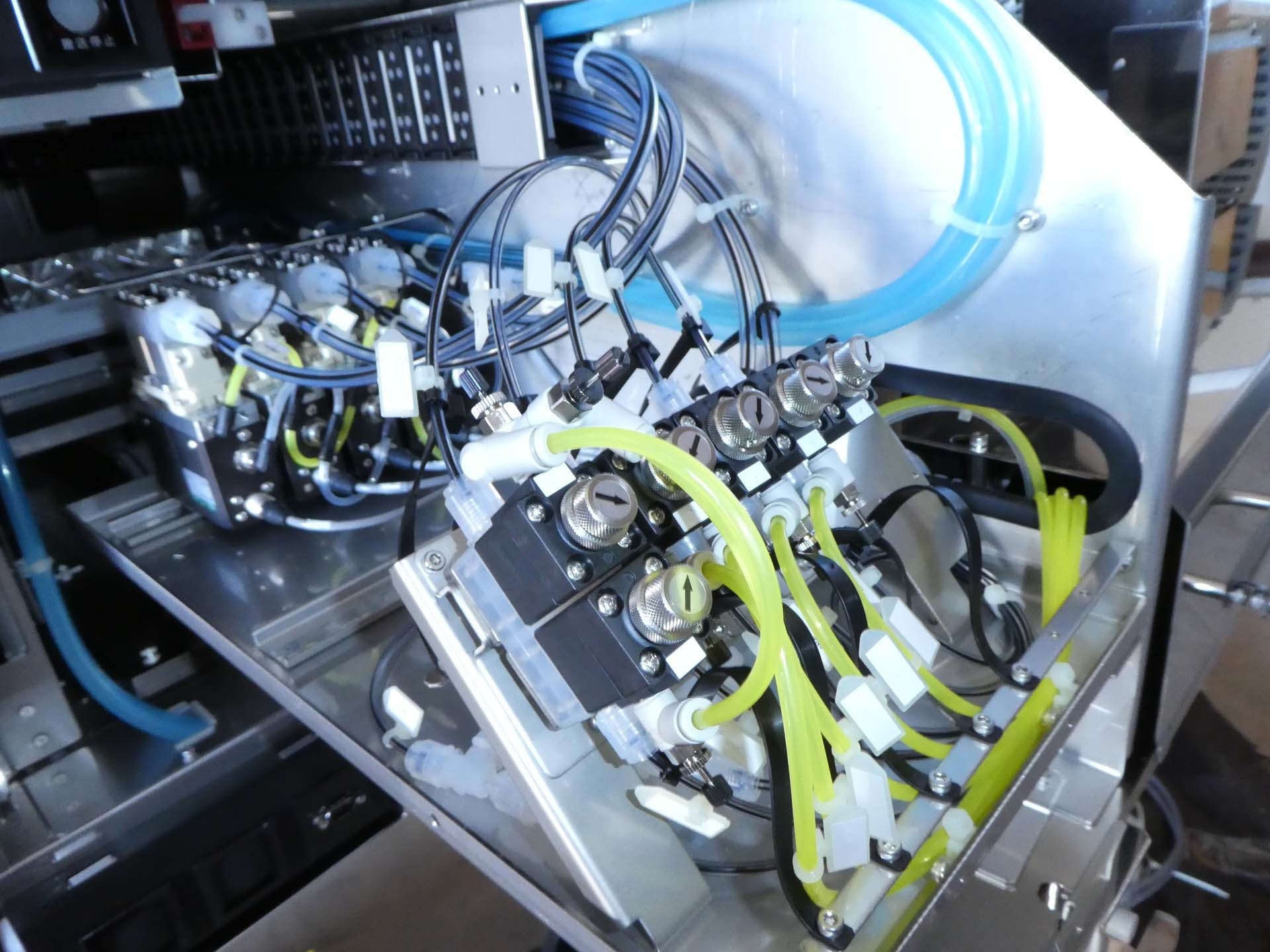

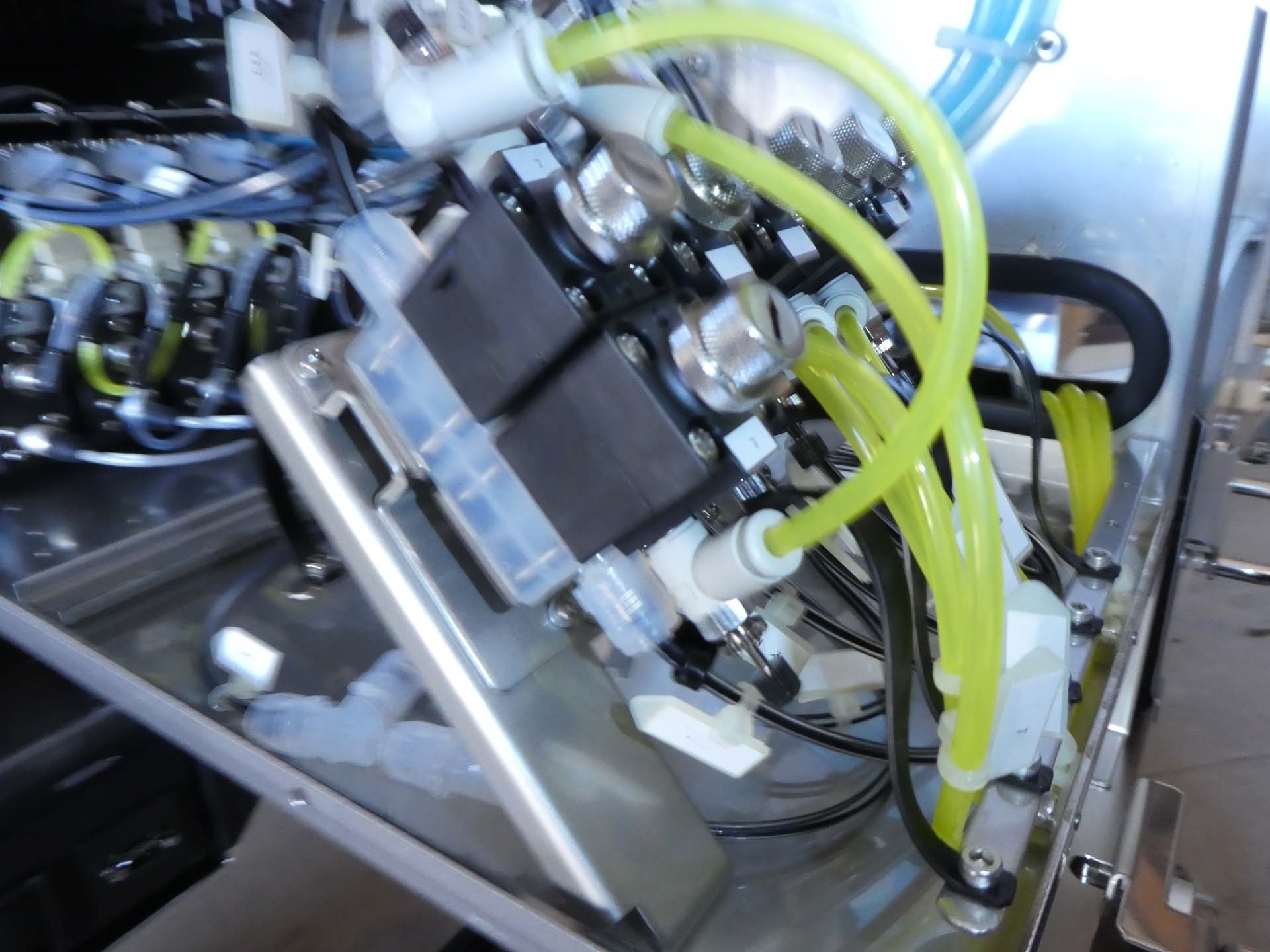

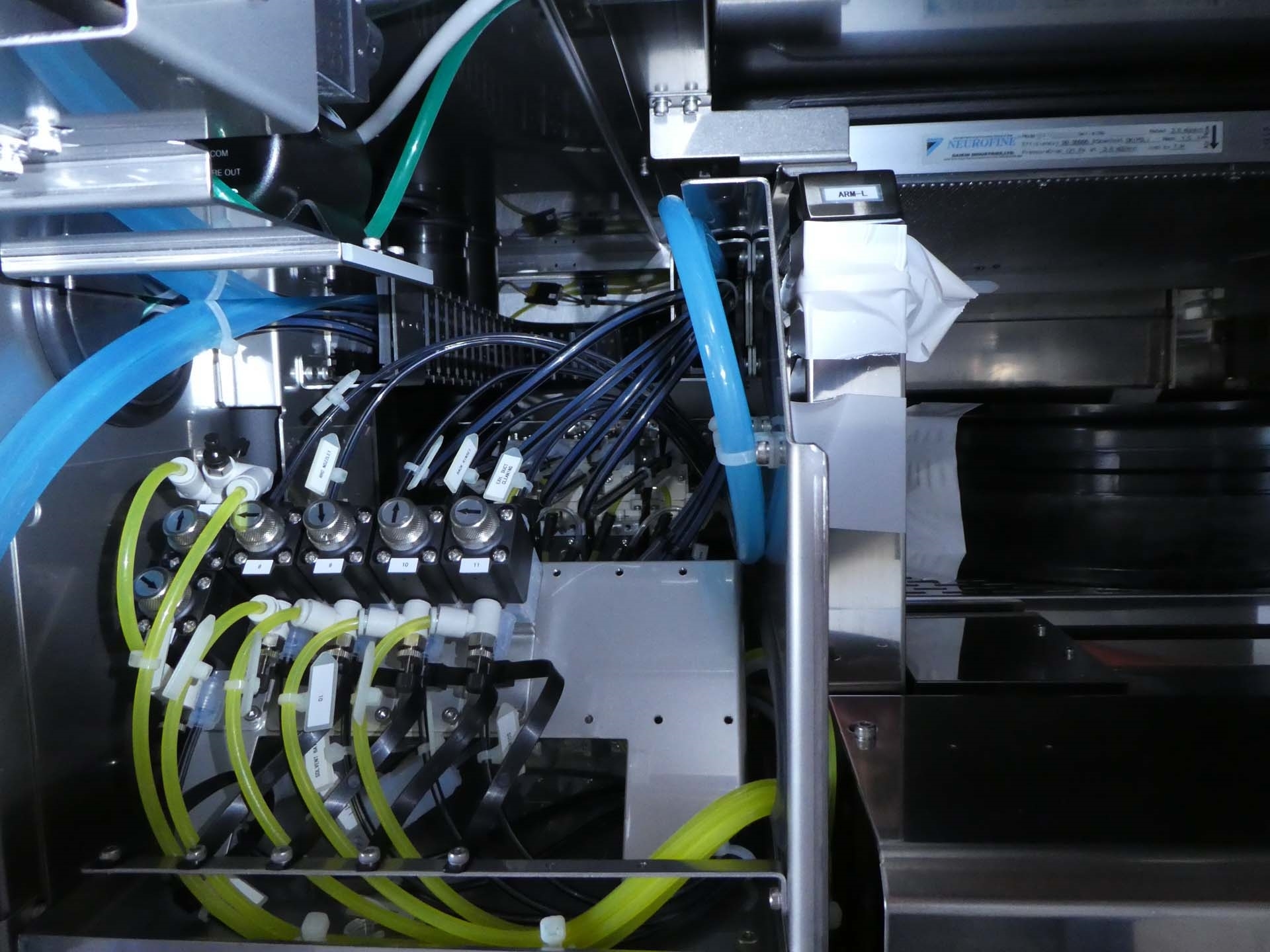

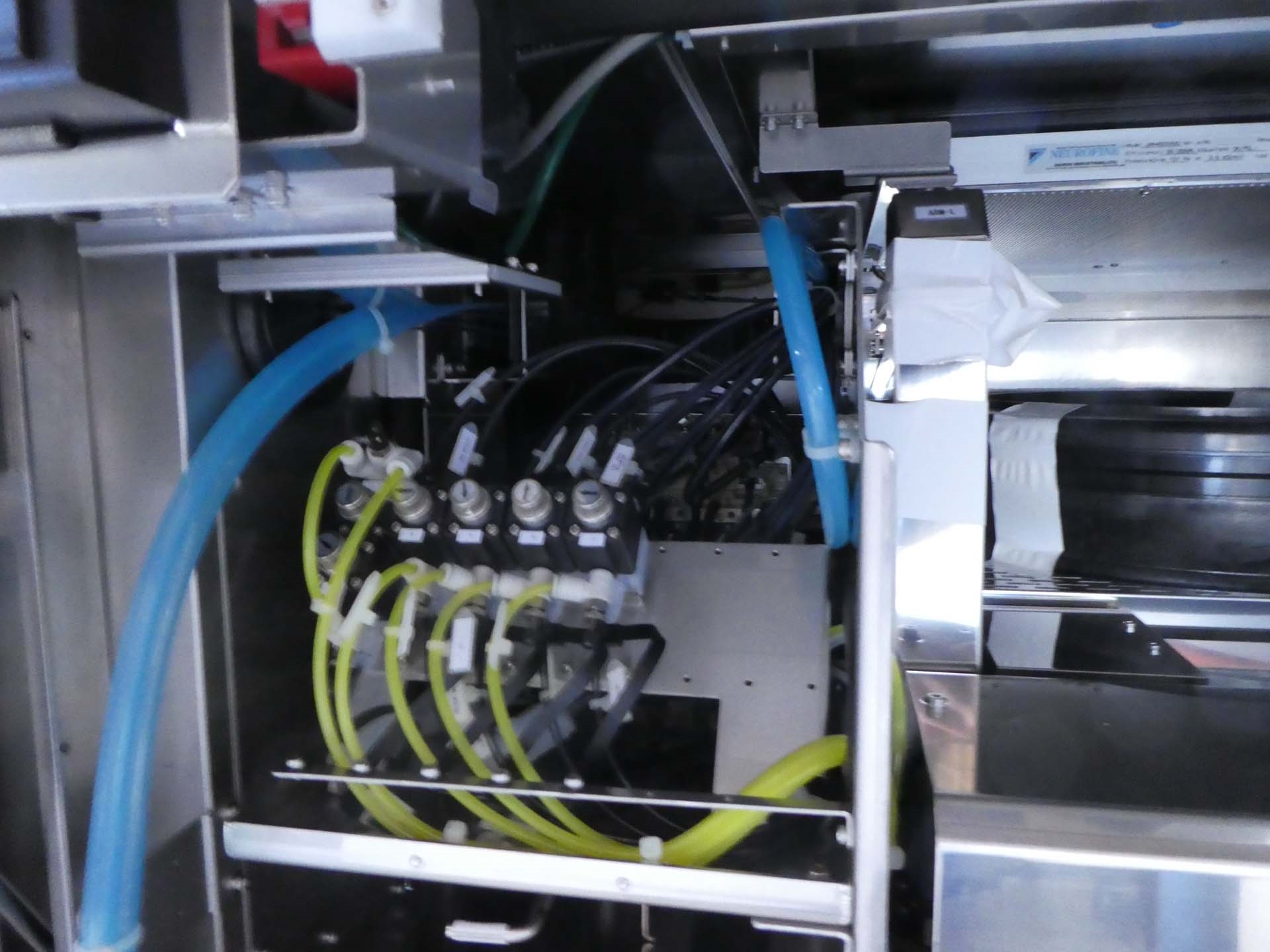

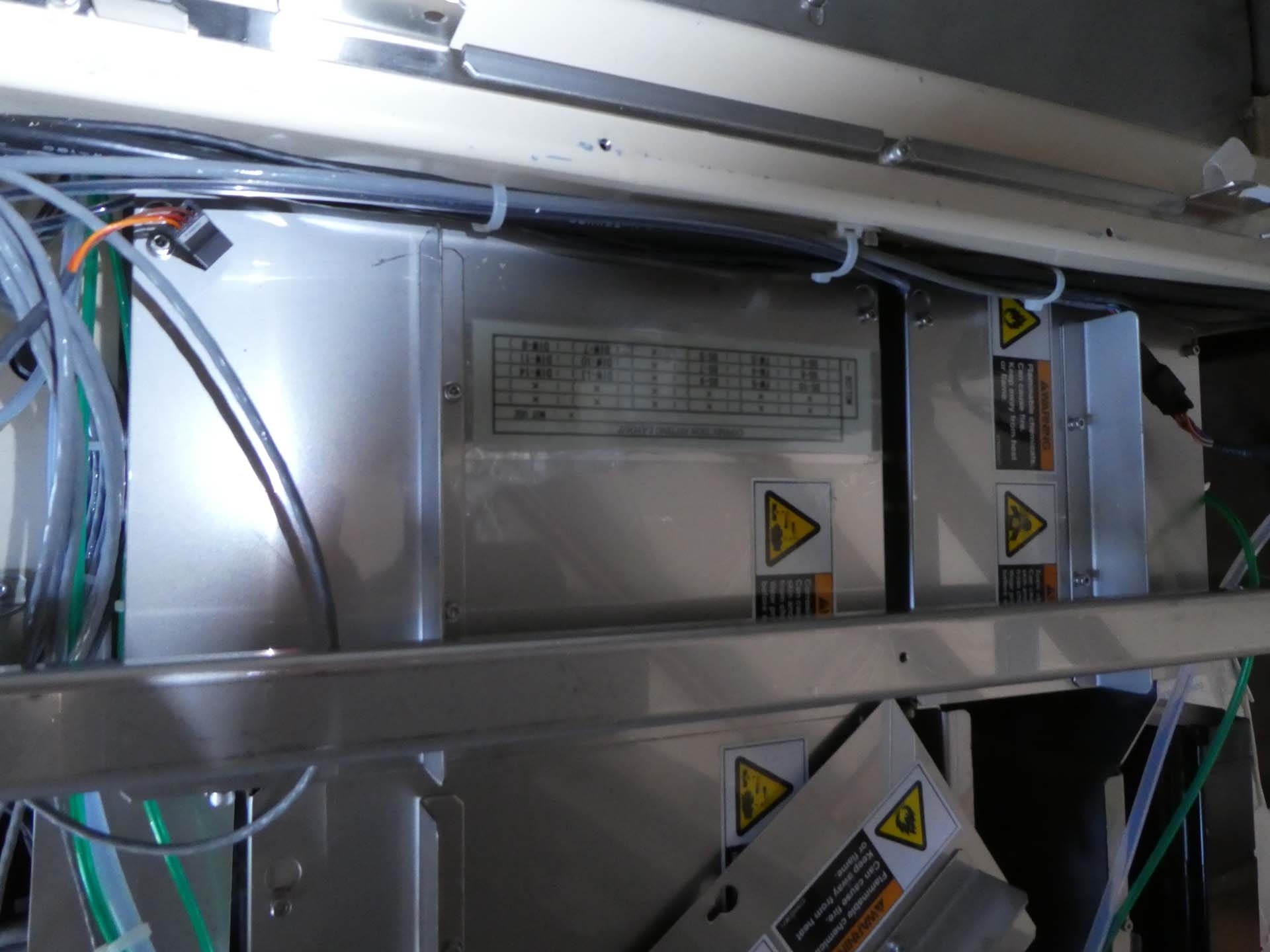

SMC Thermo-Con block

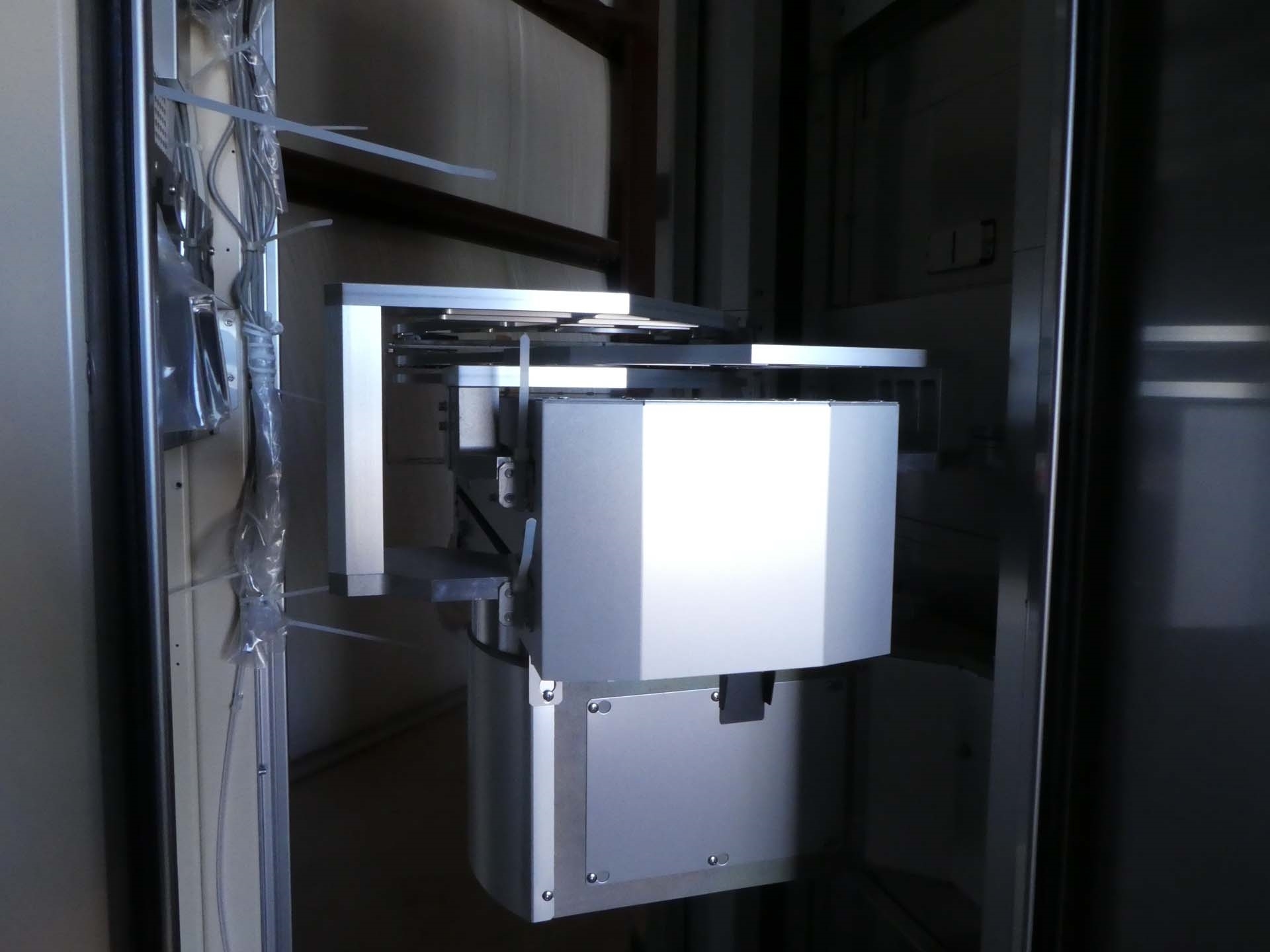

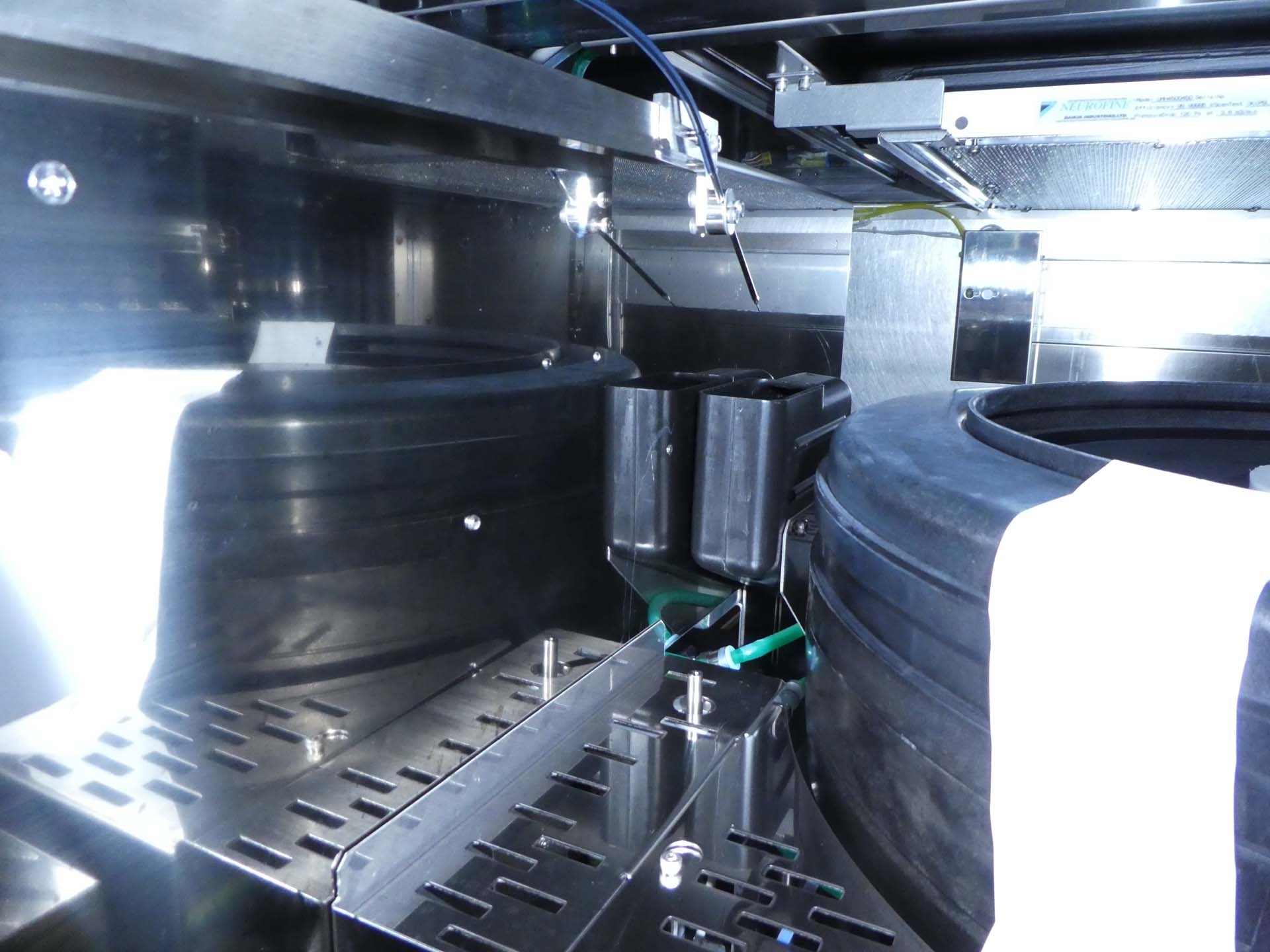

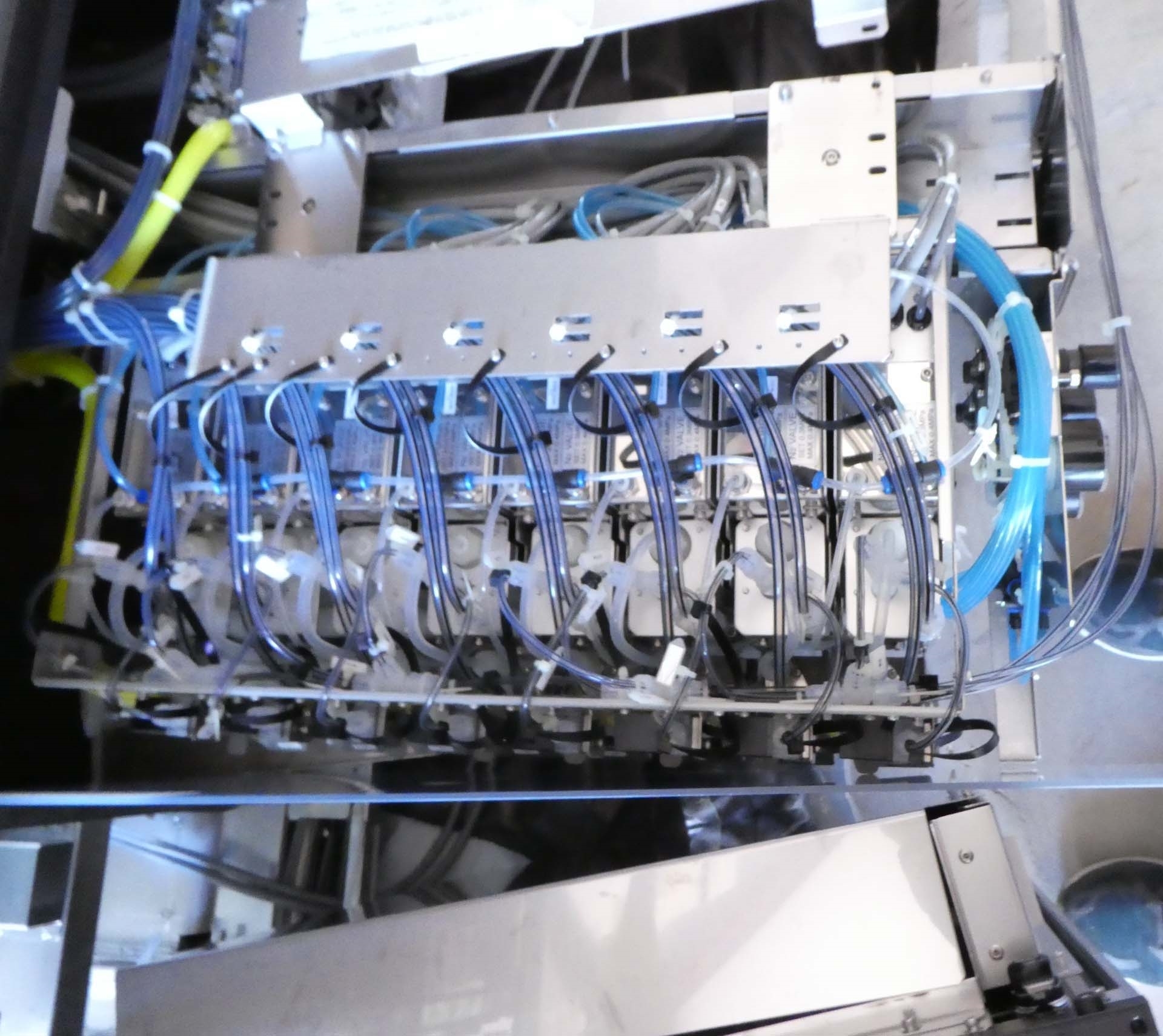

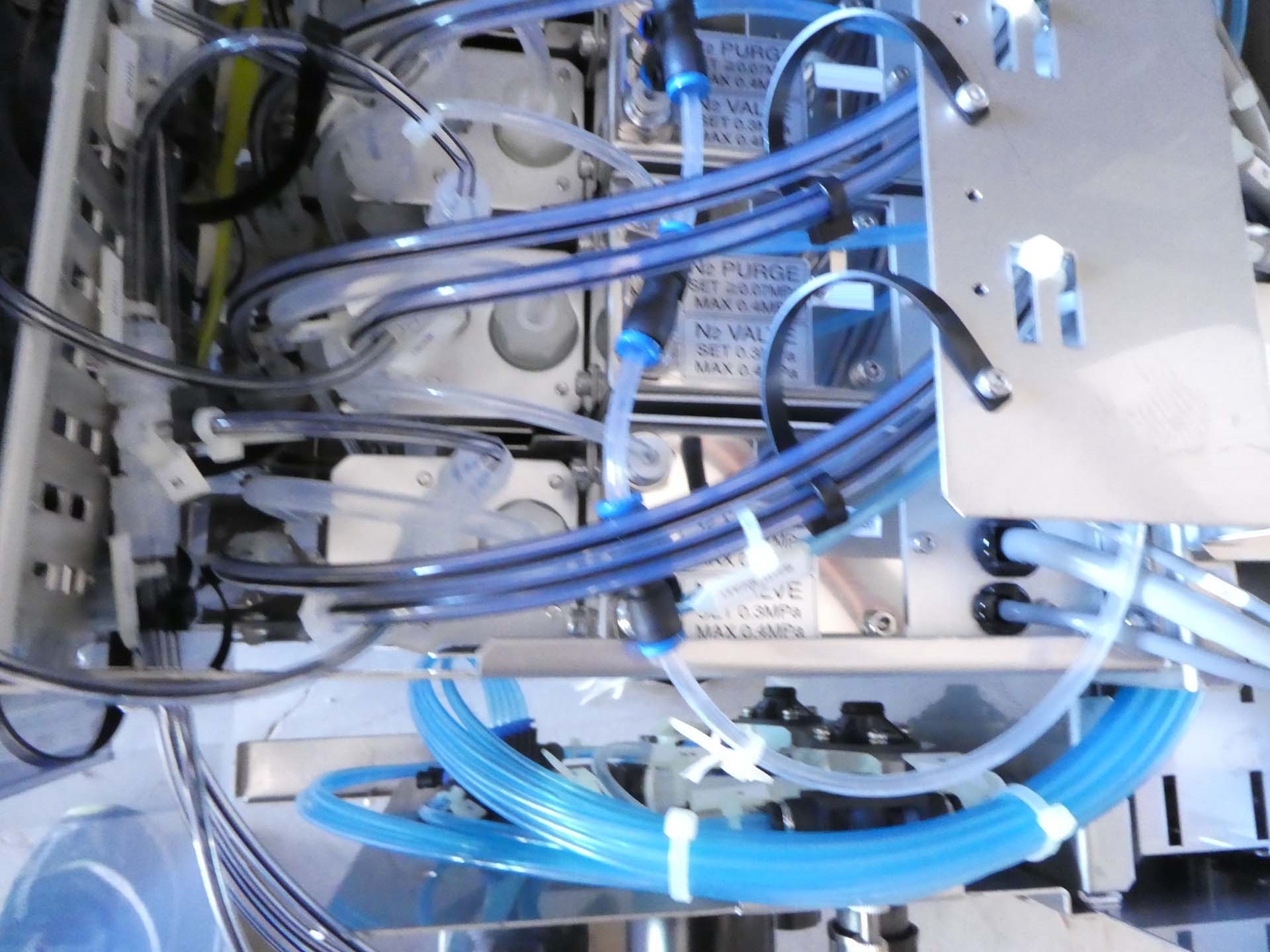

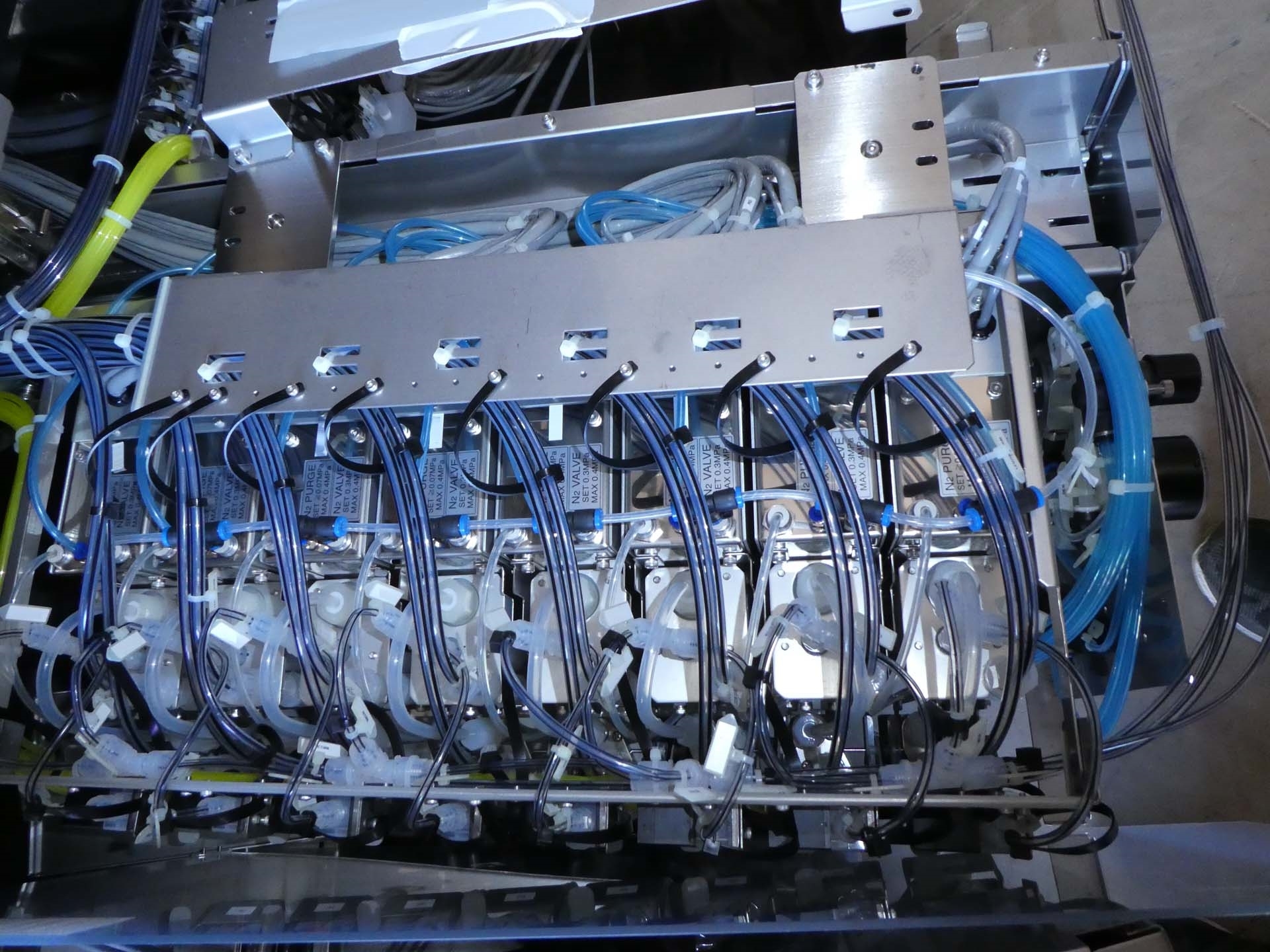

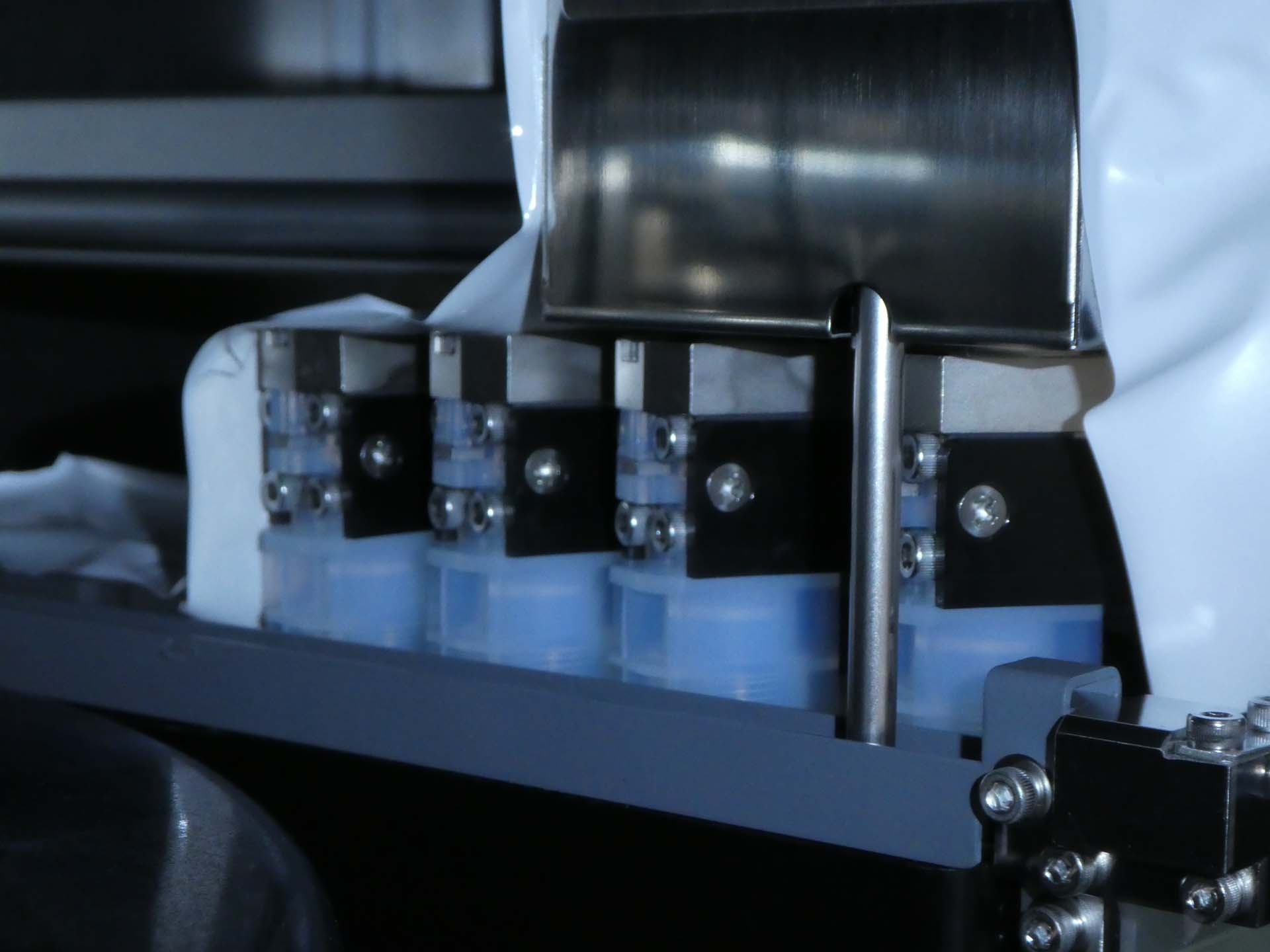

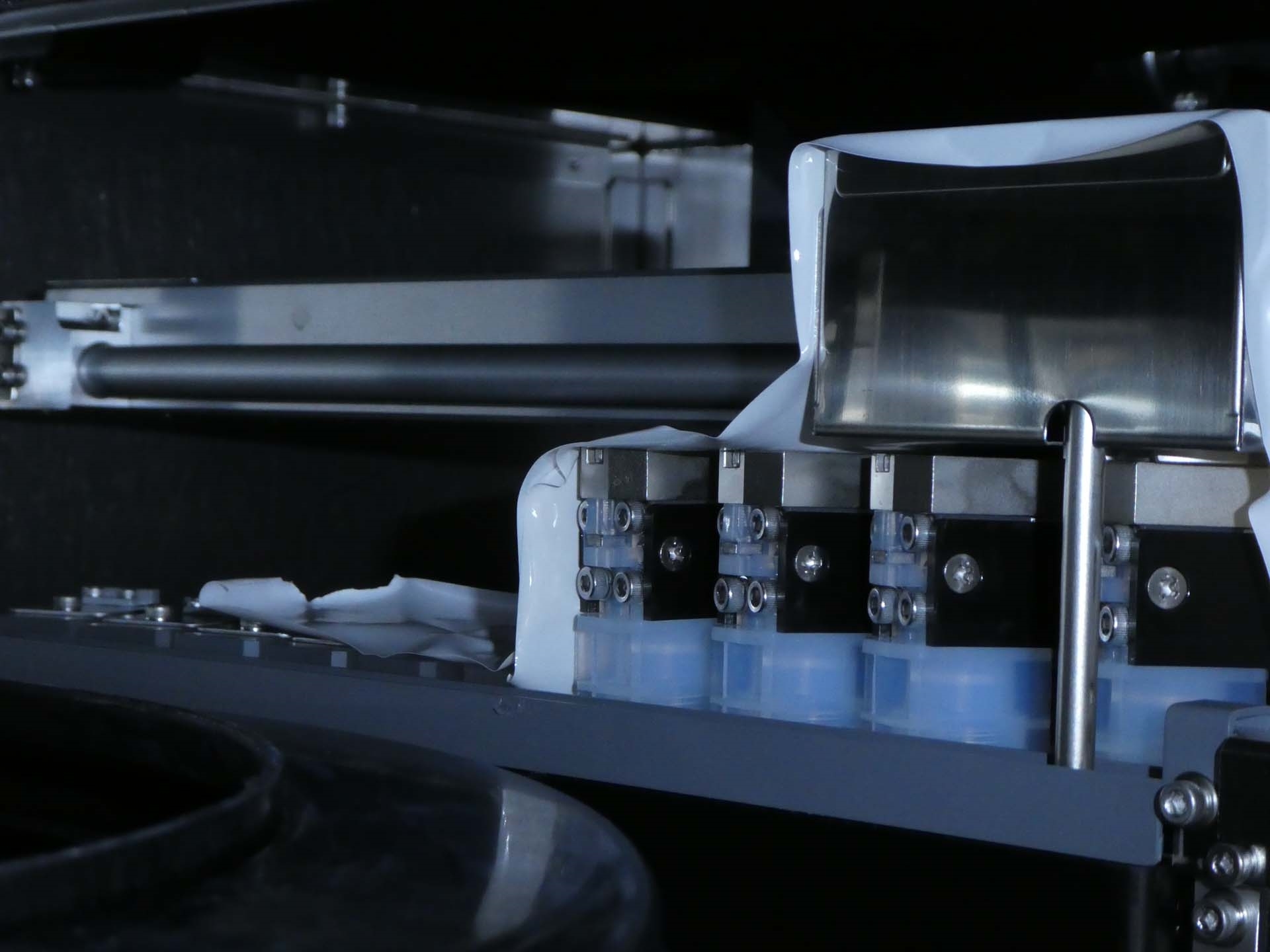

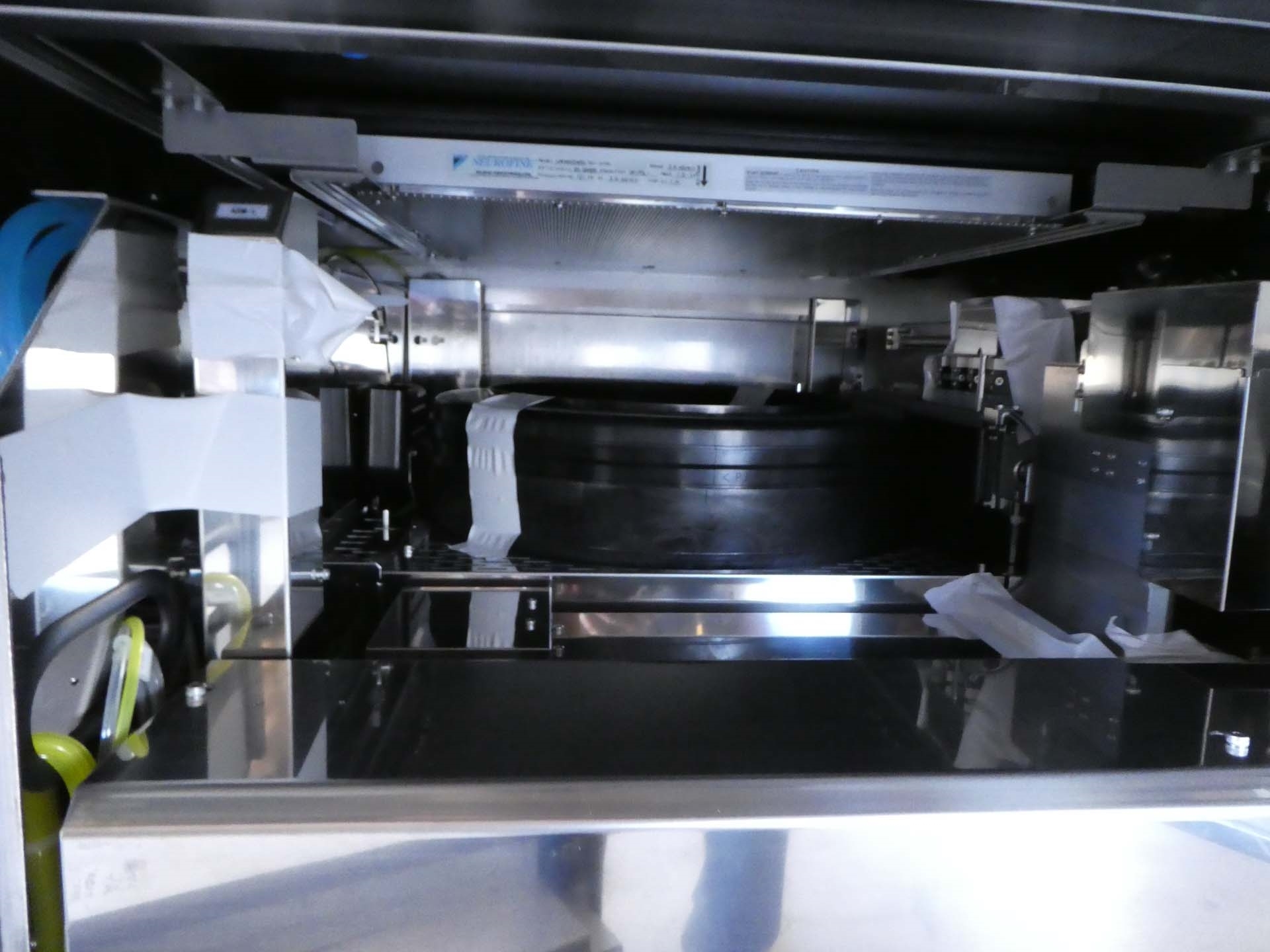

Plate stacks

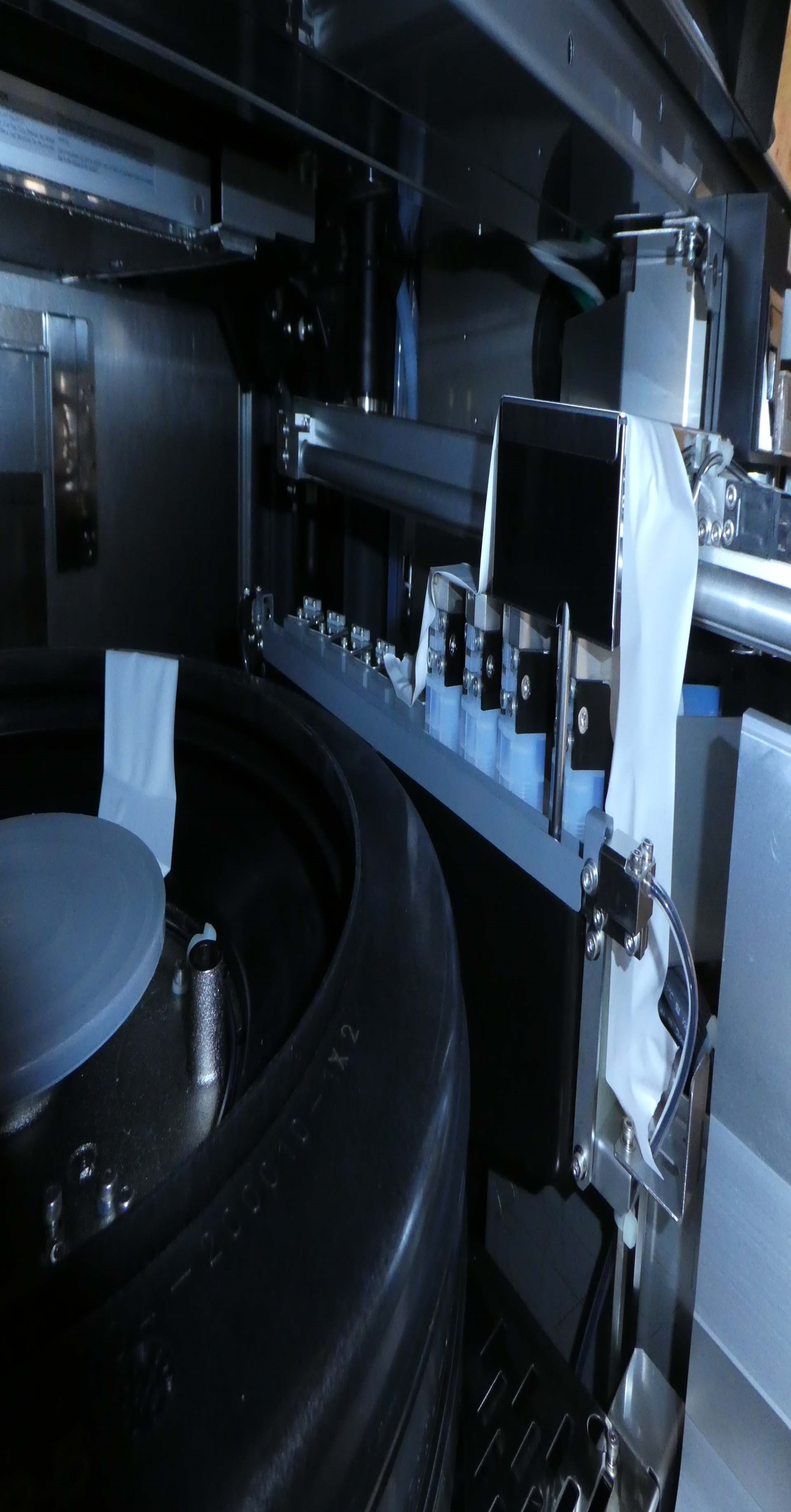

Coat develop module

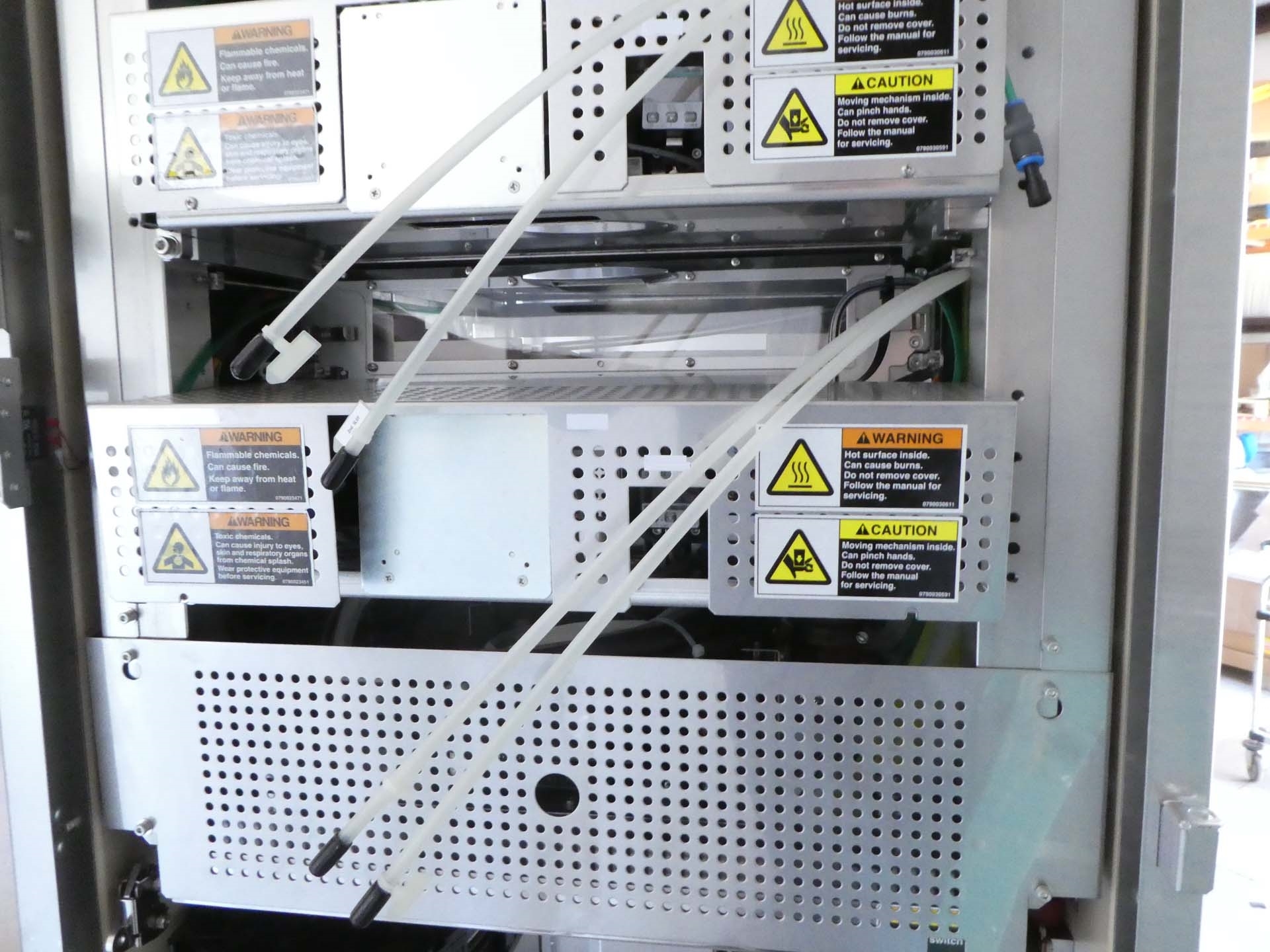

AC Power box

Miscellaneous panels.

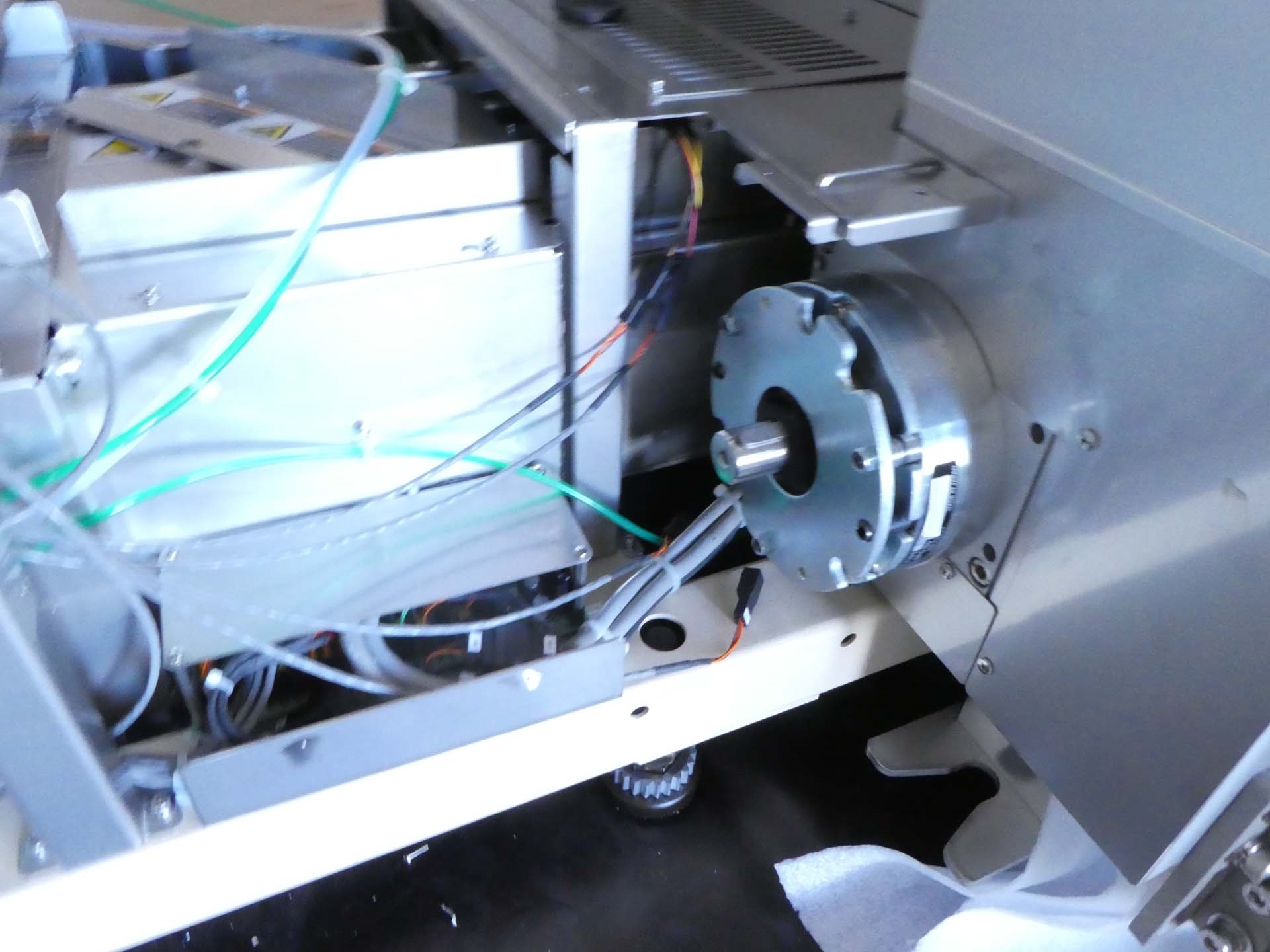

TEL / TOKYO ELECTRON Clean Track Lithius is a photoresist equipment characterized by its ability to reduce the size and complexity of the lithographic process and improve the cleanliness and productivity of the cleaning process. TEL Clean Track Lithius system is a modular and modular-style technical solution for masking/etching and cleaning technologies. It is suitable for both mass production and limited-quantity processing. The unit has an ultra-short wavelength light source that enables high-resolution patterning of photomasks and improved cleaning performance. This also enables the development of higher-resolution masks/placing patterns and reducing the minimum pitch for patterns. The pattern layout is optimized by using low-dimensional patterns (2 to 4 colors). The photoresist layer is applied in a single step, which increases throughput and reduces complexity as compared to conventional resist processing techniques. TOKYO ELECTRON Clean Track Lithius also incorporates an advanced cleaning machine into the patterning process. The cleaning tool combines both wet chemical and dry particle cleaning processes. The wet etch process utilizes a high-pressure (1.7 to 3.5 mPa) chemical solution to remove the photoresist material from the substrate. The dry particle cleaning process uses particles of various sizes to remove any remaining photoresist from the substrate. The combination of the two cleaning processes allows for higher throughput and cleaner photoresist patterning. Clean Track Lithius also offers an in-line monitoring asset for inspections and process monitoring. The model measures the light intensity of the resist material and uses the applied light intensity to generate warning signals if the light intensity is outside the acceptable range. The equipment can also be used to measure the cleanliness of the processed substrate, allowing engineers to identify any cleaning defects before the photoresist application process. Furthermore, TEL / TOKYO ELECTRON Clean Track Lithius incorporates intelligent case-handling (ICH) for quick and precise pattern placement. The ICH utilizes a multi-axis positioning analyzer to identify the accurate position of the substrate during patterning. The resulting pattern placement is uniform and precise, enabling higher yield rates and greater process stability. In conclusion, TEL Clean Track Lithius photoresist system is an advanced and advanced-level technical solution for photomask and etch patterning. The unit is designed to reduce the size and complexity of the lithographic process while at the same time, improving the cleanliness and productivity of the cleaning process. The overall result is improved yields, increased throughput, increased uniformity and greater process stability.

There are no reviews yet