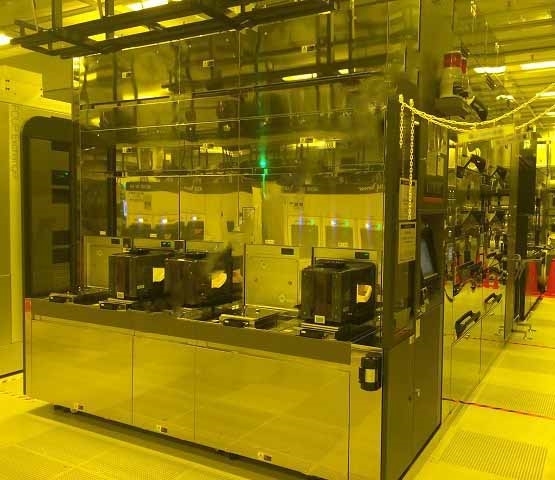

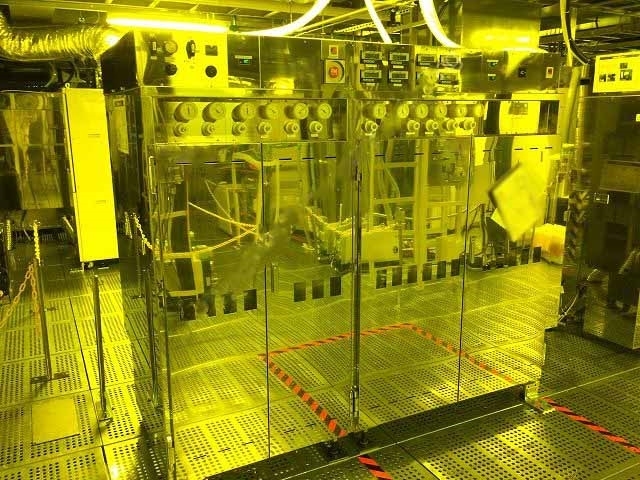

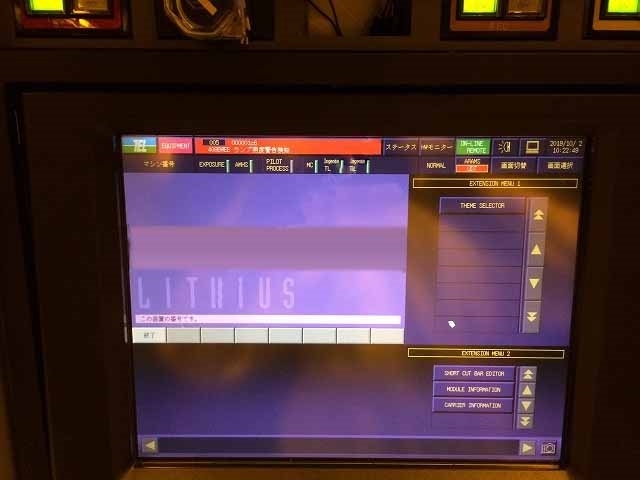

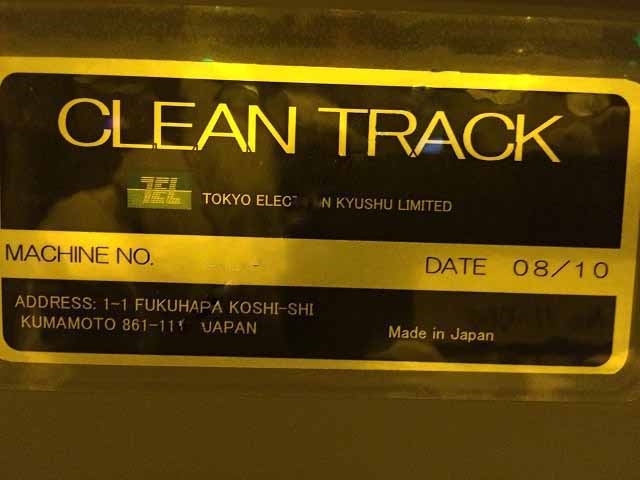

Used TEL / TOKYO ELECTRON Clean Track Lithius #9275996 for sale

URL successfully copied!

Tap to zoom

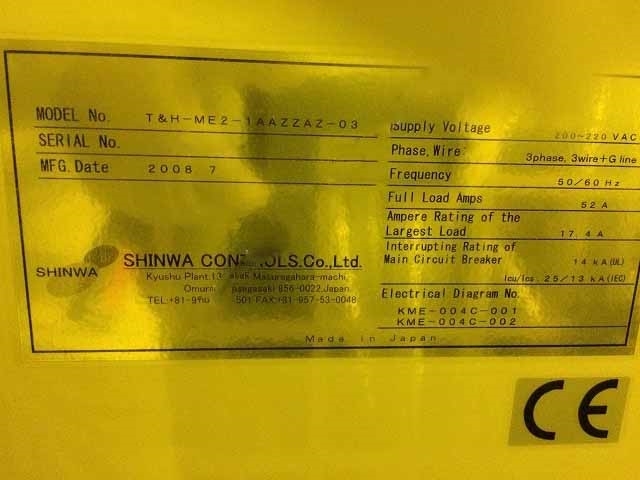

ID: 9275996

Wafer Size: 12"

Vintage: 2008

Resist coater / Developer system, 12"

Multi block

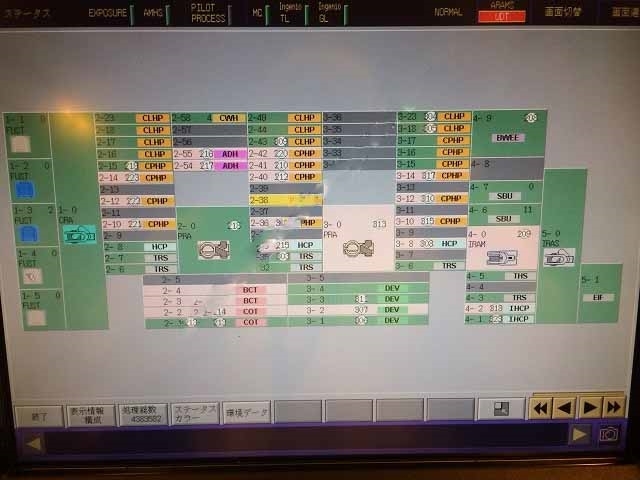

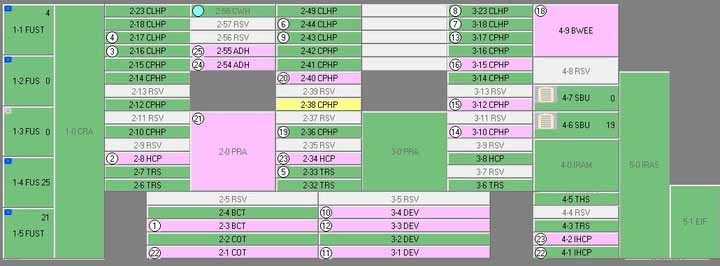

Track 1:

(2) Coater cups

(2) BCT cups

(4) Developer cups

Track 2:

Resist reduction: RRC

Dev nozzle: LD Nozzle

Resist pump: RDS 4ml

Oven:

Dehyde bake: (4) CLHP

COT: (9) CPHP

PEB: (6) CPHP

Post bake: (5) CLHP

(2) ADH

Track chemicals:

Resist supply: Gallon bottle

Thinner: OK73, LA95

Does not include HDD

2008 vintage.

TEL / TOKYO ELECTRON Clean Track Lithius is a photoresist equipment used in the semi-conductor industry for making fine etching pattern on wafers. It is one of the most advanced photoresist technologies available on the market. This system utilizes a complex light-controlling and patterning mechanism to enable accurate etching on the surface of the wafer. The first step involves applying a thin layer of positive-tone photoresist onto the wafer surface. The photoresist is then exposed to a high-intensity UV light source, which selectively modulates the exposure of the photoresist depending on the pattern desired. This pattern is then transferred to the surface of the wafer and is ready for the etching process. TEL Clean Track Lithius unit comes with sophisticated light controlling features such as a laser LDI (laser Direct Imaging) optics, an eight-channel stepper motion control, and a fast-feedback machine for uniform exposure of the photoresist. Users can also choose to switch to a contact exposure option if required. The advanced photoresist technology employed by TOKYO ELECTRON Clean Track Lithius also makes the tool suitable for multiple photoresist removal processes. This allows users to imprint several fine-level etching details on the wafers simultaneously. A wide range of photoresist variety is also available with the asset, allowing for a more tailor-made etching pattern to be achieved. Clean Track Lithius photoresist model is an excellent choice for semiconductor manufacturers who are looking for efficient, precise, and well-regulated etching processes. Its sophisticated features, user-friendly operation, and reliability make it the go-to photoresist equipment for many industries.

There are no reviews yet