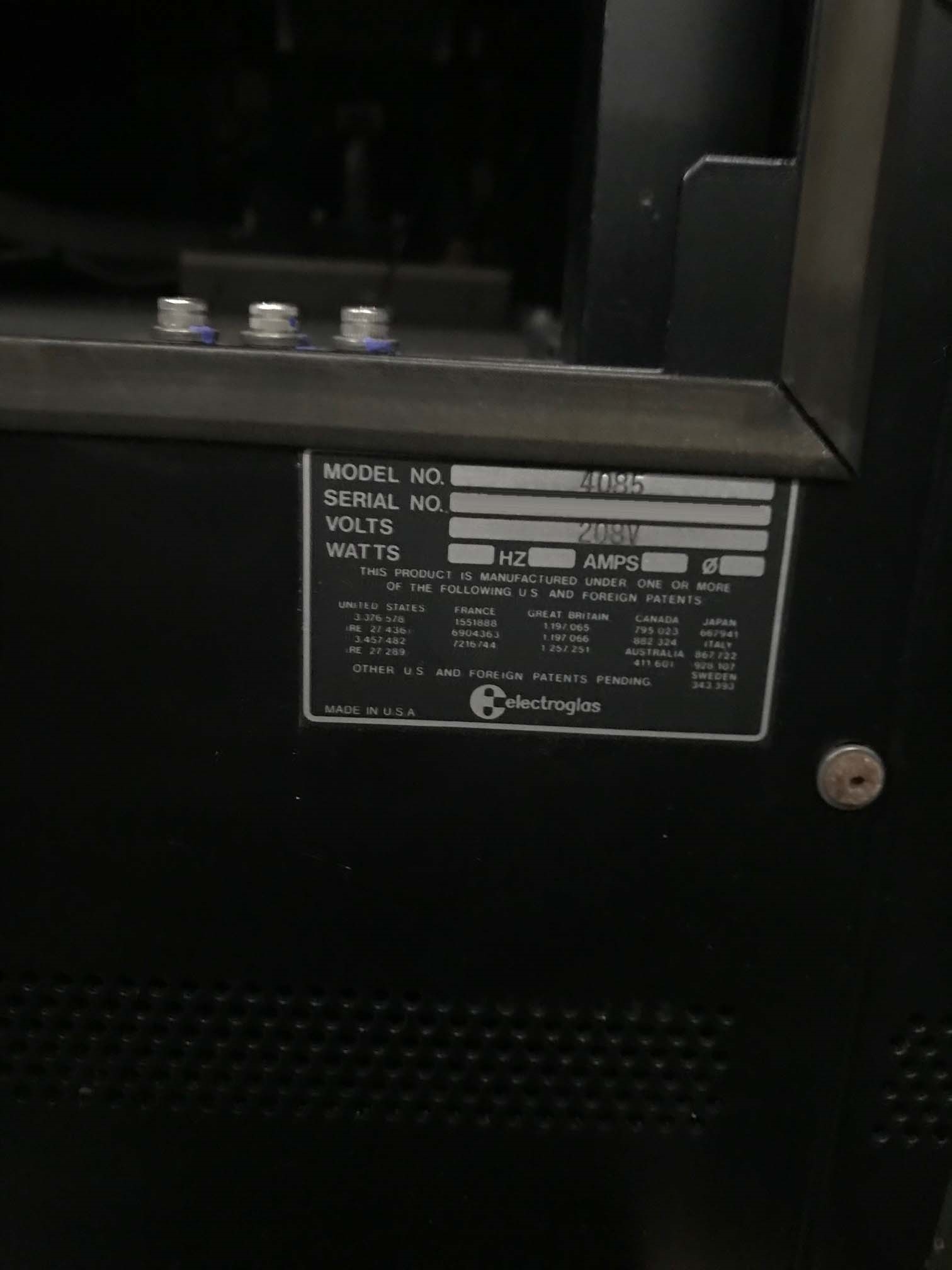

Used ELECTROGLAS 4085X #145868 for sale

URL successfully copied!

Tap to zoom

ELECTROGLAS 4085X is a high-performance prober designed for advanced semiconductor testing. This machine is complex, multi-functional, and capable of many automated functions. It is used to evaluate the performance and reliability of semiconductor devices and circuits. 4085X is equipped with an automated tool changer, allowing for multiple different technologies to be tested using a single machine. This versatility allows for switching between wafer prober and contactor applications quickly and efficiently. The automated tool changer ensures that the right tool is always ready and selected for the job. The prober is designed to cover a range of applications, from testing high-speed devices to verifying test vector patterns and switch matrices. It uses a universal probing head with pogo-pin contact that can accurately transfer signals between probes and a semiconductor device under test. The machine also includes an integrated camera system which achieves precise alignment with the help of a vision focus tool and precise alignment of wafer head and socket services. The powerful control unit on ELECTROGLAS 4085X provides precise control over machine speed, providing optimal performance for different tests. This includes the ability to optimize the speeds for complex probing operations or manage the speeds for switching patterns. The adjustable speed multiplexing capability allows for efficient wafer probing and can accommodate up to 128 individual tests per wafer. 4085X prober also has exceptional data management capabilities. The system can store up to 1,040 test vectors and support devices with densities up to 6,000 pins. This allows for extensive testing without re-programming, saving time and money. ELECTROGLAS 4085X is a reliable and multi-functional prober ideal for automated semiconductor testing. The flexible and advanced features make this machine a great choice for high-performance and high-volume applications. Its automated tool changer and adjustable speed multiplexing capability make it easy to switch between wafer prober and contactor applications. The integrated camera system ensures precise alignment and placement of wafer sockets. The powerful control unit provides precise control over machine speed, providing optimal performance for different tests. Finally, its data management capabilities make it an ideal choice for high-volume applications.

There are no reviews yet