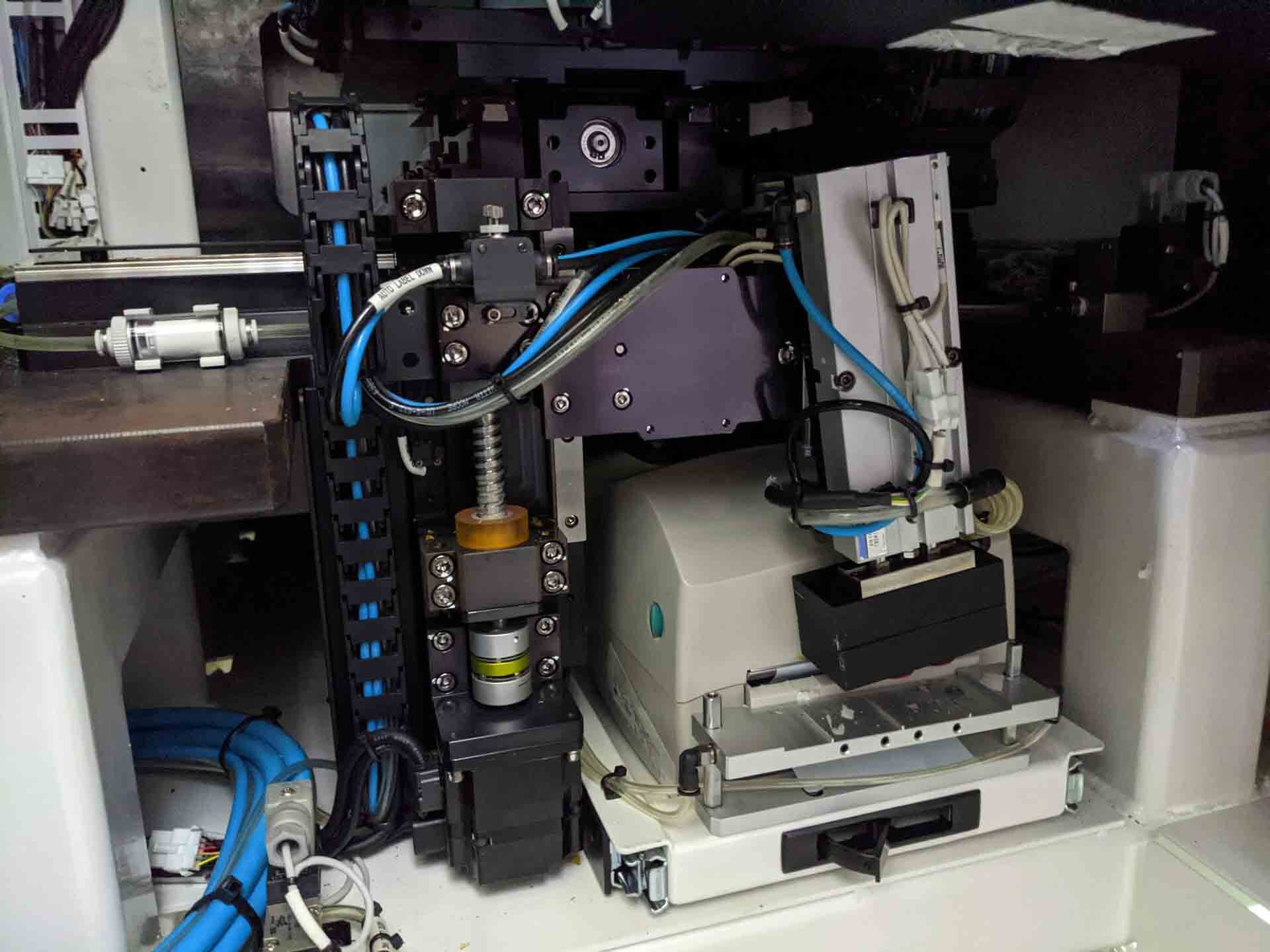

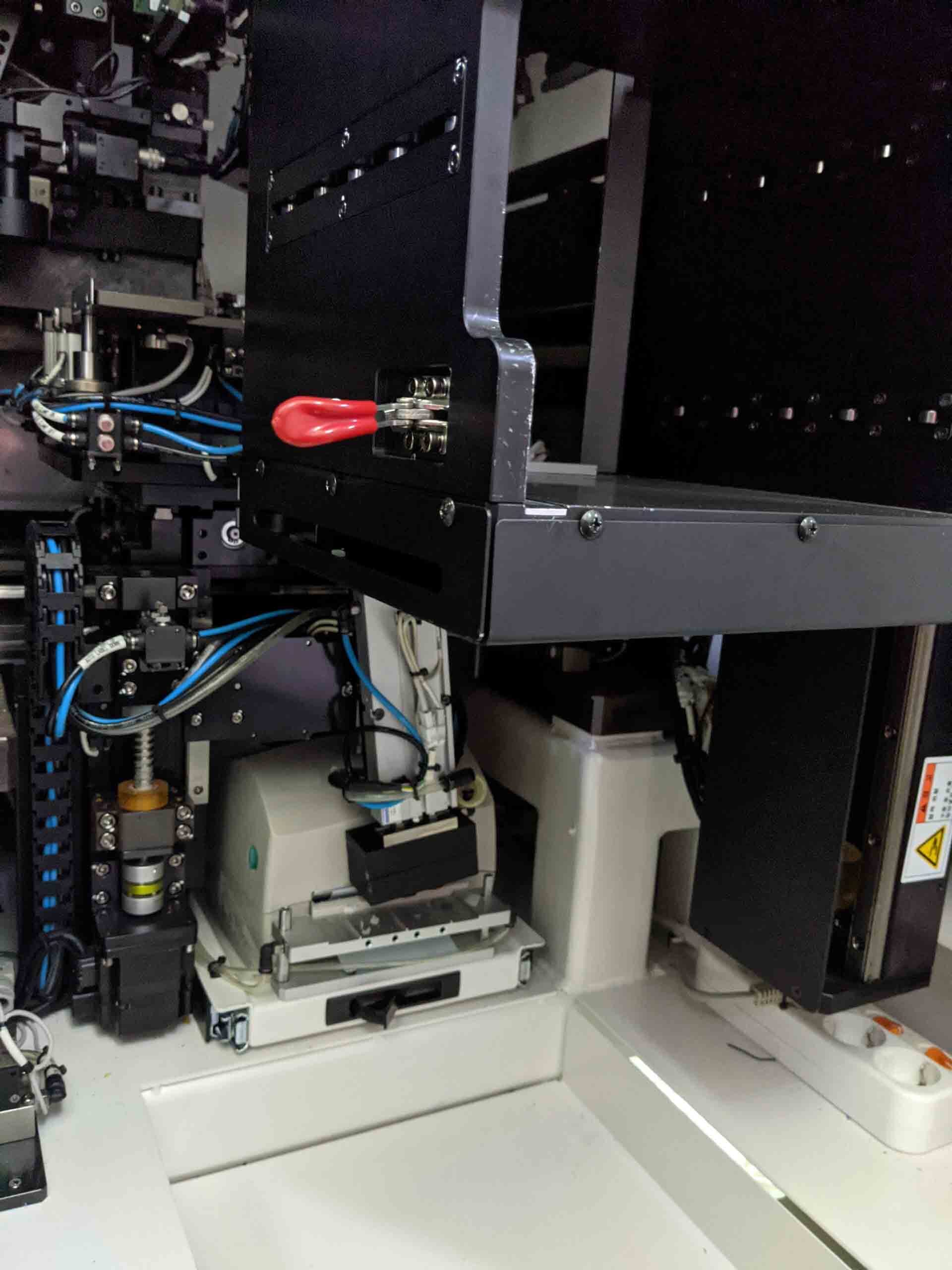

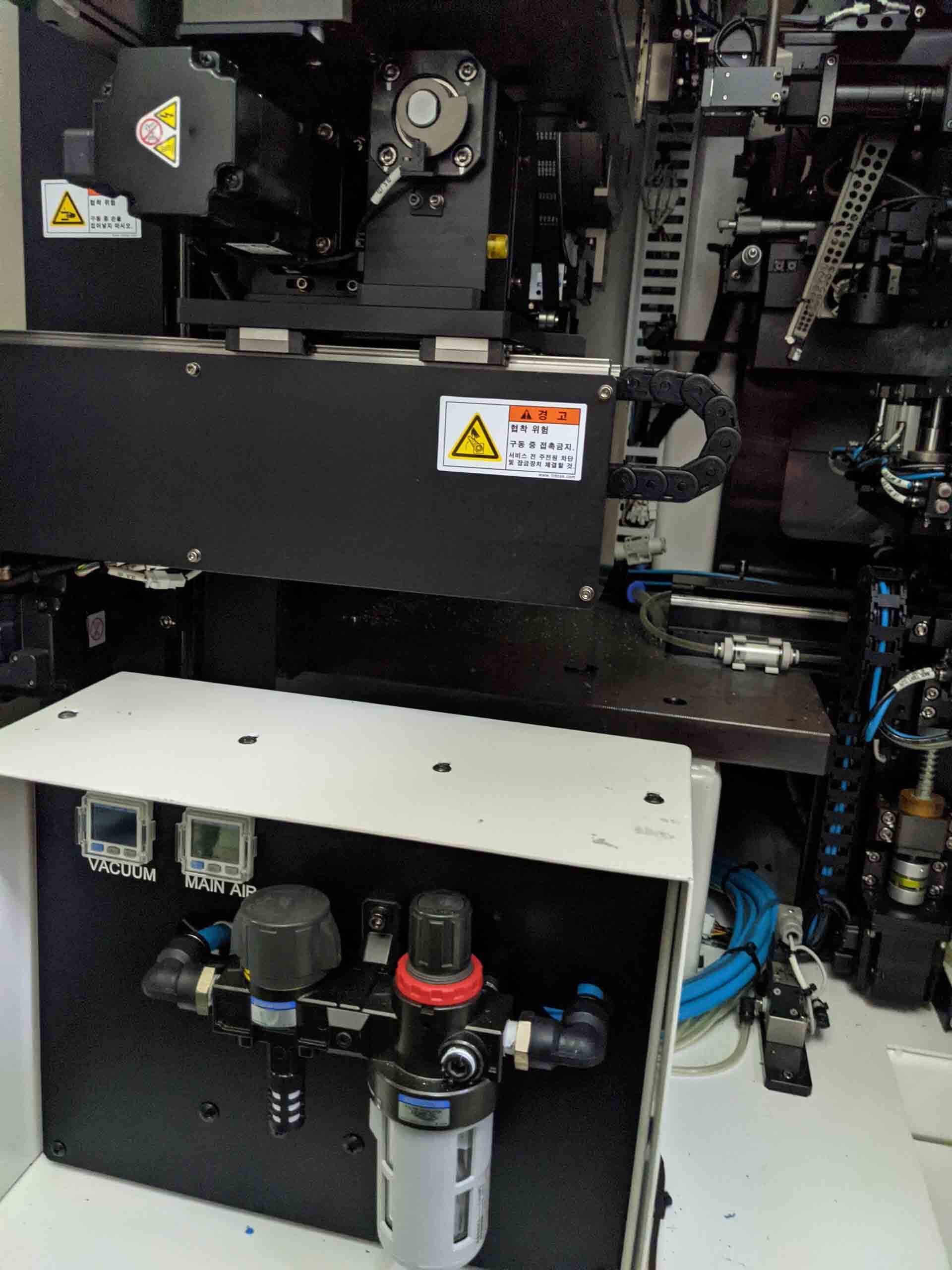

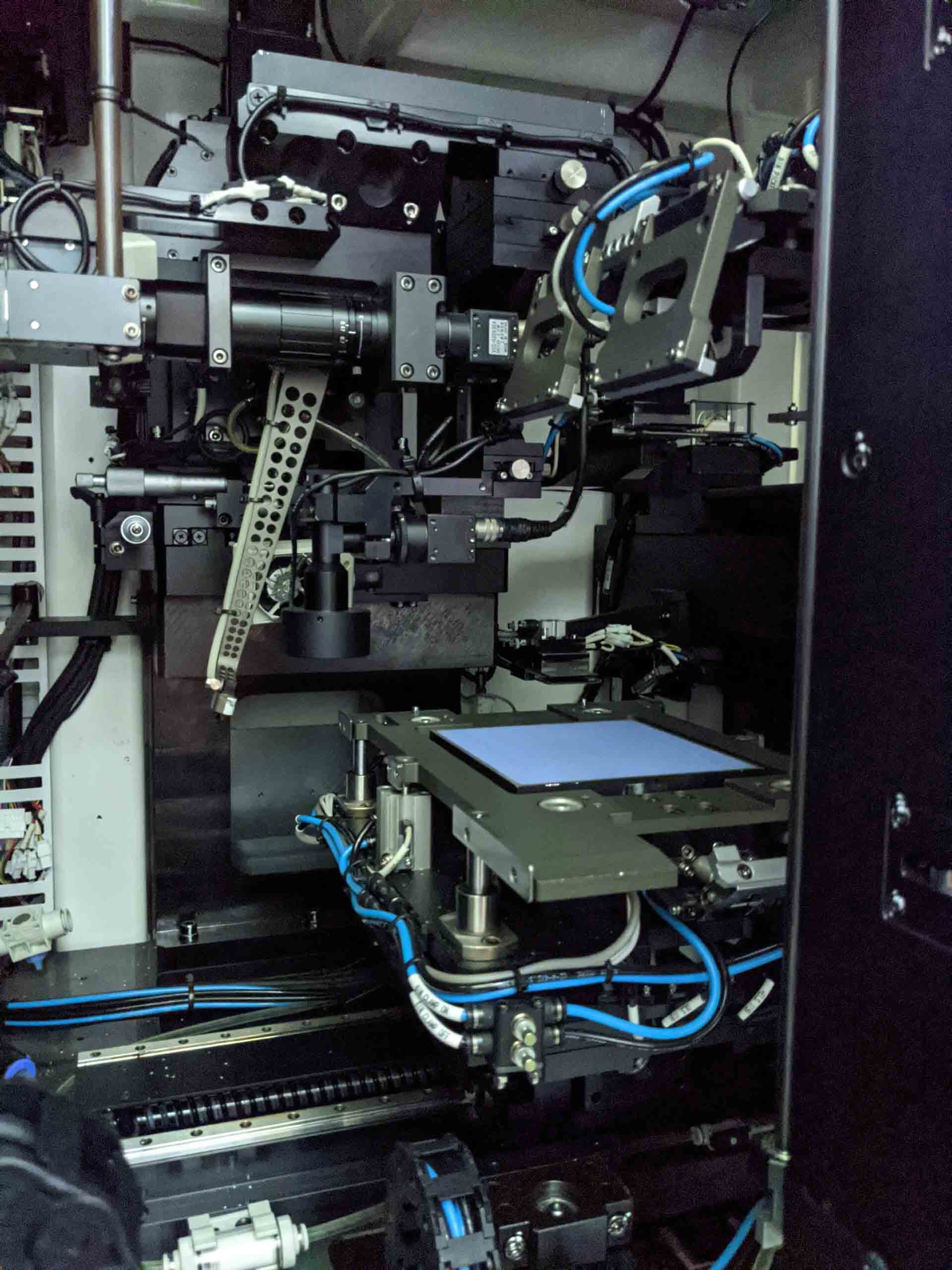

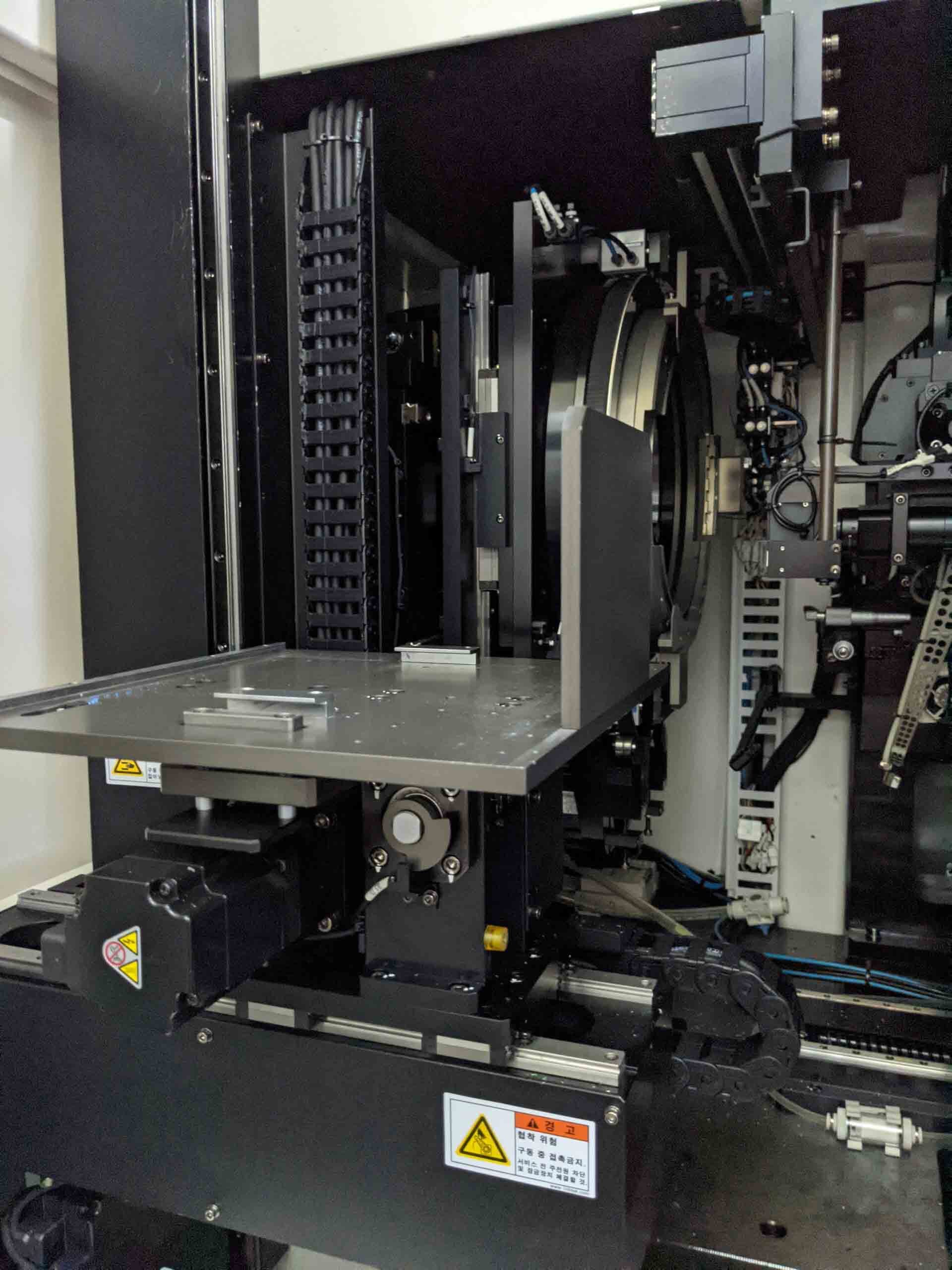

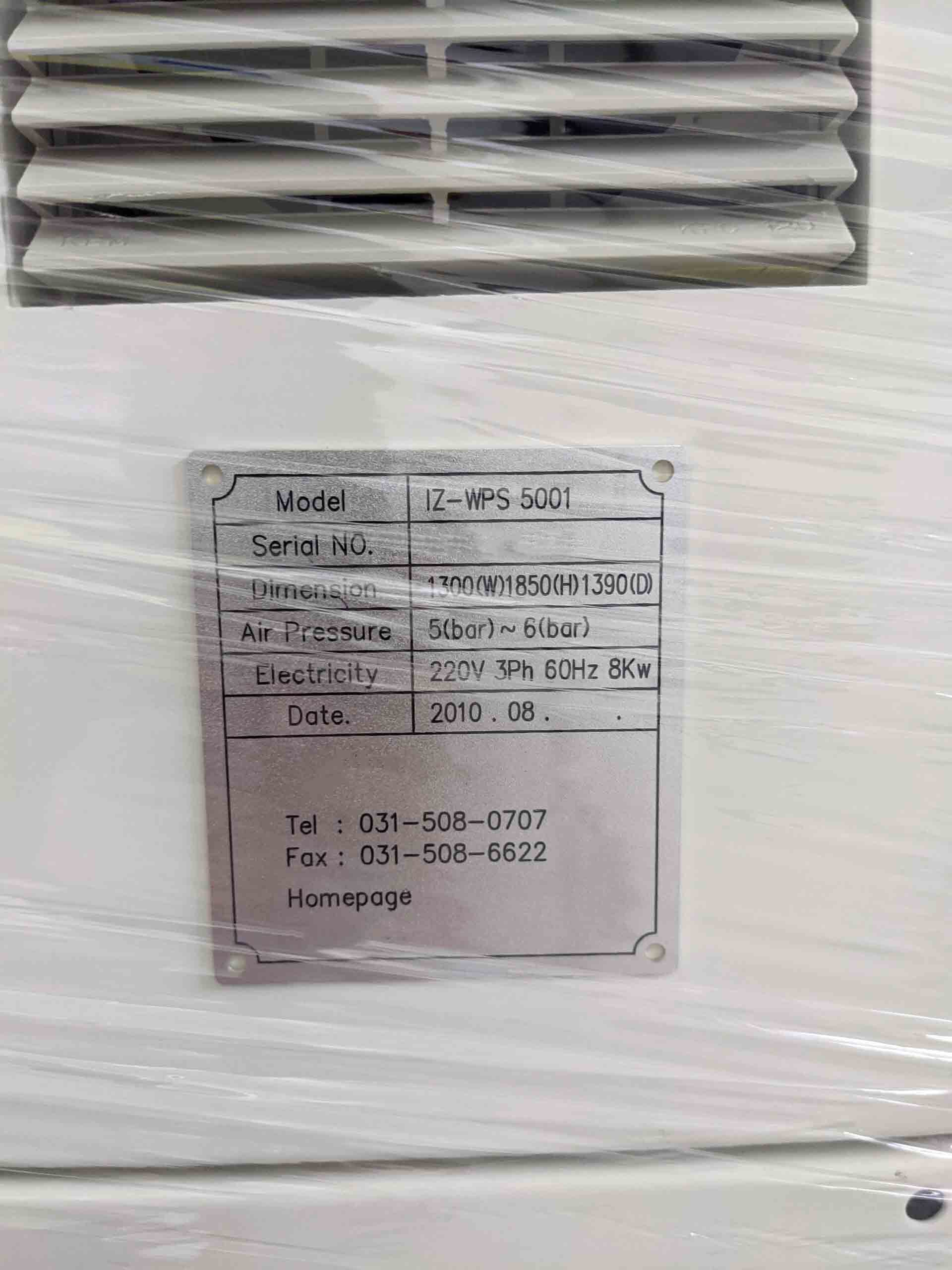

Used INNOBIZ IZ-WPS 5001 #9379296 for sale

URL successfully copied!

Tap to zoom

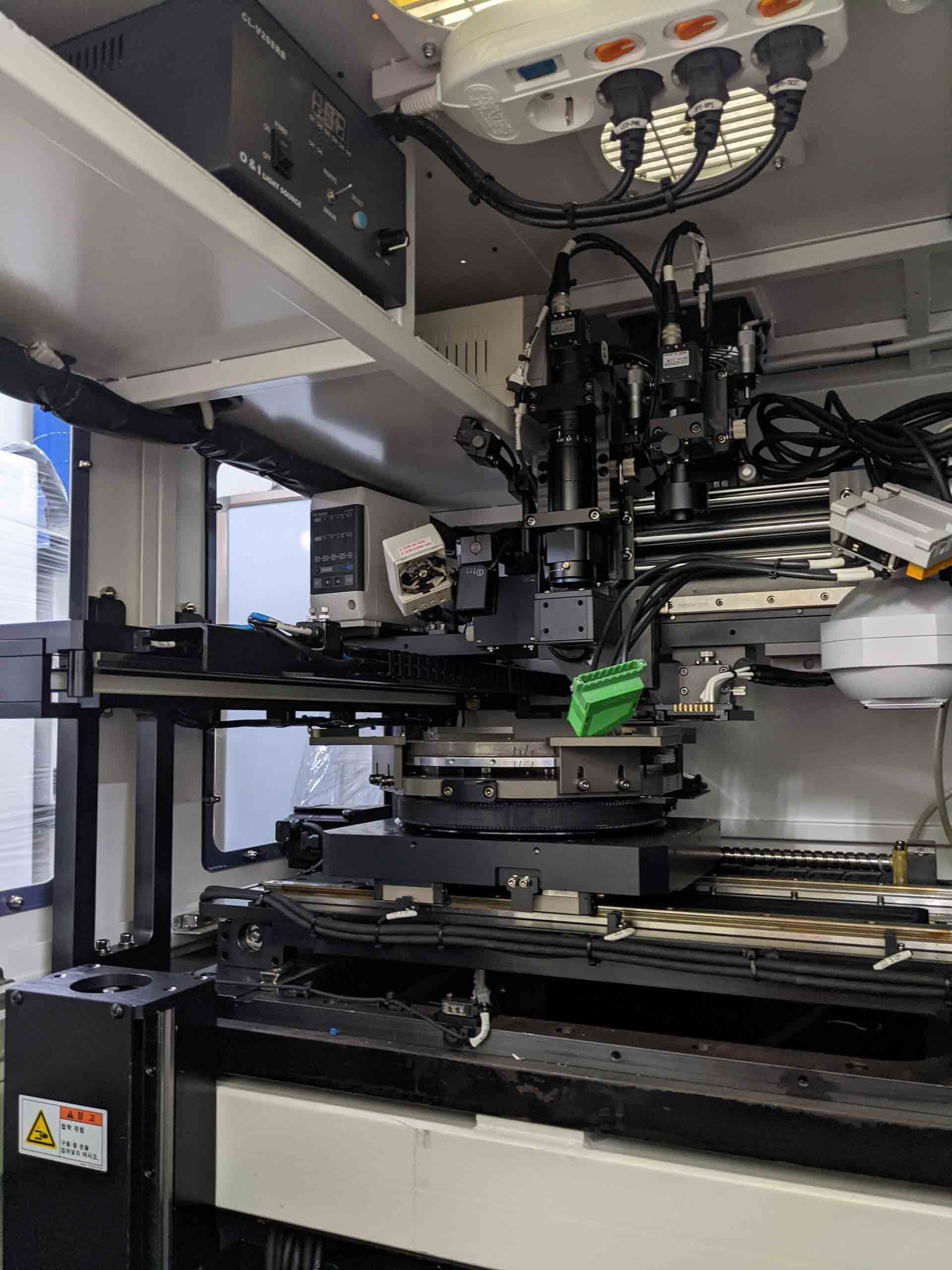

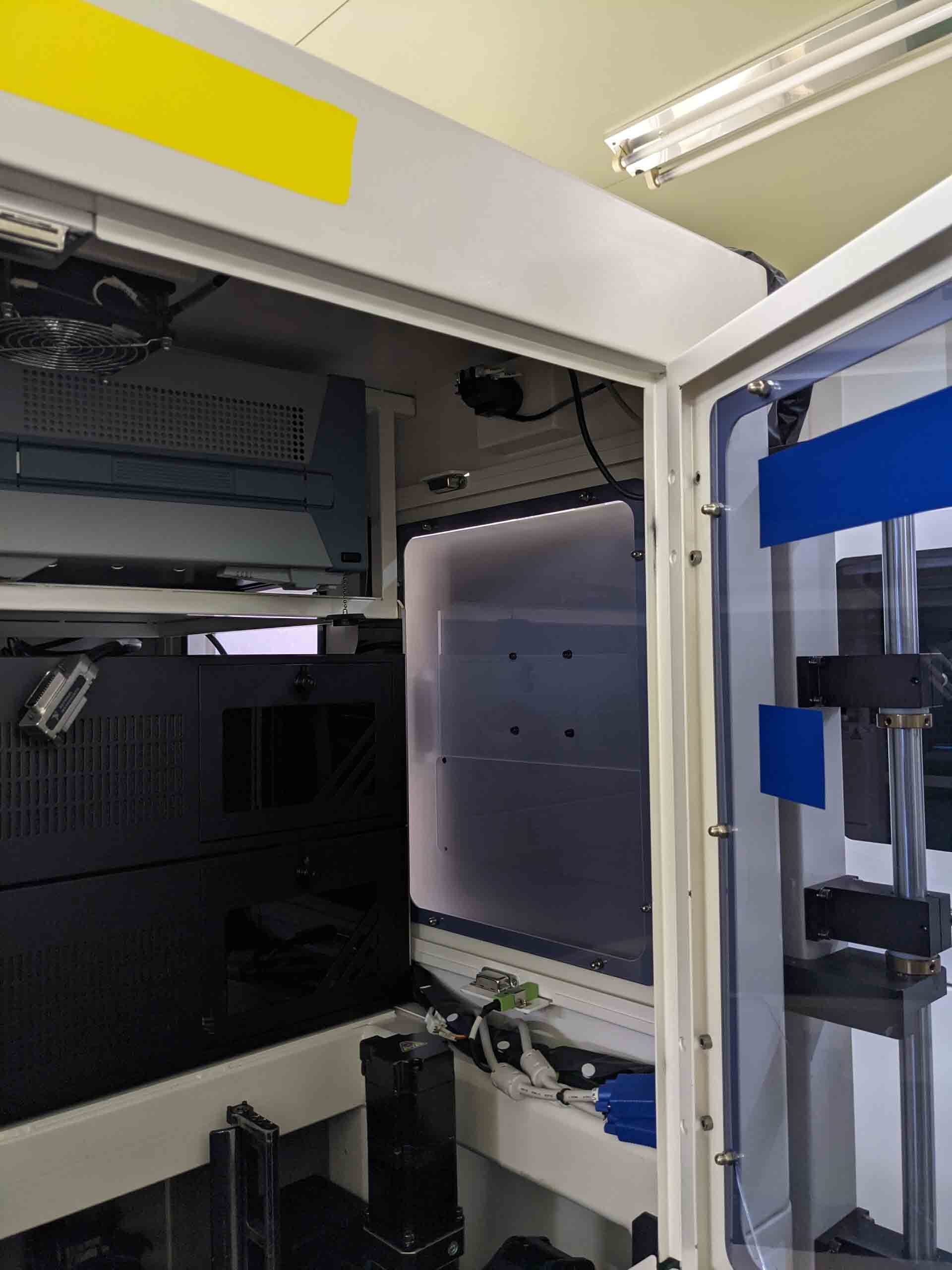

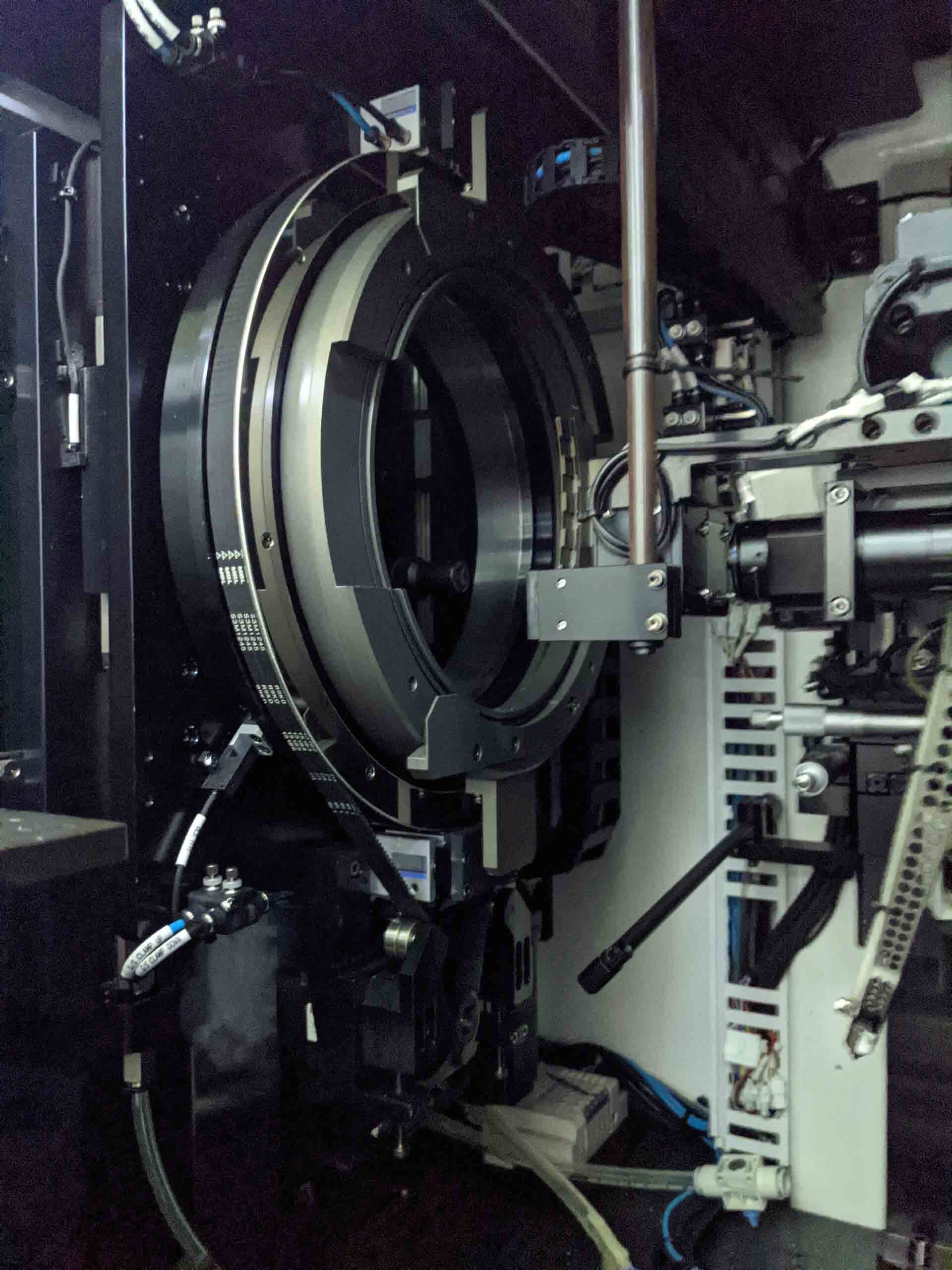

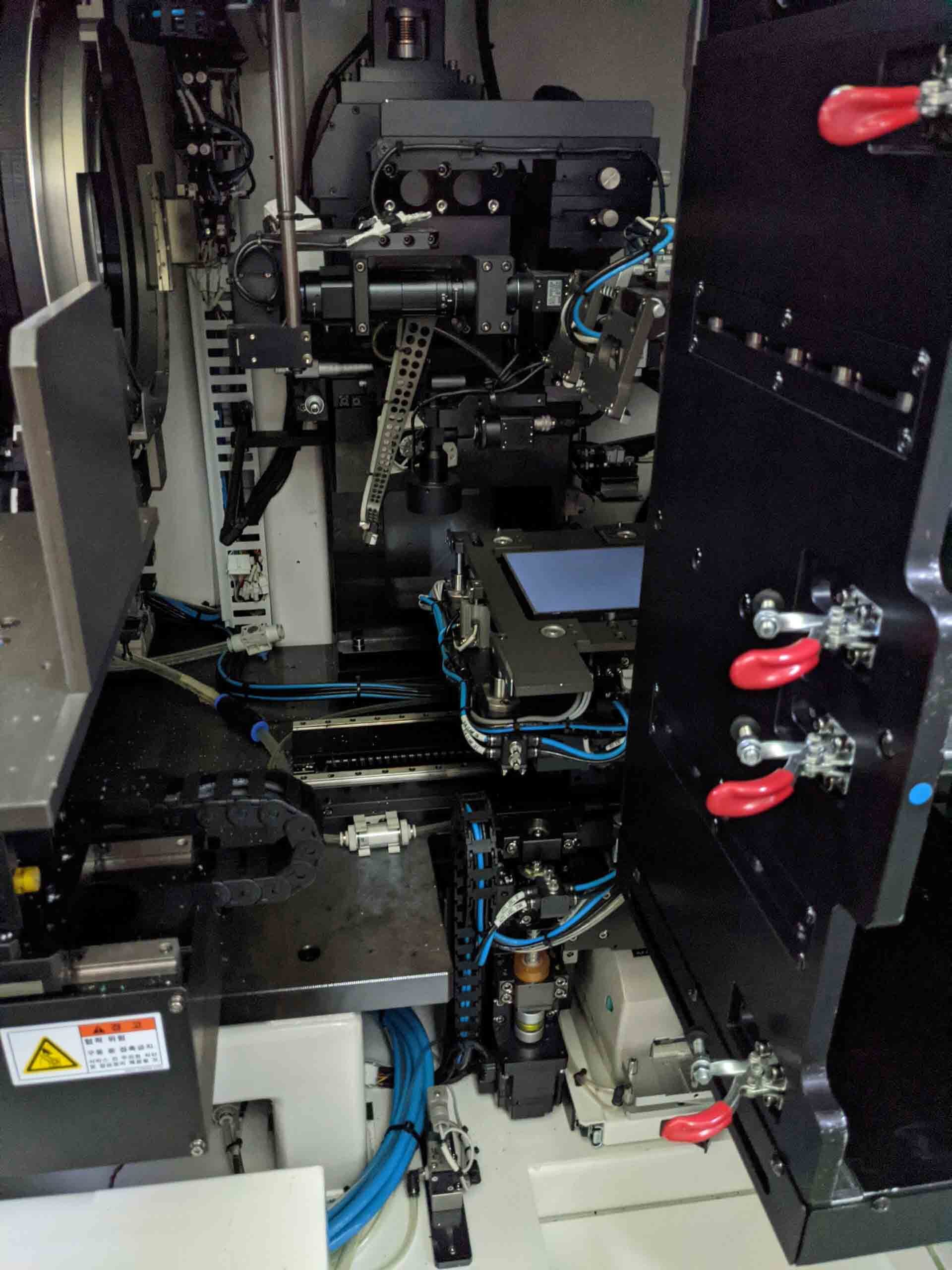

INNOBIZ IZ-WPS 5001 is an industrial dual probe prober designed to meet the requirements of high-volume manufacturing. It is a versatile, high-performance prober that can handle a wide range of probe cards up to 350mm x 250mm. This prober features a modular design, allowing easy and rapid exchange of probing and probing accessories. IZ-WPS 5001 is equipped with two independent X, Y, Z motion, and two coil based linear Z lift motion for optimized accuracy in both fast wafer probing and reticle probing. It is outfitted with a pair of tool probes, each of which has a range of 1mm to 8mm in X-axis. The tool probes feature low/high speed mode, high accuracy mode, and special modes for double probing. Additionally, the prober is equipped with a 5-axis precision chuck, 6-axis high-speed scanning, and high-speed scanning for nozzles. INNOBIZ IZ-WPS 5001 also features an optimized layout for easy operation and maintenance. It boasts a professional wafer measurement system with automatic light correction, real-time color monitoring, and a wafer-level defect detection system. With its quick change capabilities, the prober can be used for quick rework operations. This makes IZ-WPS 5001 an ideal choice for high-volume production. INNOBIZ IZ-WPS 5001 includes an advanced controller with a robust software library. It is equipped with auto point tester, sweep test, open/short test, and can support pattern comparison. Additionally, the prober offers a range of interchangeable accelerometers, thermocouples, and wafer chuck adapters. The system can store up to 400 user-defined recipe settings, which can be easily loaded and changed on the menu screen. In combination, these features offer unprecedented precision and consistency for a wide variety of probing operations. IZ-WPS 5001 is designed for easy integration with automated equipment systems such as assembly and test systems. Its robust design ensures a reliable and stable operating environment, with high reliability and repeatability. As such, it is ideal for use in high-volume manufacturing environments, ensuring efficient and high-quality repeatable results.

There are no reviews yet