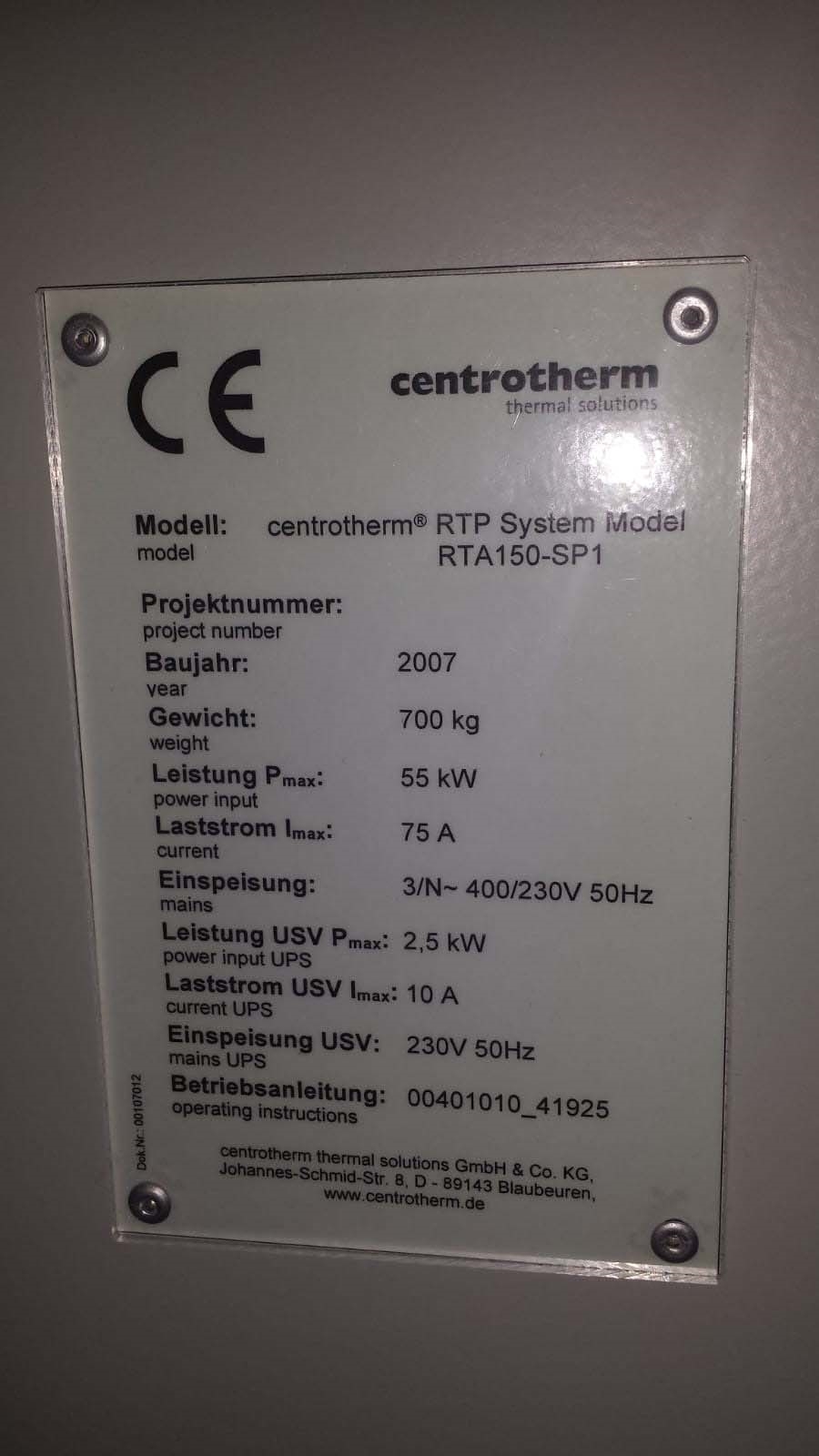

Used CENTROTHERM RTA 150 #9239213 for sale

URL successfully copied!

Tap to zoom

ID: 9239213

Wafer Size: 6"

Vintage: 2007

System, 6"

Heating power: 50 kW

Max process temperature: 1200°C

Max ramp rate: 150 K/s

Temperature accuracy: ±0.5 K

Processing gases: N2, N2H2

Heating system: (24) Lamps, PWM

Pressure controlled vacuum / Atmospheric

LEYBOLD HERAEUS Dura Dry 105 Vacuum pump

Applications:

Annealing

Dopant activation

Dry oxidation

Metal contact anneal

Barrier metal anneal

2007 vintage.

CENTROTHERM RTA 150 is a rapid thermal processor manufactured by Centrotec Sustainable AG, a technology company based in Germany. It is a reliable, efficient, and powerful tool used by semiconductor and electronics manufacturers for thermal processing. The equipment is designed to provide rapid, precise, and uniform thermal treatments for a wide variety of substrates and materials. RTA 150 is capable of heating, cooling, and curing thermal processes in a few seconds. It uses a patented cool-down technology to cool substrates as fast as 24°C per second. This rapid cool-down technology ensures consistent, repeatable, and uniform results. The system is equipped with a fast thermal processor, allowing for quick temperature transitions and accurately reproducing pre-setted temperature profiles. The versatile CENTROTHERM RTA 150 provides best-in-class temperature uniformity, with an average top temperature ±1°C over the entire course of the process. This makes the unit ideal for modern, challenging processes, such as copper pillar bumping, ultra-thin die attach, and chip scale package flip-chip assembly processes. The machine comes with several built-in safety features, including pressure sensors and safety interlocks to protect the substrates, as well as temperature and gas monitoring. RTA 150 also has a user-friendly interface, allowing for remote monitoring and control of operations, as well as data logging and review. CENTROTHERM RTA 150 is an advanced rapid thermal processor designed to meet the needs of today's semiconductor and electronics manufacturing industry. Its fast thermal transfer capabilities make it an ideal choice for advanced processes, while its non-uniformity and safety features ensure consistent, reliable results.

There are no reviews yet