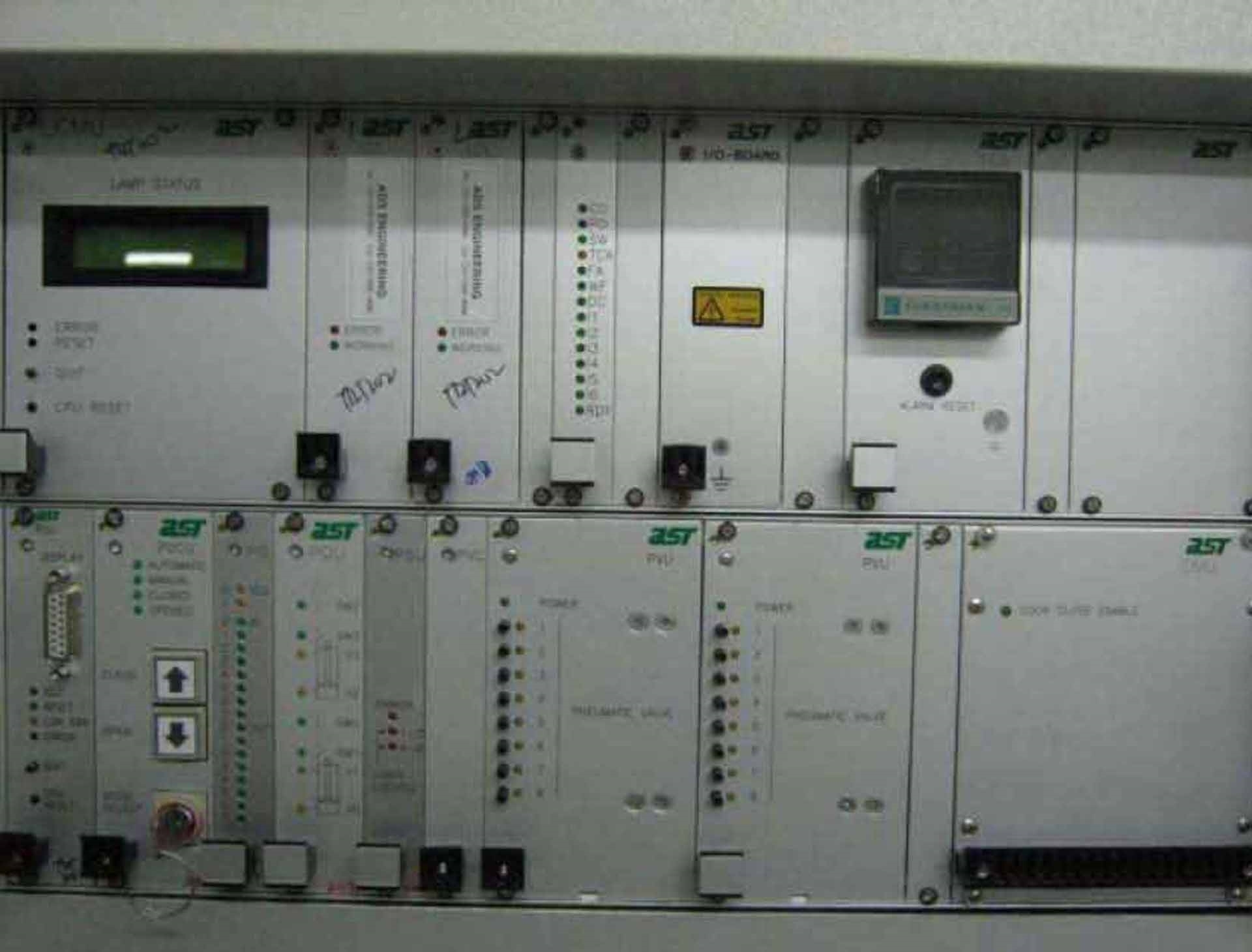

Used STEAG / MATTSON / AST 2800E #9103115 for sale

URL successfully copied!

Tap to zoom

ID: 9103115

Wafer Size: 8"

Vintage: 1994

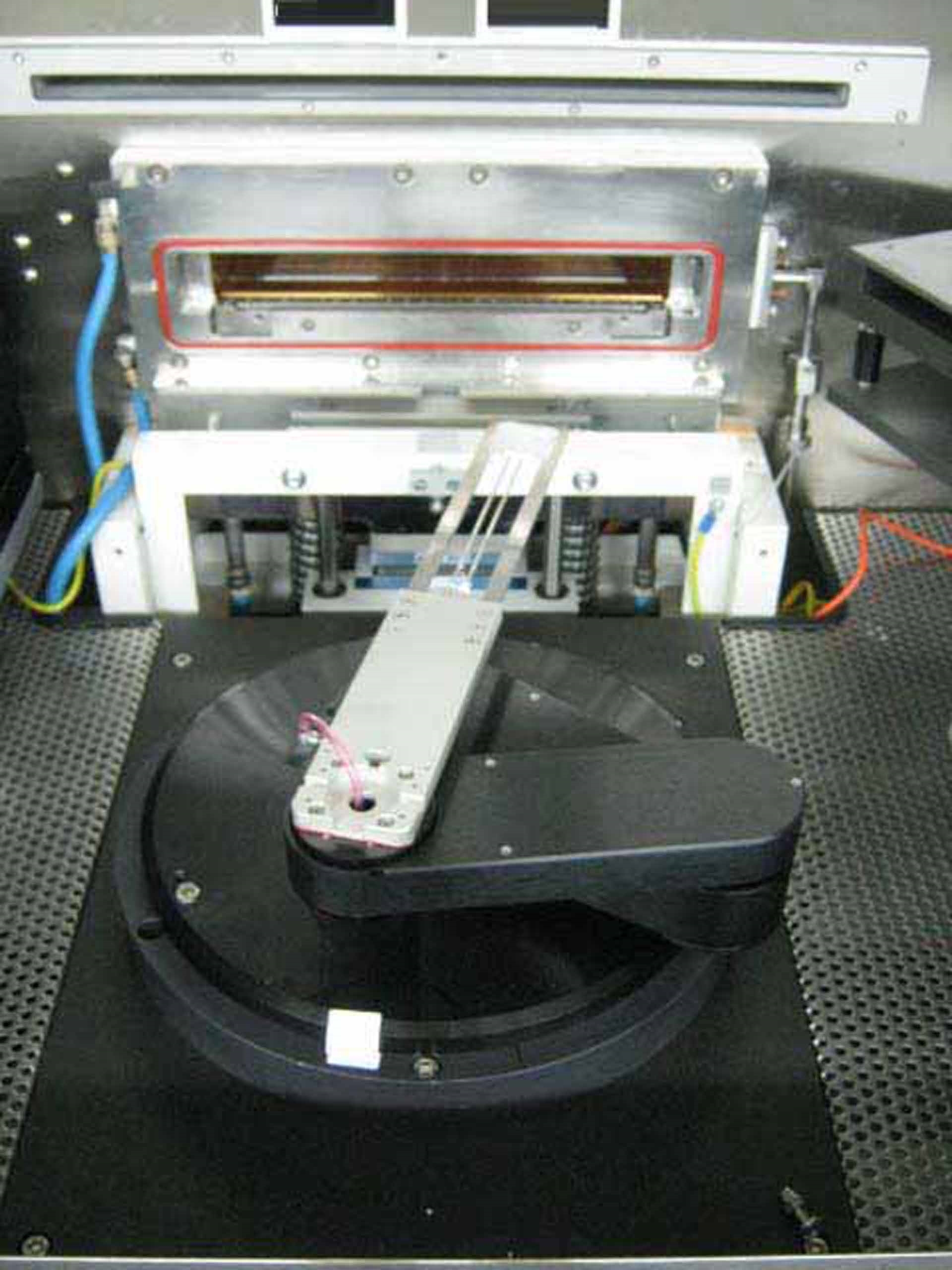

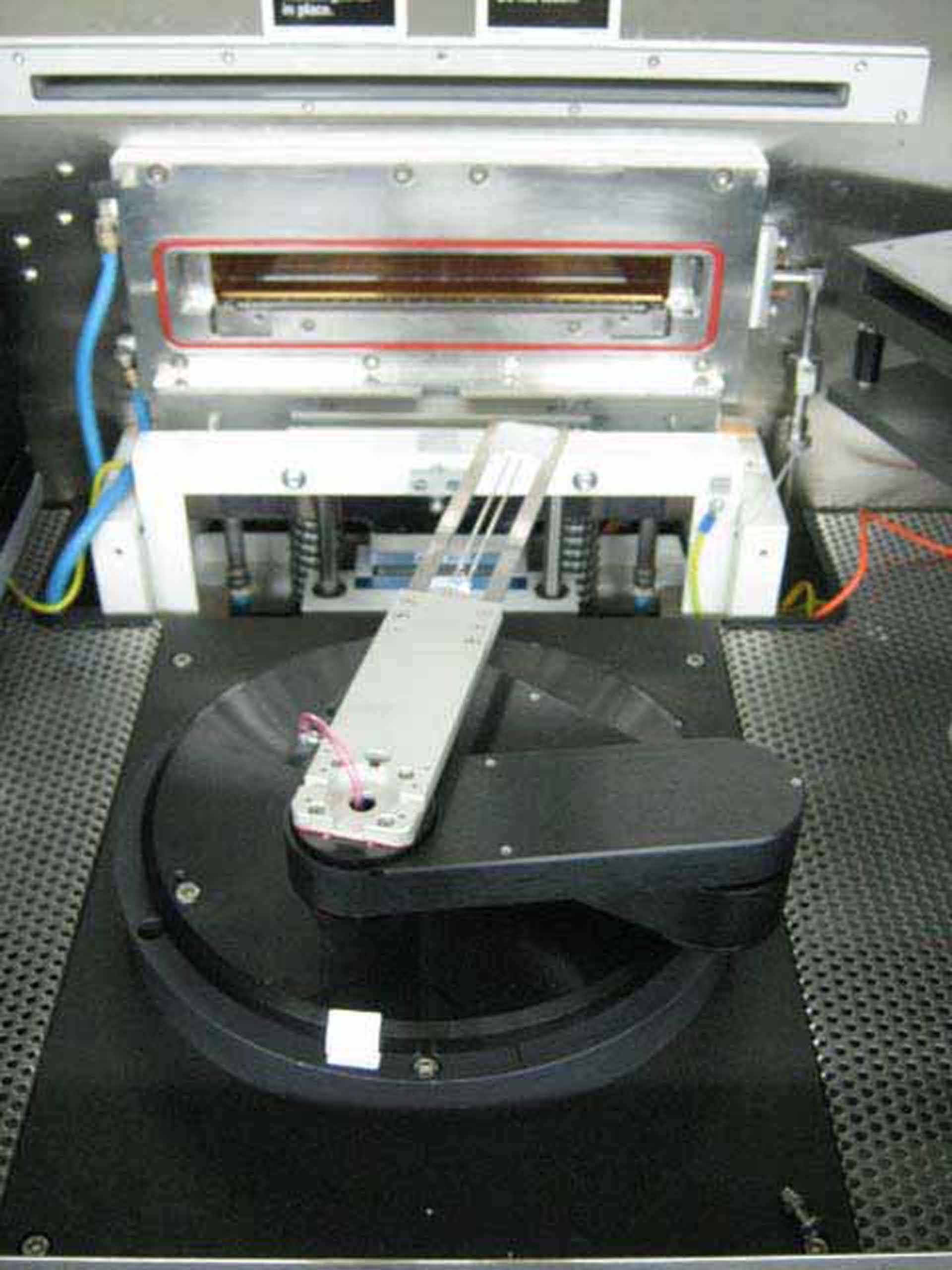

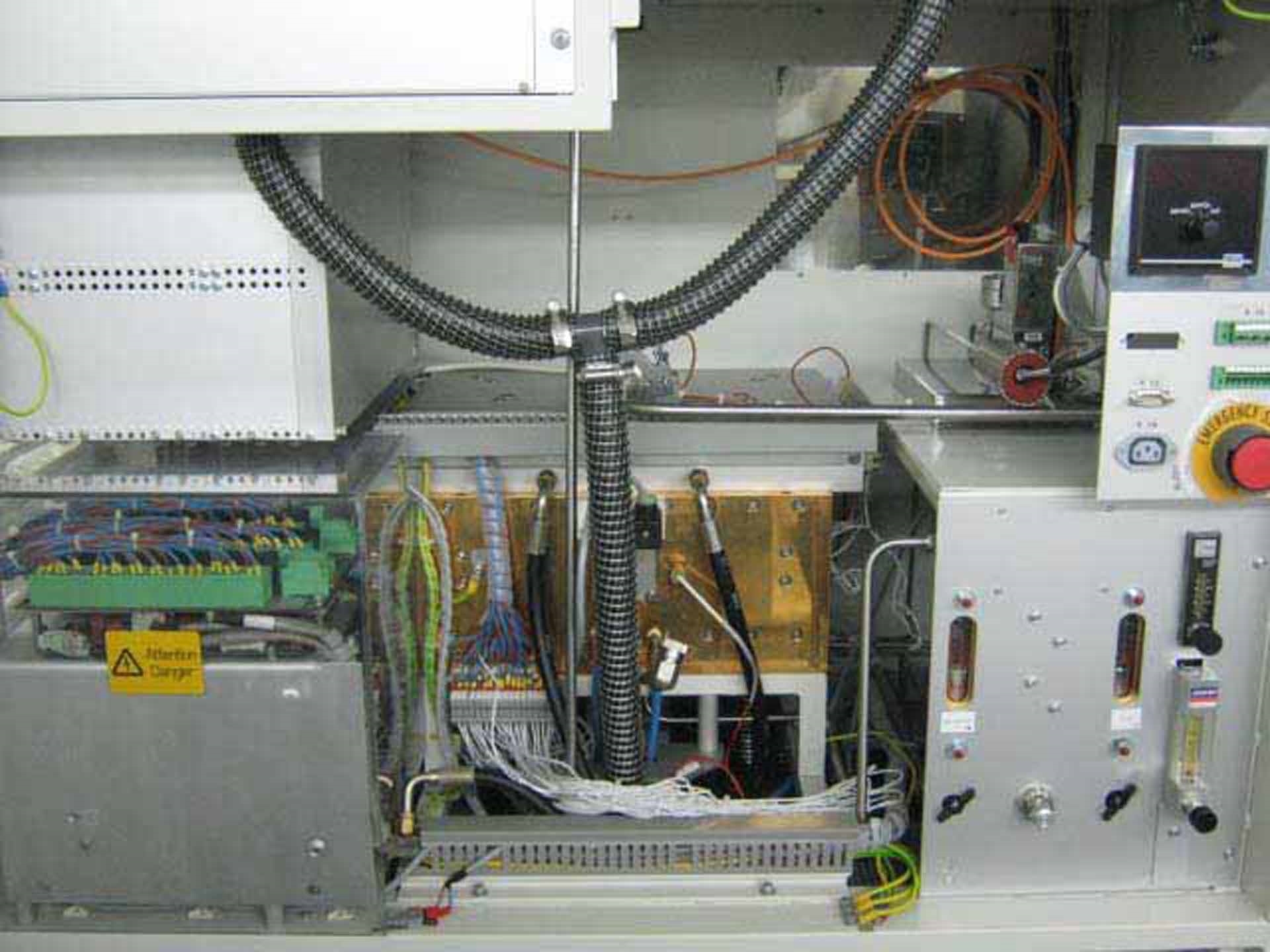

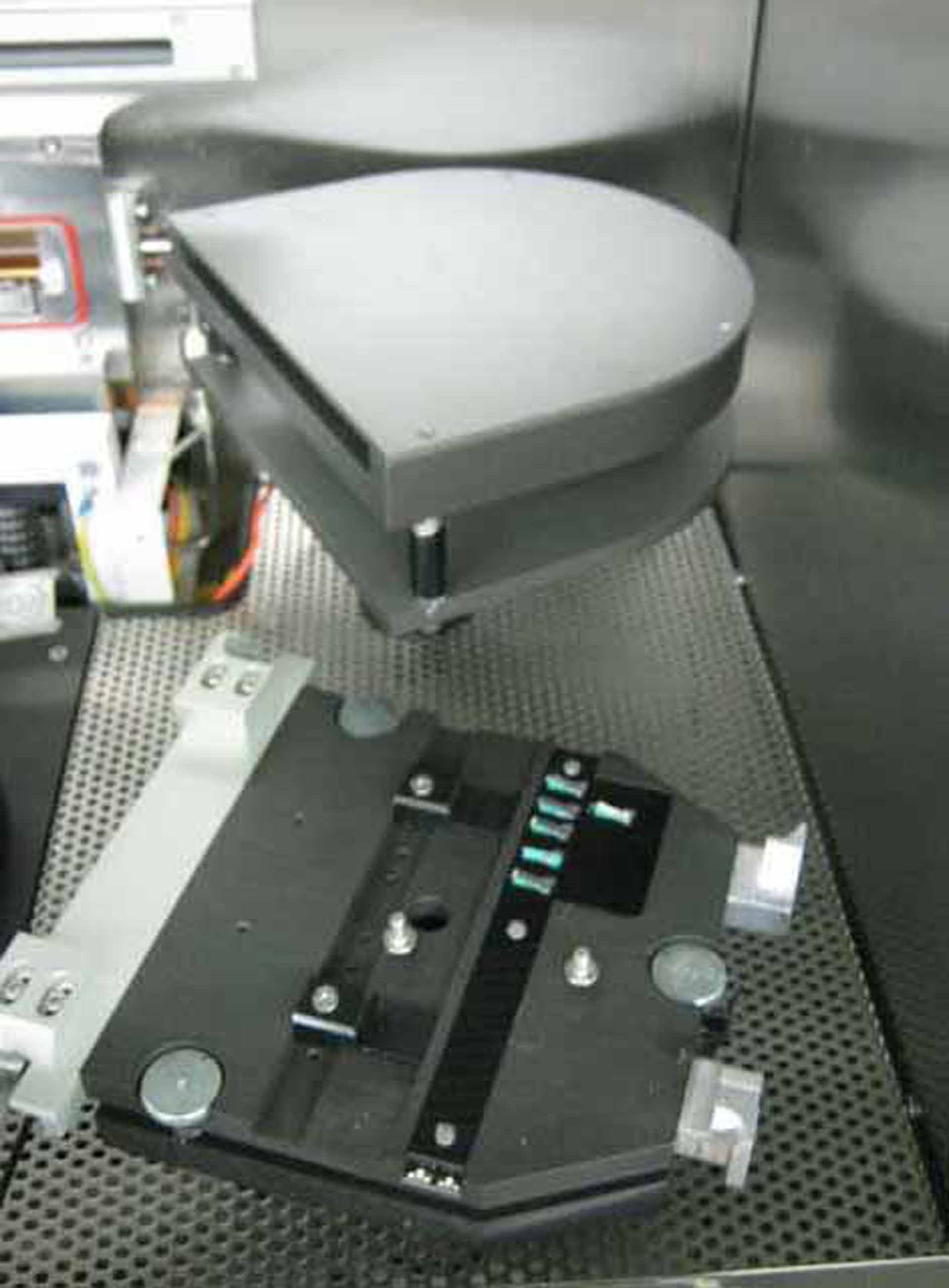

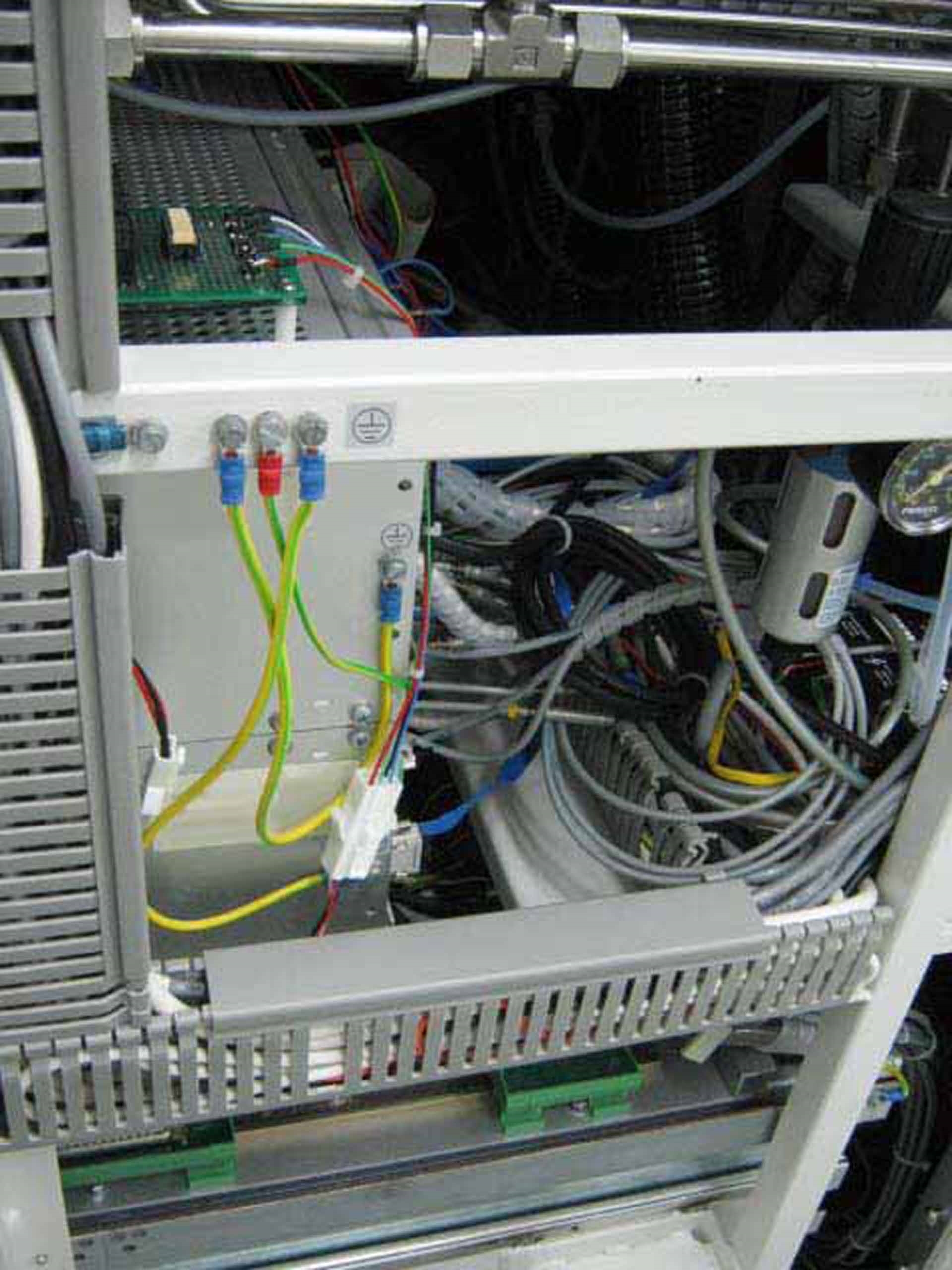

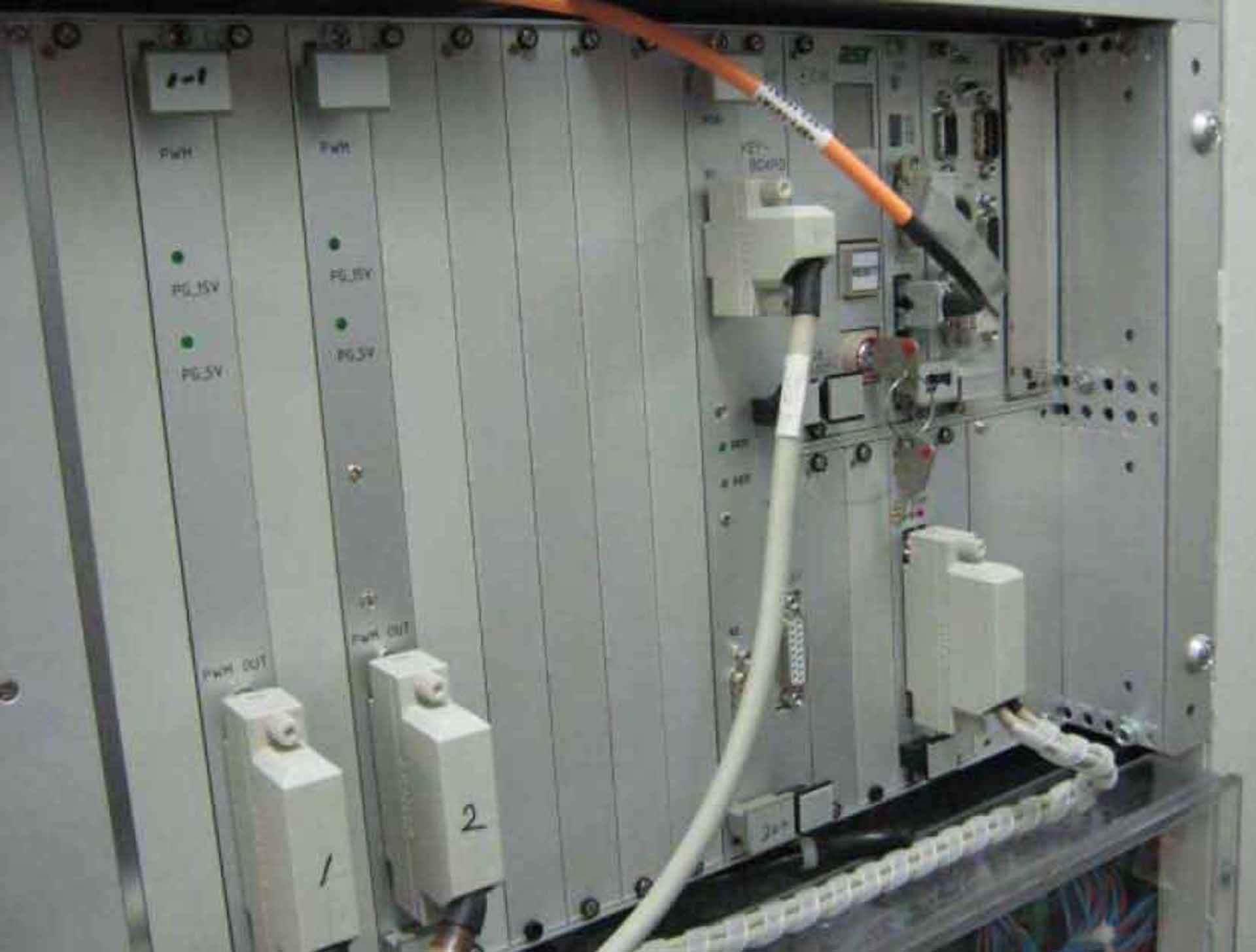

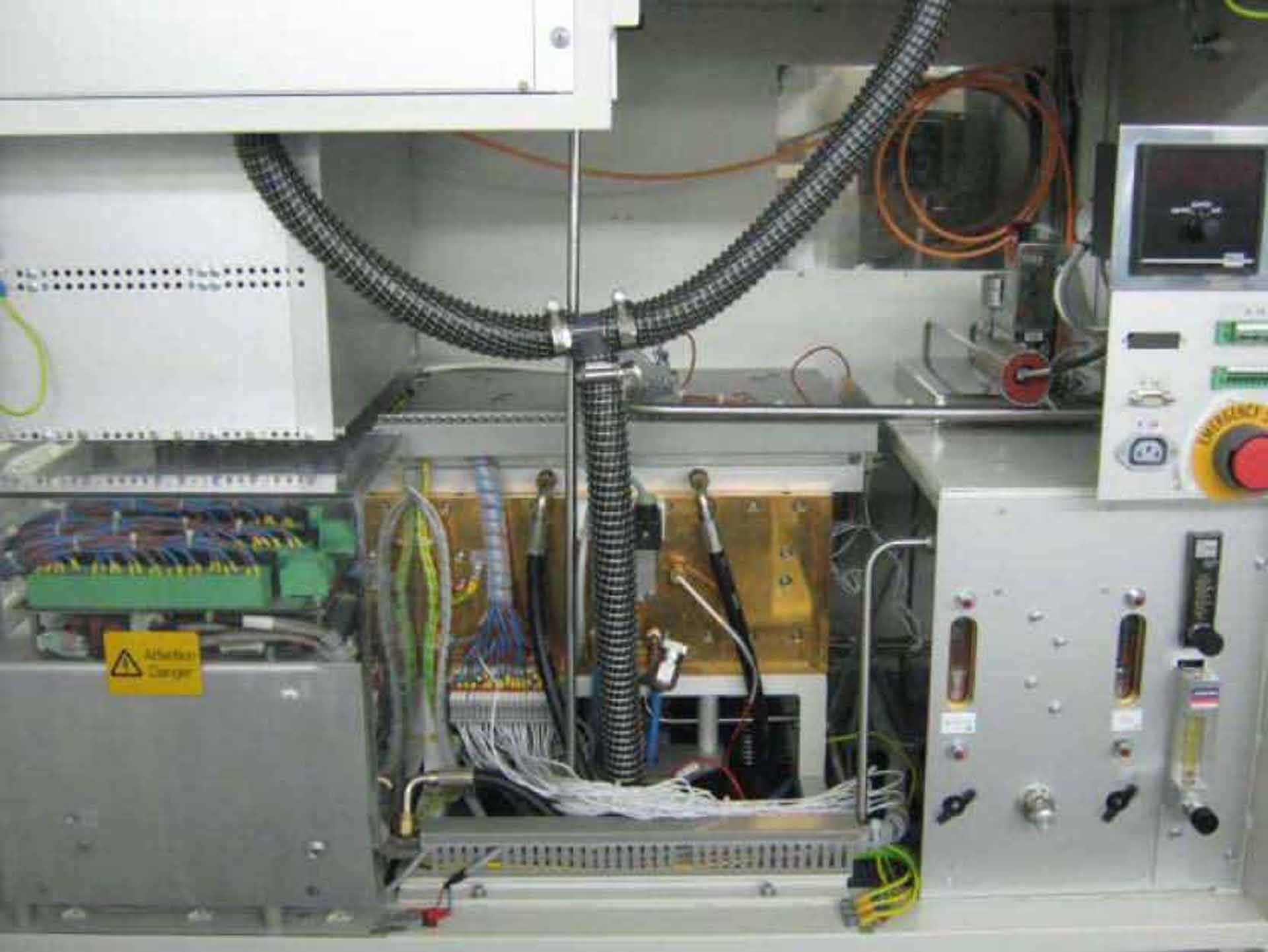

Rapid Thermal Processing (RTP) system, 8"

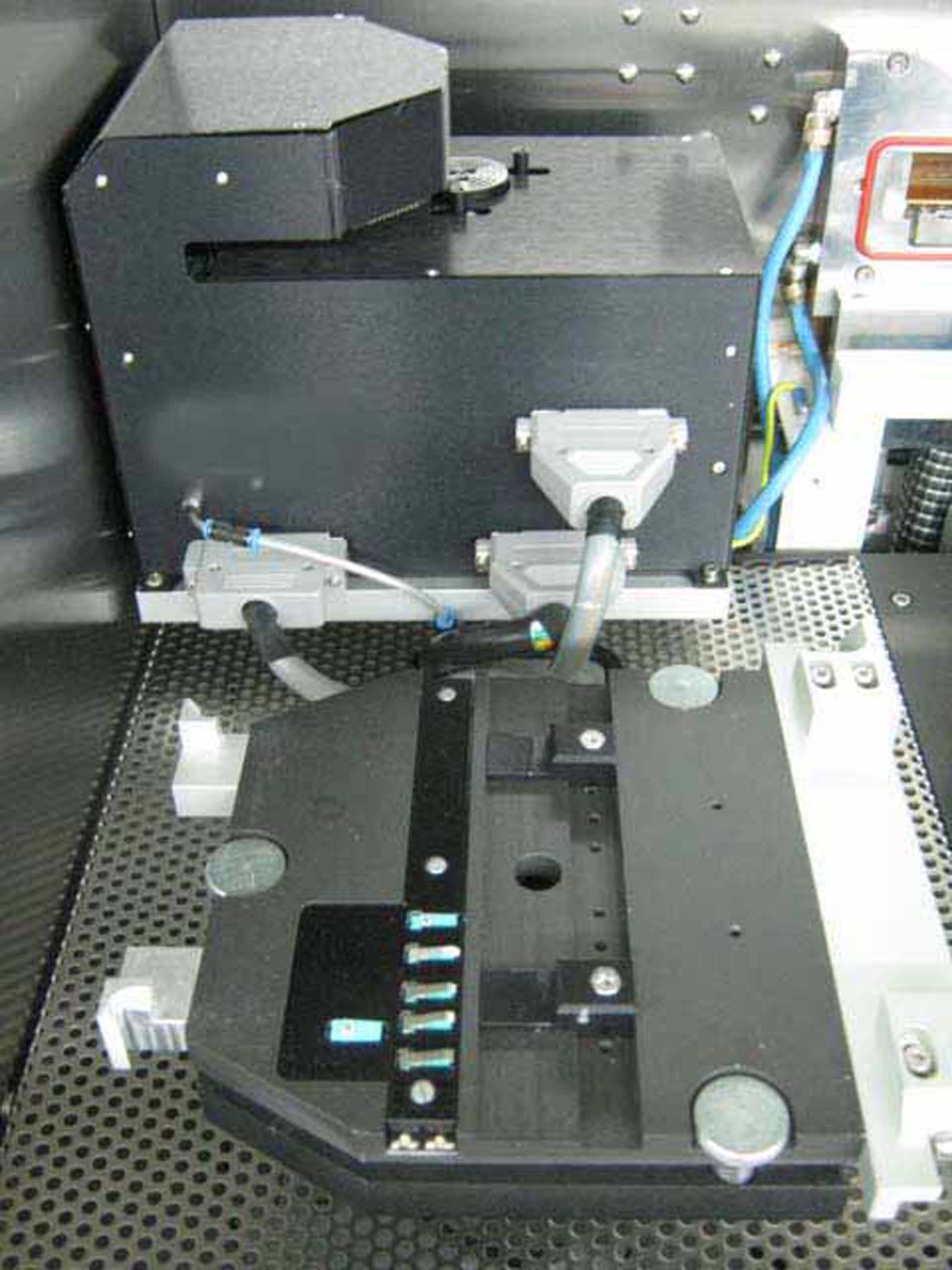

Single chamber

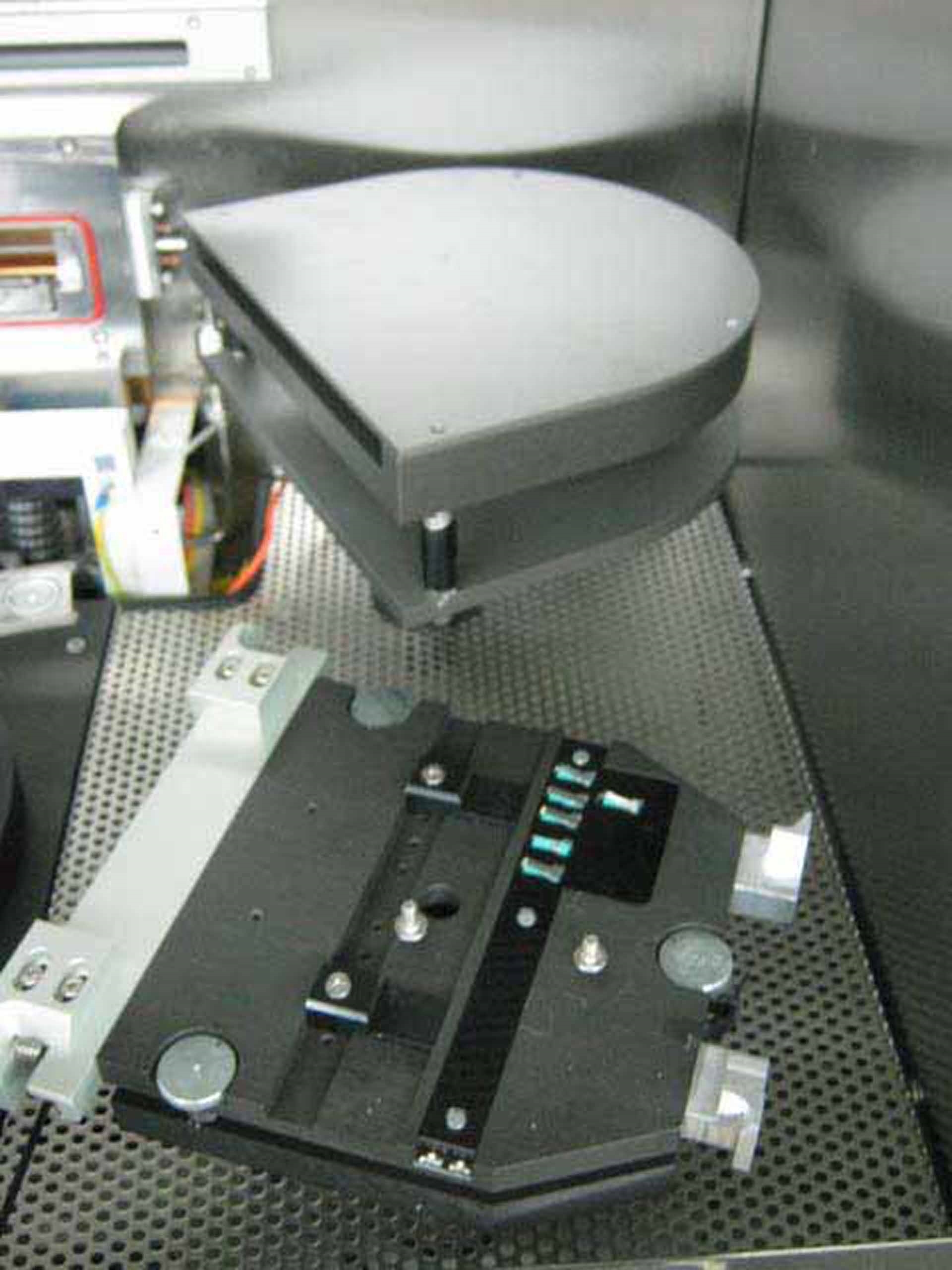

(2) Loaders

(2) Unloaders

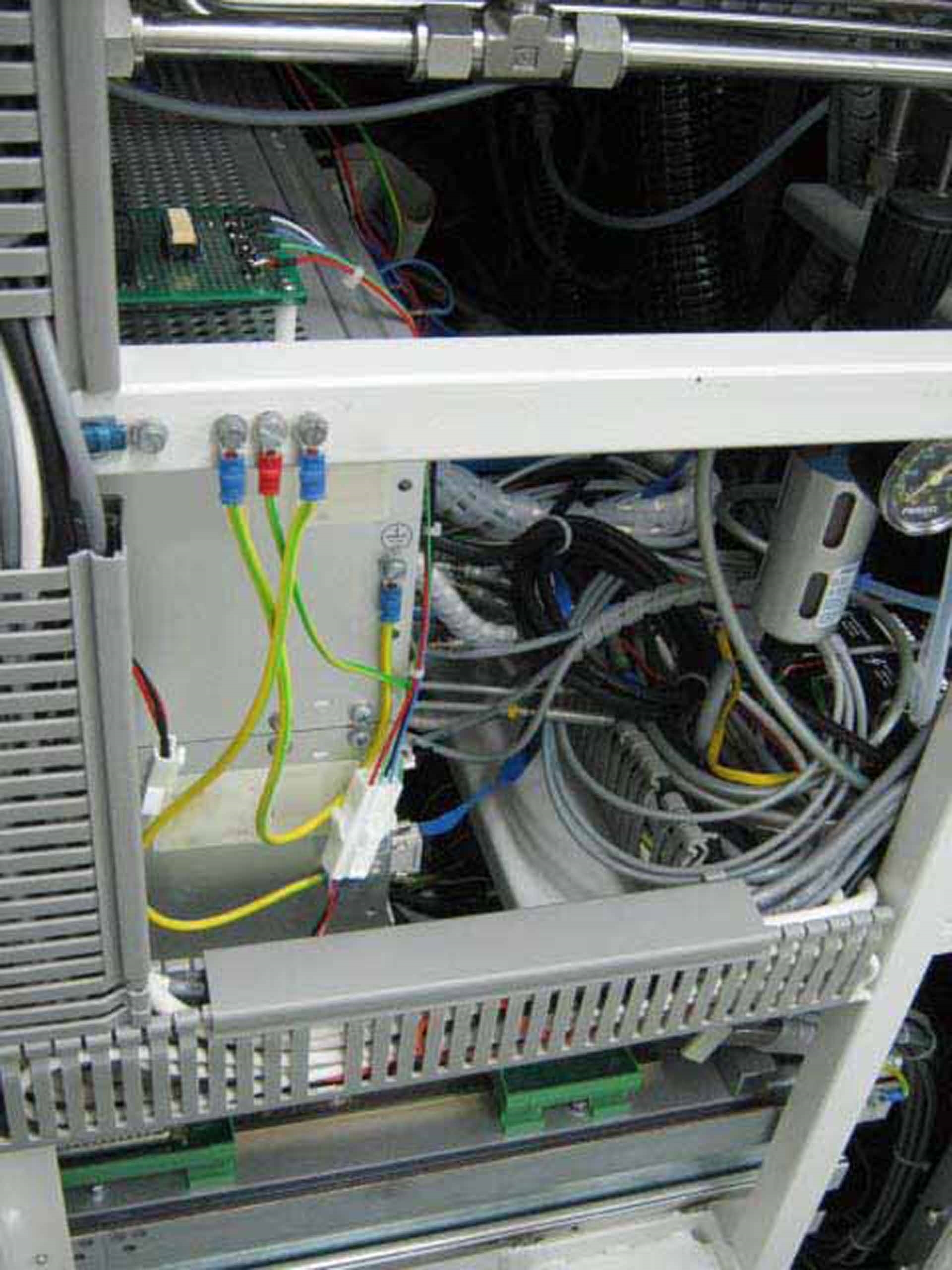

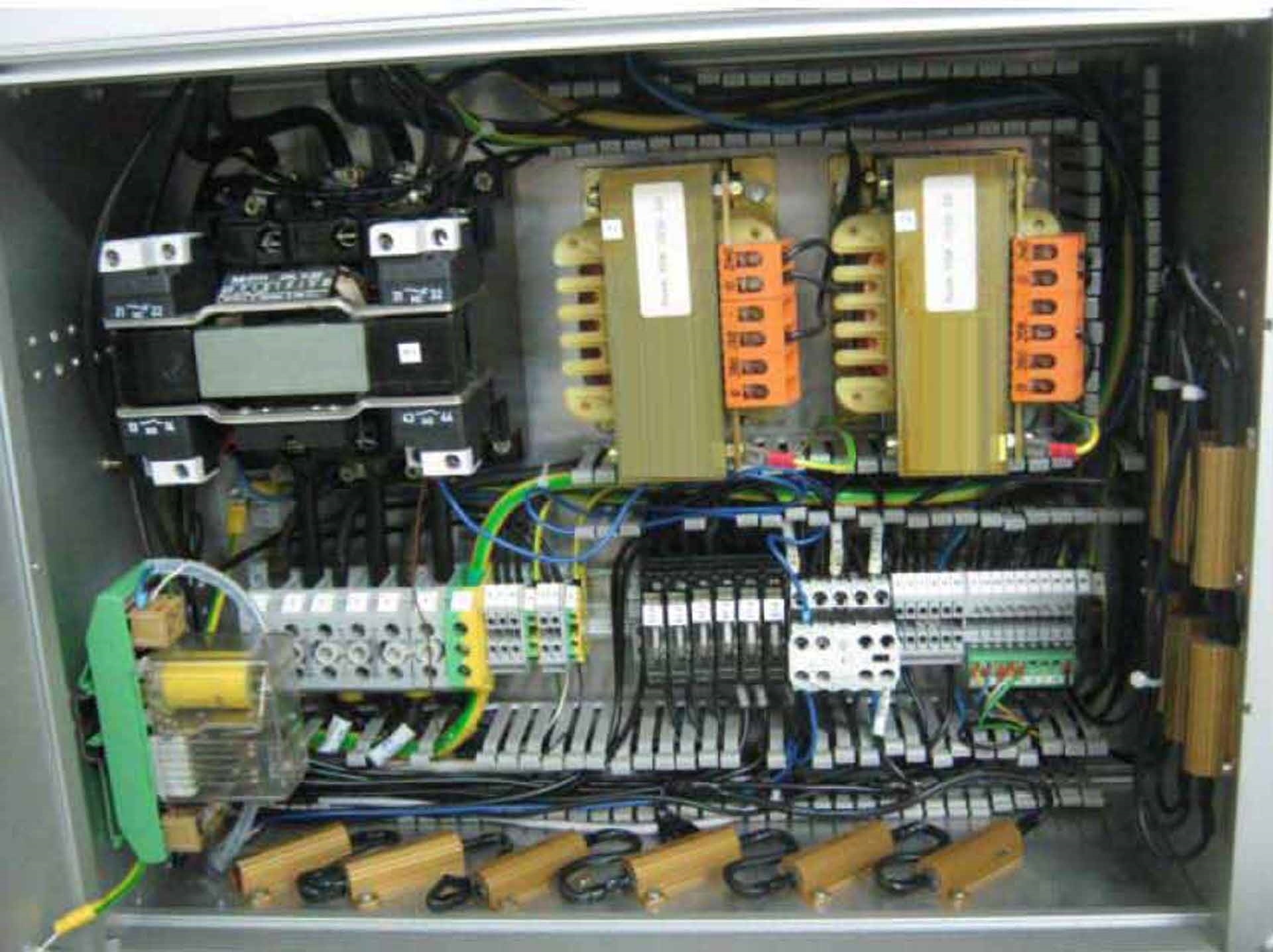

DC Power supply output stability: < 0.2 % at main power

Open cassette, 8"

Cassette rotate: Load / Unload position disable

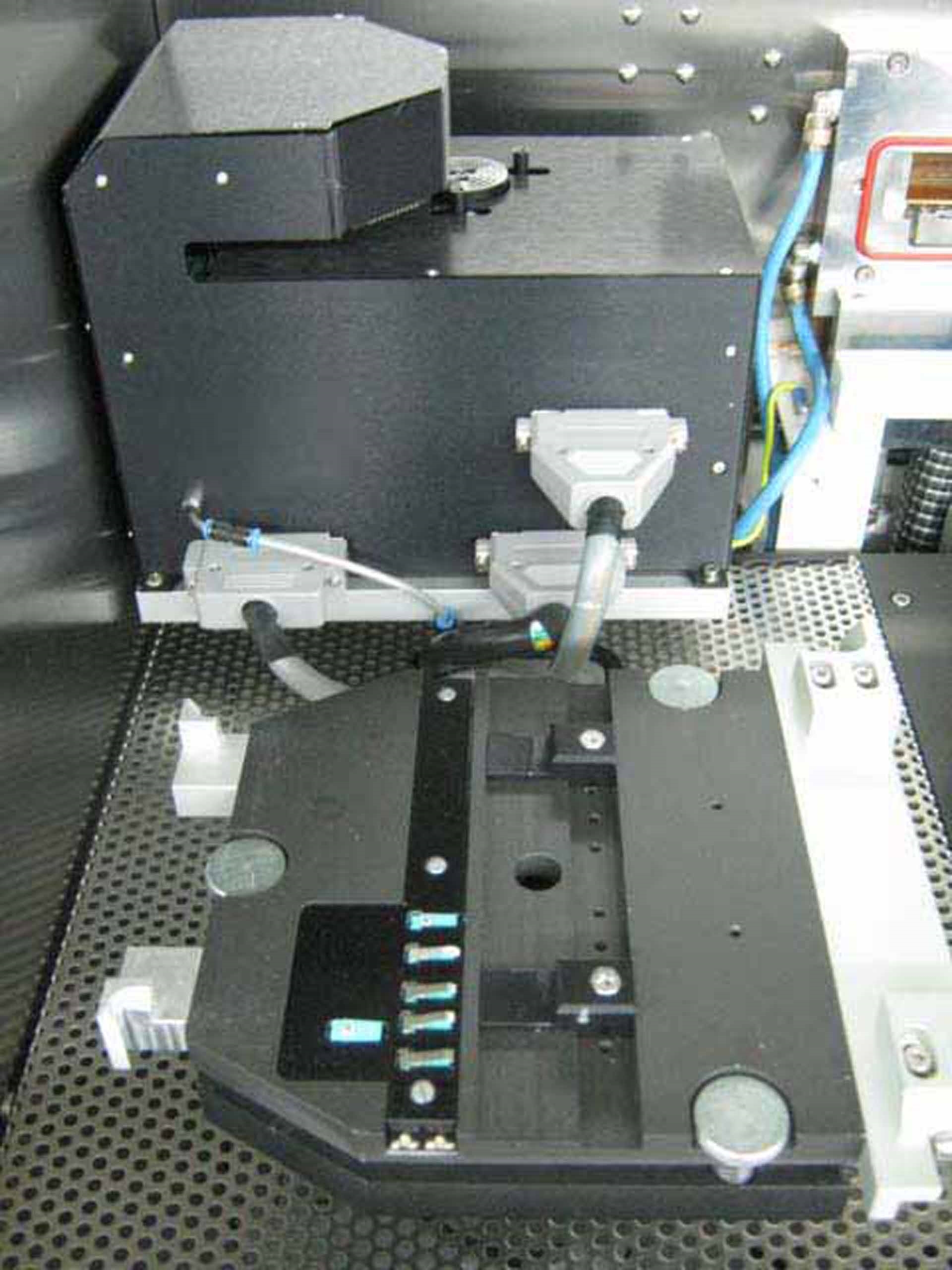

Wafer transfer: EQUIPE Robot

Flat aligner: EQUIPE Aligner

Operator panel: Touch screen LCD, 12"

Operating system: Windows NT

Process temperature range: 550°C ~ 1150°C

Temperature reading sensor: Pyrometer

O2 Contamination measurement sensor

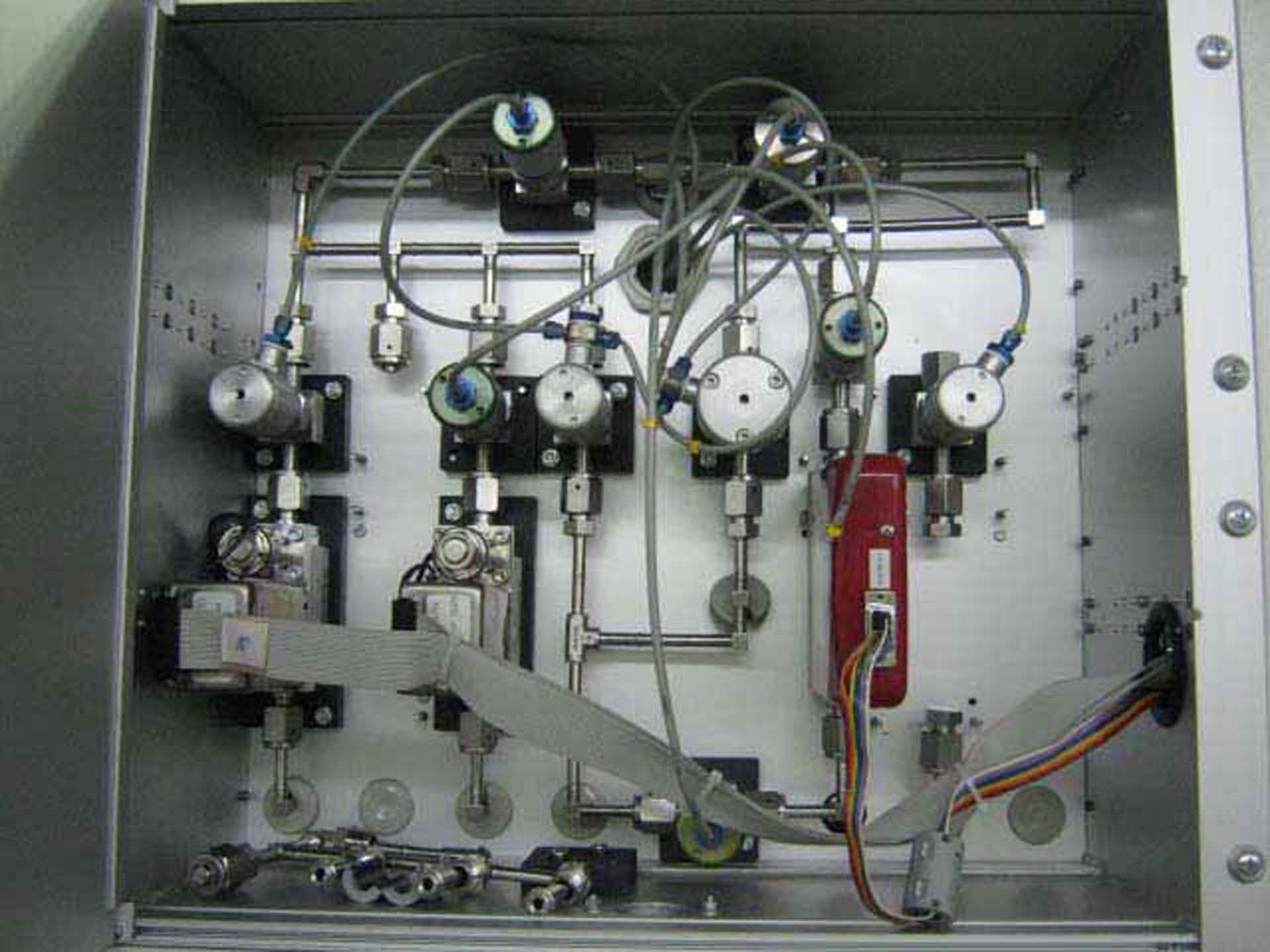

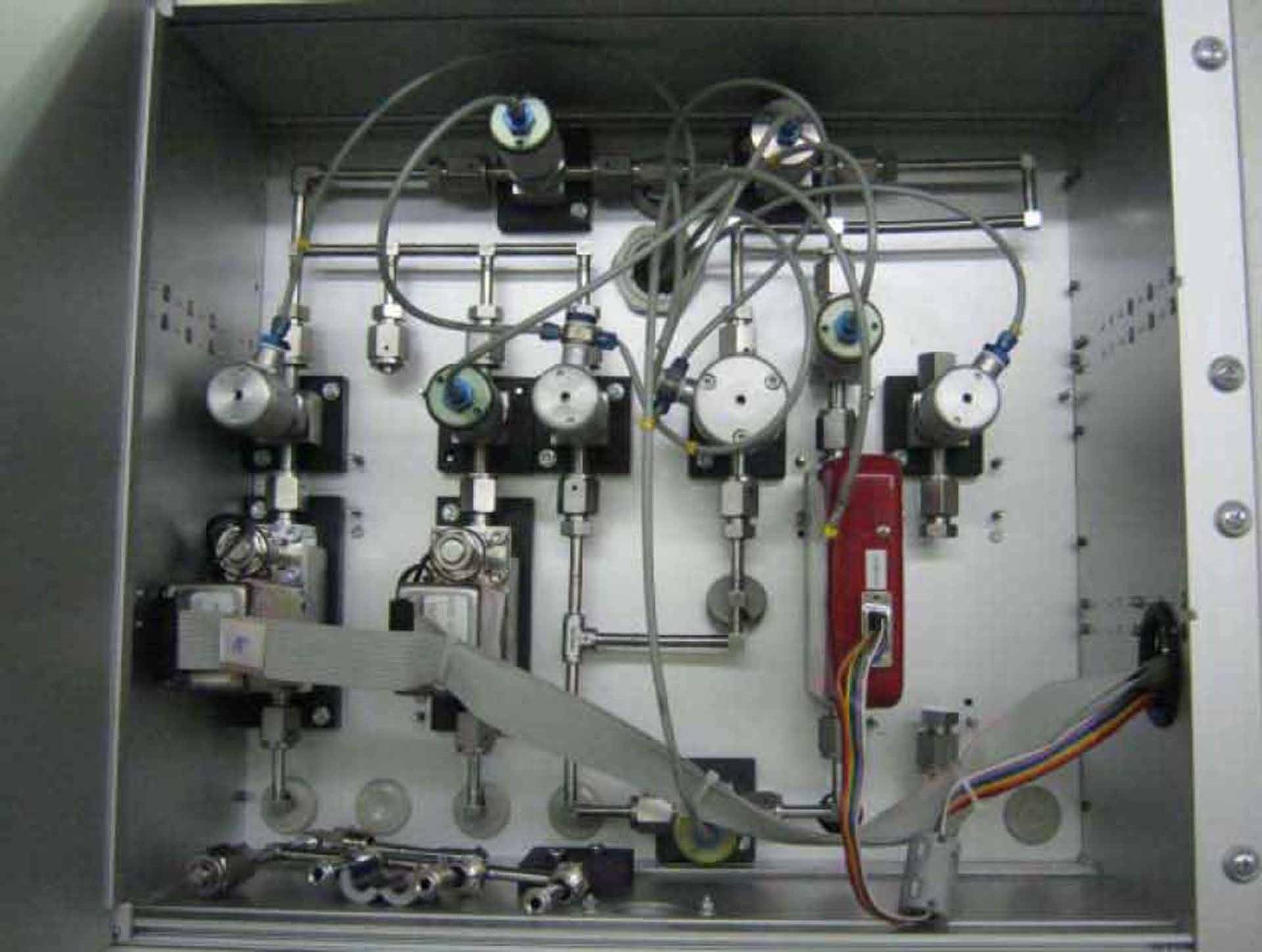

Gas lines:

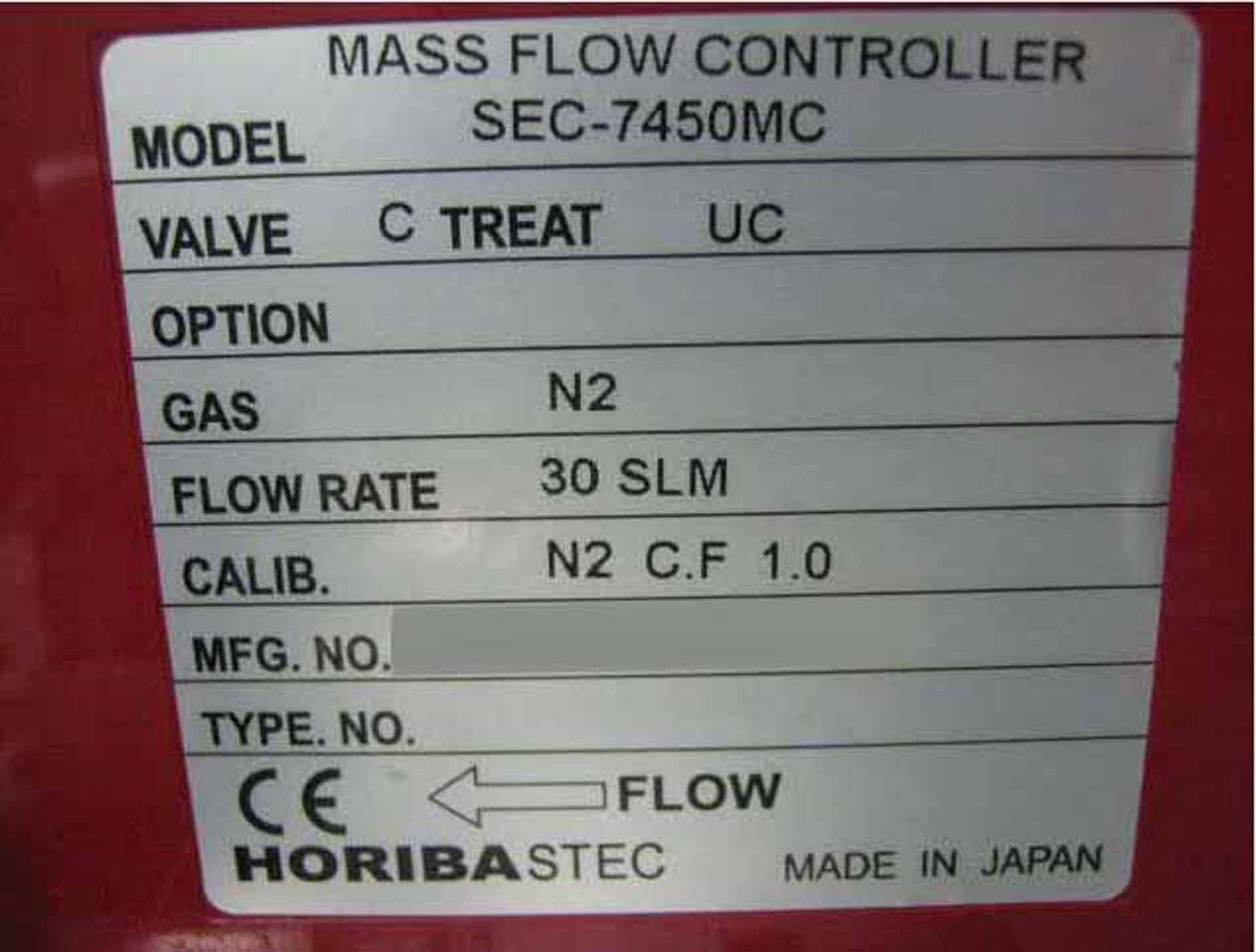

N2 (30 slm)

O2 (500 sccm)

Ar (10 slm)

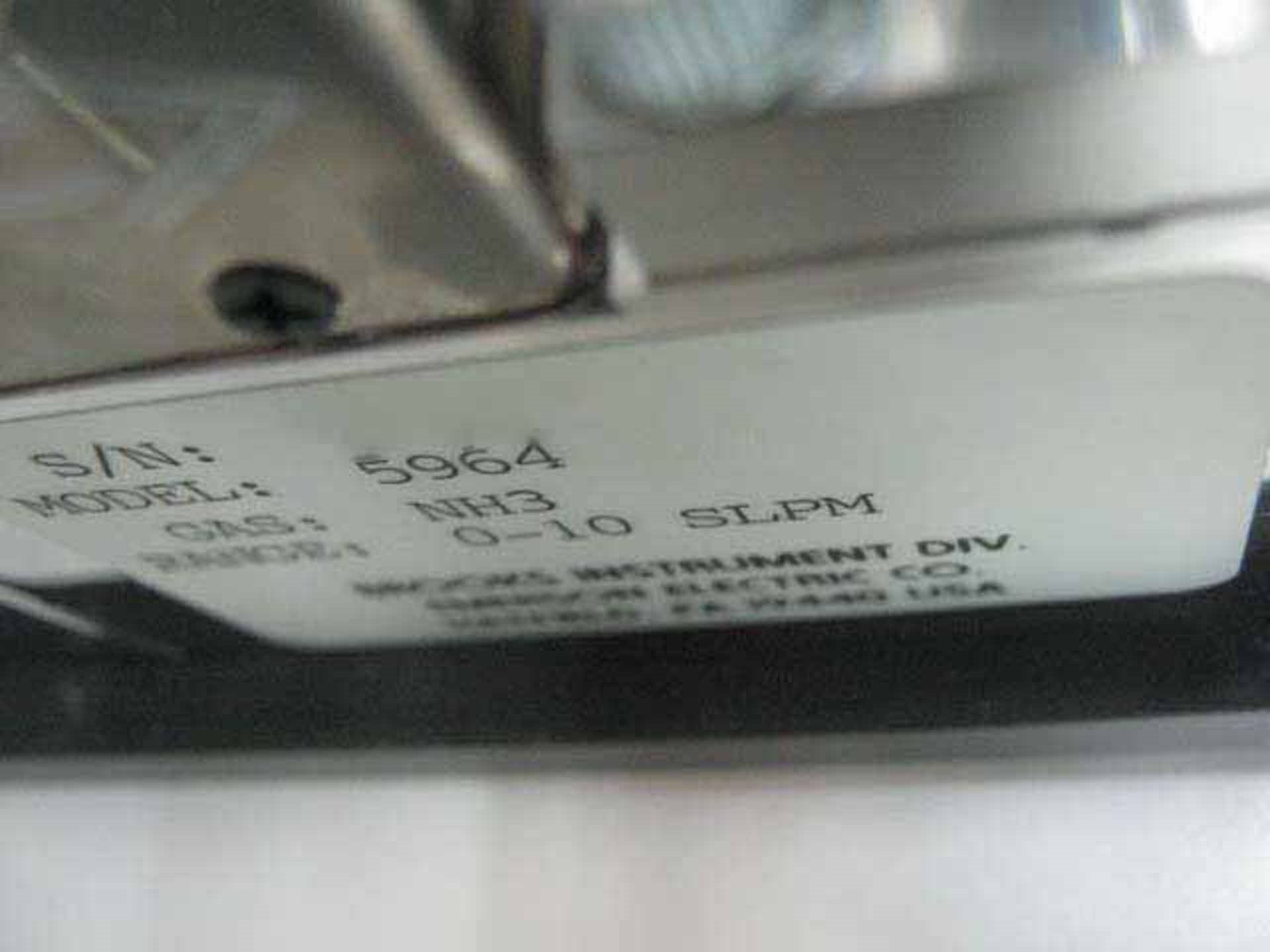

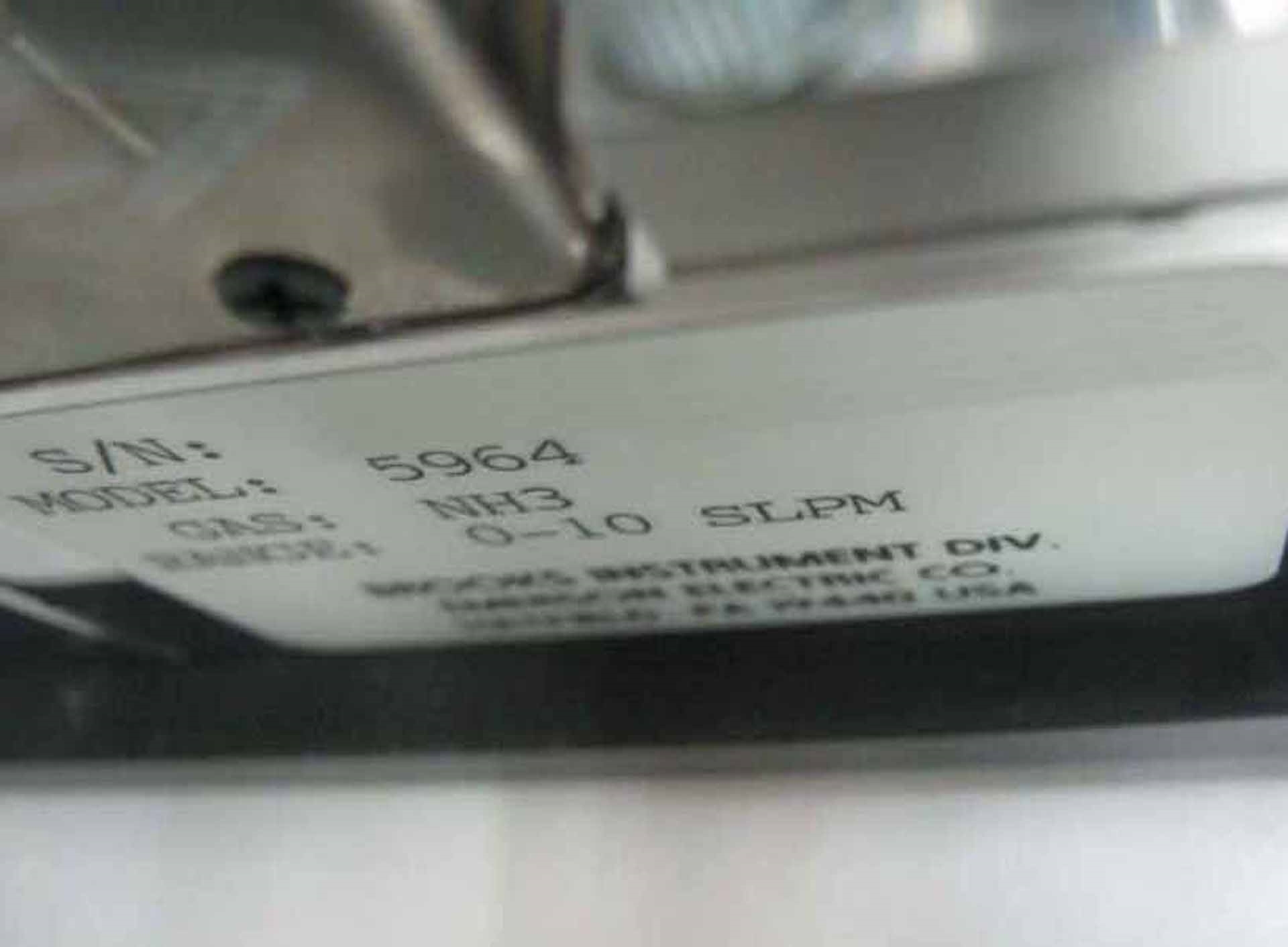

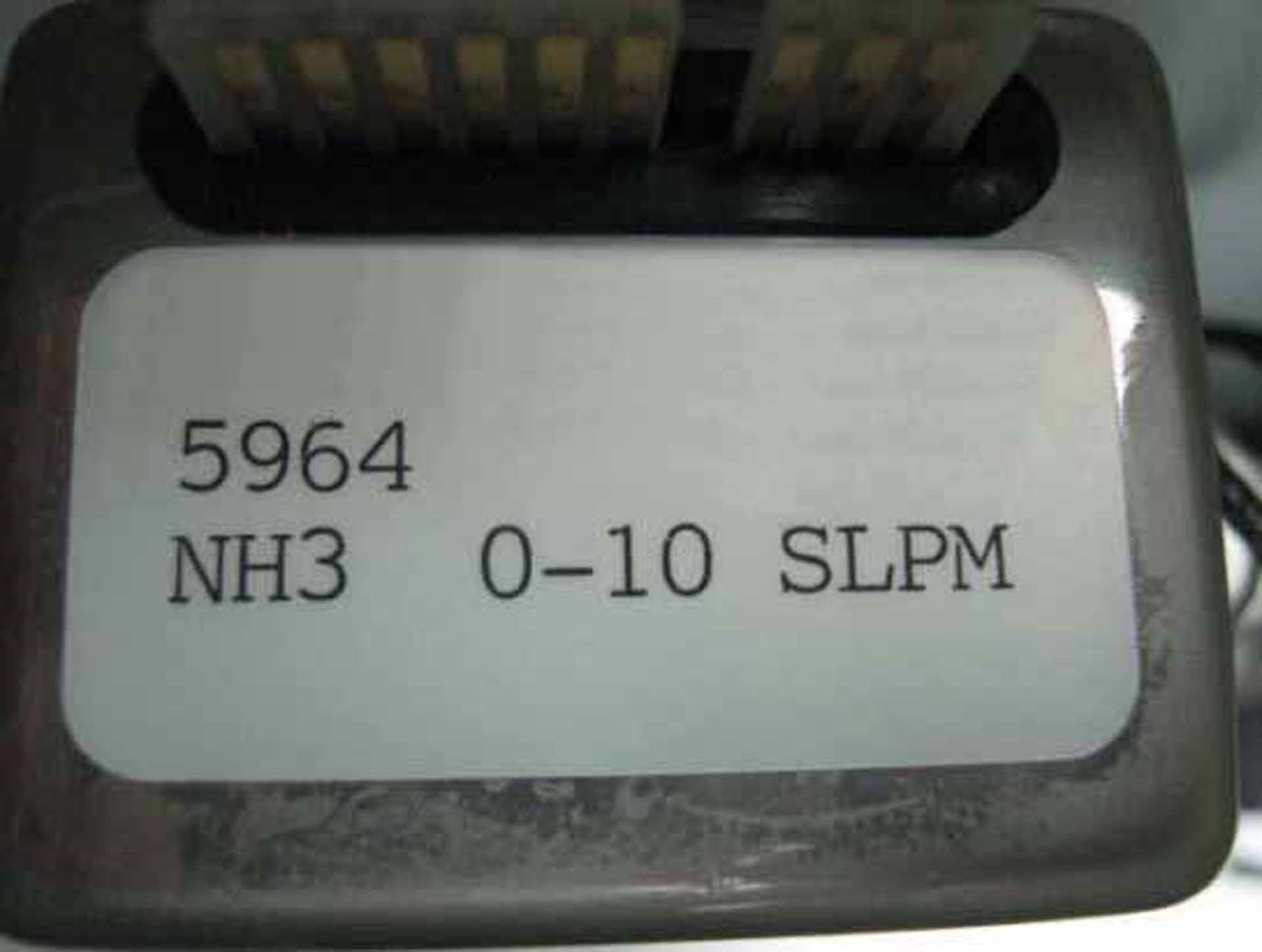

NH3 (10 slm)

Air valve

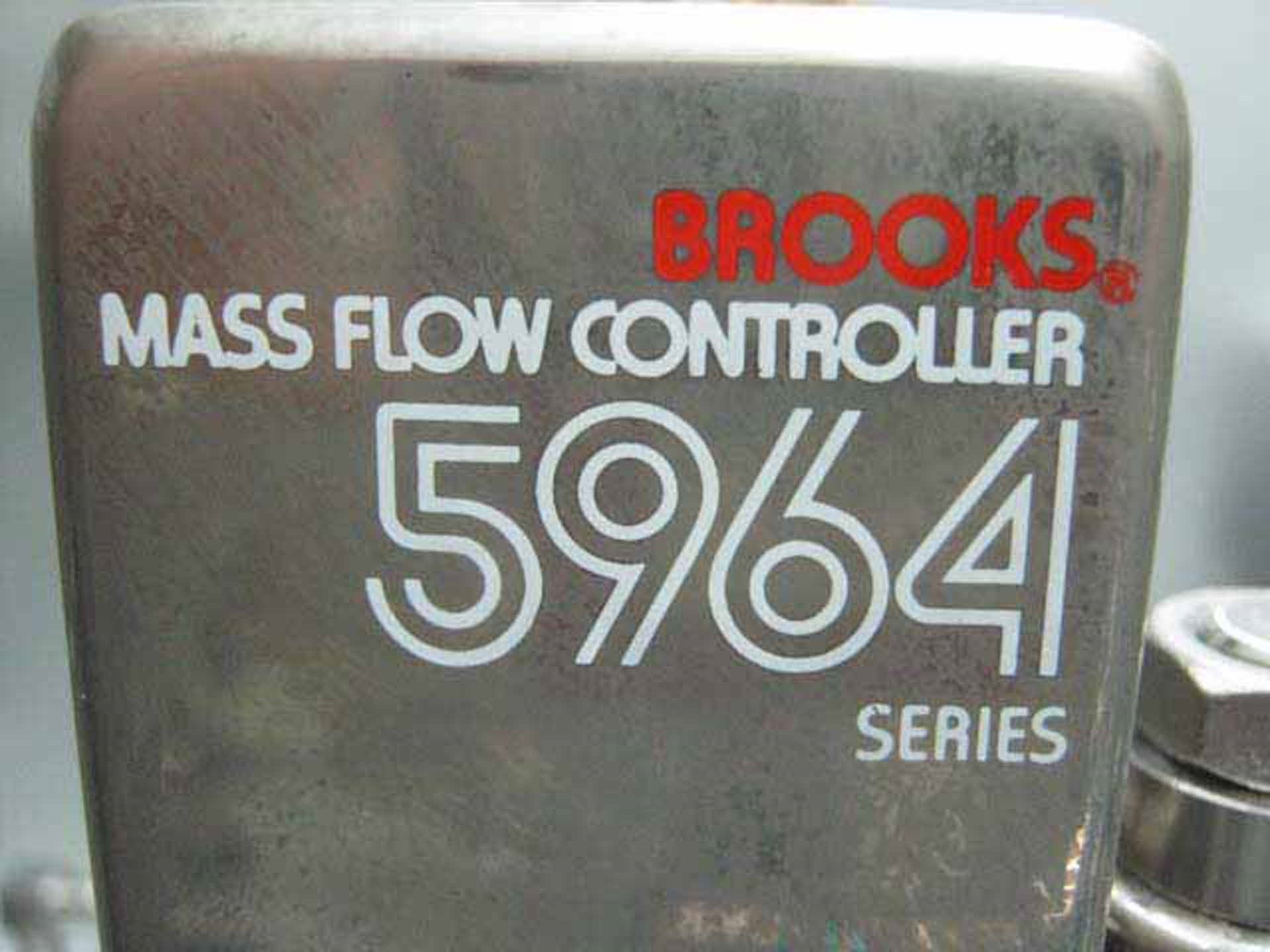

MFC

Filter

Regulator

Signal tower

Power supply: 208 VAC ±6%, 125 Amp, 3 Phase + PE 43 kVA

1994 vintage.

STEAG / MATTSON / AST 2800E Rapid Thermal Processor (RTP) is a one-stop thermal processing solution for developing and testing a variety of packaged devices. With a wide range of process temperatures (200-1000°C), fast cycle times (as low as 3 seconds), and robust temperature control, this equipment offers reliability and consistent performance. The RTP is designed for ease of use, featuring two independent temperature zones, a PLC control system, and intuitive software with automatic recipe selection. The unit is CSA certified and compliant with SEMI E63 and E77 standards. The machine's modular design makes it ideal for a wide variety of applications, including: RTP-LIN up to 1000°C; Process Optimization and Debugging; HTOL Electro Thermal Stress Test (HTEST); OTA Studies; EMISS/CIS Test; and Die-to-Die Interconnects. The LED display with intuitive user interface, full monitoring of all parameters, and flexible programming capabilities, provide users with real-time monitoring and control capabilities. The RTP is adjustable to an array of configuration options, such as wafer sizes, various process chambers, and automated loading/unloading systems. The integrated vacuum pump mechanism enables process temperatures up to 1000°C. The RTP is built with a patented, "all-in-one" convection jacket, in which the internal temperature profile is very homogenous versus traditional, limited chamber designs. The use of this critical cavity ensures a temperature variation of less than 0.25°C across the entire wafer. The RTP is also equipped with an advanced electrical clean tool to avoid any contamination from ionic particles and water. The exhaust asset features automatic ex-filtration and A/C condenser separation. The RTP is equipped with a "dry-only" protection, which avoids the use of liquid cooling. The RTP also comes with a range of process options: RTP-HTOL, RTP-STOL, RTP-HTOLES, RTP-LINC, RTP-TABLE, RTP-HSO. These options allow for various process combinations, such as high temperature ramp, rapid thermal anneal in high-vacuum up to 1000°C, electromigration, HTOL, single wafer rapid thermal processing up to 1000°C, low temperature oven for warm-up and cool-down. Overall, AST 2800E Rapid Thermal Processor is a reliable solution for a variety of thermal processing needs. It offers high-temperature performance with fast cycle times, reliable temperature control, high-quality performance, and robust design for repeatable results.

There are no reviews yet