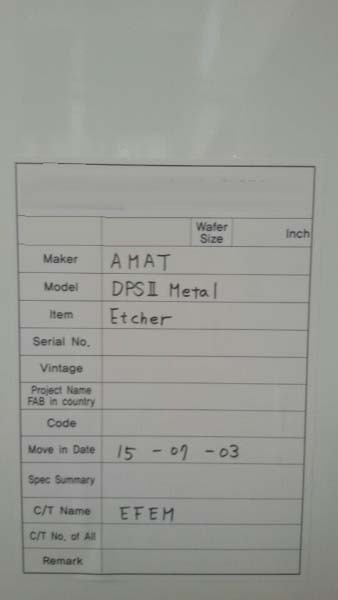

Used AMAT / APPLIED MATERIALS Centura DPS II #9189076 for sale

URL successfully copied!

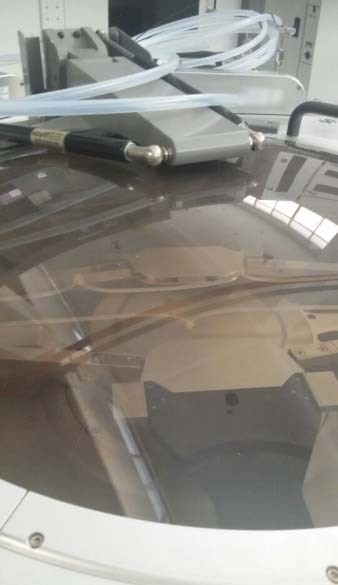

Tap to zoom

ID: 9189076

Wafer Size: 8"

Vintage: 2002

Metal etcher, 8"

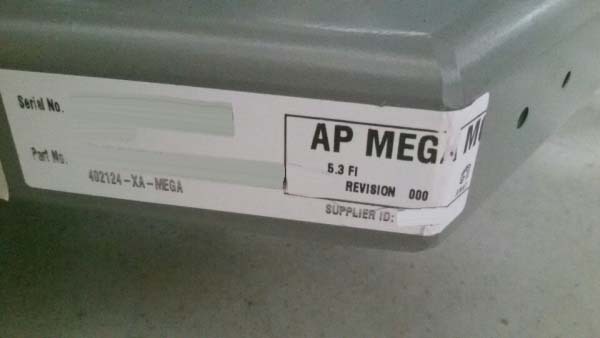

Platform type: Centura AP

Chamber configuration:

Chamber A & B: DPS II Metal bridge chamber, 8"

Chamber C: ASP II Chamber

Process chamber:

Process kits:

DPS II Metal parts / Chamber

Ceramic Lid

ESC Type: DPS II STD CESC, 8"

ESC Power supply: DPS II STD

Control type:

APPLIED MATERIALS STD (VAT)

Chamber A: 65048-PH52-AFS1 / 0583 A-664028

Chamber B: 65048-PH52-AFS1 / 0546 A-626798

EOP Type: Monochromator

Transfer chamber:

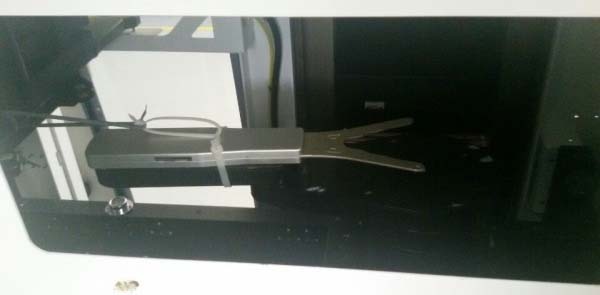

Robot type: VHP+ Dual blade

APPLIED MATERIALS STD LCF Detector

Loadlock chamber:

SWLL Body: (2) SWLL Chambers

EFEM:

(2) Loadports

ASYST Versaport 2200

Air intake system: APPLIED MATERIALS STD Intake

FI Robot: APPLIED MATERIALS Kawasaki

Wafer align: APPLIED MATERIALS STD

Wafer out of position detection: APPLIED MATERIALS STD

Remote interface:

Components interface:

Dry pump (Transfer chamber): IPUP Pump, ALCATEL A100L

Chiller

System monitor: Monitor 1 & Monitor 2

Flat panel with keyboard on stand

Components:

Turbo molecular pump: APPLIED MATERIALS STD BOC EDWARDS

RF Power system:

Source RF generator:

APPLIED MATERIALS STD / APEX 3013

Frequency / Max power: 13.56MHz / 3KW

Bias RF generator:

APPLIED MATERIALS STD / APEX 1513

Frequency / Max power: 13.56MHz / 1.5KW

RF Match box:

Source: Navigator 3013

Chamber A & B: 0190-15168

Bias: Navigator 1513

Chamber A: 0190-23623

Chamber B: 0190-15167

Utility specification:

Gas panel type: STD

Gas panel exhaust: Top center exhaust

(12) Gas lines

Gas line tape heater (for liquid gas): BCL3

MFC Configuration:

MFC type: Digital type

MFC Maker / Model (All Chamber): UNIT MFC

Gas information:

Gas Size

BCL3 200

CL2 200

NF3 100

HCL 100

NF3 20

N2 50

HE 100

O2 1L

SF6 400

CHF3 25

CF4 50

AR 400

Axiom + chamber:

Gas Size

NH3 1000

O2 10000

CF4 750

N2 1L

Independent helium control: APPLIED MATERIALS STD MKS 649A

Electricity:

AC Rack: APPLIED MATERIALS STD AC Rack

Power supply: 3 φ, 208 V, 400 A, 50/60 Hz

System controller:

FES: FEPC

FIS: Flex3

MF SBC: Flex3

CCM SBC: 166 MHz

MF Controller:

Mainframe devicenet I/O:

Cardcage and backplane board

2002 vintage.

AMAT / APPLIED MATERIALS Centura DPS II is a dual-zone rapid thermal reactor designed for advanced materials processing in a variety of applications. It features a powerful RF generator that can generate high-power with precise temperature control for precise processing of thin films, multi-layer structures, and stacks of devices. The main function of AMAT Centura DPS II is to deposit multiple layers of different materials onto a substrate in a precise and precise manner. This is done by utilizing a dual-zone configuration of the dual-zone Rapid Thermal Processor. The two zones are independent, which allows precise temperature profiles to be created in each zone. This is done by individually controlling the heaters, monitored by advanced computerized control systems. The dual-zone configuration in APPLIED MATERIALS CENTURA DPS+ II allows uniform heat distribution and precise temperature control. This is done by having both zones heat up to different temperatures, which will be determined by user-defined parameters. The RTP reactor also has the ability to contain and confine gas mixtures of different composition and concentration for precise composition controlled reactions. Centura DPS II uses active cooling to quickly cool down after each zone reaches a desired temperature for precise and consistent deposition. This multi-zone RTP configuration also allows for precise ramp up and ramp down rates for each zone, which is essential in the research of thin and thick film deposition. APPLIED MATERIALS Centura DPS II also features advanced diagnostic features that allow engineers and scientists to precisely monitor and measure the materials being processed in the RTP reactor. This monitoring is especially useful in multilayer and stack device experiments where precise layer properties are desired. CENTURA DPS+ II is a valuable tool for scientists and engineers in the advanced materials processing industry due to its precise temperature control, precise deposition rate, and precise monitoring capabilities. The reactor has been used in many applications, ranging from semiconductor device fabrication, thin film deposition, and many more. The central heating, cooling, and monitoring capabilities of AMAT CENTURA DPS+ II make it an invaluable tool in research and industrial production.

There are no reviews yet