Used AMAT / APPLIED MATERIALS Centura DPS II #9189888 for sale

URL successfully copied!

Tap to zoom

ID: 9189888

Wafer Size: 12"

Vintage: 2006

Metal etcher, 12"

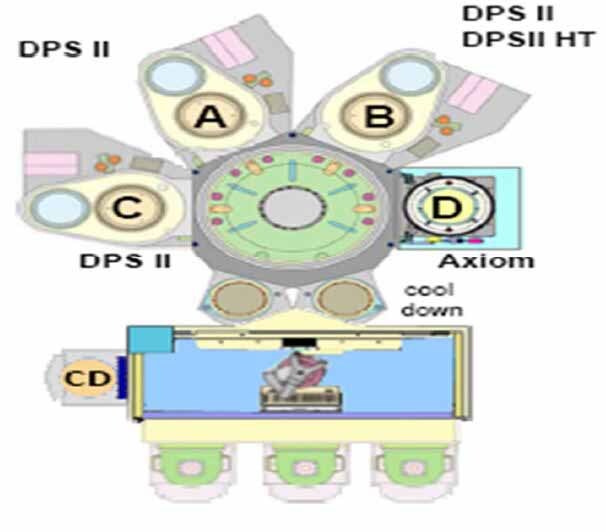

Chamber configuration:

(3) DPS II

Axiom

Chamber configuration:

Chamber A:

Chamber model: DPS II

Bias generator: AE APEX 1513, 13.56 MHz, maximum 1500 W

Bias match: AE 13.56 MHz,3 kV navigat

Source generator: AE APEX 3013, 13.56 MHz, maximum 3000 W

Source match: AE 13.56 MHz,6 kV navigat

Lid: Ceramic lid, Single gas nozzle

Turbo pump: STP-A2503PV

Throttle valve: VAT Pendulum valve DN-250

ESC: Dual zone ceramic ESC

Endpoint type: Monochromator

Cathode chiller: SMC POU

Wall chiller: SMC INR-496-016C

Process kits coating: Anodize coating

Cooling: HT 200 / FC 40

Chamber B:

Cathode chiller: SMC POU

Chamber C:

Cathode chiller: SMC POU

Wall chiller: SMC INR-496-016C

Mainframe configuration:

IPUP Type: ALCATEL A100L

Gas panel type: NextGen

VHP Robot: Dual blade

MF PC Type: CPCI

Factory interface configuration:

Frontend PC type: 306 Server

FIC PC type: 306 Server

(3) Load ports

Atmospheric robot: Yaskawa track robot

Side storage: Right side

MFC Configuration:

Chamber A:

Gas line Gas name Max flow MFC Type

Gas 1 BCL3 200 ARGD40W1

Gas 2 C2H4/HE 400 AAPGD40W1

Gas 3 NF3 200 AAPGD40W1

Gas 4 CL2 400 SC-24

Gas 5 N2_50 50 AAMGD40W1

Gas 6 N2_300 300 AAPGD40W1

Gas 7 CF4 100 AAPGD40W1

Gas 8 O2 1000 AASGD40W1

Gas 9 SF6 100 AAPGD40W1

Gas 10 CHF3 50 AANGD40W1

Gas 12 AR 400 AAPGD40W1

Chamber B:

Gas line Gas name Max flow MFC Type

Gas 1 BCL3 200 AARGD40W1

Gas 2 C2H4/HE 400 AAPGD40W1

Gas 3 NF3 200 AAPGD40W1

Gas 4 CL2 400 AARGD40W1

Gas 5 N2_50 50 AAMGD40W1

Gas 6 N2_300 300 AAPGD40W1

Gas 7 CF4 100 AAPGD40W1

Gas 8 O2 1000 AASGD40W1

Gas 9 SF6 100 AAPGD40W1

Gas 10 CHF3 50 AANGD40W1

Gas 12 AR 400 AAPGD40W1

Chamber C:

Gas line Gas name Max flow MFC Type

Gas 1 BCL3 200 AARGD40W1

Gas 2 C2H4/HE 400 AAPGD40W1

Gas 3 NF3 200 AAPGD40W1

Gas 4 CL2 400 AARGD40W1

Gas 5 N2_50 50 AAMGD40W1

Gas 6 N2_300 300 AAPGD40W1

Gas 7 CF4 100 AAPGD40W1

Gas 8 O2 1000 AASGD40W1

Gas 9 SF6 100 AAPGD40W1

Gas 10 CHF3 50 AANGD40W1

Gas 12 AR 400 AAPGD40W1

2006 vintage.

AMAT / APPLIED MATERIALS Centura DPS II is a high-energy, high-throughput plasma etch reactor specifically designed for semiconductor device fabrication. The etch rate of AMAT Centura DPS II is among the highest available in the market. This capability enables manufacturers to reduce cycle time and increase production throughput. The reactor can also reduce the temperature of the substrate during etching, thus helping to preserve the structural integrity of the semiconductor device. APPLIED MATERIALS CENTURA DPS+ II is powered by AMAT High Density Plasma (HDP) technology, providing superior uniformity across the entire substrate surface and excellent etch selectivity. This superior control of plasma-generated species also reduces defect density on the substrate. The reactor's HDP source has a low-power, pulsed electron source and multiple inductively coupled plasma sources with integrated gas control systems which provide a great deal of flexibility in substrate etching processes. Centura DPS II has a maximum substrate size of 200mmx200mm. It also provides variable pressure control, vacuum exhaust and adjustable process temperature, allowing for fine-tuned plasmaprocess conditions. Additionally, the reactor can be tuned to optimize shallow trenches, narrow cells, and other challenging features that require low ion- or laser-etch damage. The closed-loop-cartridge-type platform design helps keep the process gas clean, further helping to reduce defect formation. Its large PDLT cell and low-ion-encounter chamber design also minimize processing time and maximize production throughput. Finally, APPLIED MATERIALS set of process monitoring and optimization software helps enable both reliable and repeatable process results, meeting the most stringent industry standards.

There are no reviews yet