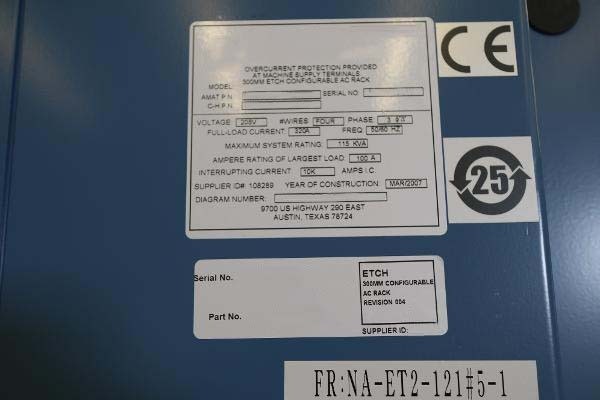

Used AMAT / APPLIED MATERIALS Centura DPS II #9189889 for sale

URL successfully copied!

Tap to zoom

ID: 9189889

Wafer Size: 12"

Vintage: 2007

Poly etcher, 12"

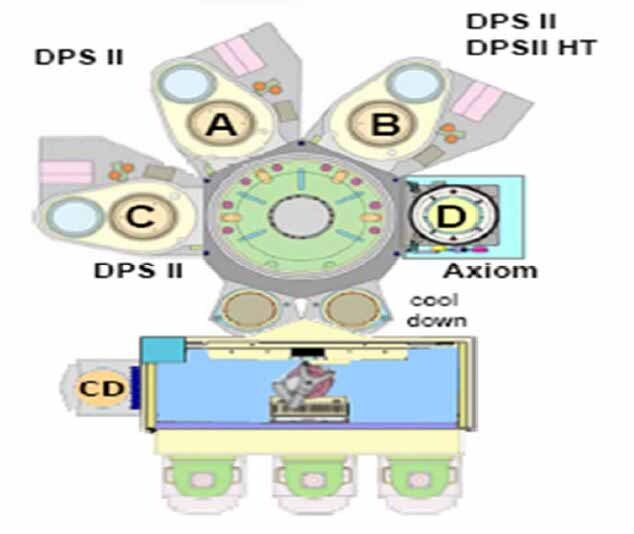

(4) Chambers:

(3) DPS II

Poly

Axiom

Chamber configuration:

Chamber A:

Chamber model: DPS II

Bias generator: AE APEX 1513, 13.56 MHz, Maximum 1500 W

Bias match: AE, 13.56 MHz,3 kV navigat

Source generator: AE APEX 3013, 13.56 MHz, Maximum 3000 W

Source match: AE, 13.56 MHz,6kV navigat

Lid: Ceramic lid, dual gas nozzle

Turbo pump: EDWARDS STP-A3003CV

Throttle valve: VAT pendulum valve DN-320

FRC: MKS FRCA-52163310, 500/500 1/4VCR

ESC: Dual zone ceramic ESC

Endpoint type: EyeD IEP

Cathode chiller: SMC POU

Wall chiller: SMC INR-496-016C

Process kits coating: Anodize coating

Cooling: HT 200 / FC 40

Chamber B:

Cathode chiller: SMC POU

Chamber C:

Cathode chiller: SMC POU

Wall chiller: SMC INR-496-016C

Chamber D:

Chamber model: AXIOM

Source generator: 5000 W

Source match: AE match (RF System)

Throttle valve: Throttling gate valve

ESC: Pedestal heater

Mainframe configuration:

IPUP Type: ALCATEL A100L

Gas panel type: Standard

VHP Robot: Dual blade

MF PC type: CPCI

Factory interface configuration:

Frontend PC type: 306 Server

FIC PC type: 306 Server

(3) Load ports

Atmospheric robot: KAWASAKI Single fixed robot (A3 Type)

Side storage: Right / Left side

MFC Configuration

Chamber A:

Gas line Gas name Max flow MFC Type

Gas 1 CL2 300 DSPGD1XM

Gas 2 NF3 50 DSNGD1XM

Gas 3 SF6 100 DSPGD1XM

Gas 4 HBR 500 DSRGD1XM

Gas 5 N2 20 DSLGD1XM

Gas 6 N2 200 DSPGD1XM

Gas 7 O2 50 DSMGD1XM

Gas 8 O2 400 DSPGD1XM

Gas 9 HE 500 DSPGD1XM

Gas 10 CHF3 200 DSPGD1XM

Gas 11 CF4 300 DSRGD1XM

Gas 12 AR 500 DSPGD1XM

Chamber B:

Gas line Gas name Max flow MFC Type

Gas 1 CL2 300 DSPGD1XM

Gas 2 NF3 50 DSNGD1XM

Gas 3 SF6 100 DSPGD1XM

Gas 4 HBR 500 DSRGD1XM

Gas 5 N2 20 AALGD40W1

Gas 6 N2 200 DSPGD1XM

Gas 7 O2 50 DSMGD1XM

Gas 8 O2 400 DSPGD1XM

Gas 9 HE 500 DSPGD1XM

Gas 10 CHF3 200 DSPGD1XM

Gas 11 CF4 300 DSRGD1XM

Gas 12 AR 500 DSPGD1XM

Chamber C:

Gas line Gas name Max flow MFC Type

Gas 1 CL2 300 DSPGD1XM

Gas 2 NF3 50 DSNGD1XM

Gas 3 SF6 100 DSPGD1XM

Gas 4 HBR 500 DSRGD1XM

Gas 5 N2 20 AALGD40W1

Gas 6 N2 200 DSPGD1XM

Gas 7 O2 50 DSMGD1XM

Gas 8 O2 400 DSPGD1XM

Gas 9 HE 500 DSPGD1XM

Gas 10 CHF3 200 DSPGD1XM

Gas 11 CF4 300 DSRGD1XM

Gas 12 AR 500 DSPGD1XM

Chamber D:

Gas line Gas name Max flow MFC Type

Gas 5 N2 1000 DSSGD1XM

Gas 7 4%H2/N2 5000 DSVGD1XM

Gas 8 O2 10000 DSVGD1XM

2007 vintage.

AMAT / APPLIED MATERIALS Centura DPS II is an advanced process reactor equipment which can be used to carry out various processes for the production of a wide range of products from consumer electronics and automotive components to aerospace parts and medical devices. The system is designed to provide flexible and reliable processing capabilities, enabling a consistent and efficient management of production cycles. AMAT Centura DPS II uses high quality materials, such as stainless steel, to ensure a long lifespan. It is composed of 5 main components which are the reactor chamber, the feed cup, the tool cup, the exhaust flow control device and the drive control unit. The reactor chamber is designed to provide an optimal environment and temperature for chemical reactions, as well as providing an inert atmosphere to protect against corrosive vapours. The feed cup is equipped with a feed machine which is used to introduce raw materials into the tool for processing. The tool cup is used to house precision tools and accessories, which are necessary for the successful completion of processes. The exhaust flow control device is responsible for controlling the amount of gas and vapour which is released from the reactor chamber, ensuring that it is maintained at a safe level. Finally, the drive control asset is used to regulate the speed of the reactor's movement and to ensure precise temperature control. APPLIED MATERIALS CENTURA DPS+ II also contains many safety features which protect both operators and the model itself. These safety features include an emergency shut off switch, a pressure monitoring equipment, an oxygen monitoring system, and an inert gas monitoring unit. In addition, the machine's software is capable of displaying detailed diagnostics which help to quickly identify any faults or risks which may occur during operation. All in all, AMAT CENTURA DPS+ II is an advanced and reliable tool which is capable of performing a variety of processes for the production of products. Its robust design and comprehensive safety features make it an ideal choice for any manufacturing setup.

There are no reviews yet