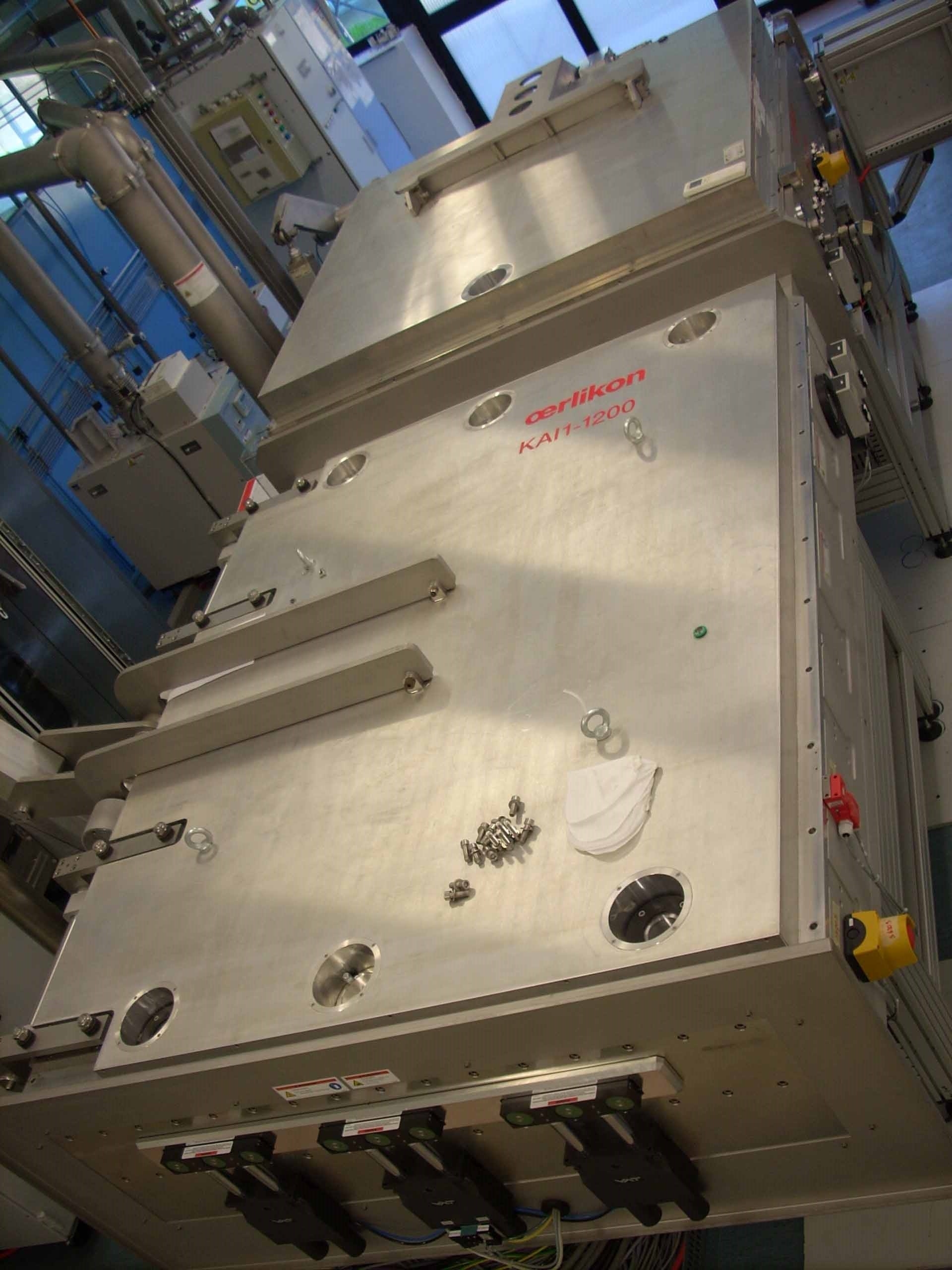

Used UNAXIS / OERLIKON / ESEC KAI-1 1200 Gen 5 #9195317 for sale

URL successfully copied!

Tap to zoom

ID: 9195317

Vintage: 2008

PECVD System

Reactor (Industrial glass size):

Version of commercial KAI 1200 machines inside

OERLIKON PV module turn-key production lines

Amorphous and microcrystalline thin silicon film deposition

1.1 m x 1.3 m glass substrates of 2-4 mm thickness

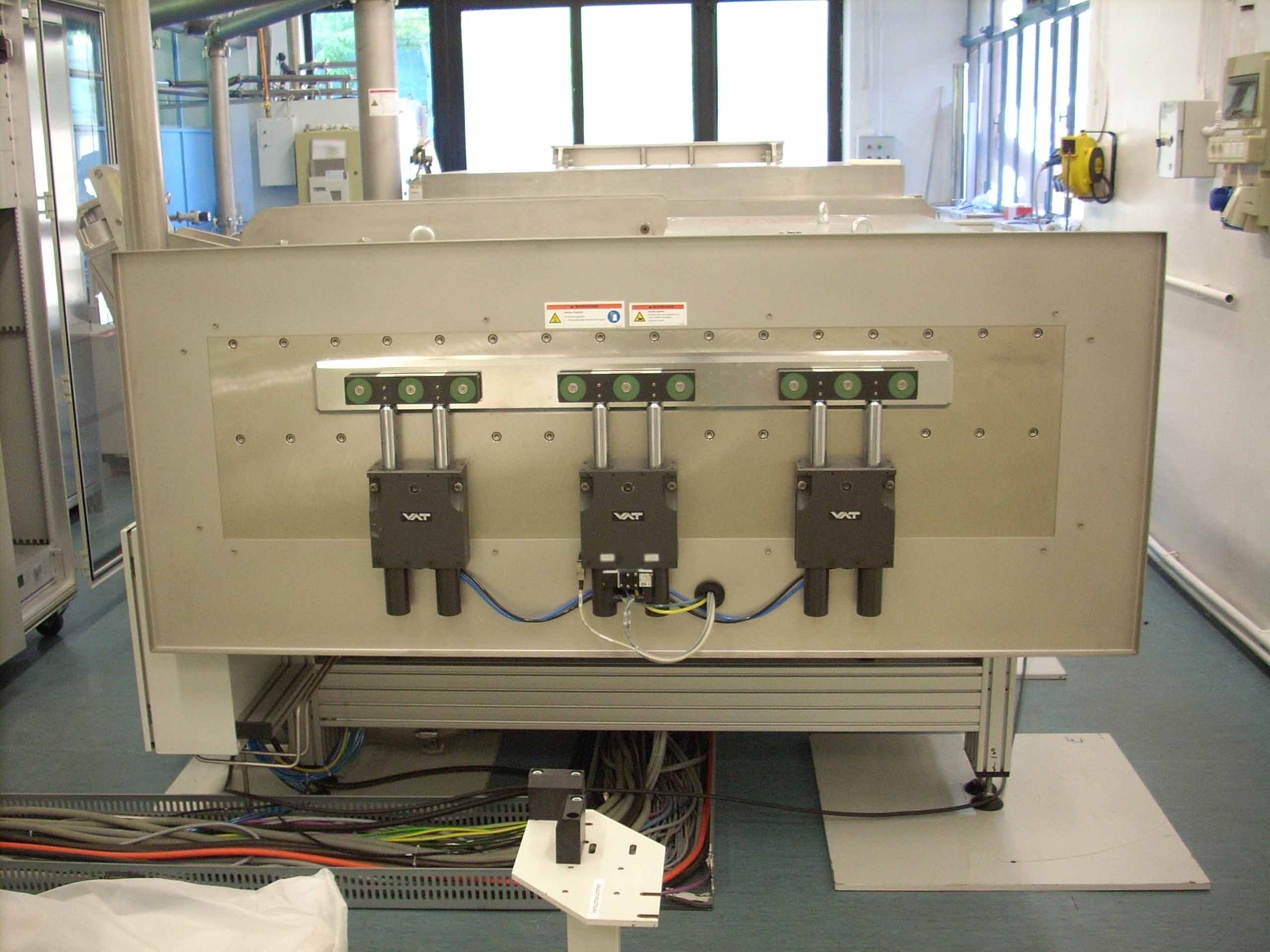

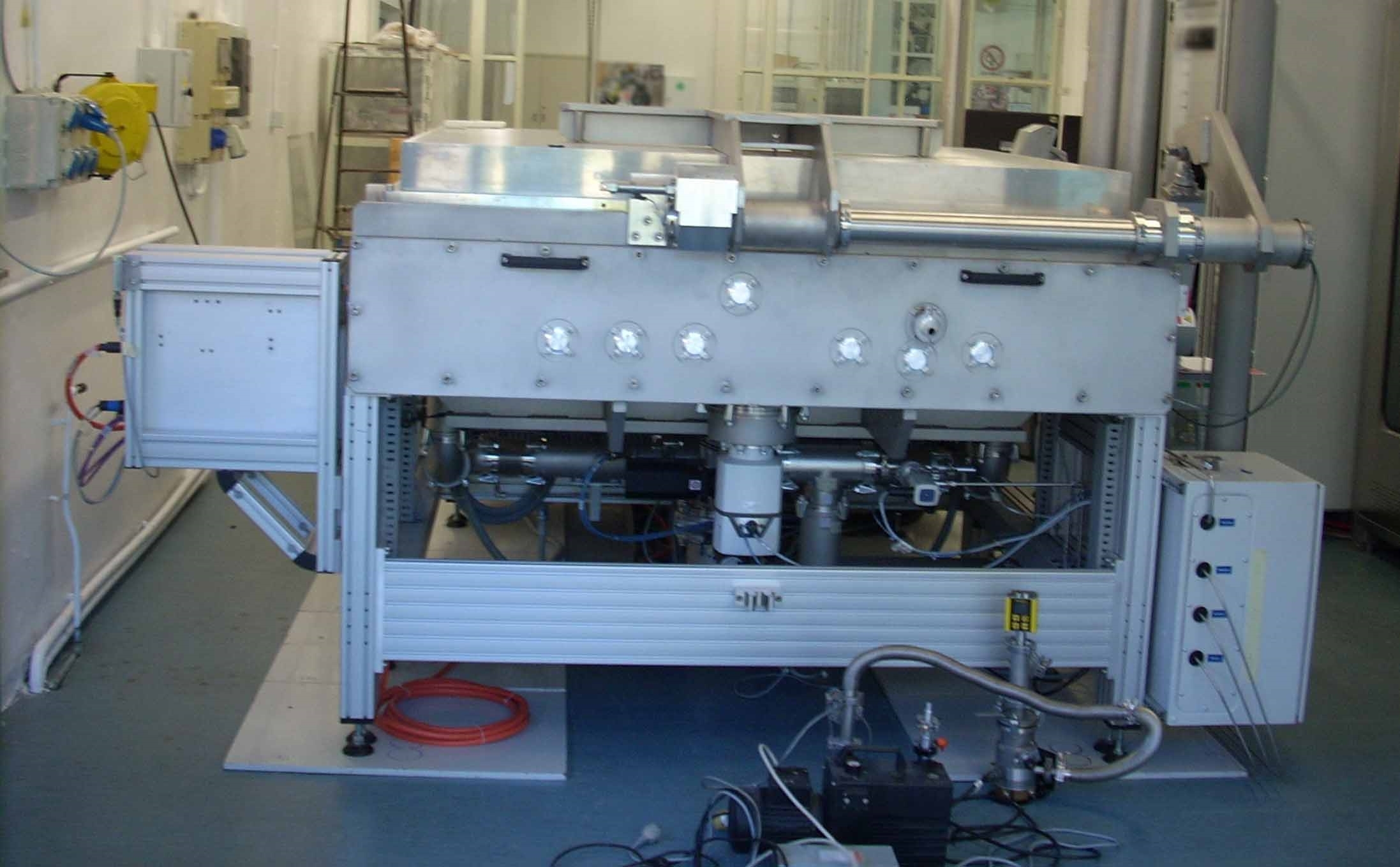

(2) Reactors: aSi, µcSi layer deposition

Load lock

Glass loading table (Extractable to deliver glass into load lock)

Process unit with (2) PECVD reactors

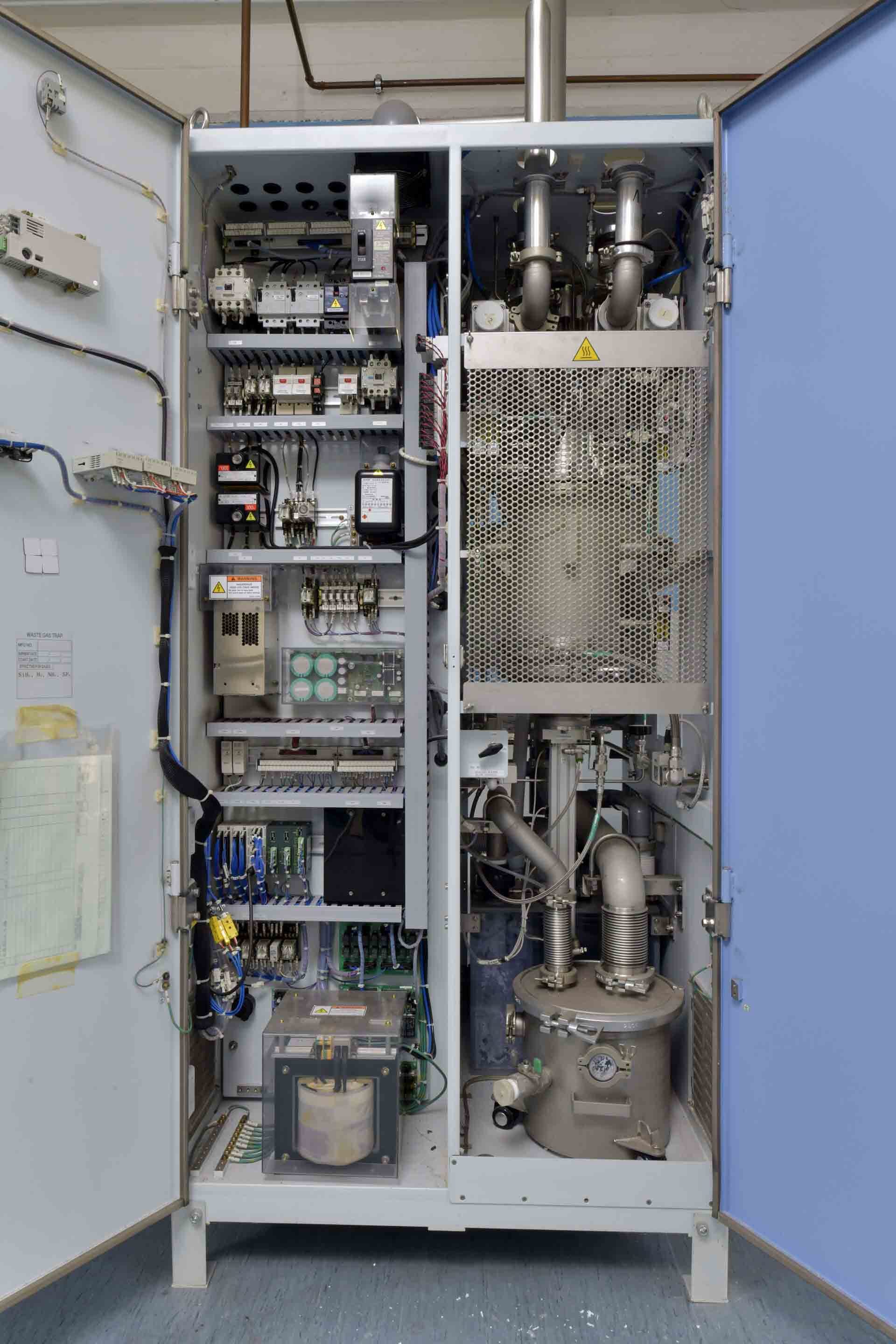

Equipped with ADVANCED ENERGY Cesar 4 kW 40.68 MHz RF Generator

(15) Mass flow controllers

IDEM MFCs

Max temp: 200°C

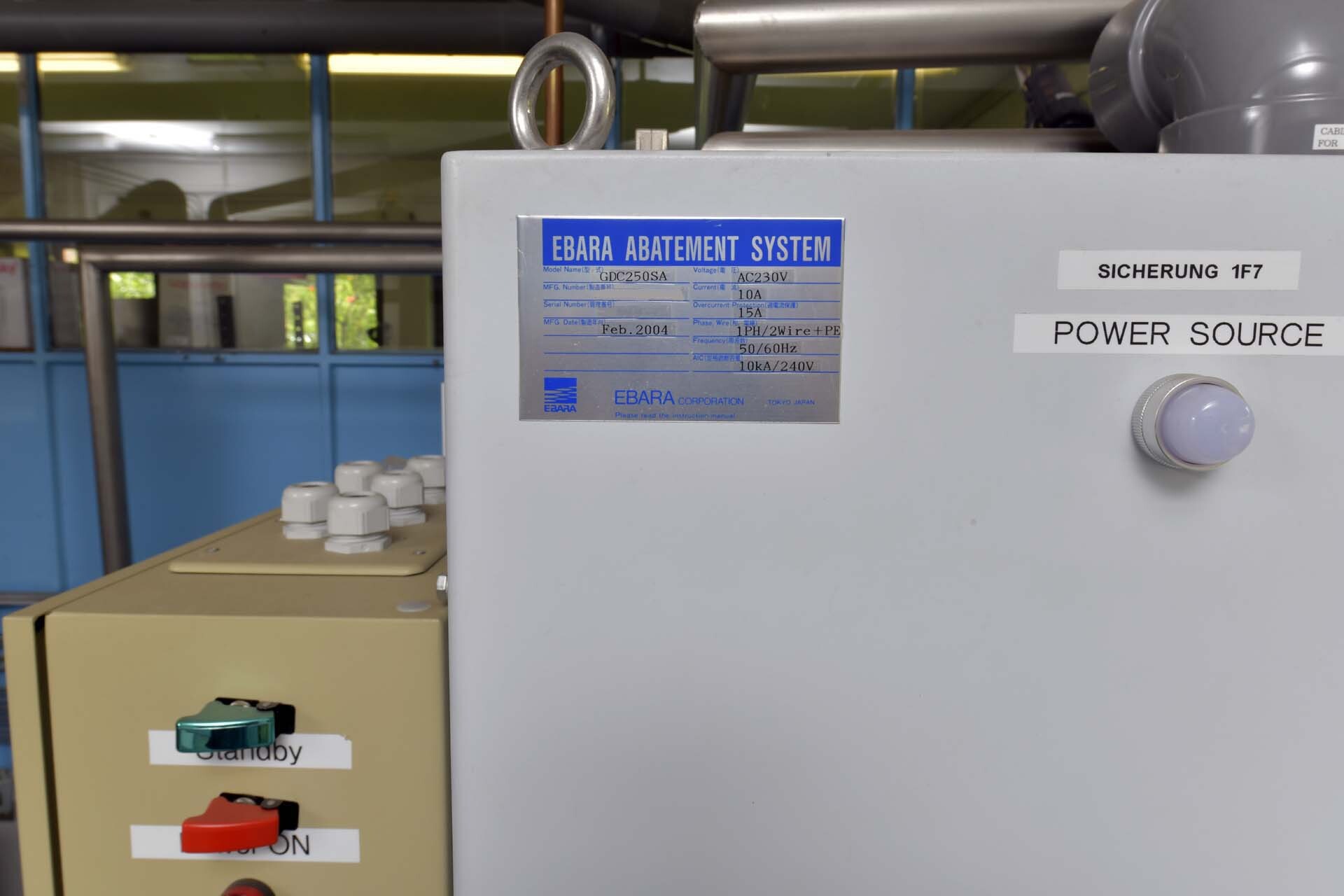

EBARA Dry pumps

Front loader system

Films deposited:

aSi/µcSi tandem thin film silicon solar cells

With (Containing intrinsic aSi and µcSi films and their carbon-containing /p- and n-doped declinations)

Self cleaning process with NF3 (No residues in both reactors)

Gas supply and pump connected

Spare parts included

2008 vintage.

UNAXIS / OERLIKON / ESEC KAI-1 1200 Gen 5 reactor is a high-performance advanced technology etch tool that offers enhanced performance in a variety of production applications. The tool is a one-piece design and features powerful variable power, advanced uniformity, and flux delivery control. Its high-resolution RF generator is capable of working with a wide range of frequencies, allowing the user to program process conditions for a variety of etch applications. It also has an integrated coil and load-adjust feature to provide additional control. The reactor is designed and engineered for the production of a variety of electronic device applications, including transistor gate etches, fin etches, and CPW etches. It also features a sophisticated load and coil-adjust to optimize process performance. Additionally, the tool allows the user to input recipes directly from a CD, memory stick, or via the device's touchscreen display. ESEC KAI-1 1200 Gen 5 reactor comes equipped with advanced vacuum management capabilities. It has a enclosed cylindrical spiral geometry to provide a stable atmosphere for etching processes. This allows the user to continue to etch with consistent results at different process levels, even when pressure is applied. The tool's integrated liquid injection system and RF generator offer greater control over etching process performance. The user is able to adjust etch chemistry, as well as the flux levels, to achieve higher yields with greater uniformity. This allows for faster and more efficient etch production processes. Additionally, the tool is designed with a unique water-cooled system to provide the user with increased efficiency. Finally, UNAXIS KAI-1 1200 Gen 5 reactor is designed with safety and power efficiency in mind. It is equipped with an automatic shut-off system, as well as an anti-static body. Additionally, the tool's status reporting feature enables the user to monitor and assess the device's overall performance and power draw.

There are no reviews yet