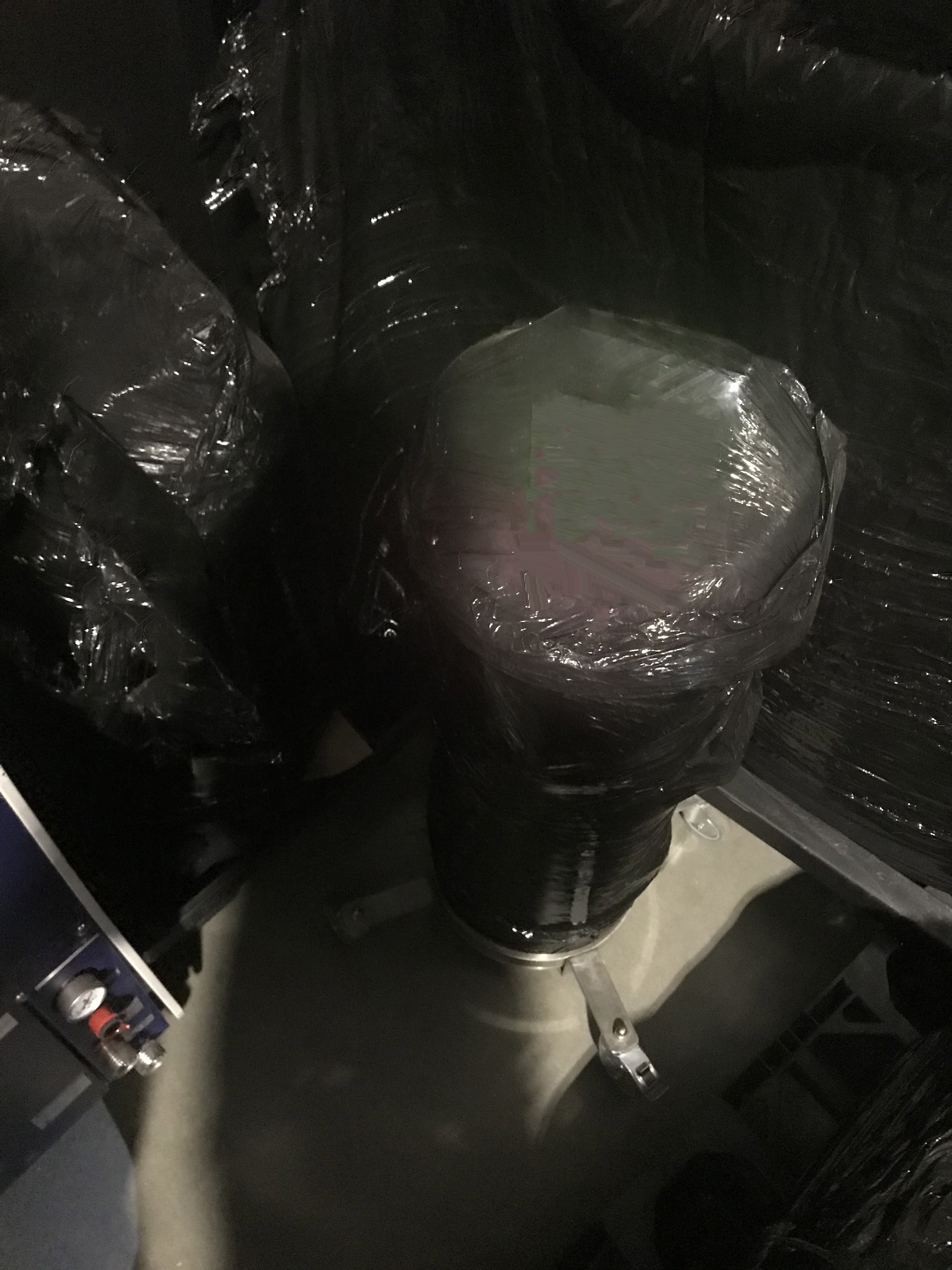

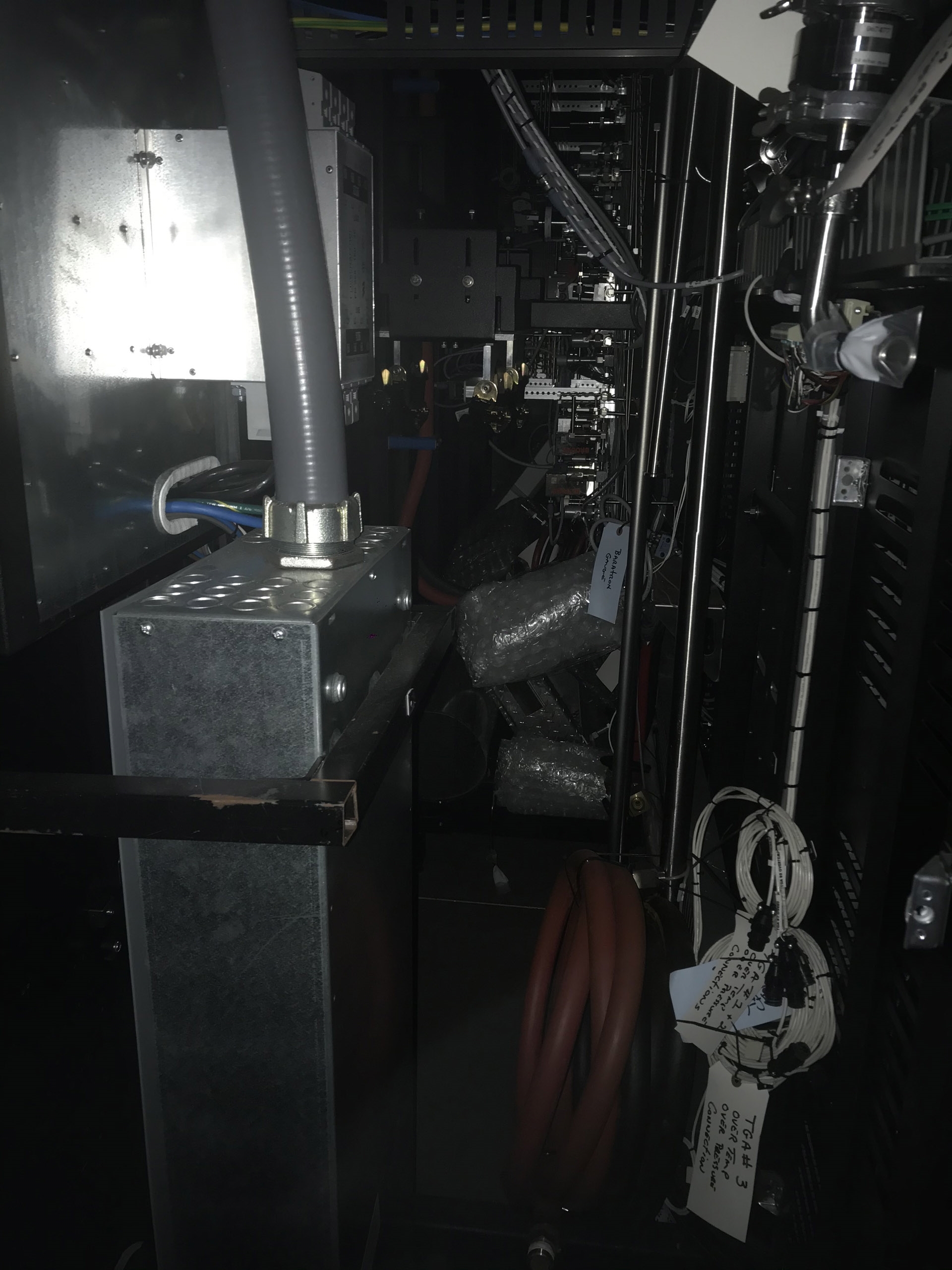

Used VEECO / EMCORE E450 #9283612 for sale

URL successfully copied!

Tap to zoom

VEECO / EMCORE E450 reactor is a high-precision plasma etch equipment designed for semiconductor applications. The system is designed to be used in the manufacture of solid-state devices, optoelectronics, and optical systems. VEECO E450 offers the highest performance and the most precise etching processes available in the industry. The platform provides a wide variety of parameters, precision, stability, selectivity, and repeatability for enhanced process control. EMCORE E450 features an advanced plasma source design that provides a uniform gas plasma density over the entire wafer plane. This capability allows the unit to provide optimal etching performance over a wide variety of device designs. The source design enables the machine to deliver high etch rates with low ion energy, and accurate etching width control capability. E450 is designed to work effectively at high pressures, providing precise etching selectivity. The tool can be configured to work with a wide range of gases, including F2, C4F8, SF6, NF3, and CHF3, providing a versatile etching platform. Additionally, VEECO / EMCORE E450 is able to provide high etching rates without producing large plasma instabilities. The integrated VEECO E450 asset includes a sophisticated gas supply package, a high-precision mechanism for delivering the central electrode to the wafer plane during etching, and an integrated hardware interface platform. The platform is designed to provide seamless integration with other model components. This allows the reactor to operate in a variety of process settings, such as batch and single-wafer processing. The equipment's high-precision mechanism allows for accurate and repeatable etching of microstructures. The mechanism is also able to deliver the central electrode to the wafer plane, providing optimized etching profiles and prevents edge beads. Additionally, EMCORE E450 platform is designed to provide low-voltage wafer scans with high-precision movement control to accurately profile structures. E450 platform provides a variety of advanced process control and diagnostic capabilities. It is also designed to interface with a wide range of accessory equipment, such as mass spectrometers, pressure controllers, and temperature controllers, allowing for versatile operation. The system can be configured to provide full integration with an external network for data telemetry. VEECO / EMCORE E450 platform is designed to enable higher throughput and improved yields. The unit provides automated startup and shutdown capabilities, allows users to monitor etching results in real-time, and provides statistical process control feedback. The versatile machine features an intuitive graphical user interface that allows operators to monitor and control process variables. Additionally, users can store data for later review and analysis. Overall, VEECO E450 platform provides a wide range of advanced capabilities and features that make it an ideal tool for precise etching applications. The high-precision mechanism, advanced plasma-source design, and integrated process control and monitoring make the tool ideal for the manufacture of semiconductor devices, optoelectronics, and optical systems.

There are no reviews yet