Used VEECO / EMCORE E450 #9363532 for sale

URL successfully copied!

Tap to zoom

ID: 9363532

Wafer Size: 2"

Systems, 2"

Wafer capacity: Up to (48) wafers

Group III MO sources:

(2) TMGa

(2) TMIn

(2) TMAl

Group V hydride sources:

(2) AsH3

PH3

Dopants MO:

CP2Mg

CBr4

Dopants hydride: H2/SiH4

(2) NESLAB Baths

(7) Lorex piezocons

2-Channels for TMI expendable to 4 (For 2 additional TMG)

EBARA A70W Pump

Exhaust system:

(2) Particle filters

Housing

Phosphorus trap

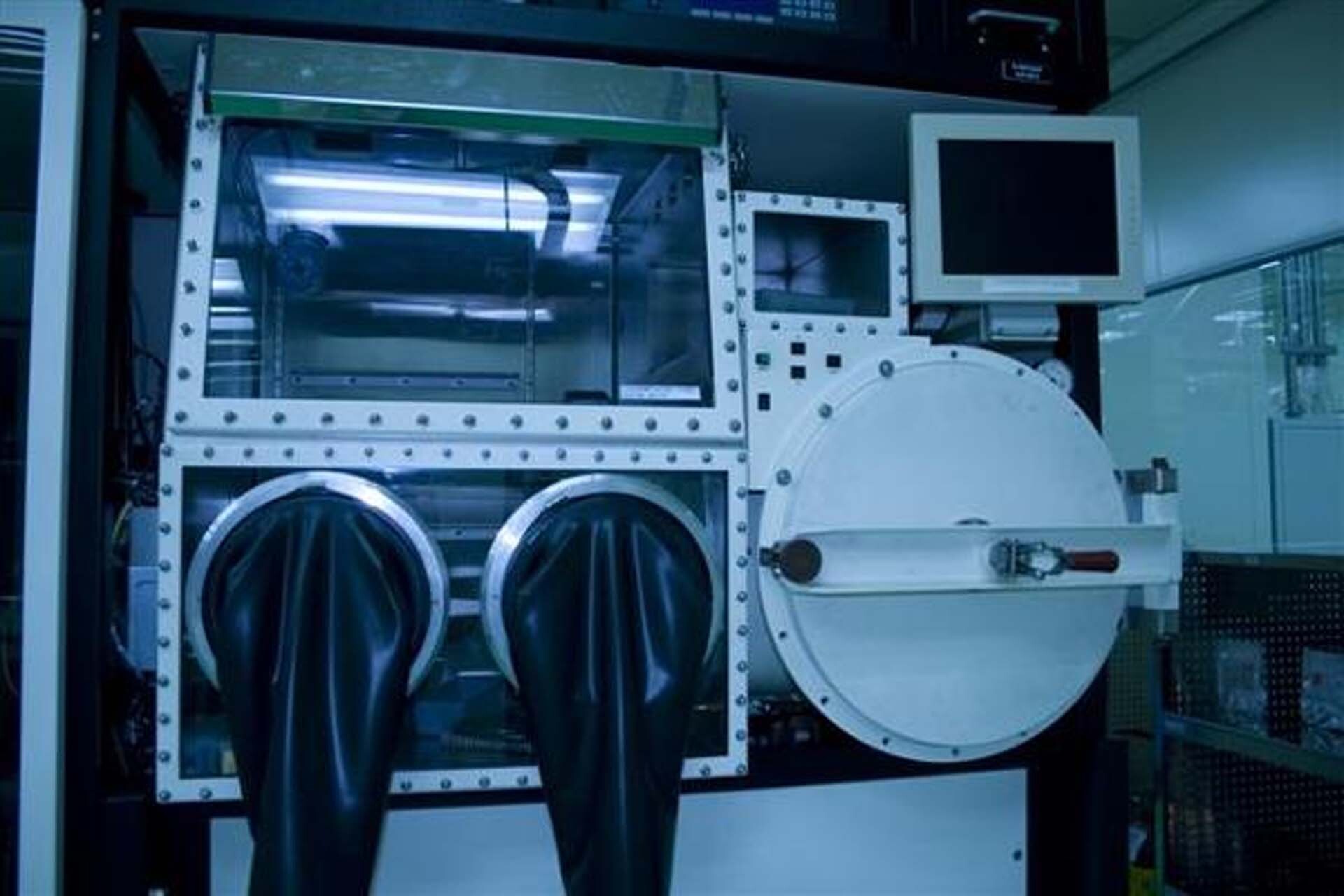

P-Trap automatic regeneration system loadlock: Loadlock chamber

Glove box

Moisture monitor

Wafer carrier transfer robotic system heater

(3) Heater elements:

Inner

Middle

Outer graphite heater temperature control

Temperature monitor 3-point T/C

YOKOGAWA Controller

3-Point SEKIDENKO pyrometer

Gas monitoring:

Gas leak monitor

Toxic gas

H2 Gas monitor system

Epi Windows 2000.

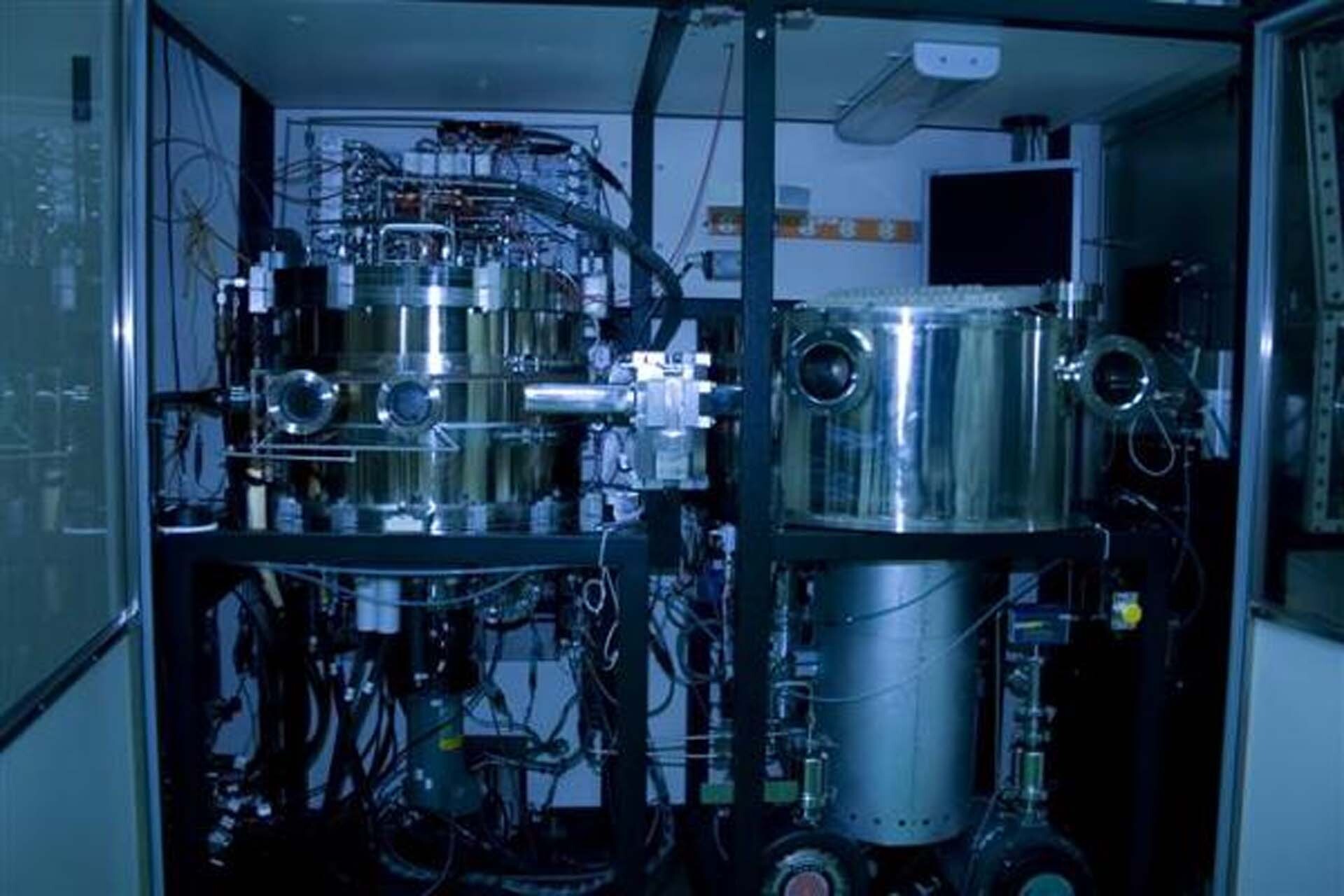

VEECO / EMCORE E450 Epitaxial Reactor is a highly advanced chemical vapor deposition (CVD) equipment designed to optimize high-performance semiconductor devices with maximum efficiency. The system features a unique high-temperature, high-pressure process chamber which is capable of producing the highest quality semiconductor films in the shortest amount of time. VEECO E450 reactor has been designed with a single-lift, iron-base furnace construction for maximum efficiency and reliability. The advanced dual vaporizer control unit is capable of both independent and simultaneous vaporizer operations for precise temperature regulation of the process gases. EMCORE E450's enhanced control machine allows full flexibility in controlling process gas flows and preprogrammed recipes for optimal epitaxial growth. An inert gas purified nitrogen flow is used to maintain an ultra-clean process environment as part of the advanced vacuum control tool, ensuring excellent device yields. The integrated water loop furnace provides optimum temperature uniformity throughout the entire chamber and helps to reduce contamination and particle intrusion from the process environment. The state-of-the-art reactor supports substrate sizes up to 6-inch diameter and uses a standard 6-inch wafer carrier asset for easy sample loading. The unique 'head-in' mech design of E450 also provides quick and easy sample loading and unloading and maximizes the uniformity of the film deposition. The fine oxide etching process feature utilizes a unique, non-uniform profile design to increase the etch rate without compromising film uniformity or creating surface damage. VEECO / EMCORE E450 is considered an essential tool for producing high quality and robust semiconductor devices. The advanced high-temperature process control model, inert gas purification controls, and the ultra-quiet vacuum equipment ensure an ultra-clean environment for maximum yields and device stability. In addition, the built-in furnace offers maximum temperature and uniformity control across the full range of process temperatures. All of these features combine to make VEECO E450 Epitaxial Reactor an unparalleled platform for advanced device fabrication.

There are no reviews yet