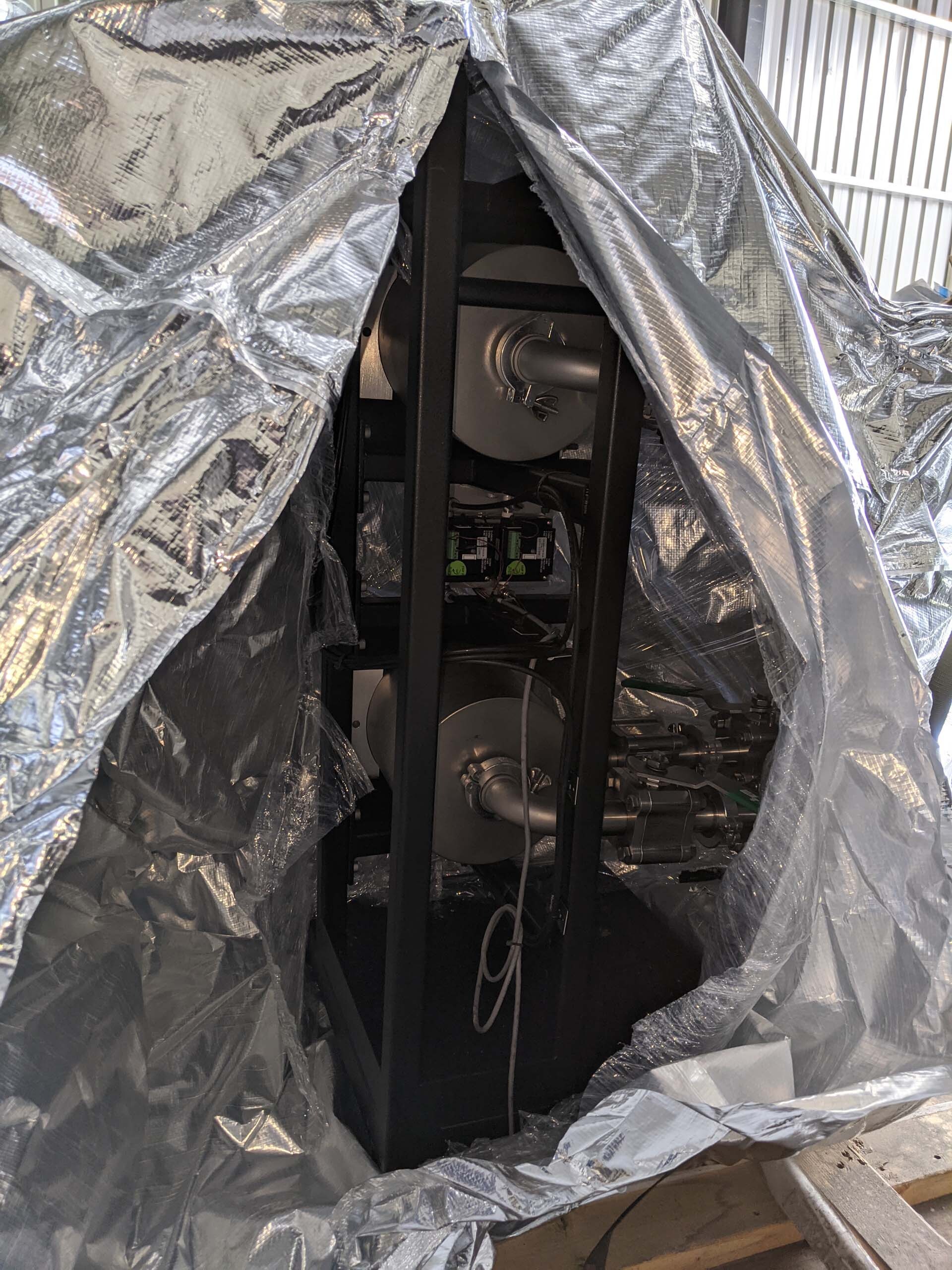

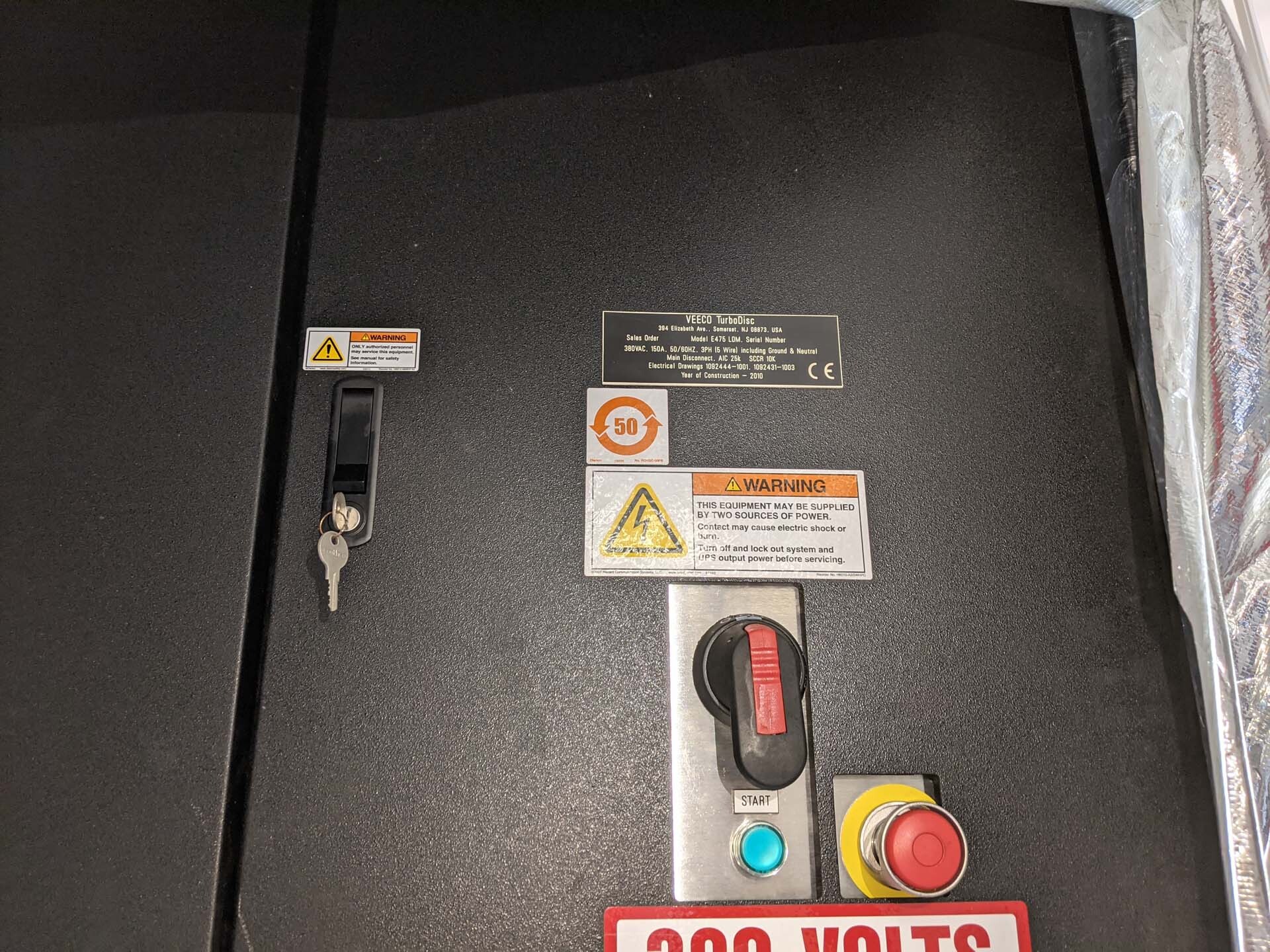

Used VEECO TurboDisc E475 LDM #9401869 for sale

URL successfully copied!

Tap to zoom

ID: 9401869

Vintage: 2010

MOCVD System

High-brightness LEDs: Red, orange and yellow

Multi-junction III-V concentrator solar cells

Operation: 200 300 Epitaxy

Control PC

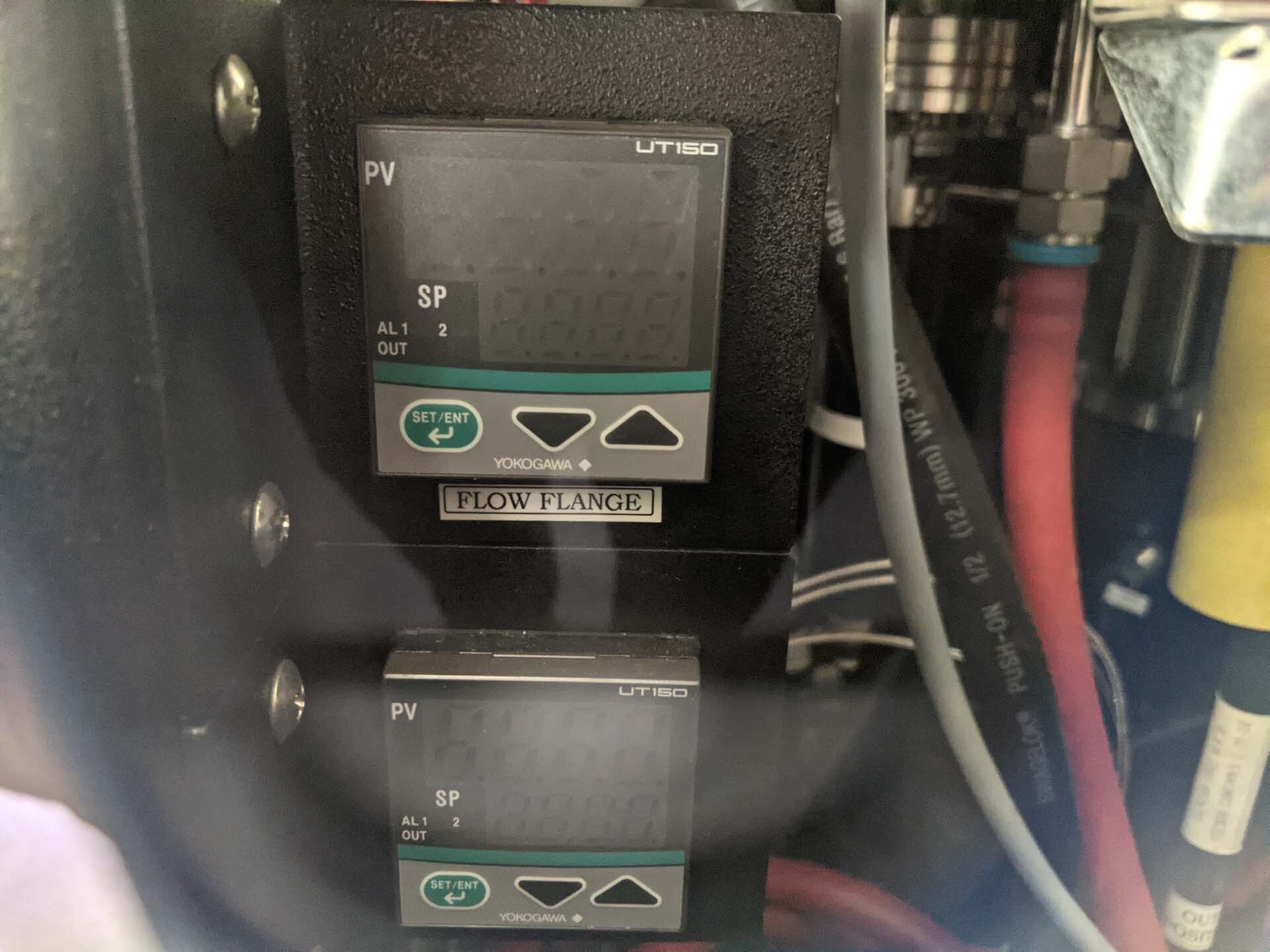

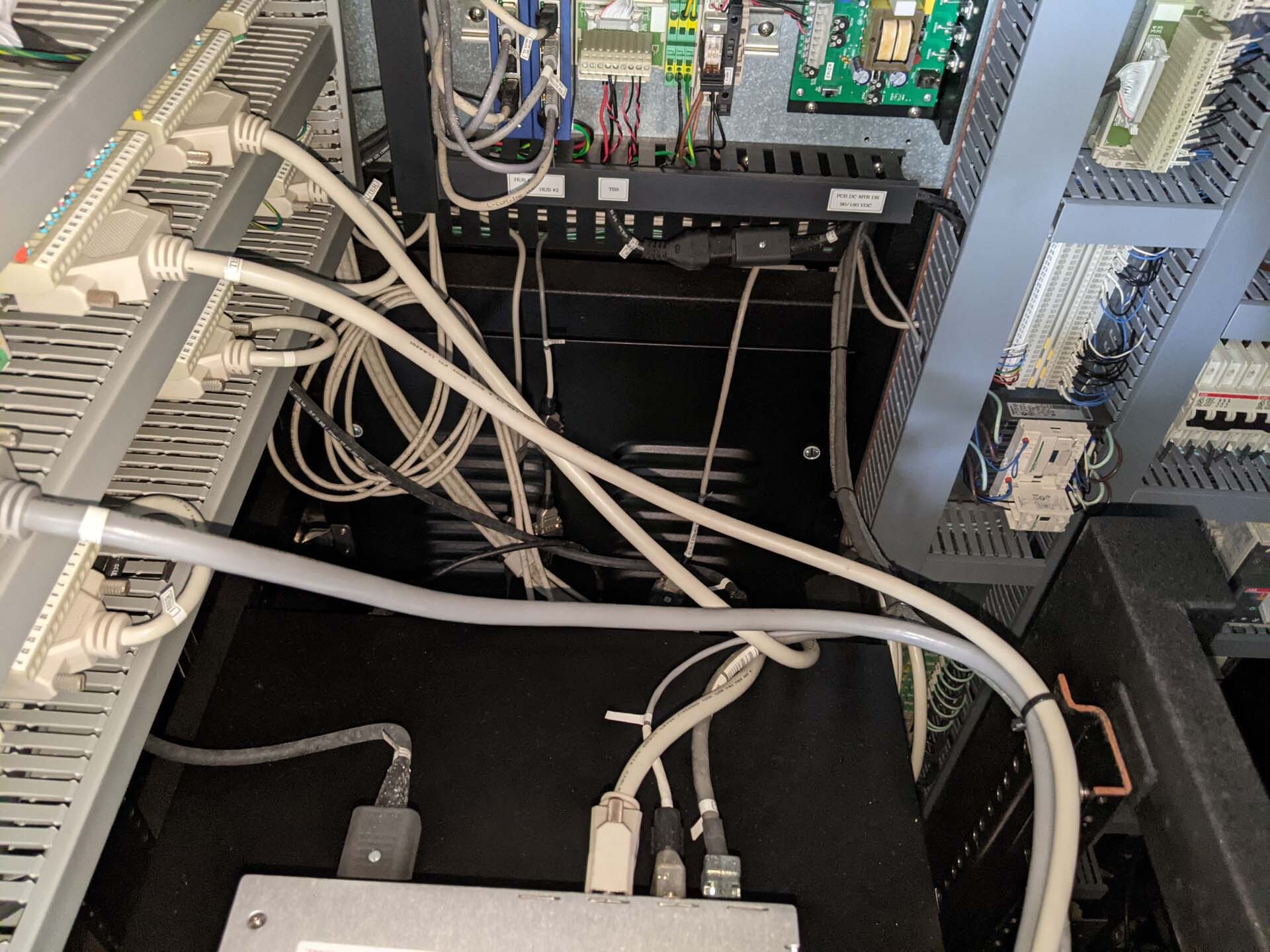

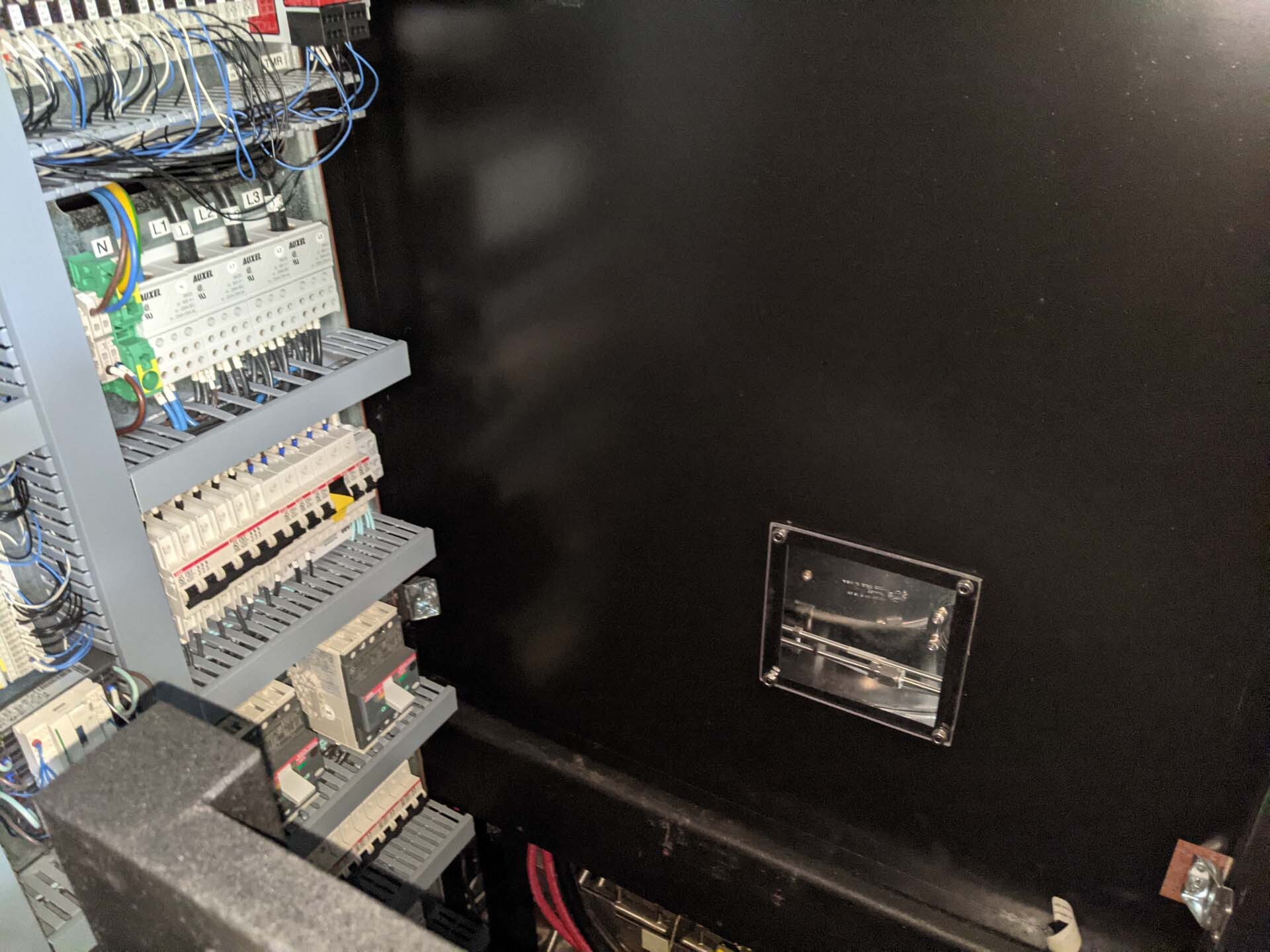

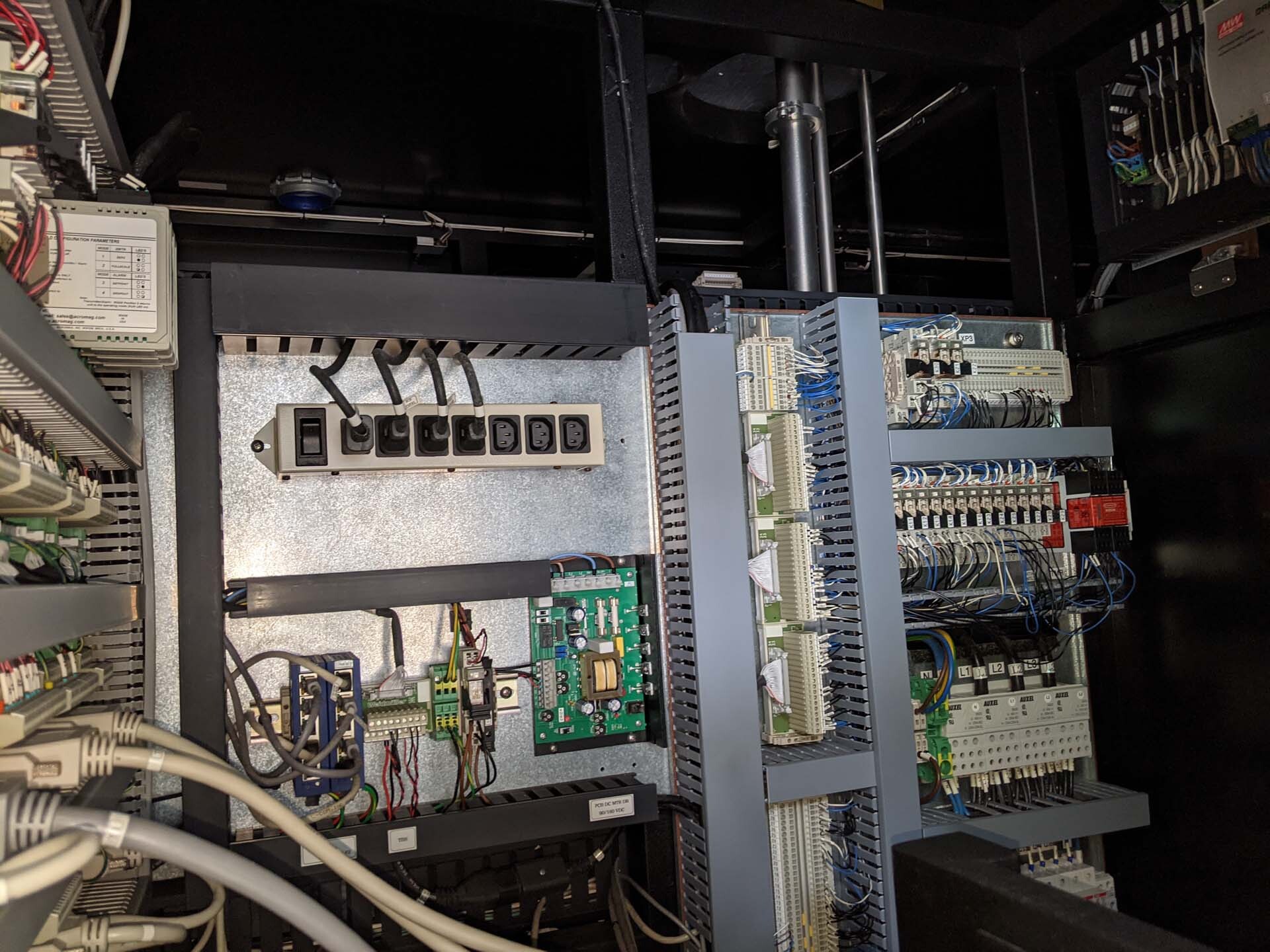

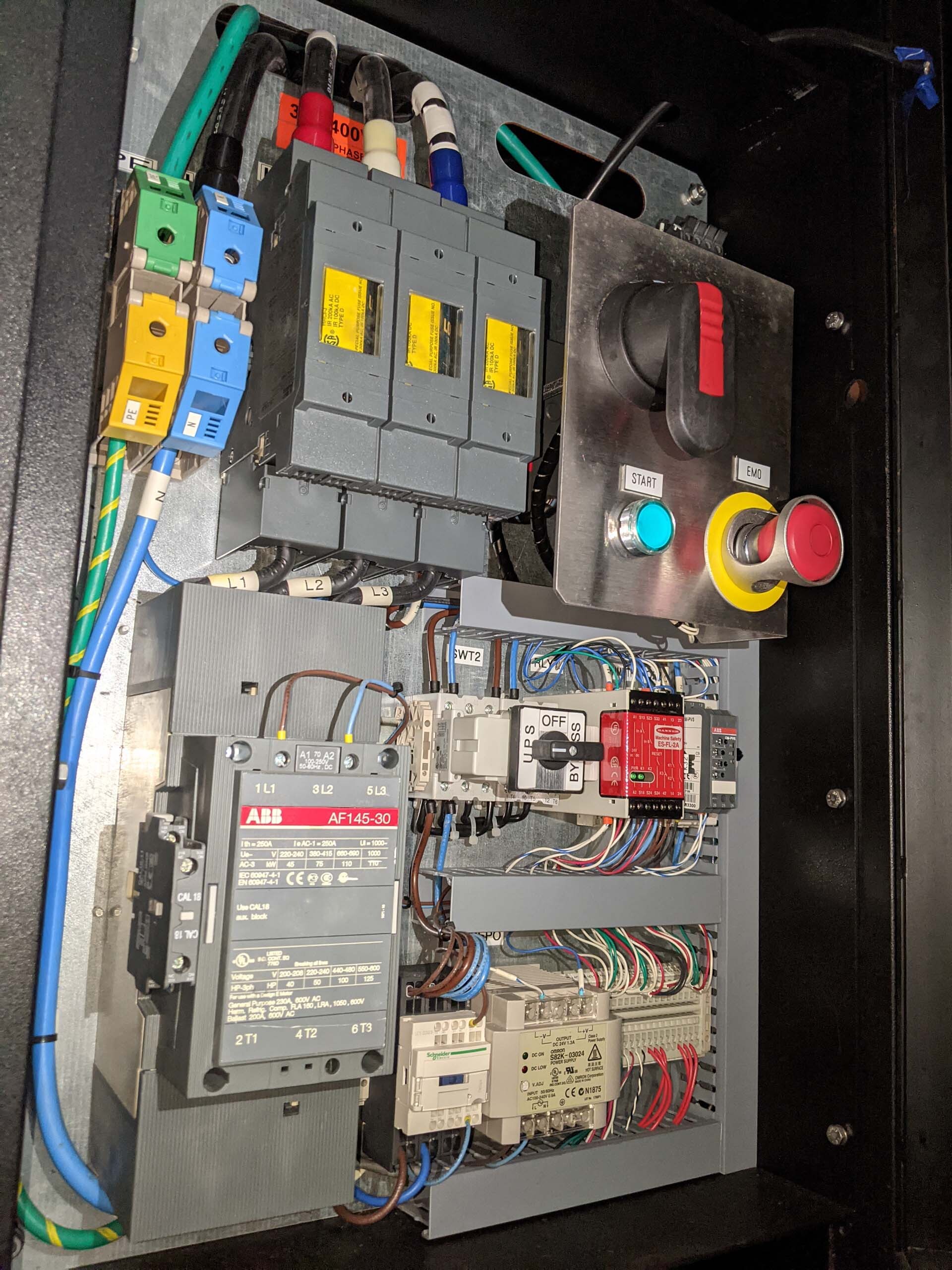

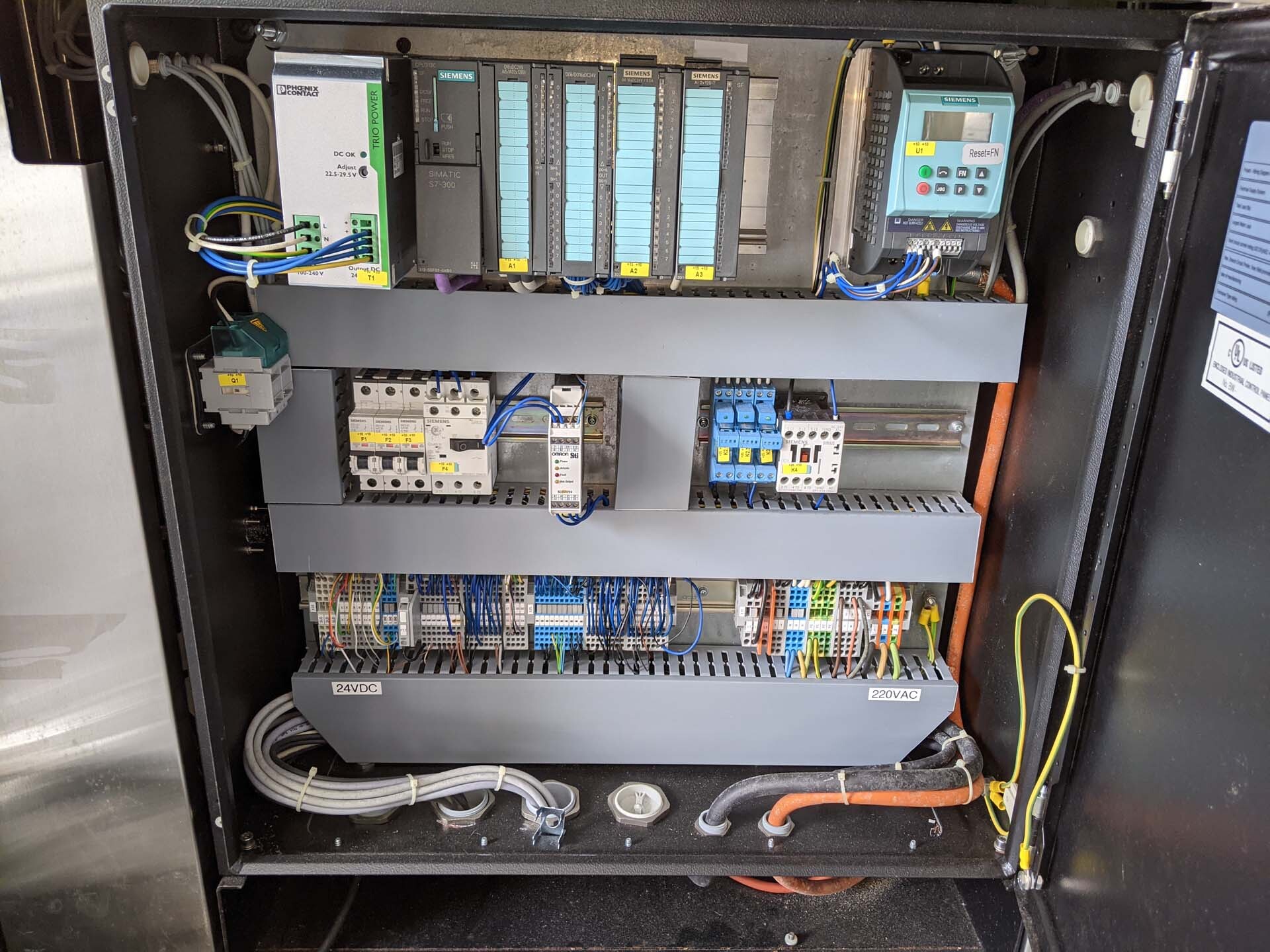

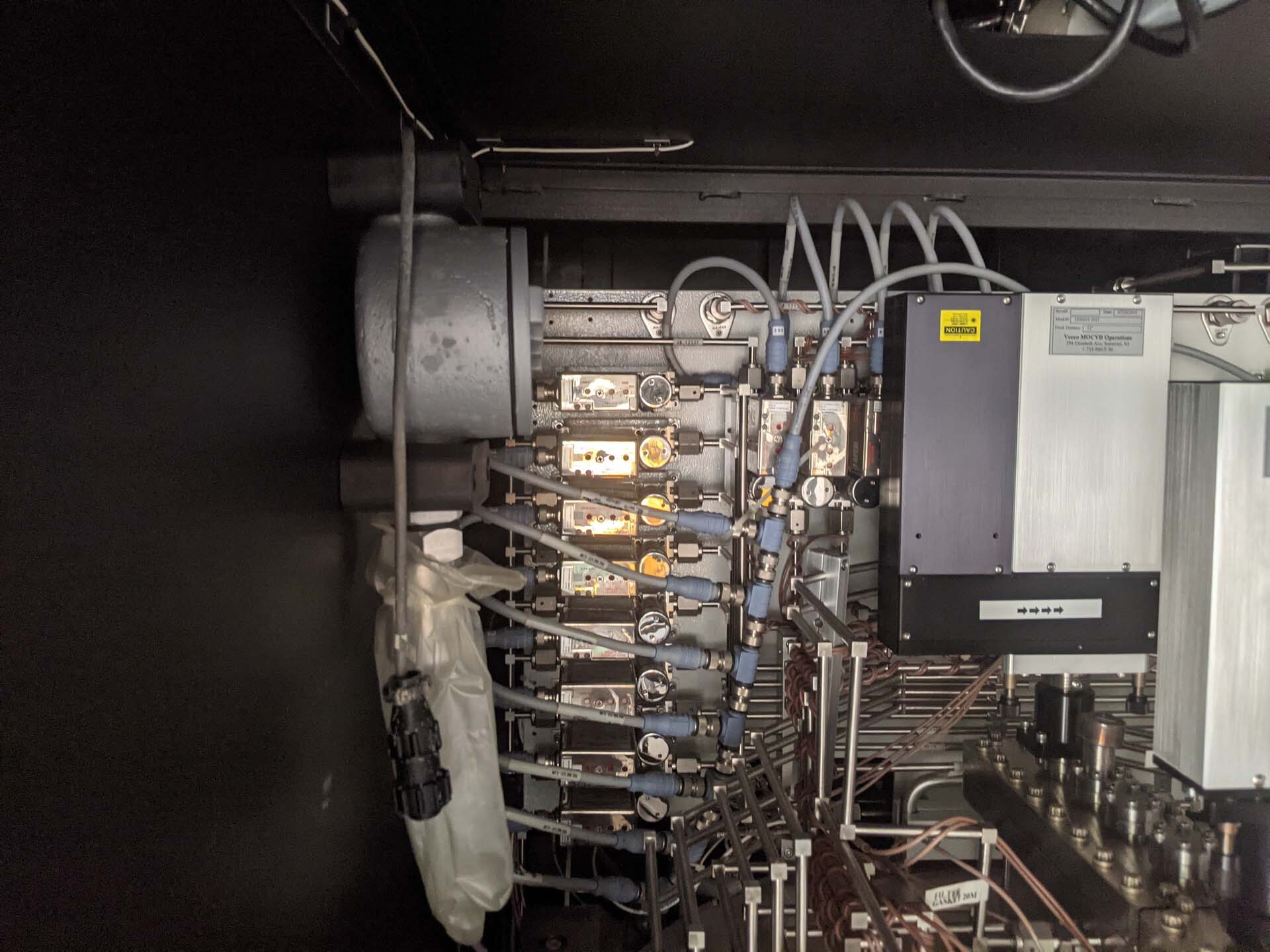

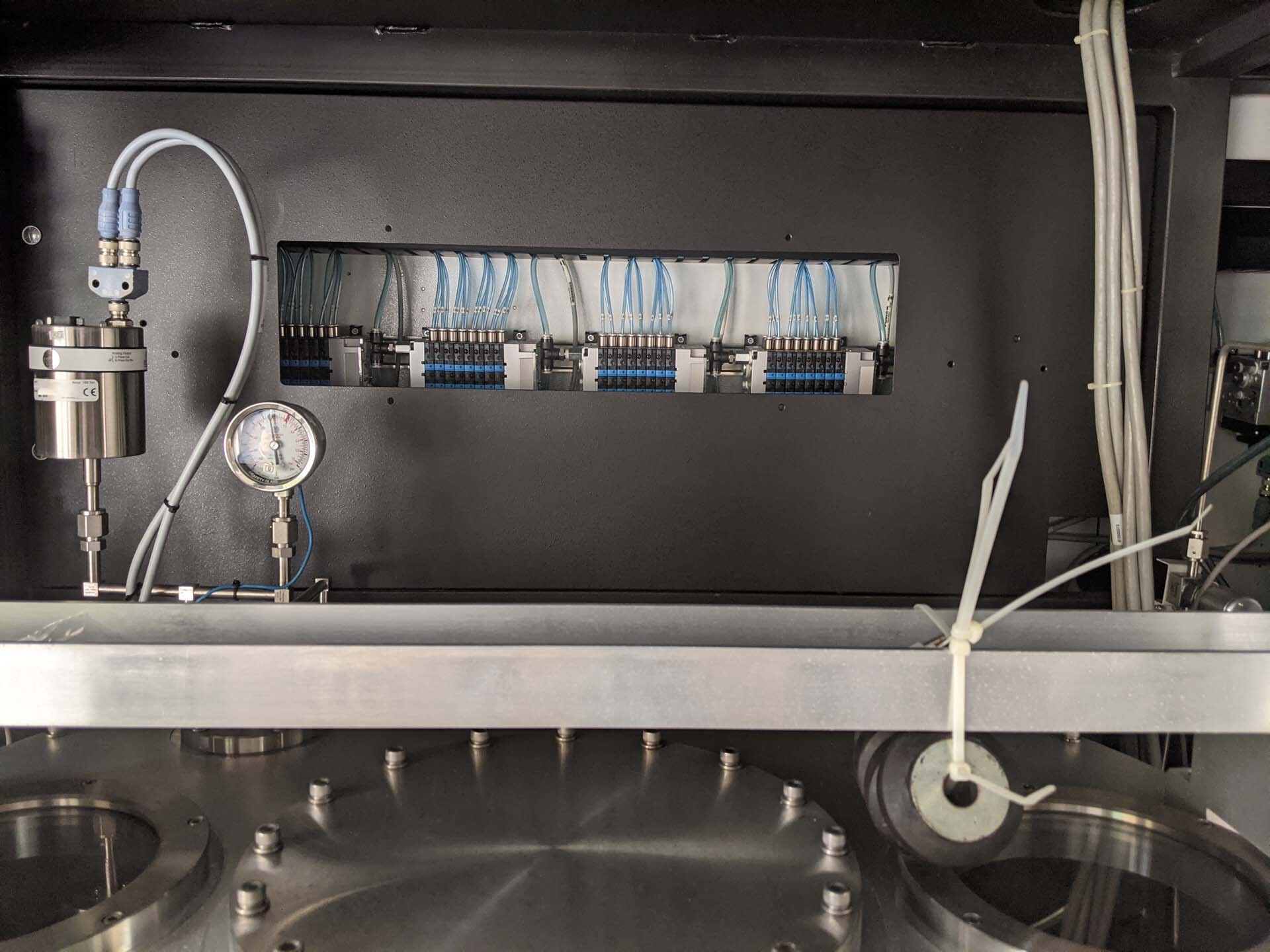

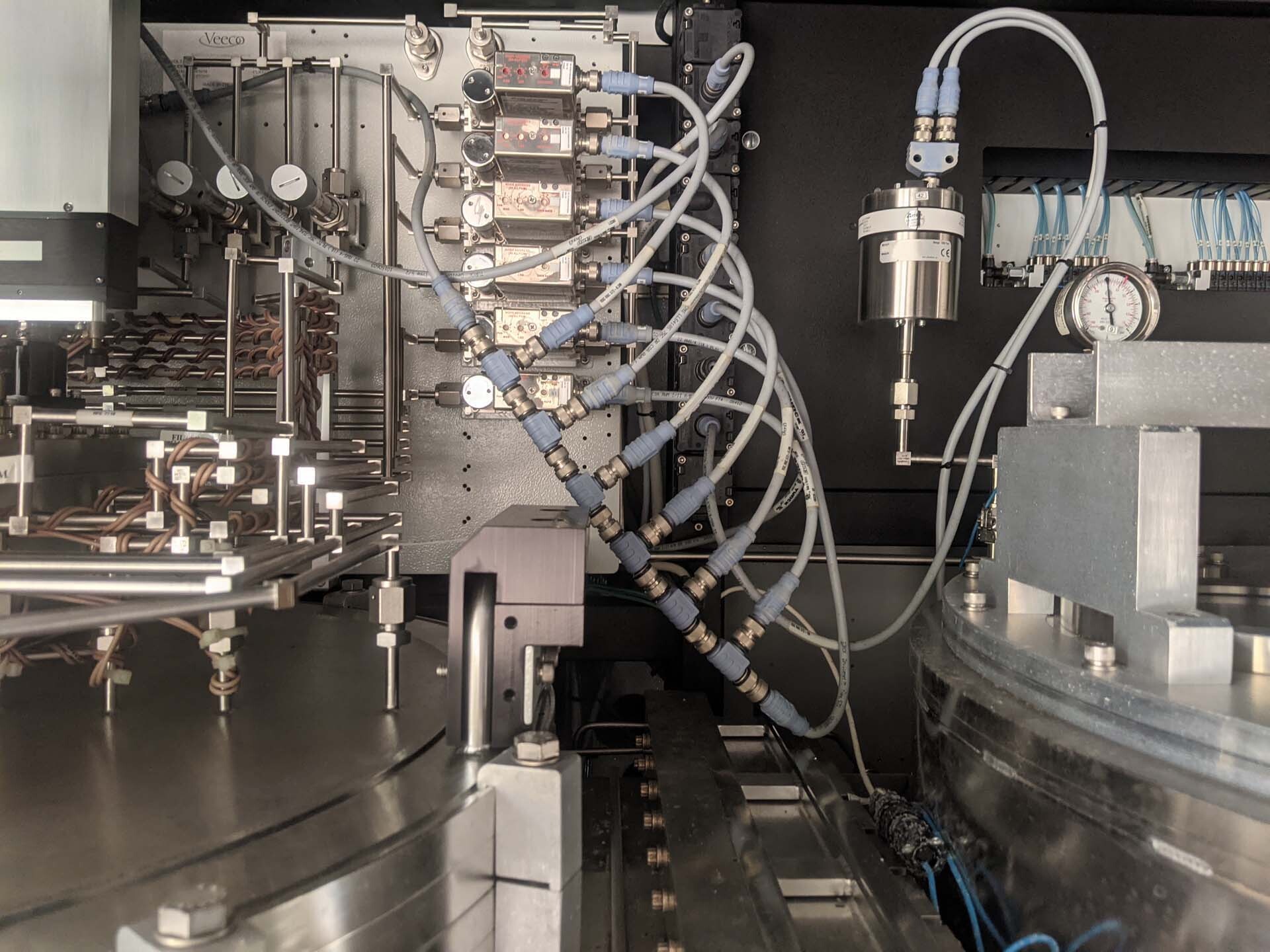

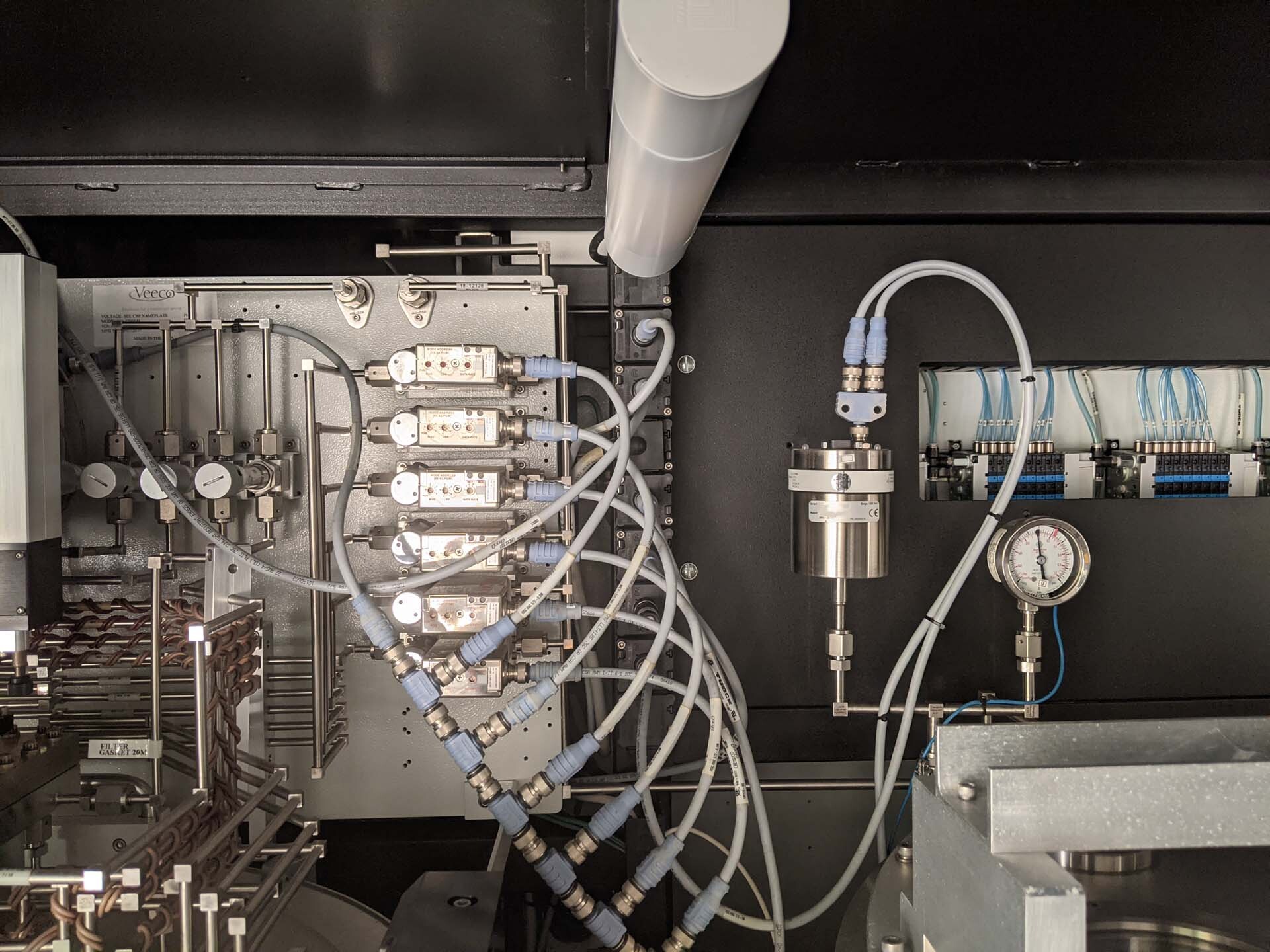

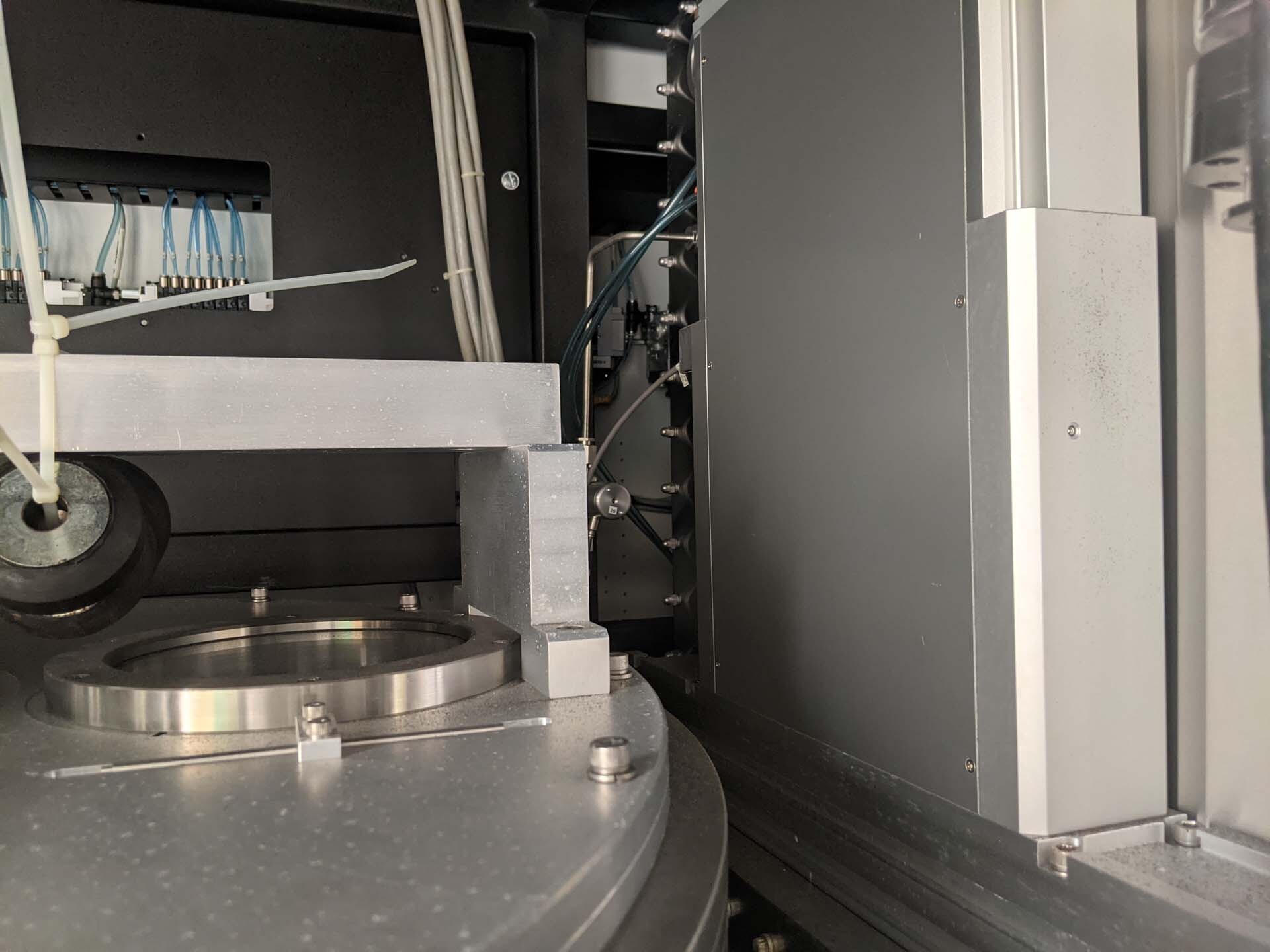

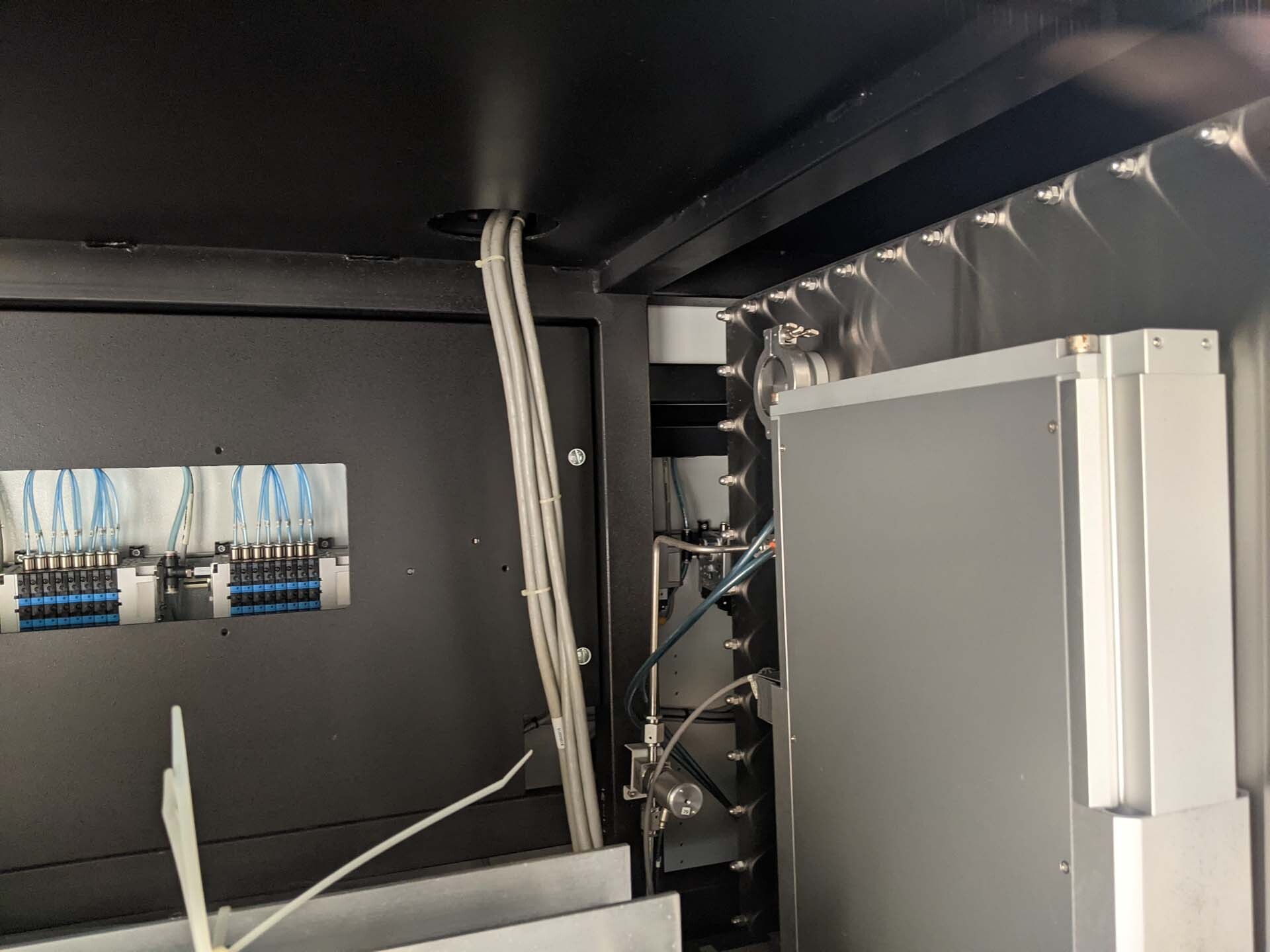

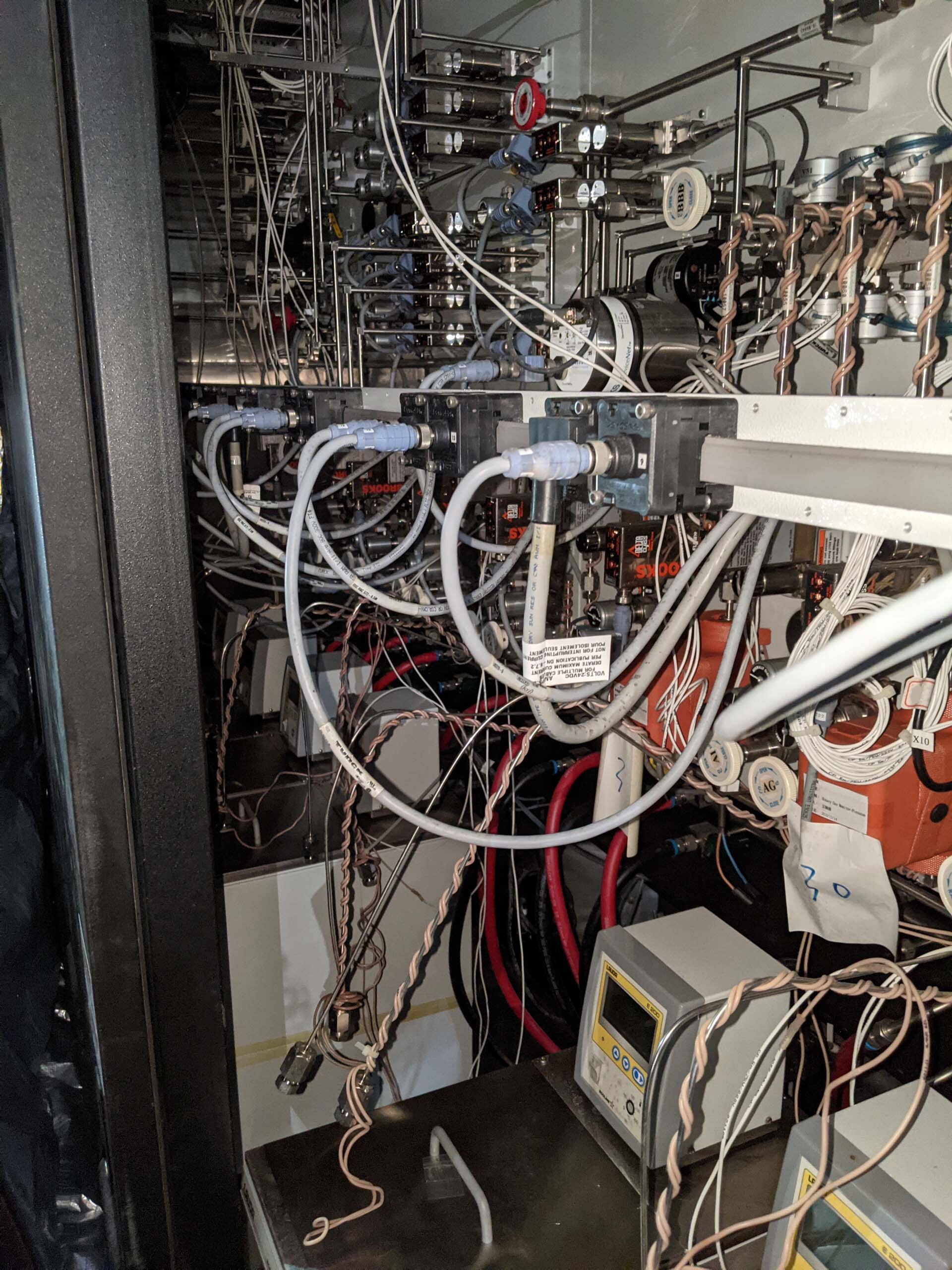

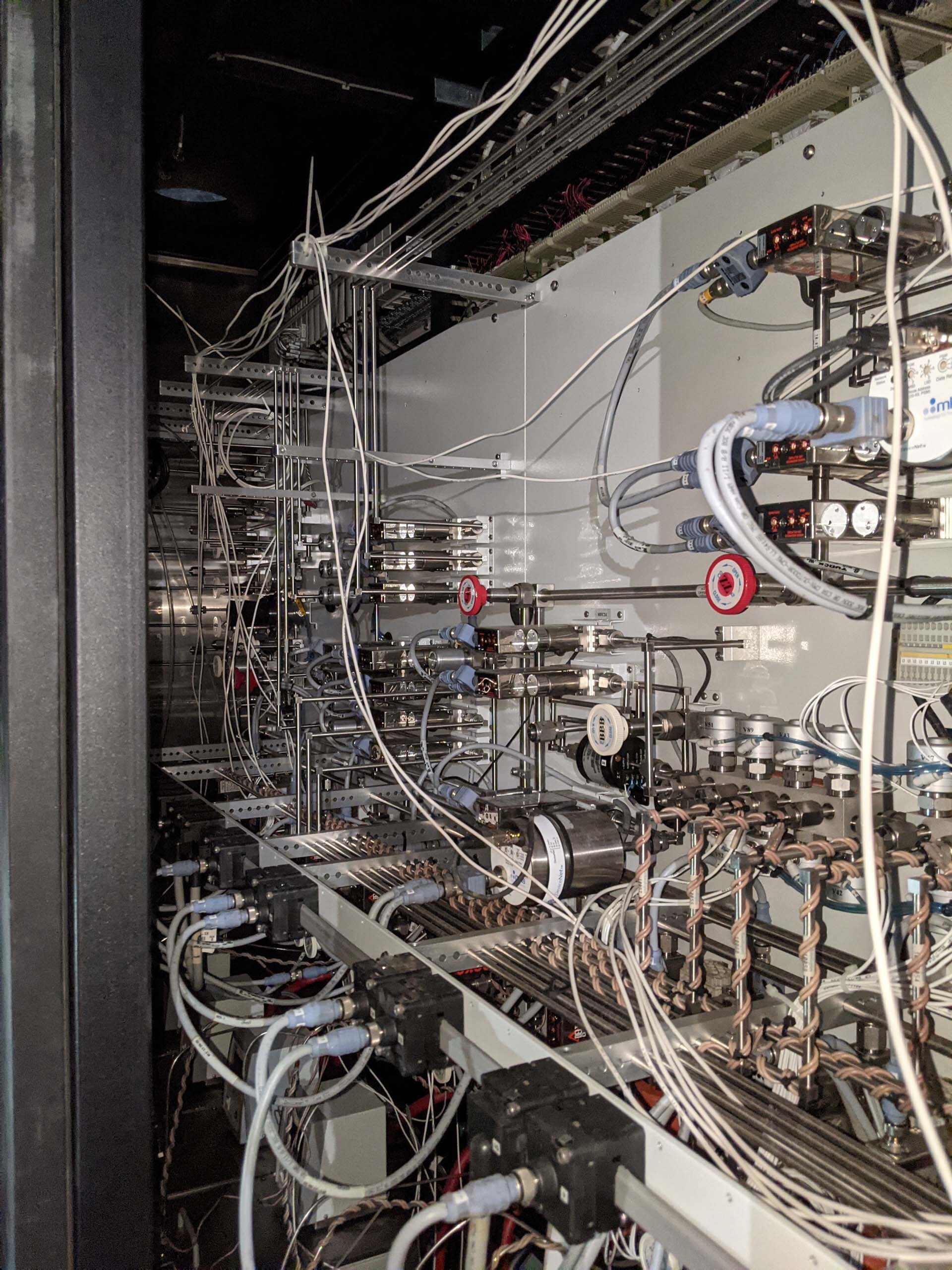

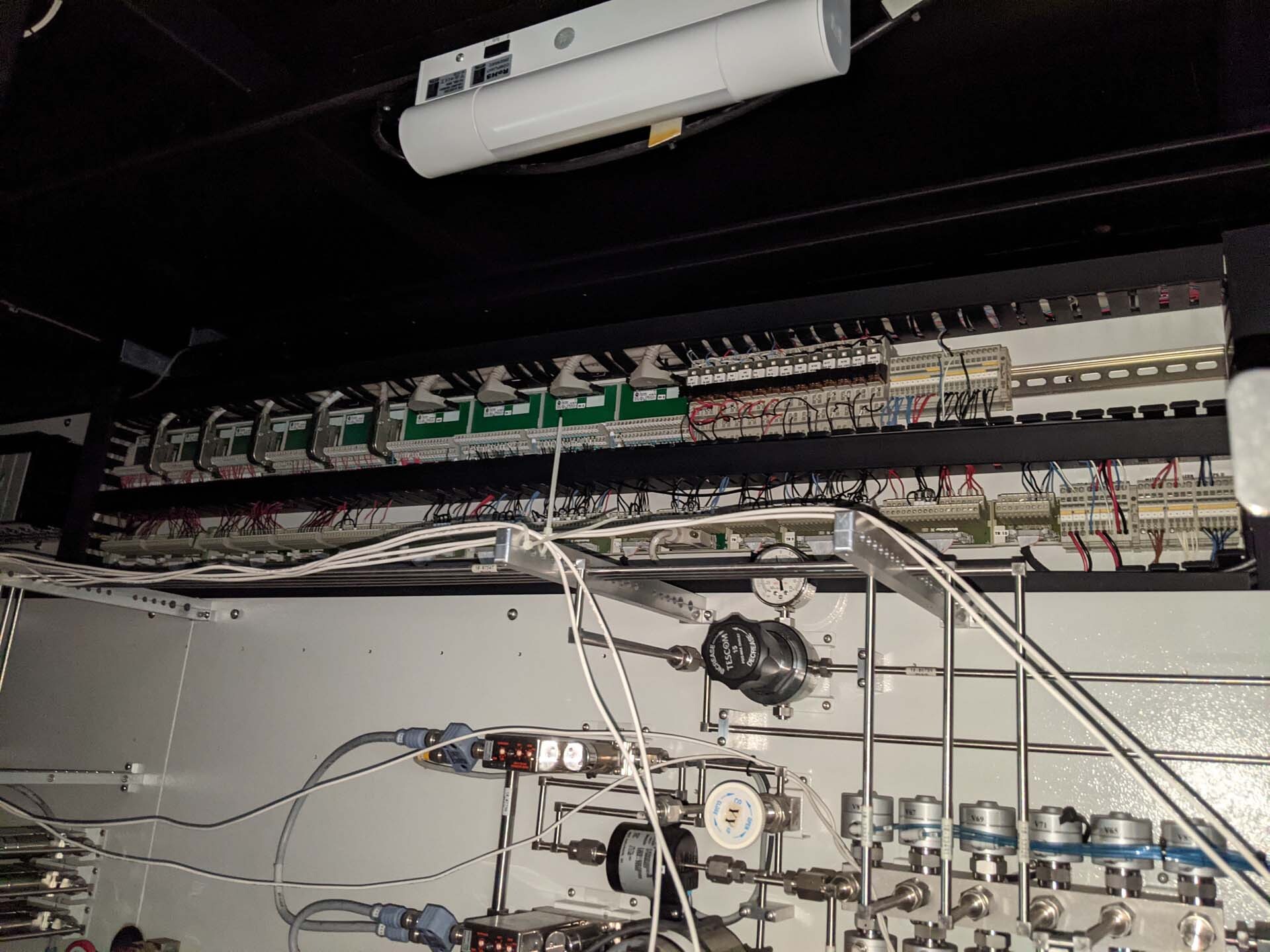

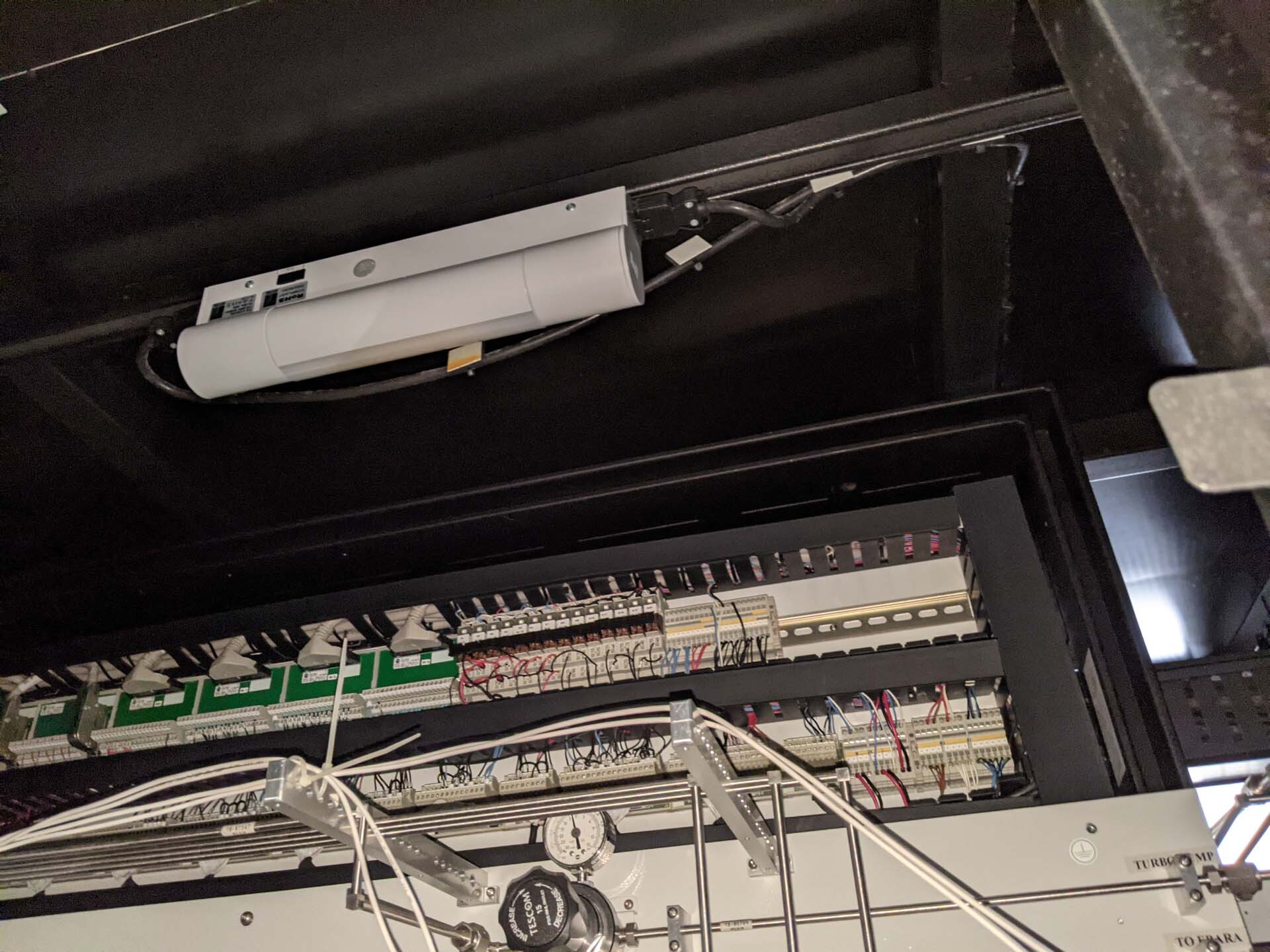

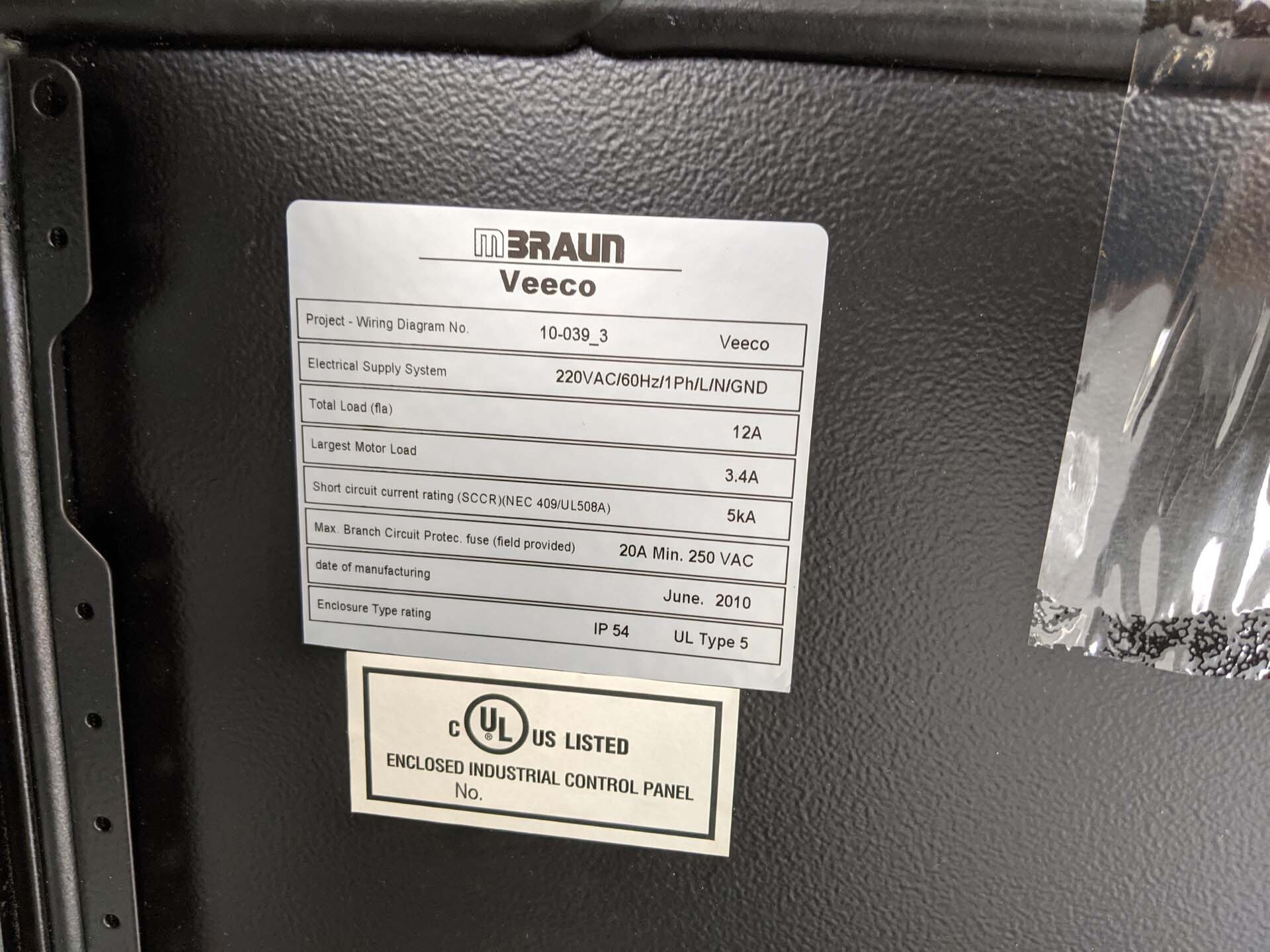

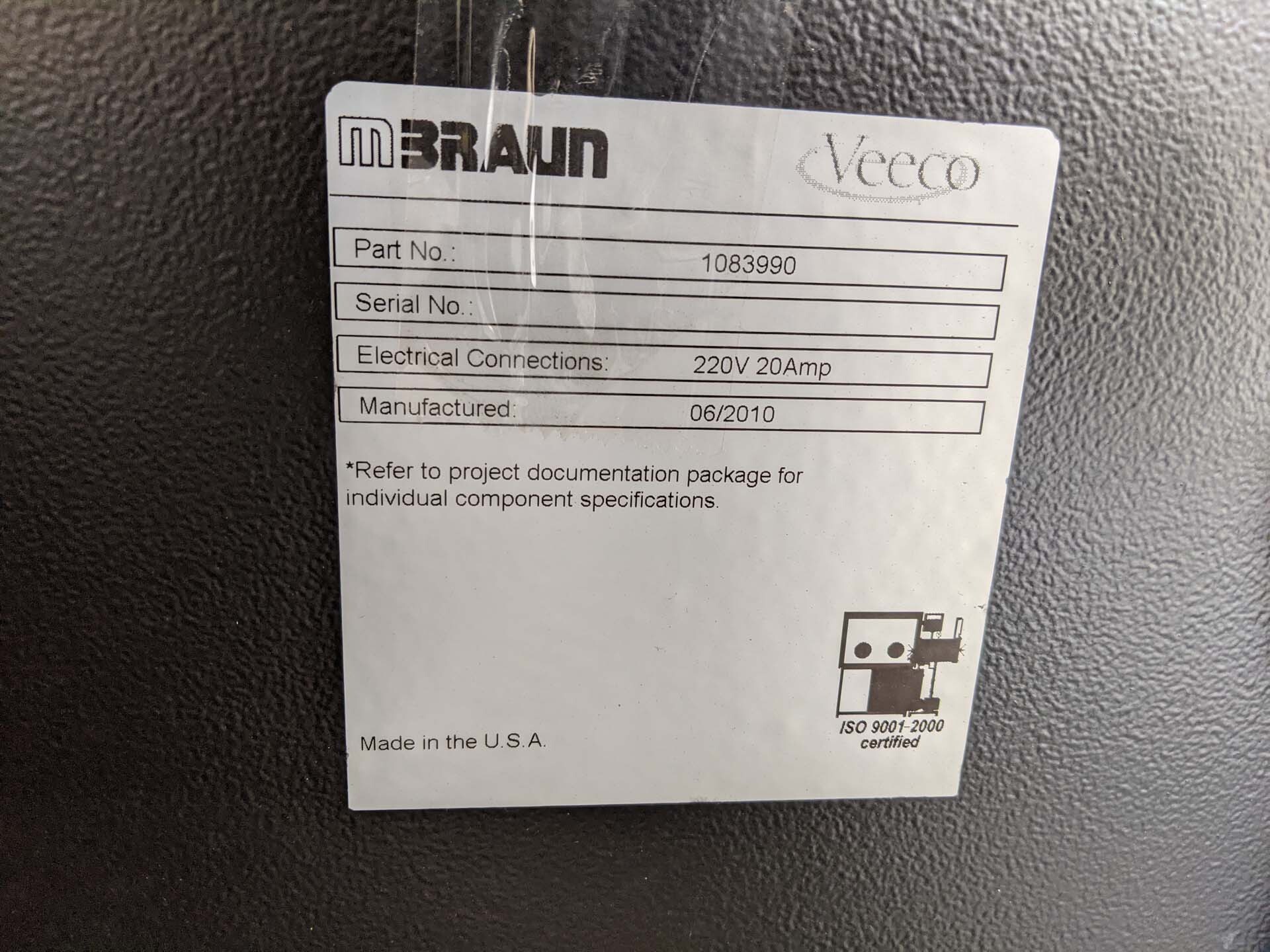

Electrical and control part

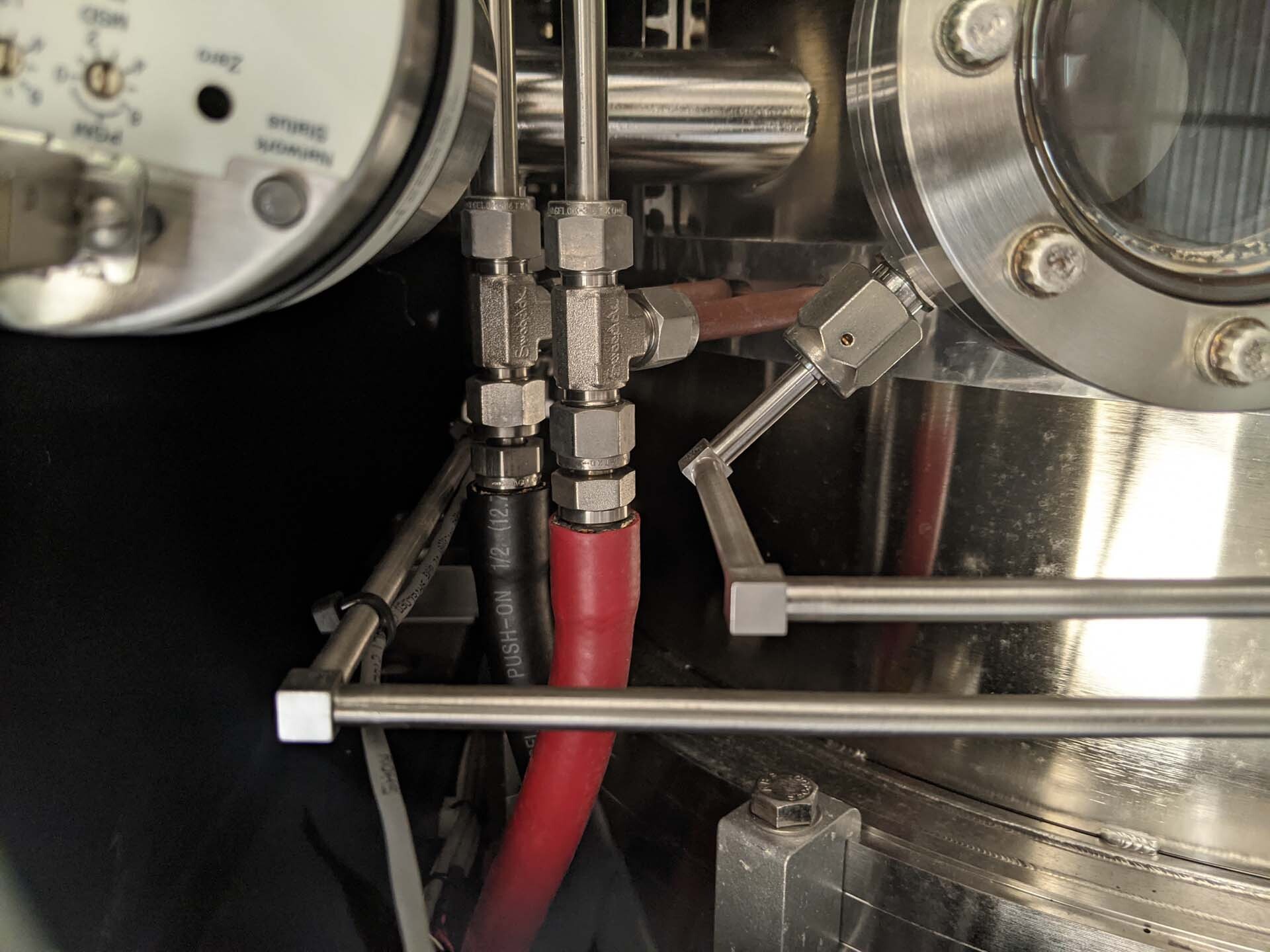

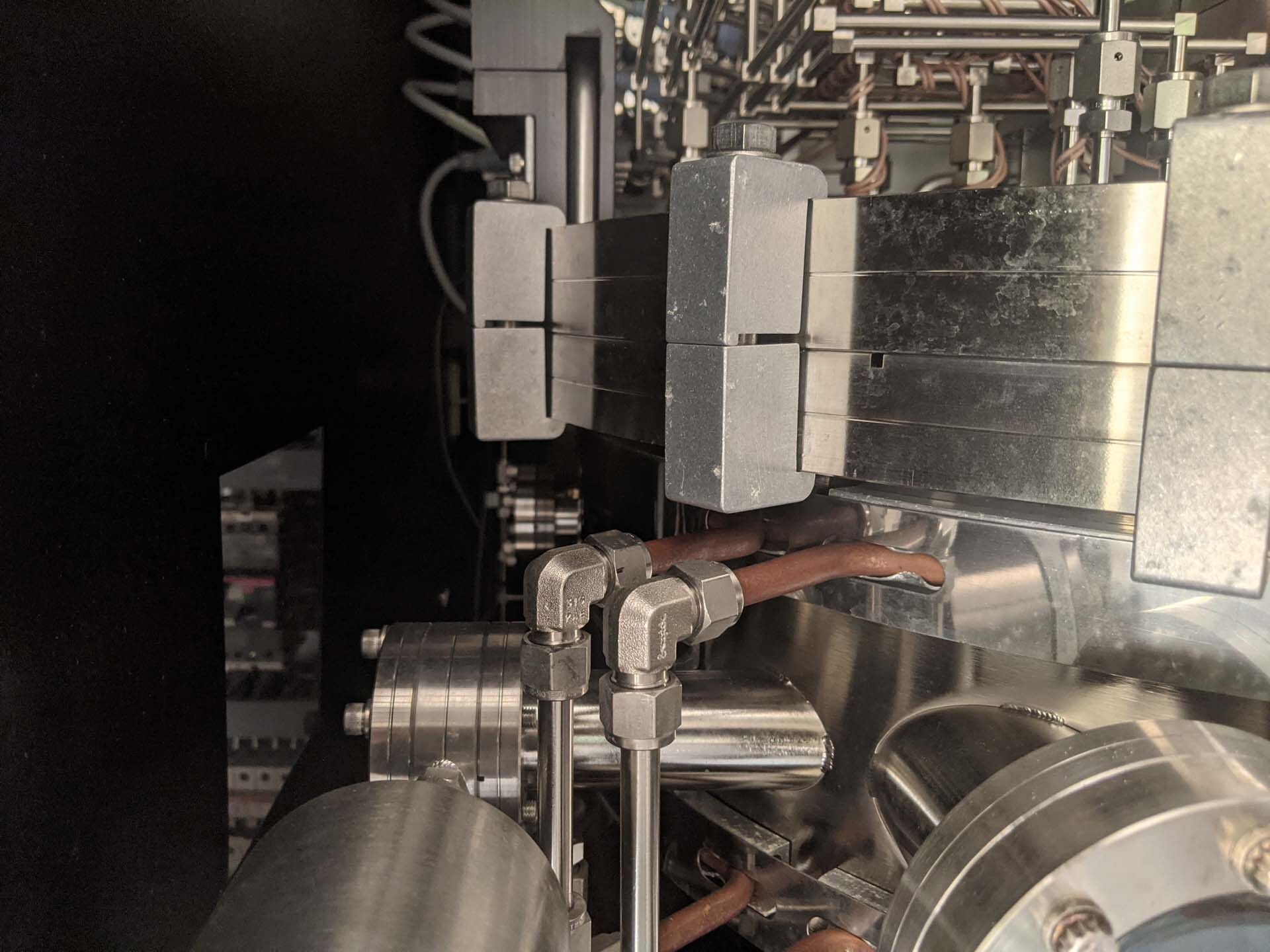

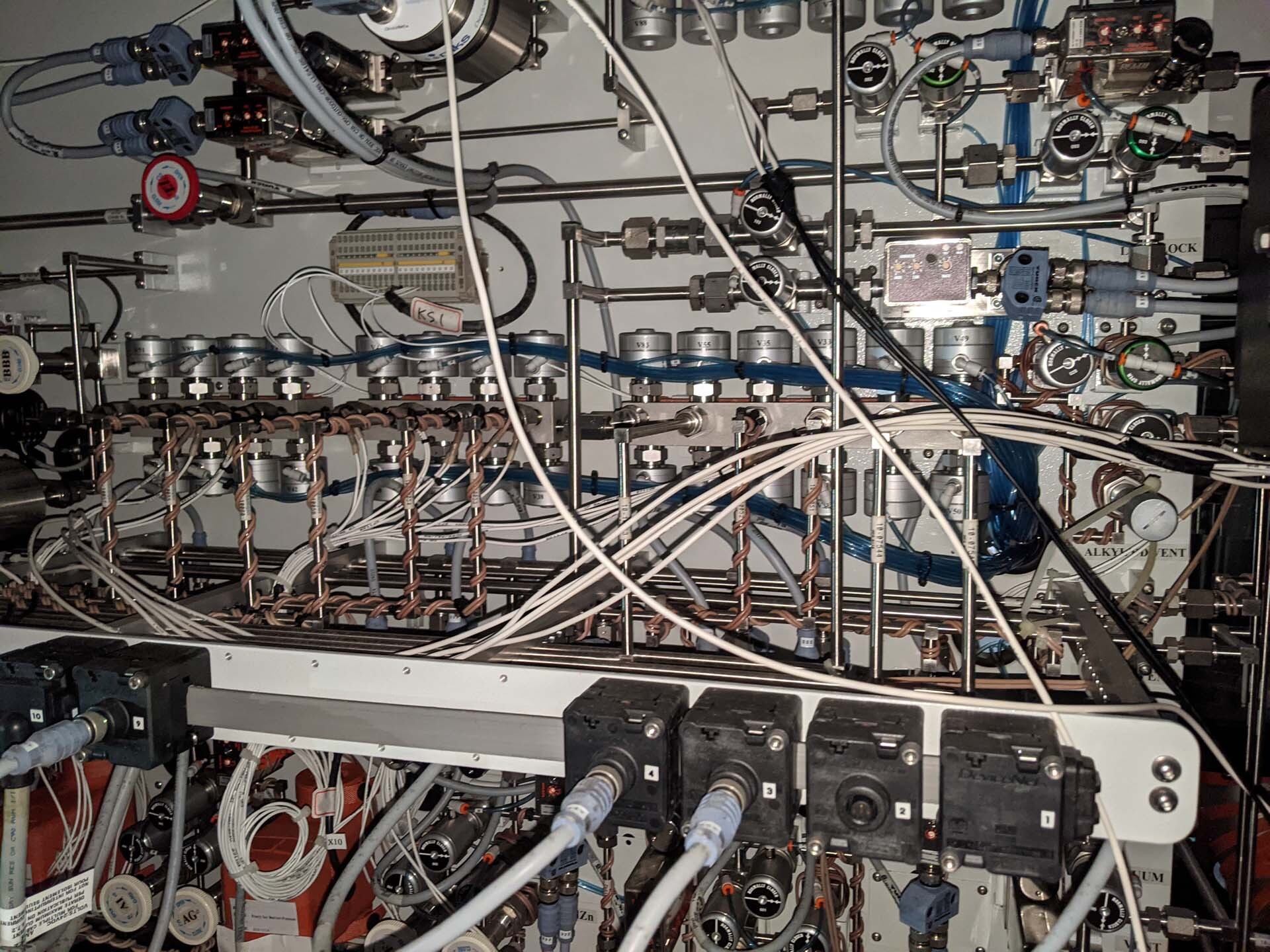

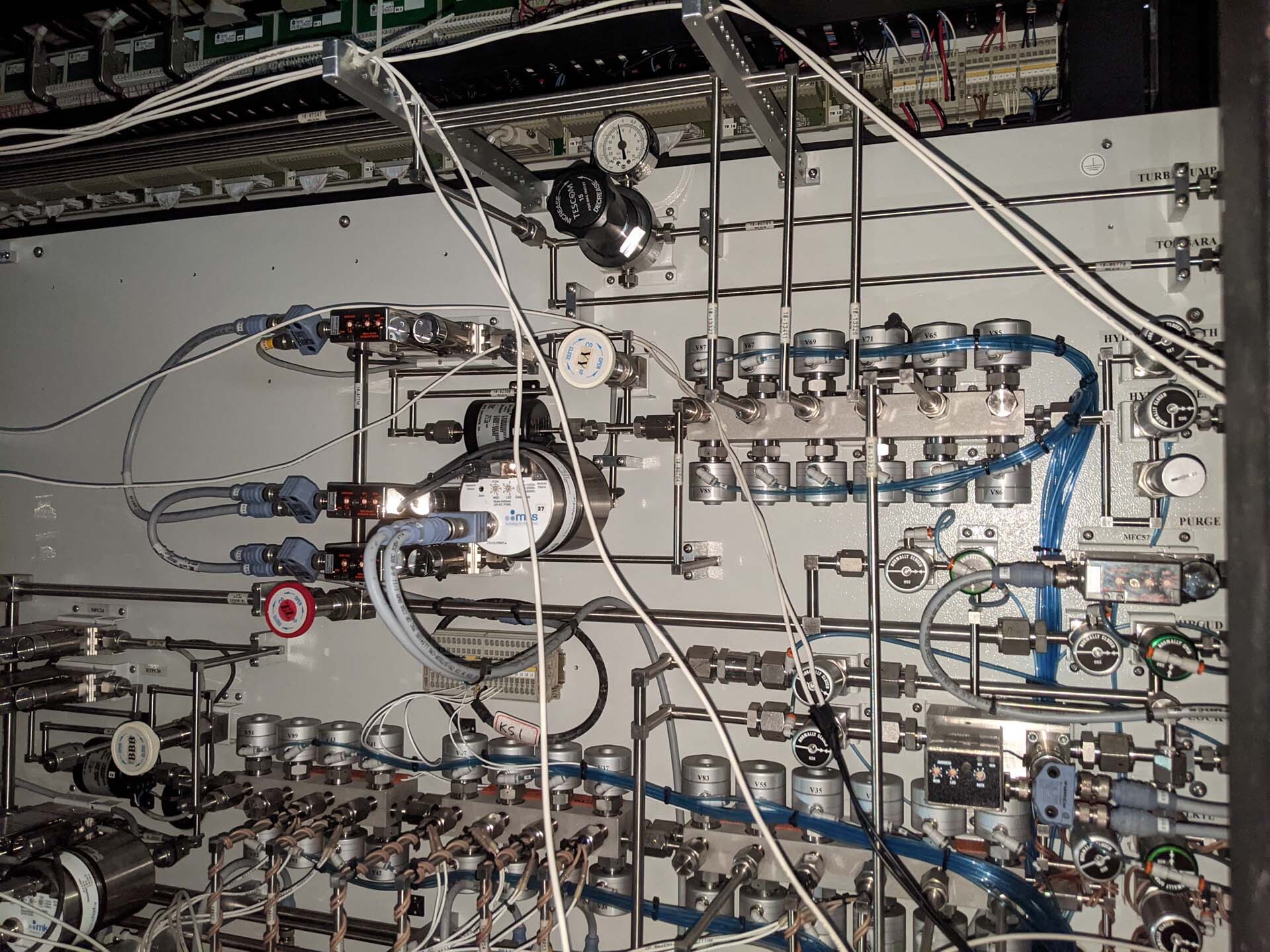

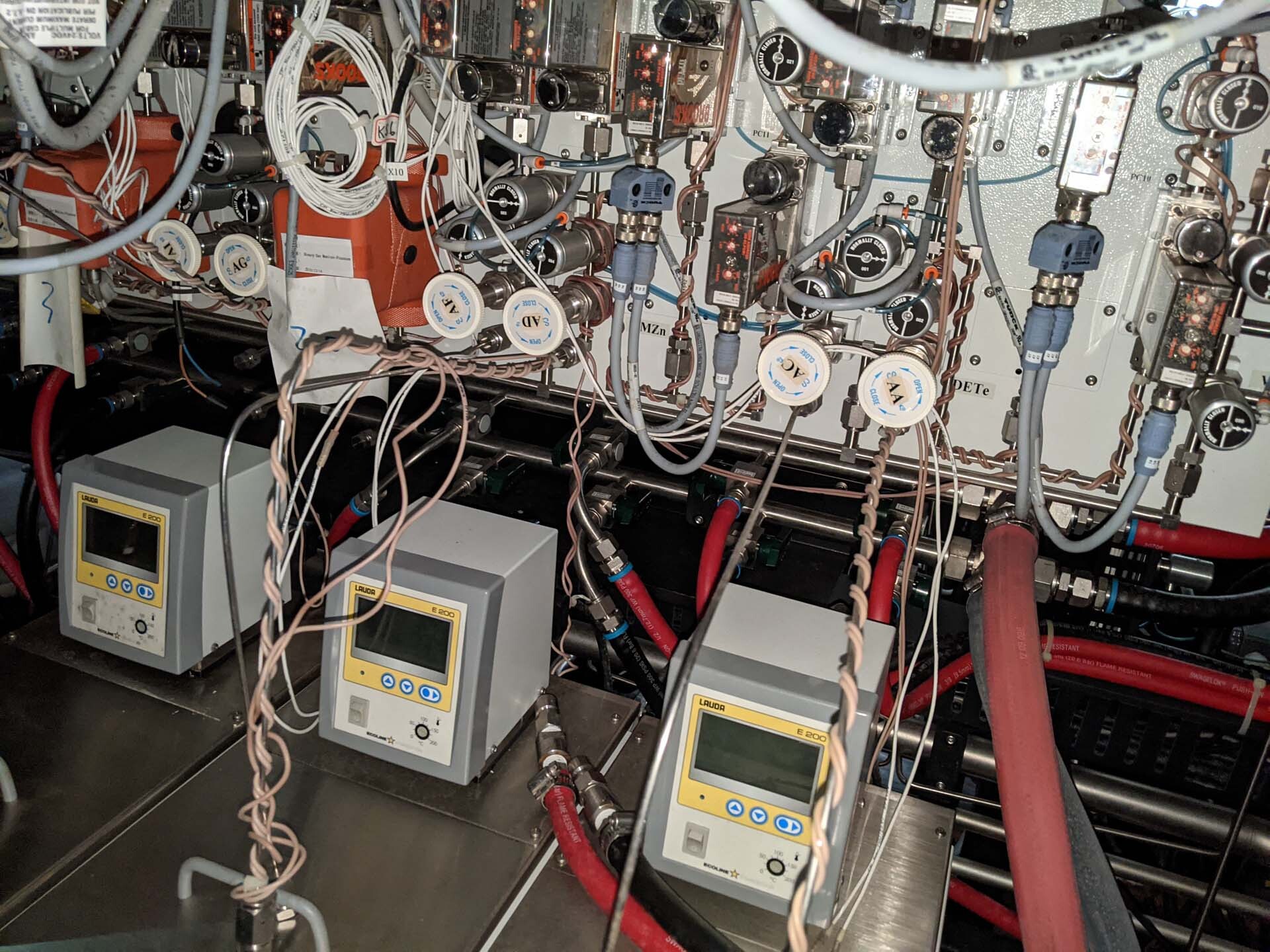

Gas panel part

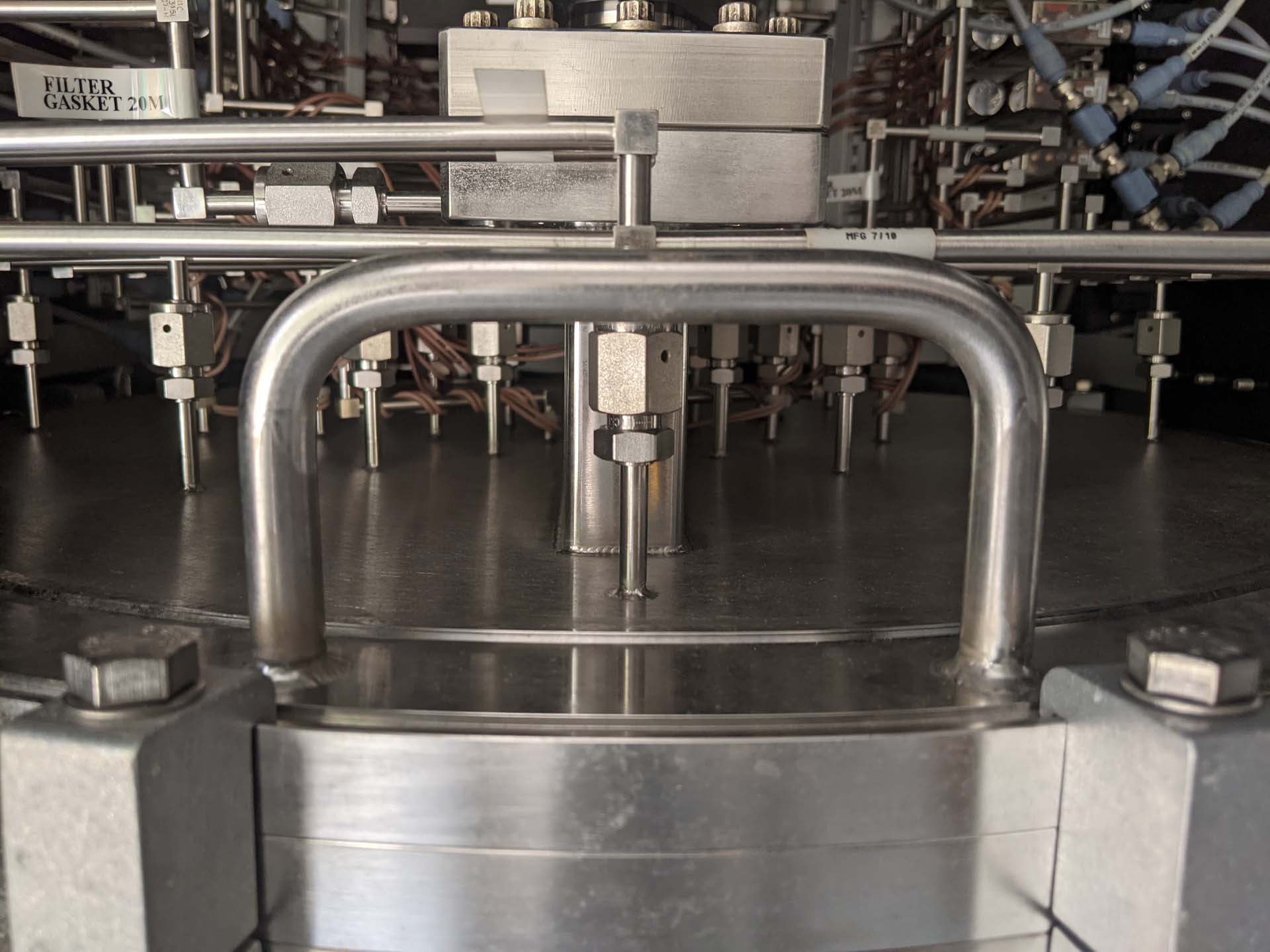

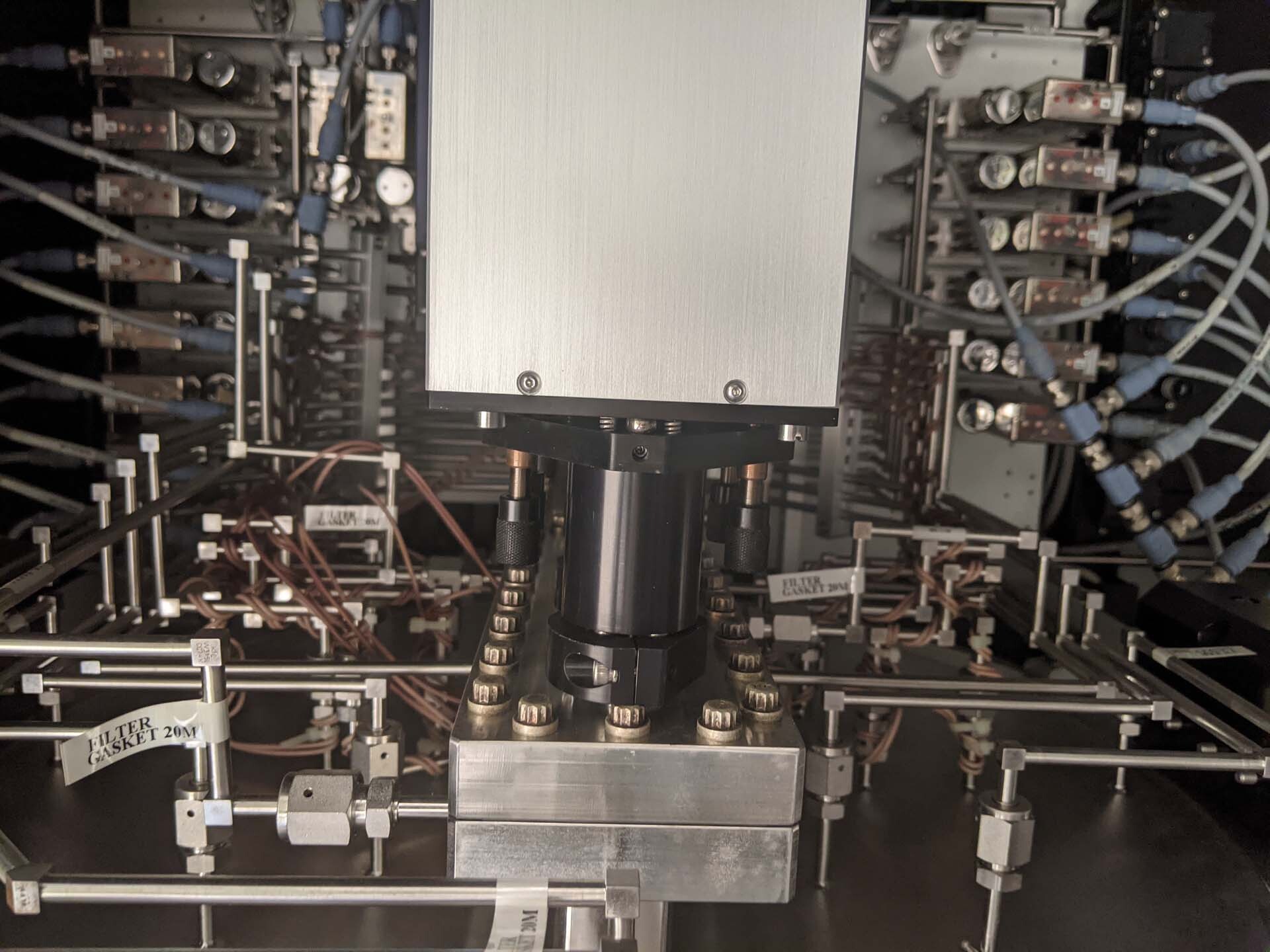

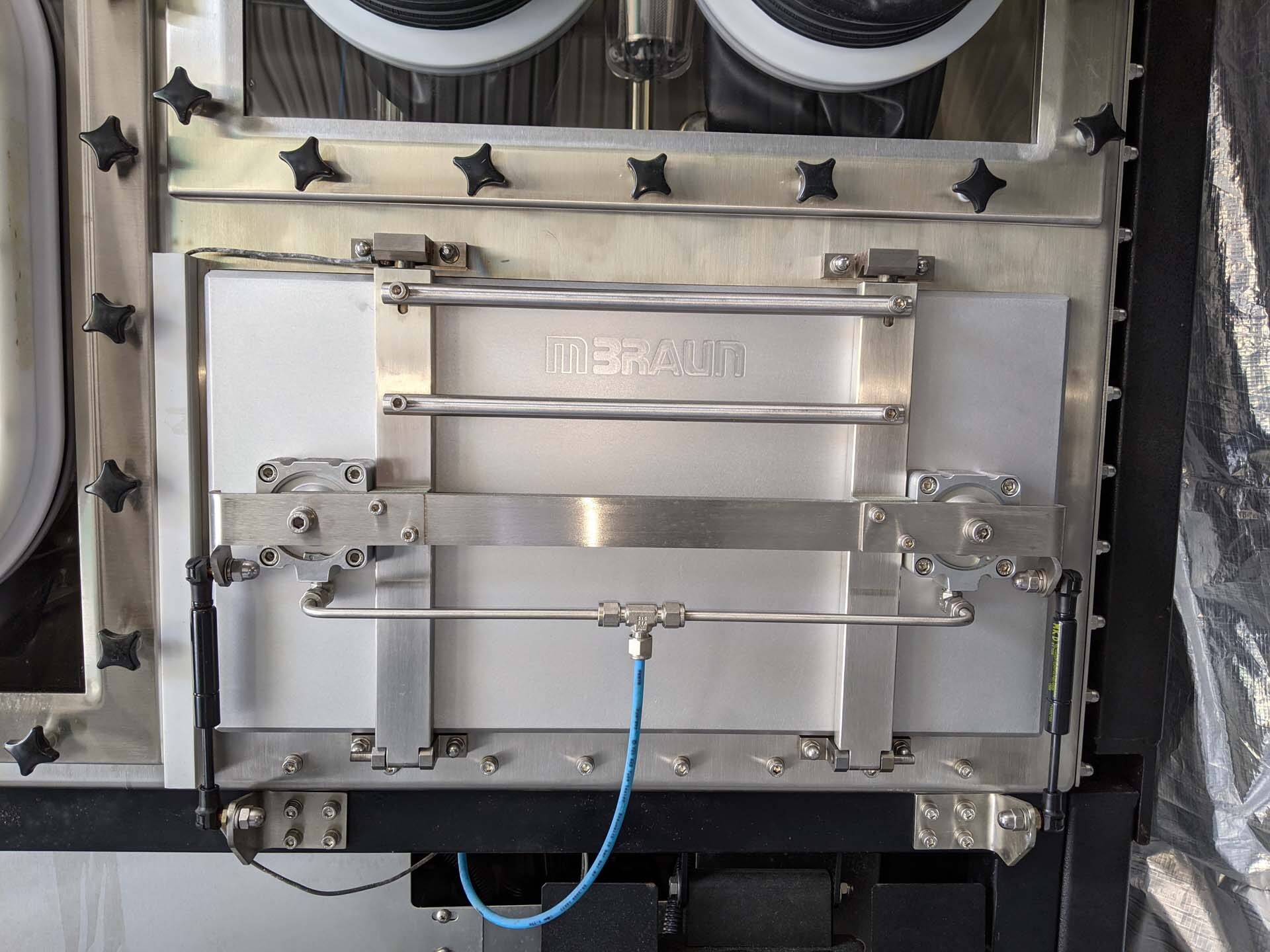

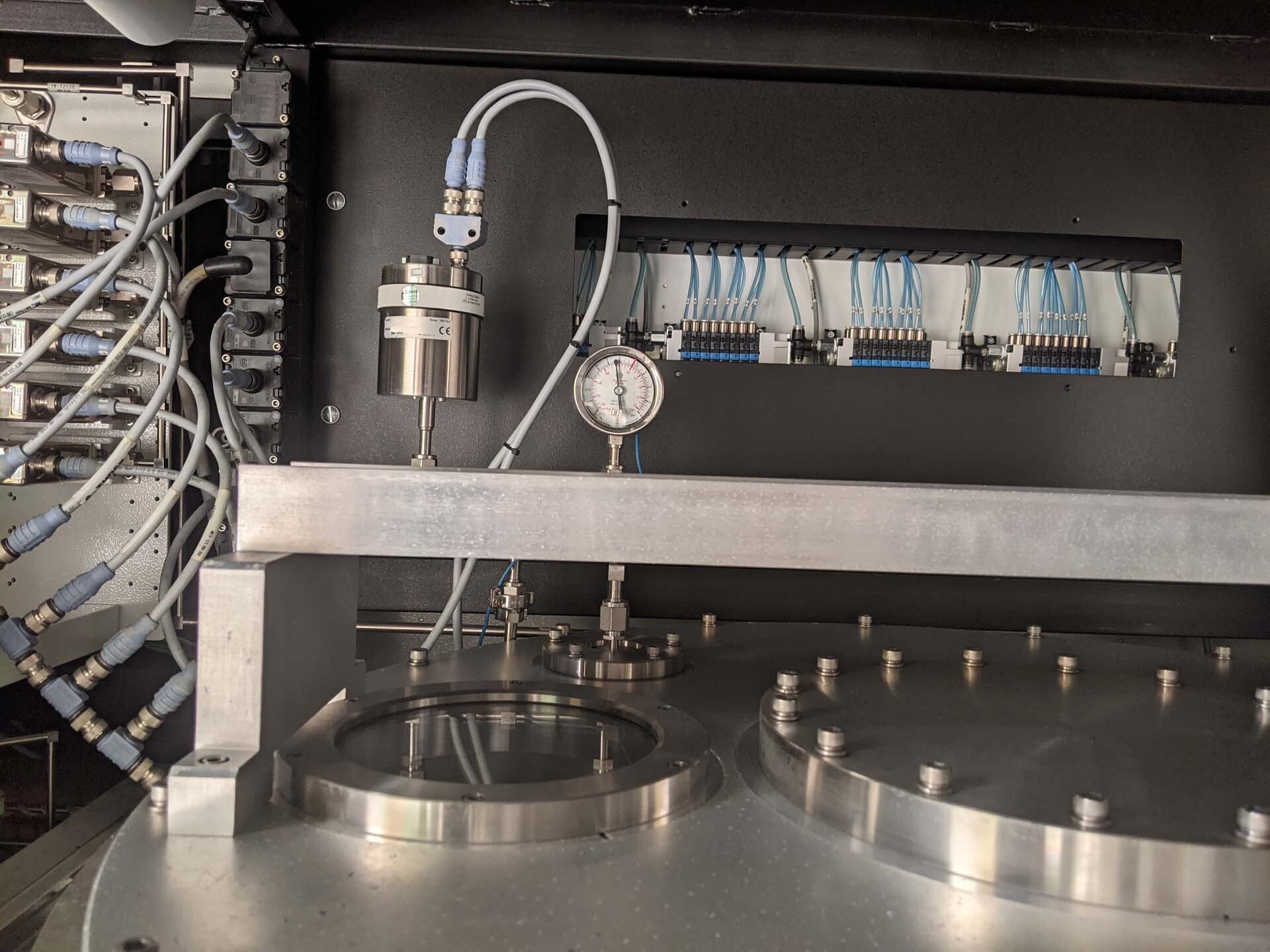

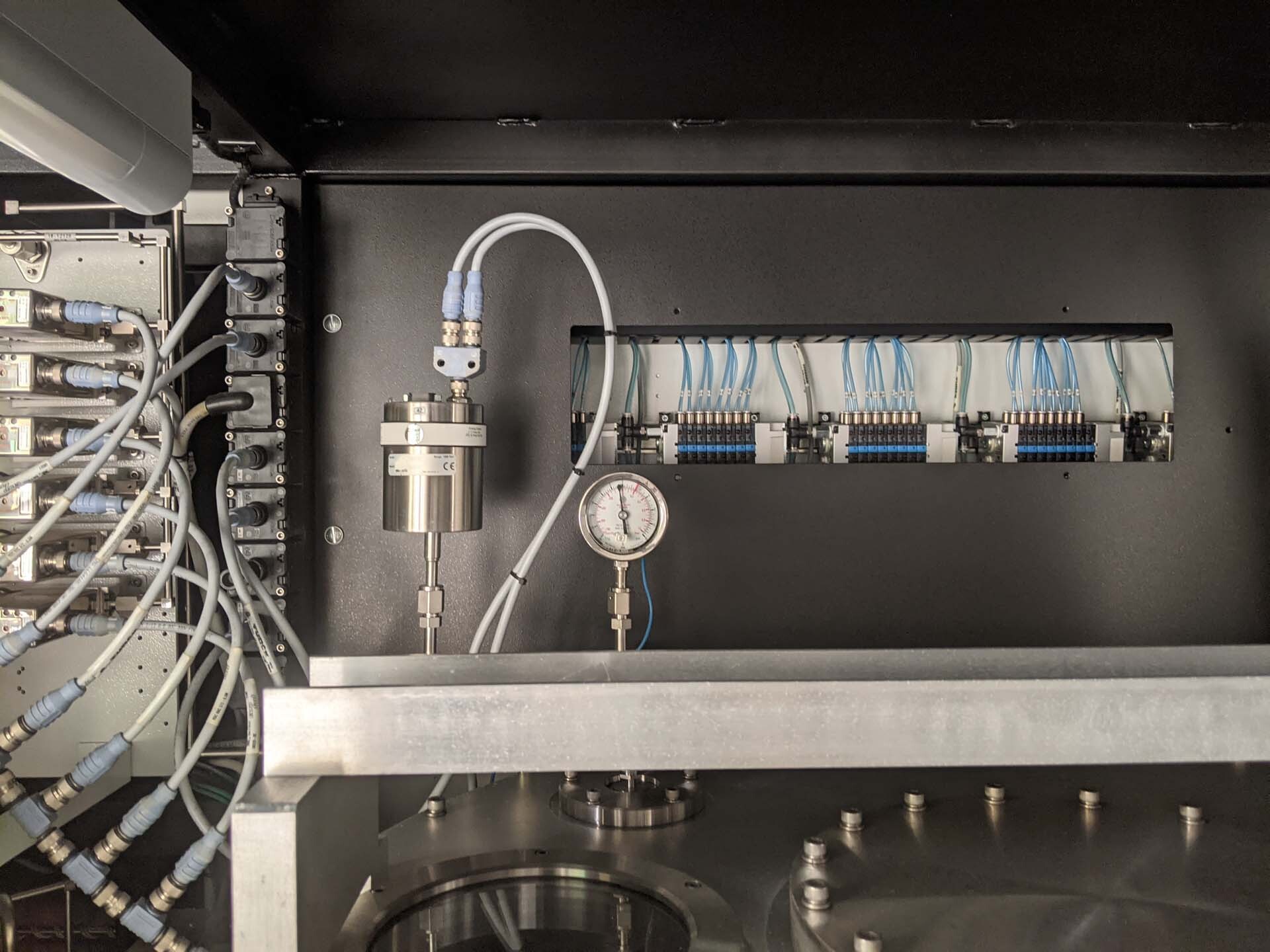

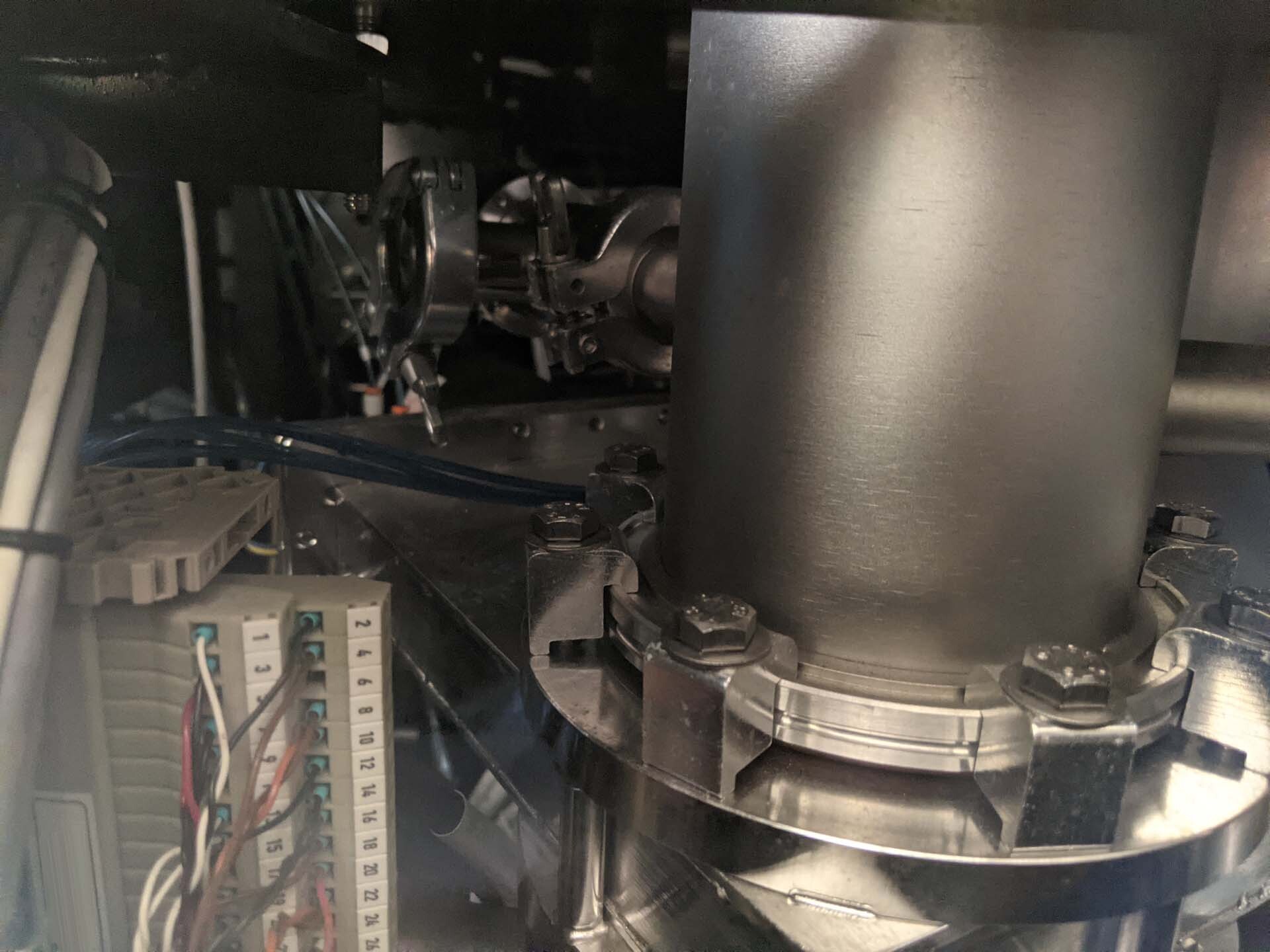

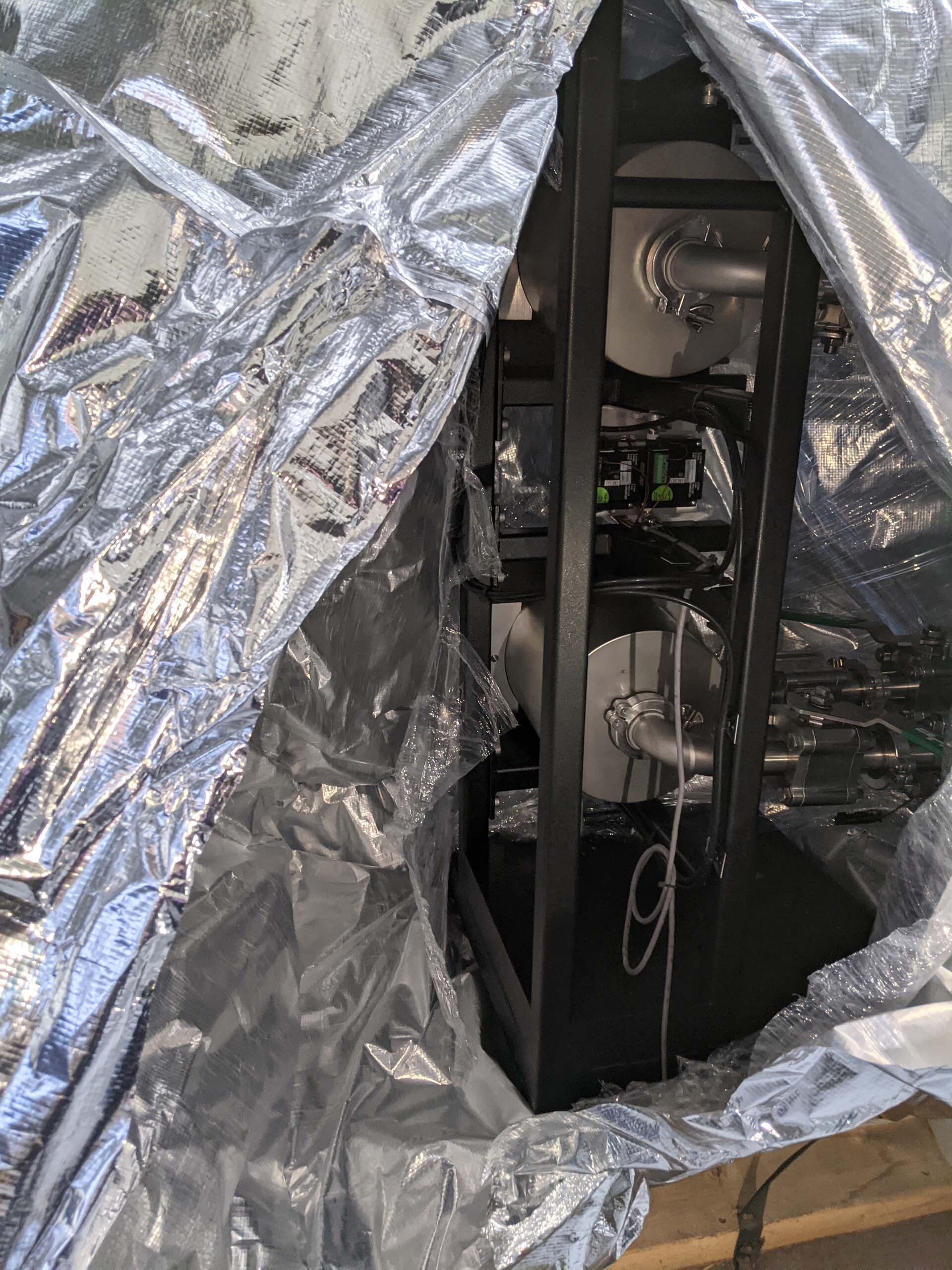

Reactor part

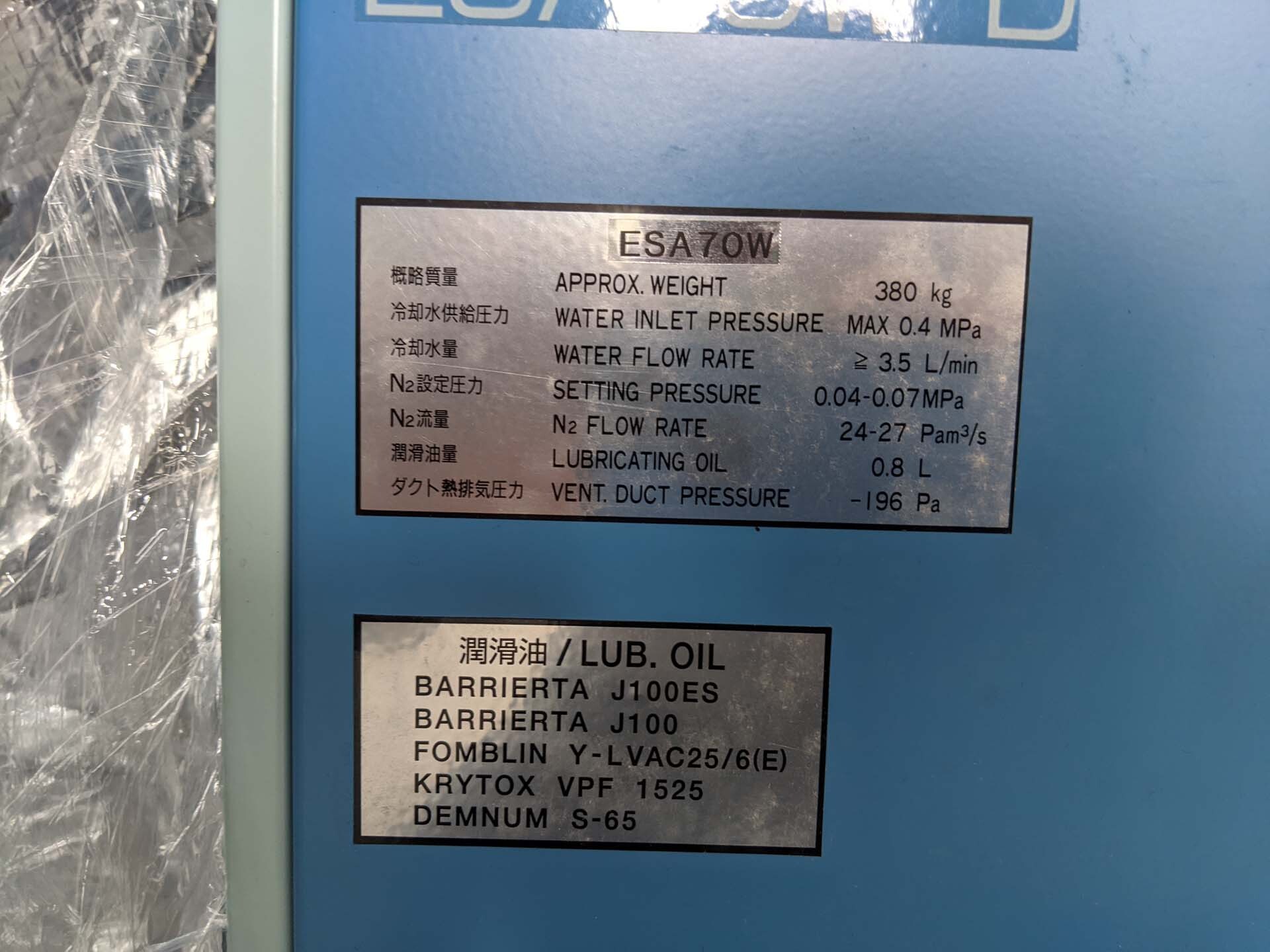

EBARA ESA70WD

Dry pump

Includes:

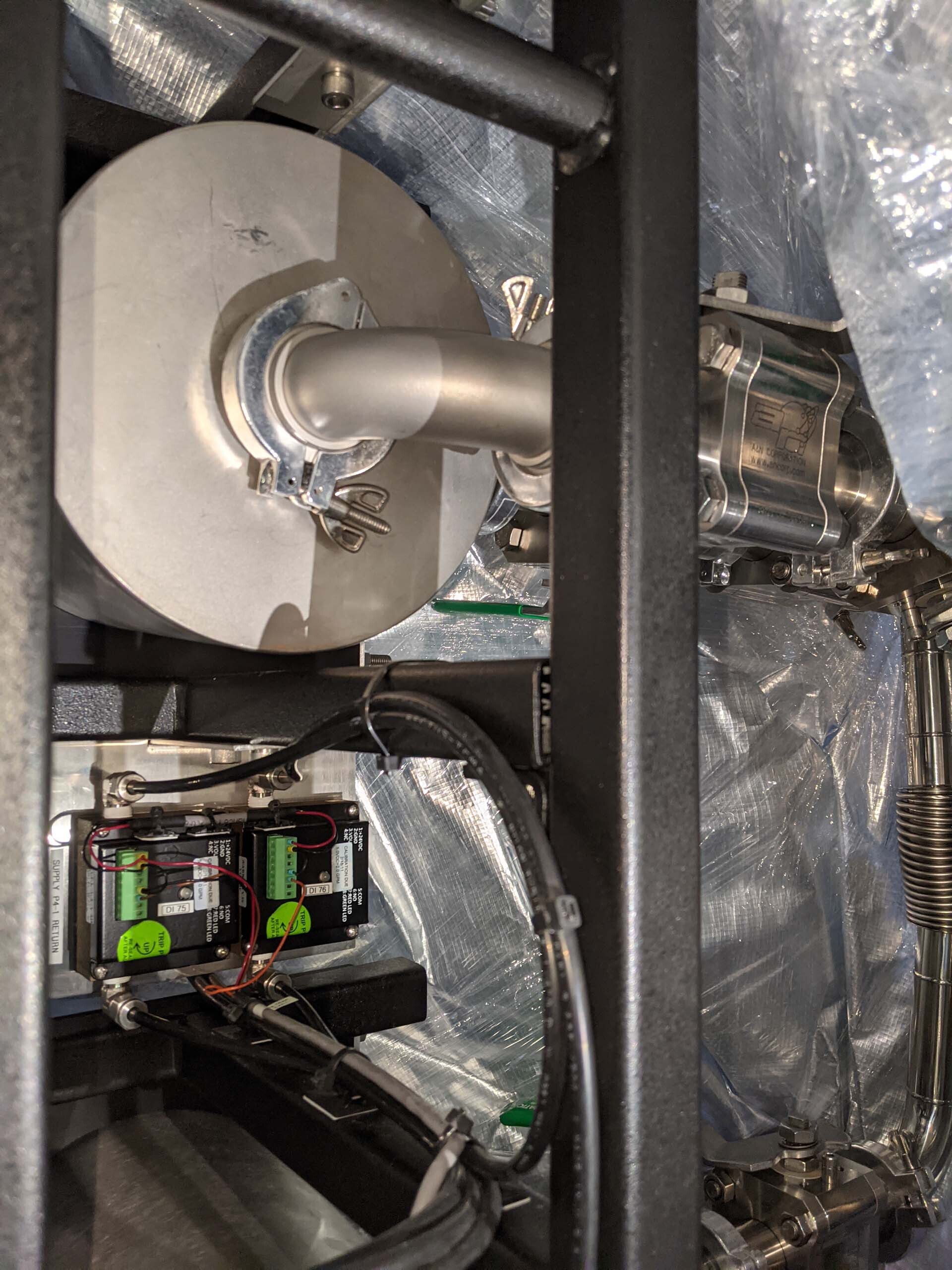

As/P Growth chamber

Growth chamber exhaust system

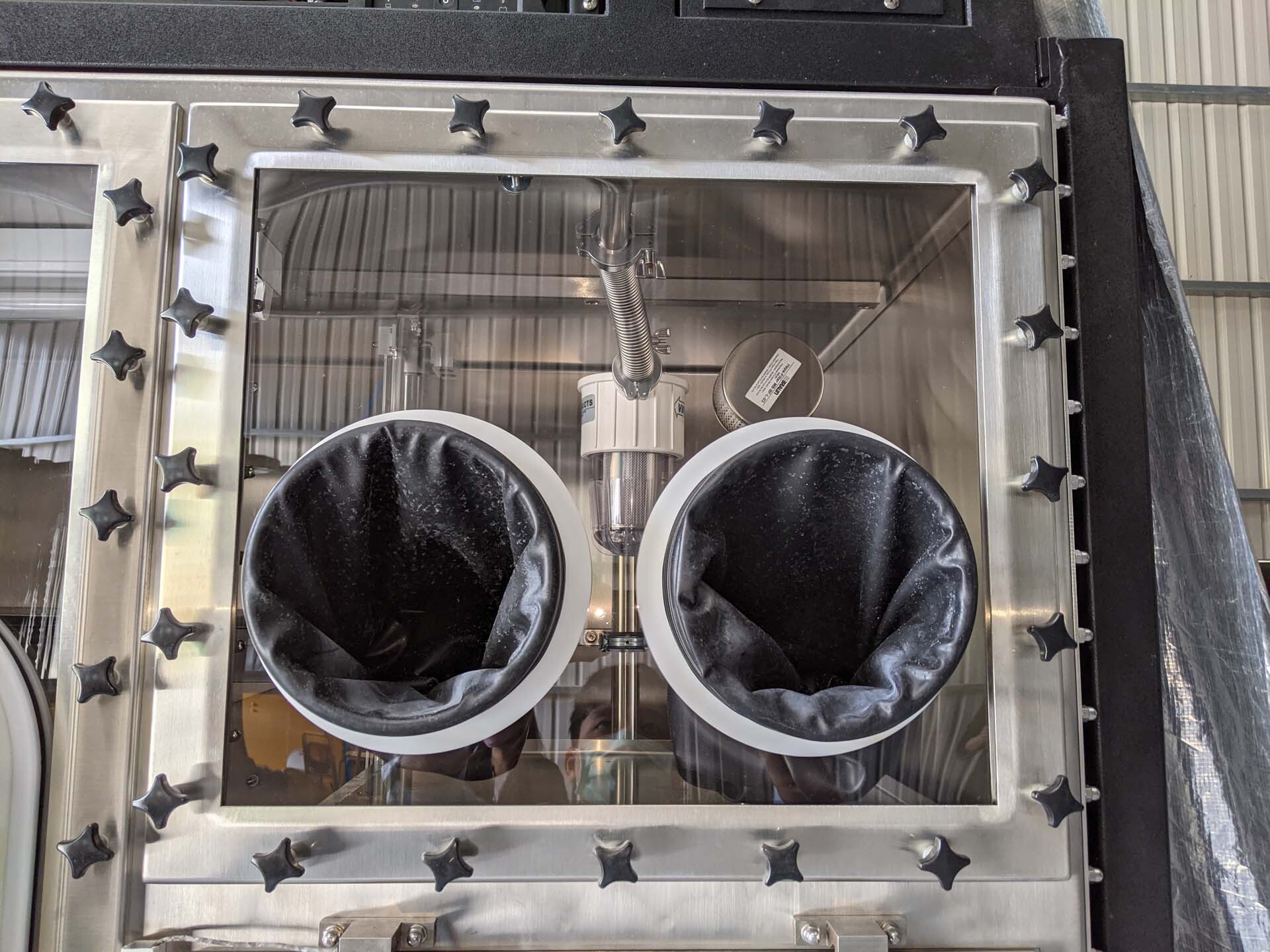

Load lock and platter transfer

Load lock exhaust system

Glove box

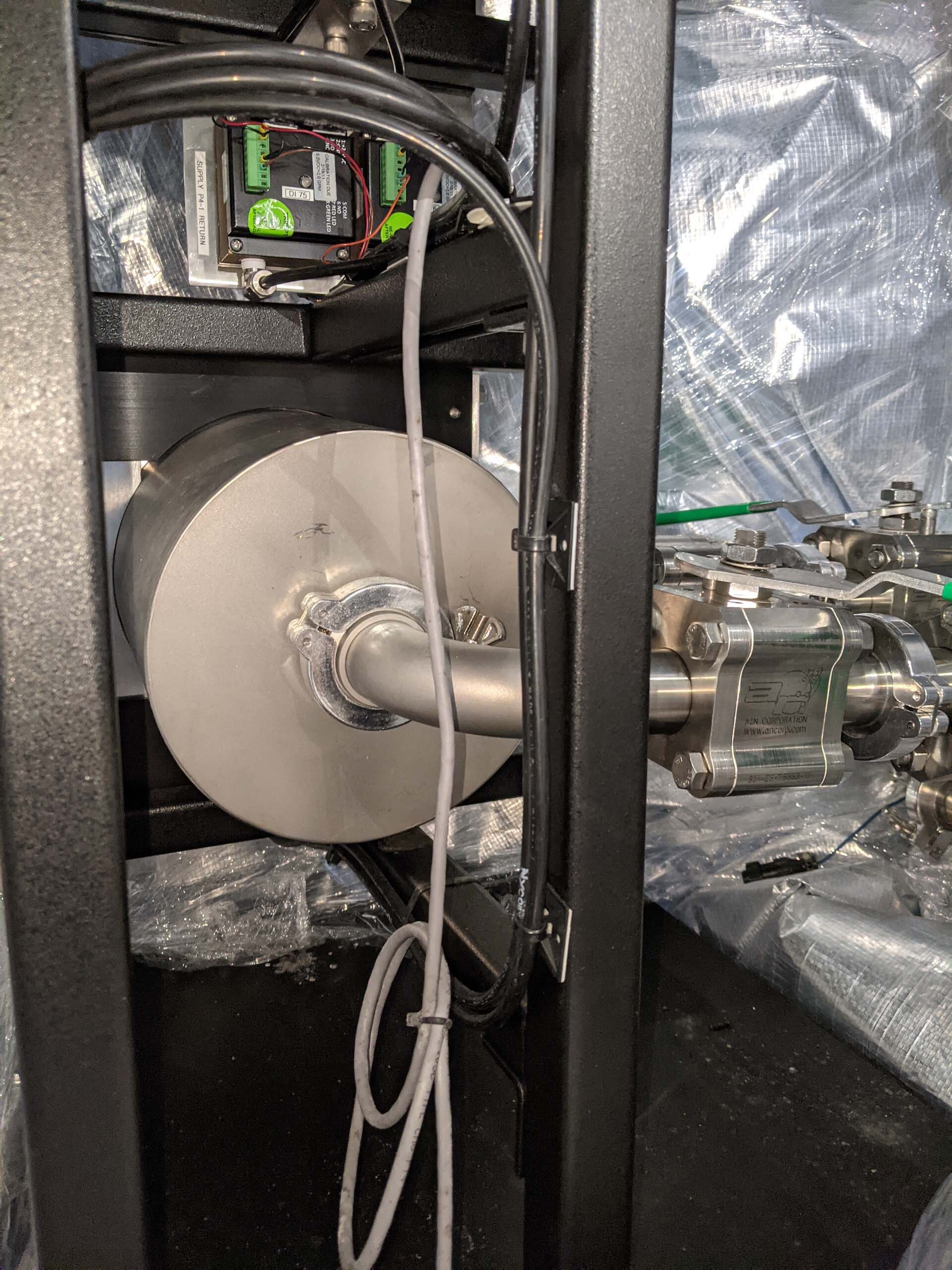

Water cooling assembly

Dual Phosphorous trap assembly

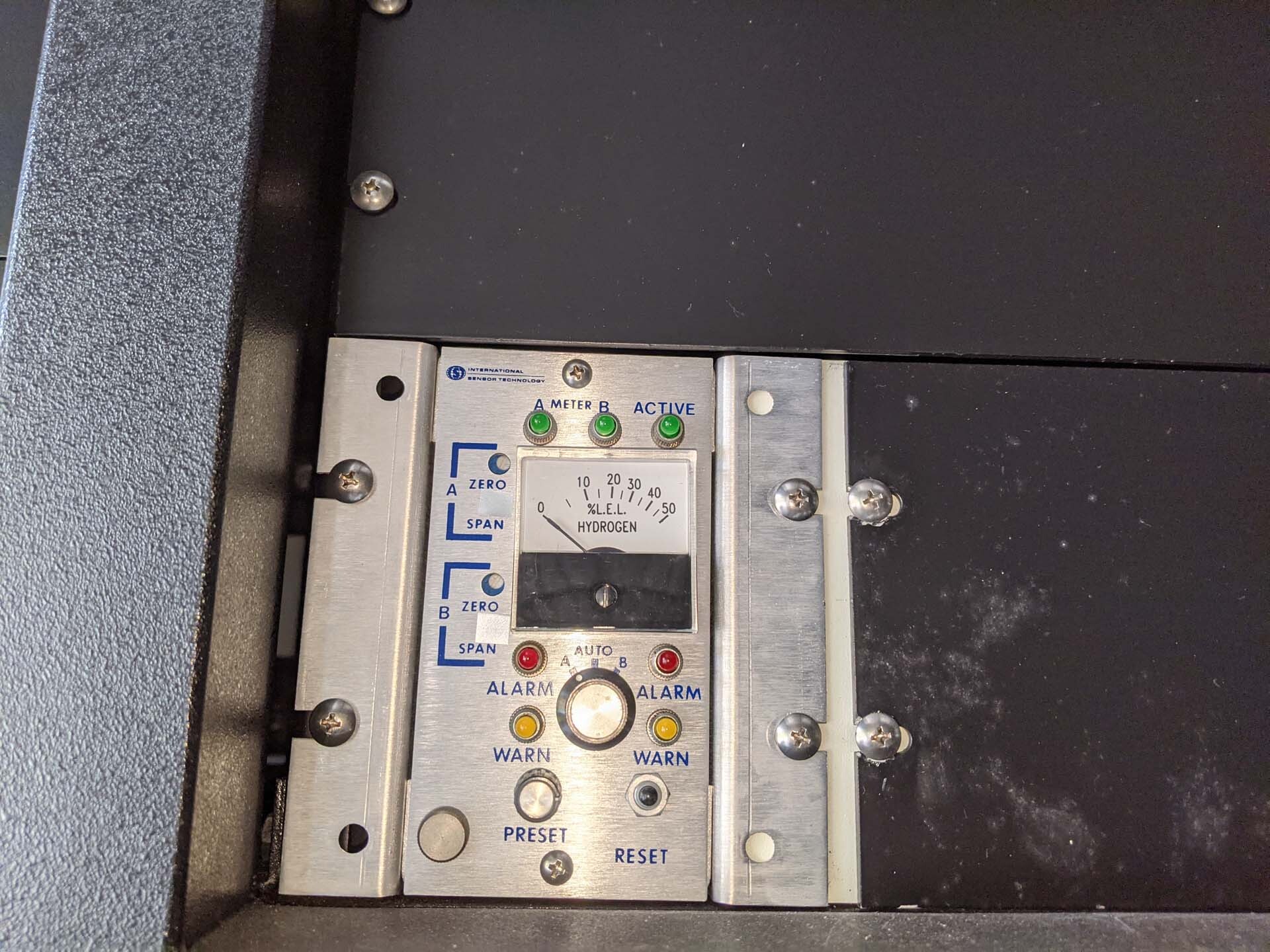

Hydrogen detector

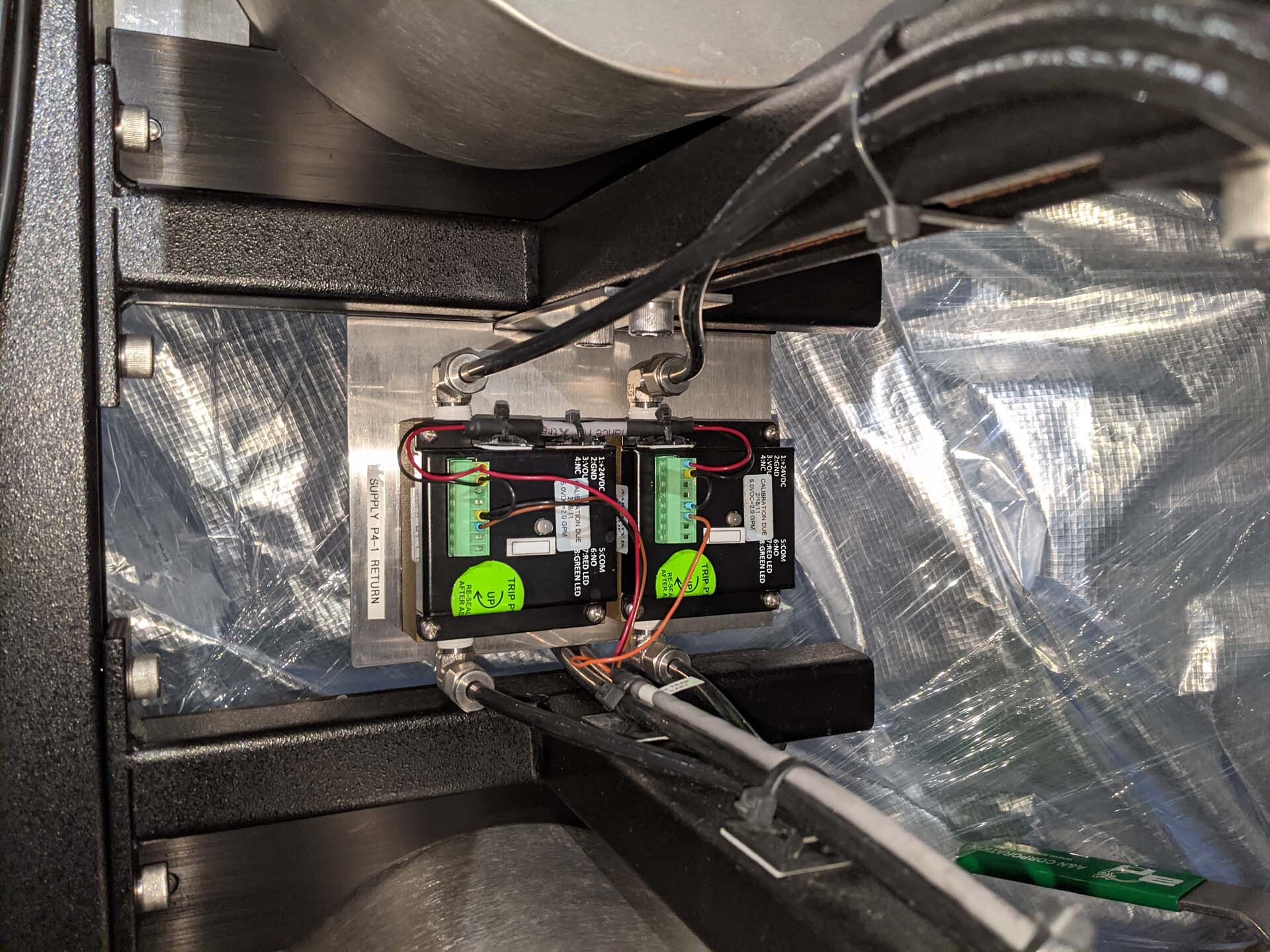

System electronics and control modules 380 V

EpiView Local control interface

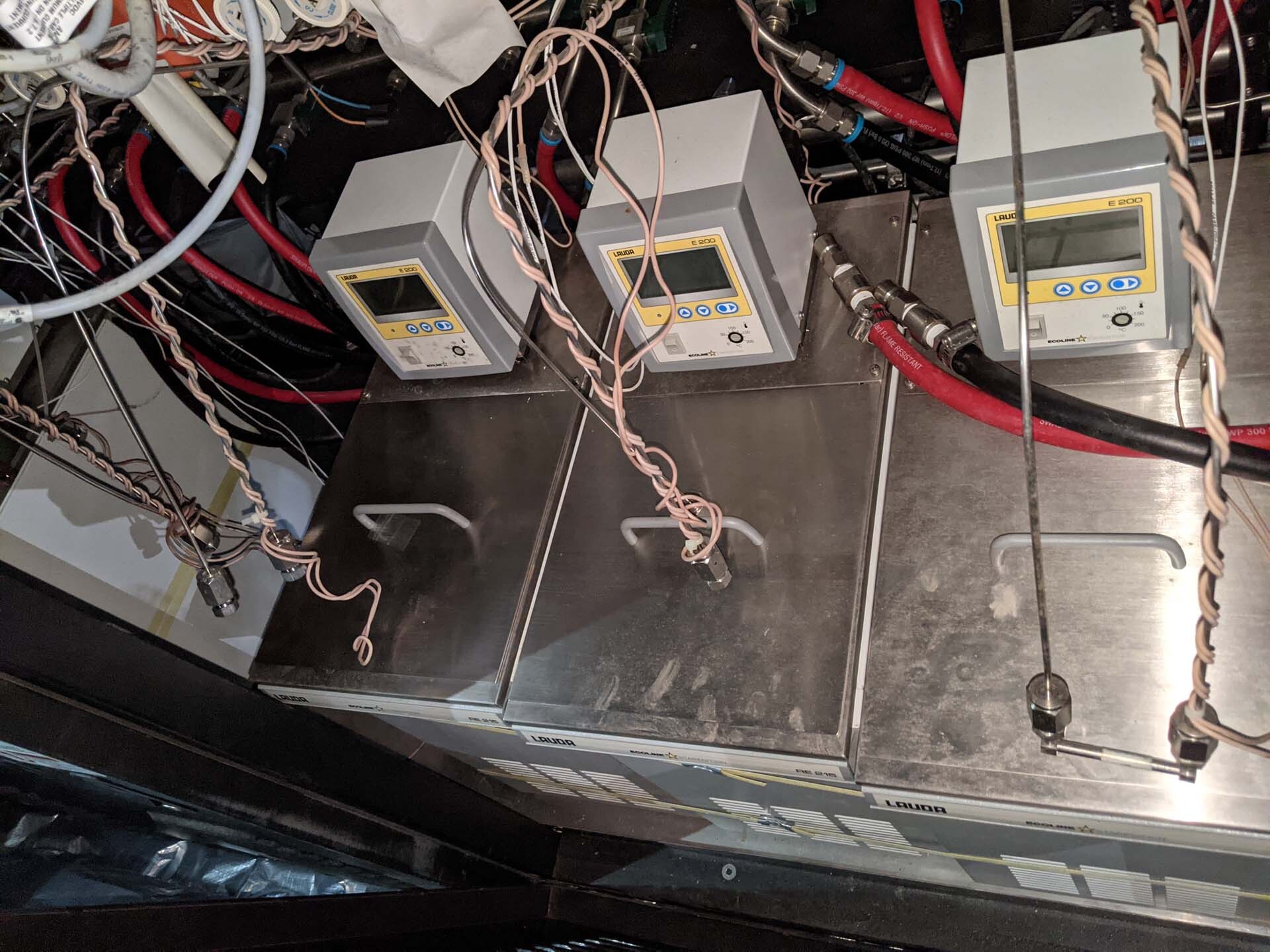

(7) Liquid refrigerator baths

(9) SS Bubbler legs, 1/8"

Gas panel

In-Situ monitoring system:

(3) REALTEMP 200 Monitoring systems

IDRT/RT Local control assembly

Step up platform

Custom gas panel controller bubbler:

DETe

DMZn

(2) TMIn

(2) TMGa

TMAI

CBr4

TBA

Disilane

Dilution network source manifold (Single bubbler)

Hydride:

Dopant1: Dislane

Dual input Hydride with single standard and single dilution network manifold

Dopant2: Dopant single input Hydride

2010 vintage.

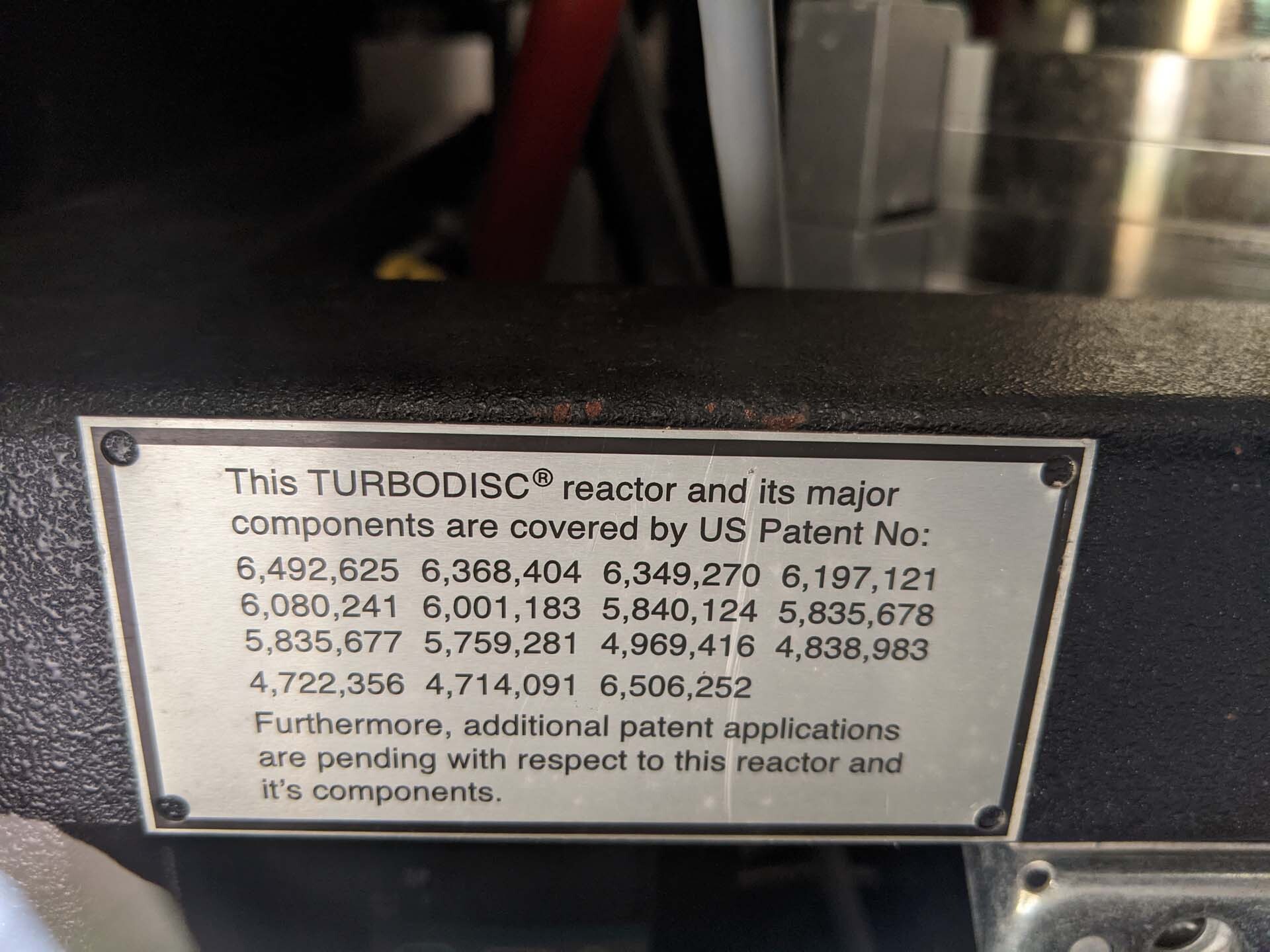

VEECO TurboDisc E475 Low-Density Metallization (LDM) reactor is a tool designed for the production of thick-film, high-performance electronic devices. It is used to deposit metal films onto substrates using a low-pressure, plasma-activated chemical vapor deposition (CVD) process. The equipment utilizes a unique hot, rotating disc to create a uniform film deposition over a large area. The reactor was designed specifically with high throughput and reliability in mind, making it the ideal choice for mass production of semiconductor devices. The system is comprised of a process chamber, upper and lower disc platen assemblies, a baseframe, and alignment and control systems. The E475 reactor process chamber has a short gas line configuration, which allows for rapid, precise gas delivery and rapid startup. The chamber is equipped with wafer transport and support, as well as a gas distribution manifold. The discs are constructed from a high-performance aluminum alloy, providing excellent thermal and mechanical stability. The discs can rotate at up to 3500 rpm and have a maximum temperature of approximately 400°C. The unit is designed for the deposition of metal films, including copper and aluminum metallization, barrier layers, and adhesion layers. It is capable of depositing high-performance films with excellent uniformity and high deposition rates. The machine offers precise control over film thickness and adhesion, providing a high degree of process and material consistency. The E475 also includes process monitoring and control systems which allow the user to precisely adjust deposition parameters. The user interface utilizes an intuitive, graphical operator interface to simplify the setup, start-up, and monitoring of processes. The tool includes a secure login and an audit trail which makes it easier to track process data and results. The reactor is also designed to meet stringent safety requirements, reducing the risk of accidents and improving safety in the workplace. The E475 LDM reactor is an ideal tool for the manufacture of high-performance, reliable electronic devices. With its advanced design and reliable performance, it has been designed for low overall maintenance requirements, making it an effective tool for both small-scale production and large-scale mass production.

There are no reviews yet