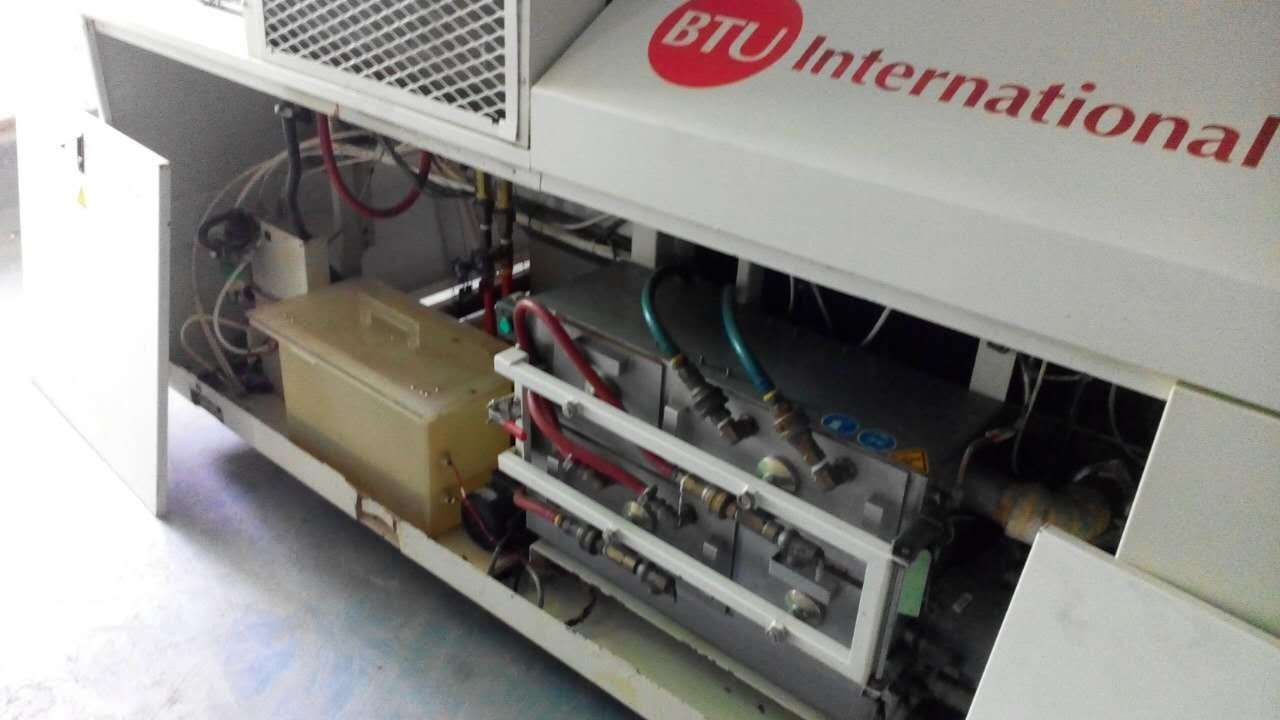

Used BTU Pyramax 98N #9127643 for sale

URL successfully copied!

Tap to zoom

ID: 9127643

Vintage: 2008

Reflow ovens

Flow: Left to right

Conveyor: Mesh and rail

Rail front fix

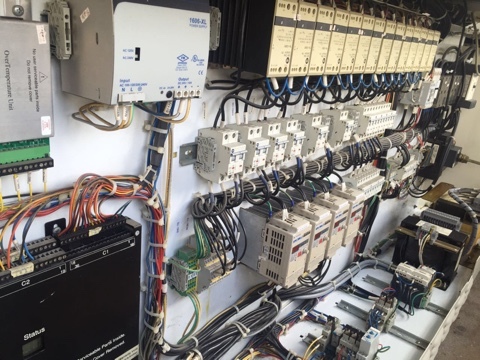

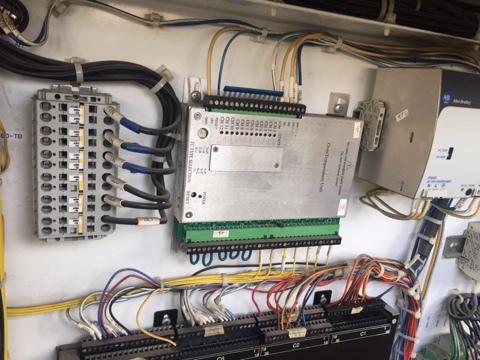

(7) Heat zones (top & bottom)

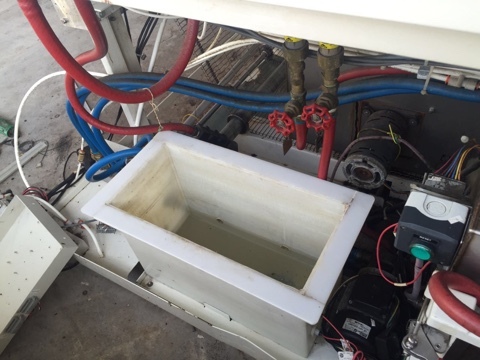

Cooling: 2 Water cool

Option: In build cycling system

2008 vintage.

BTU Pyramax 98N is a nitrogen-based reflow oven that is designed for use in medium- to high-volume SMT production lines. Its nitrogen-based design allows for faster cooling, better dam-bar adhesion, with greater control over transport lines, making it a reliable reflow oven choice for modern, production line based SMT processes. Pyramax 98N comes equipped with the company's patented pyramax profiling software, which allows users to customize the operation of the oven and perform a variety of powerful profile-making functions. This is a great tool for creating intricate reflow waveforms and is a great choice for manufacturers looking to stay ahead of the curve in terms of customization and control. BTU Pyramax 98N offers a wide range of adjustable parameters, including temperature, dwell time, and conveyor speed. A powerful thermal curve scan process is included, allowing users to easily monitor the reflow process, ensuring the parts are soldered perfectly, without the need for manual intervention. Adjustable force knives and horizontal blades are also available, which enable users to set the oven to the optimal soldering conditions for the model being soldered. Pyramax 98N also features an environmental control system, which allows for a cleanroom atmosphere inside the oven. This helps to prevent dust and particles from entering the oven chamber during the soldering process. This added feature helps ensure that soldered parts remain in top condition for longer. Like most modern SMT soldering processes, BTU Pyramax 98N uses infrared heaters, with the adjustable height conveyor making it ideal for handling both medium- and high-volume production. Up to four zones can be selected for configuring, with two integrated preheating zones available, allowing users to easily adjust the process parameters. In terms of safety, Pyramax 98N has been designed with several safe shutdown alarms. This includes fault shutdowns, pallet jams, and overheating alarms, allowing users to remain safe when using the oven, even when working with very high temperatures. In conclusion, BTU Pyramax 98N is an excellent choice for medium- to high-volume SMT production lines. Its patented pyramax profiling software provides users with a great amount of control over the entire reflow process, while its adjustable parameters and integrated thermal curve scan process make it perfect for getting the job done quickly and efficiently. Finally, its environmental control system and safe shutdown alarm systems make this model a safe, reliable choice for any production environment.

There are no reviews yet